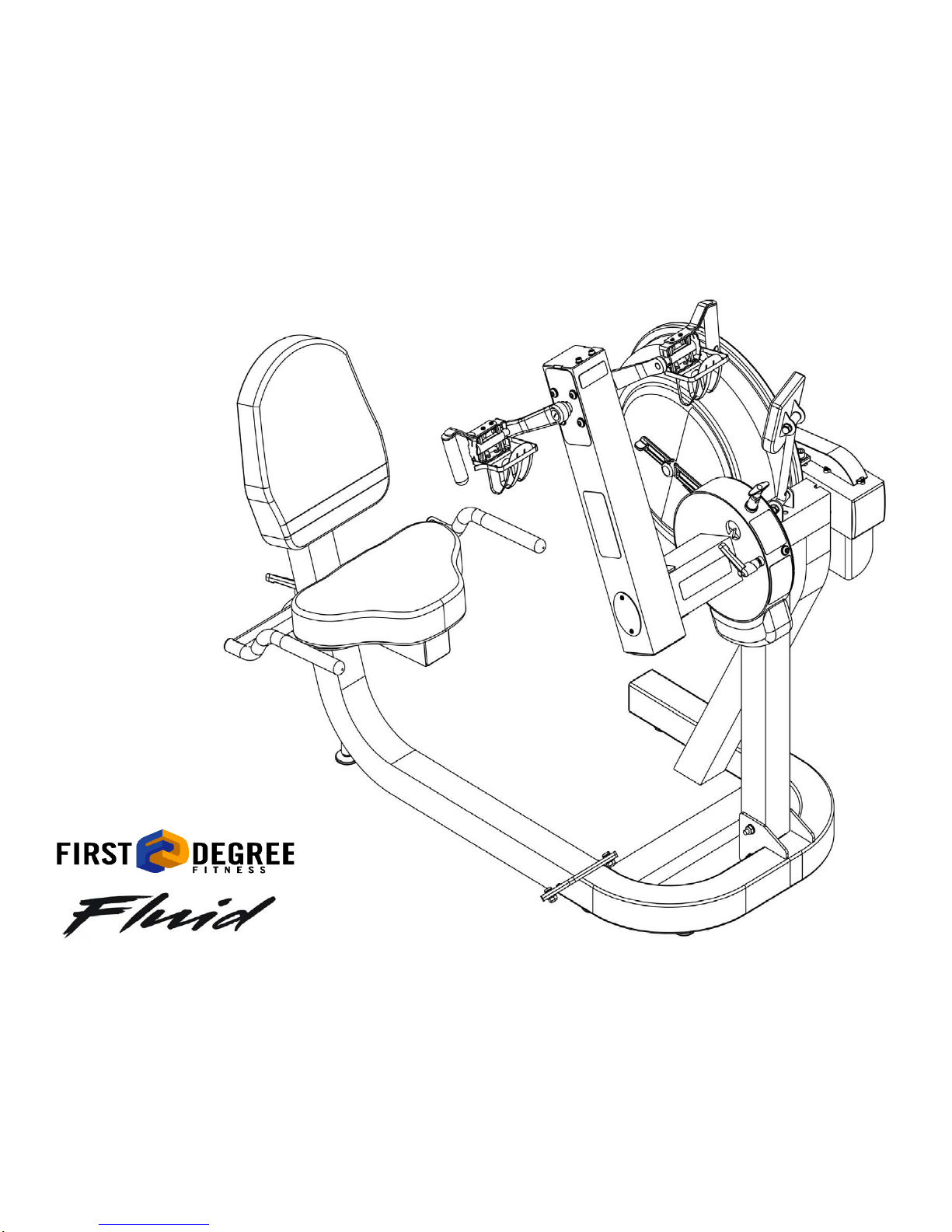

First Degree FLUID E720 User manual

1

Owners Manual

E720

2 Contents

1. Contents of E720 Box.

2. E720 assembly instructions.

3. Tank filling and water treatment.

4. Long term water treatment and basic

operation.

5. E720 Control arm.

6. Maintenance.

7. Troubleshooting guide

8. The E720 Ergometer.

9. Tank belt drive adjustment.

10. Parts list and Warranty.

As with any piece of fitness equipment, consult a physician before

beginning your E720 exercise program.

CAUTION

Use two hands and follow all safety in-

structions whenever raising or lower-

ing the E720 control arm.

Warning

Do not remove feet or hands while crank is in motion. The crank

will continue to rotate and could cause injury.

Training with E720

3

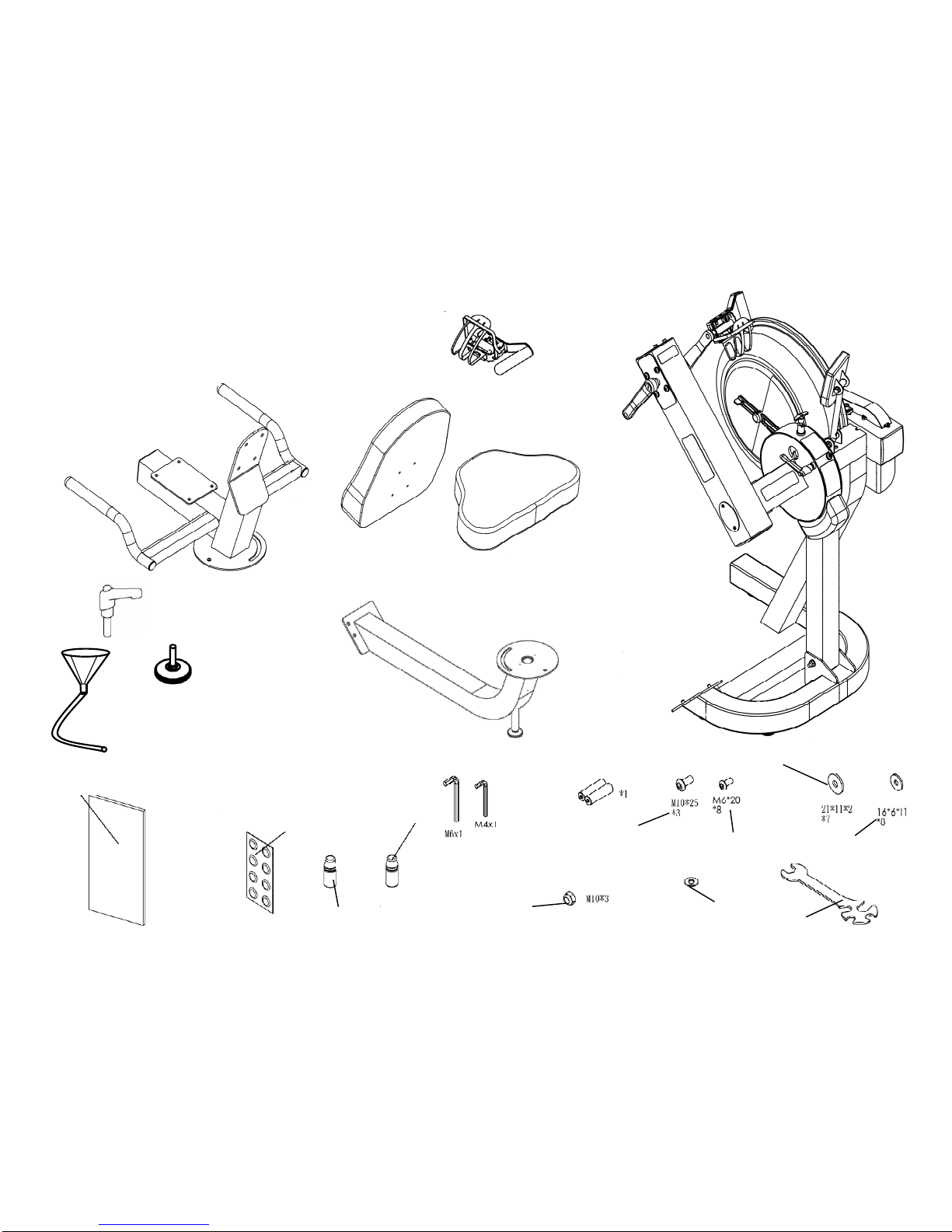

Box Contents

1x Upper seat frame

1x Main frame

1x Upper/Lower seat

frame

1x Lower seat frame

1x Right crank

pedal

1x L-pin

1x Fill funnel/hose

3x Leveler

Hex Keys 2x Batteries

3x Frame bolts 8x Seat bolts

7x Frame bolt washers

8x Seat bolt

washers

3x Main frame

Nylock nut 1x Multi-tool

M10 Plastic

Washer

Blue Dye

Owners Manual Touch Up

Paint

Chlorine Tab-

lets x 8

4

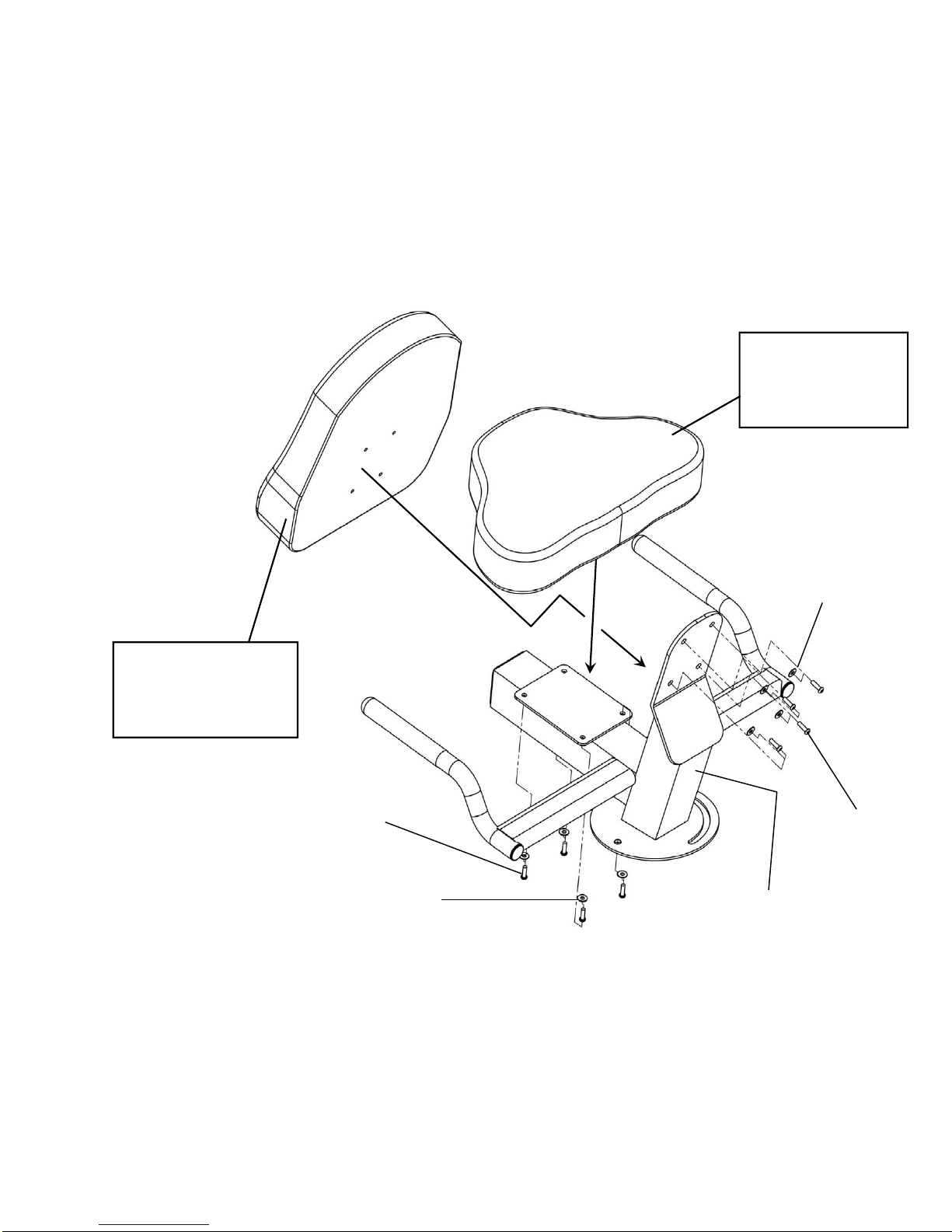

E720 Assembly Instructions

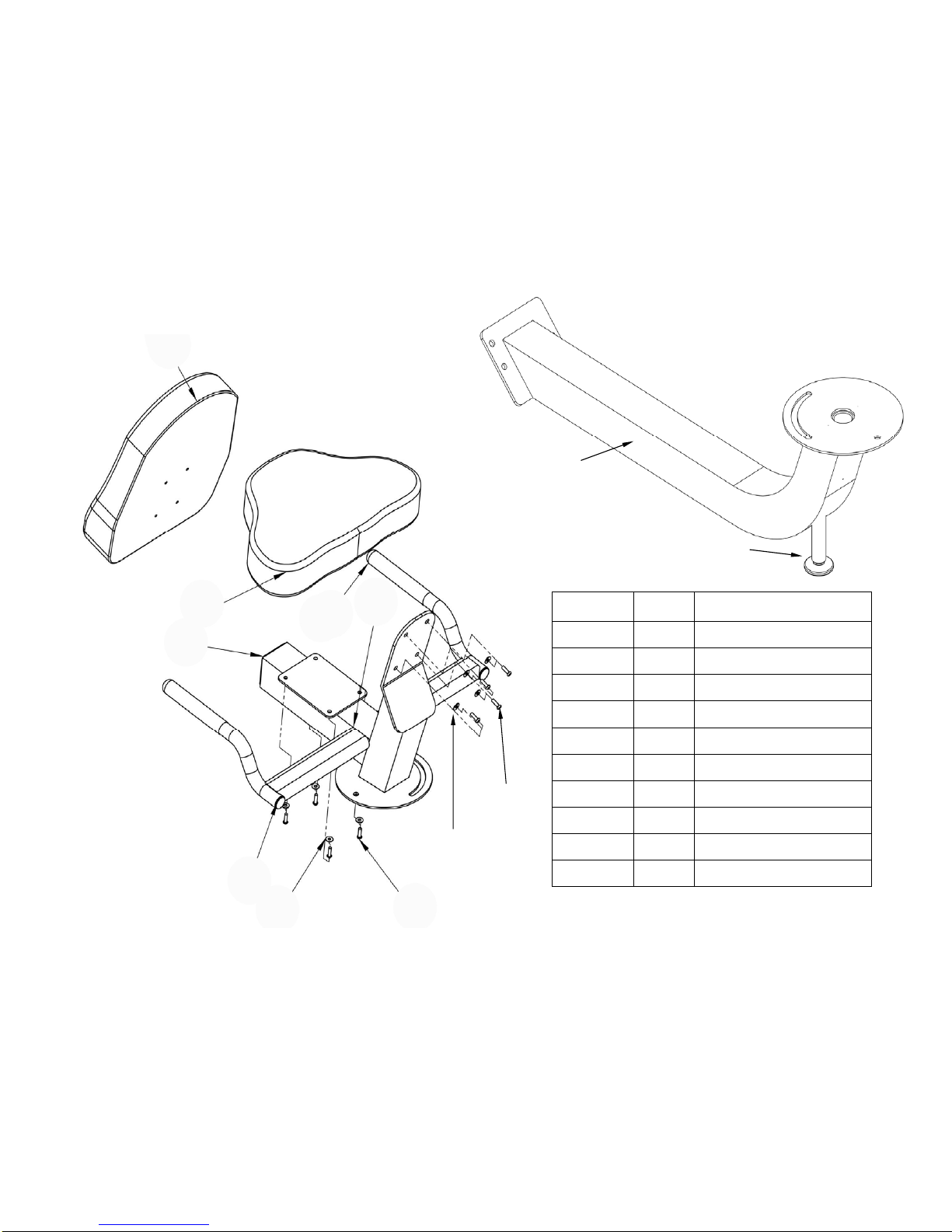

Upper seat

Lower seat

Step 1: Attach upper seat to

upper seat frame using 4x

M6x20mm bolts and 4x

16*6*l washers.

Step 2: Attach lower seat

to upper seat frame using

4x M6x20mm bolts and 4x

16*6*l washers.

Upper seat frame

M6x20mm bolt

M6*16*1 washer

M6*16*1 washer

M6x20mm bolt

5

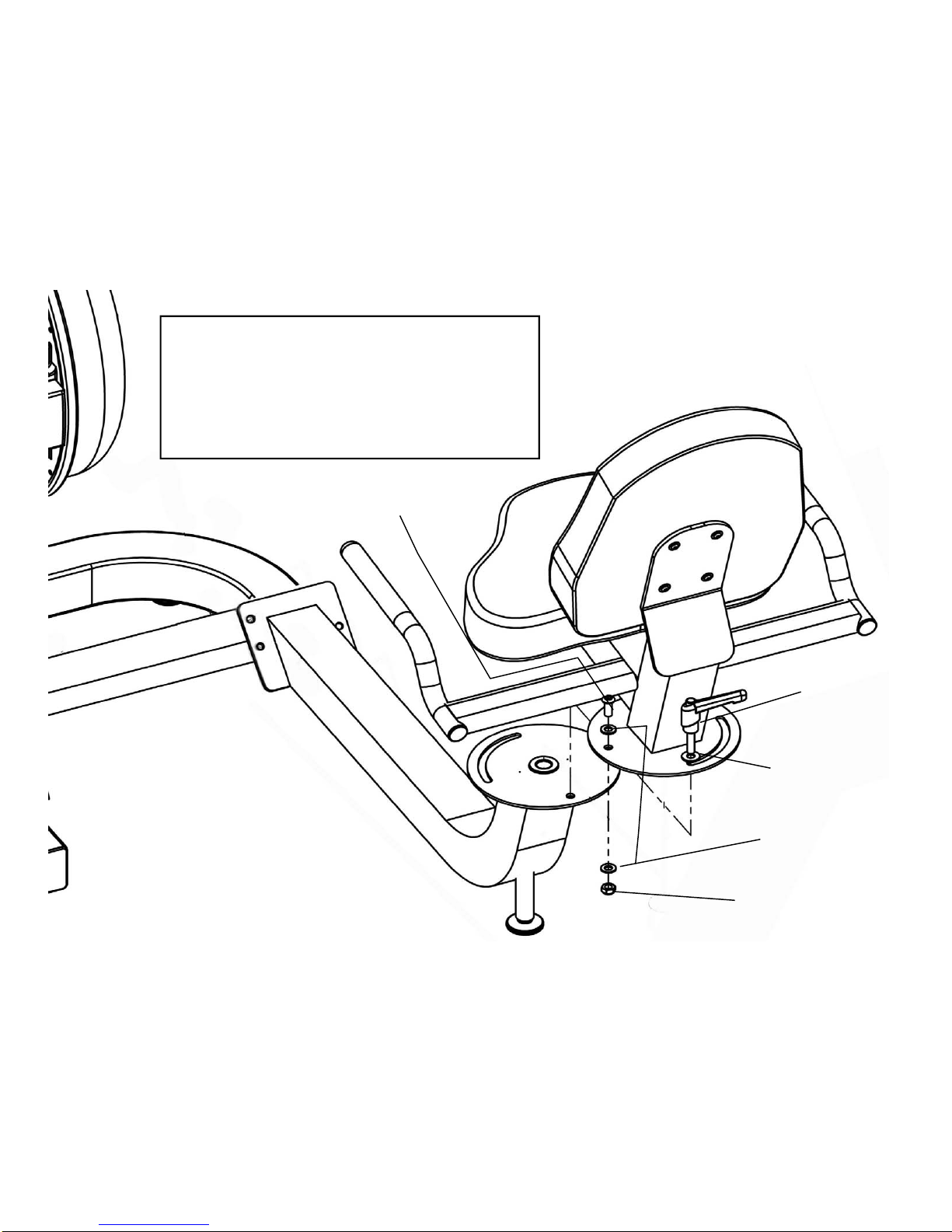

Step 3: Attach lower seat to lower

mainframe using 2x M10x25mm

bolts, 2x M10 Nylock nuts and 4x

21*11*2 washers

M10 Nylock nut

21*11*2 washer

M10x25mm bolt

E720 Assembly Instructions

6

L-Pin

M10x25mm bolt

M10 Nylock nut

21*11*2 washer

Step 4: Lower upper seat frame onto lower mainframe and

secure using 1x M10x25mm bolt, 1x M10 Nylock nut, 3x

21*11*2 washers and L-pin.

Note: Tighten the M10x25mm bolt, washers and Nylock until

lightly snug only. Over-tightening will prevent the seat from

rotating. Use the L-pin to tighten the upper seat frame once

rotated into place.

E720 Assembly Instructions

M10 plastic washer

7

Step 5: Secure right pedal onto Crank arm. The

pedal threads have a blue coating which will feel very

tight when threaded onto the crank arm. This is a

type of thread locker, and once in contact with the

crank arm threads will activate in approximately

15minutes.

Caution! Extreme over-tightening could damage the

aluminum threads on the crank arm.

Note: Allow 15 minutes for the

thread-locker to activate before

first time use.

Check pedal tightness on a regular

basis and tighten as needed with a

15mm wrench.

E720 Assembly Instructions

8

Note: A large bucket is required for filling (Not included)

In areas where tap water quality is known to be

poor, FDF recommends the use of distilled water.

Tank filling and water treatment

Open the rear upper yellow tank plug and insert hose into

tank (rotating the impeller slightly may be necessary to al-

low the hose to pass), move the tank adjuster handle to

level 20 and begin filling. Do not fill the tank higher than

the level indicator on the front of the clear shell. A prop-

erly filled tank holds approximately 8liters of water.

Warning: Do not under any circumstances put

fingers into the tank. Use the end of the hose to

move the impeller should the need arise.

Water Treatment Procedures:

1. Add Chlorine tablet.

2. Wait a minimum of 72 hours.

Then add very small amount of blue

dye and check for desired color. Im-

portant! Do not add blue dye for at

least 72 hours following Chlorine

treatment. The blue dye adds visual

appeal as well as cutting down the

amount of light affecting the tank water,

thus extending the amount of time be-

tween water treatments.

Note: The blue

dye is extremely

concentrated and

will readily stain

carpet or clothing.

Caution: Use a drop cloth when filling or

adding blue dye

Blue Dye

Yellow

tank plug

Filling hose

and funnel

9

CAUTION

Caution: It is important that a drop

cloth be used under the fluid tank whenever

the tank plug is opened for water treatment.

The level of resistance is deter-

mined by the level indicator located

on the front of the tank. Level one

indicates lightest resistance, level

twenty represents heaviest resis-

tance. Allow three to four seconds

after adjusting resistance handle for

the correct resistance level to be

achieved.

Long term water treatment:

Do not use any water treatment other than the tablets

supplied with this machine. For replacement tablets, con-

tact your local First Degree Fitness distributor.

Water treatment schedules for the E720 will vary according

to the fluid tanks exposure to sunlight, but expect 8-12

months near a bright, sunlit window and 2 years or more for

a darker location. At the point of finding the water slightly

cloudy, add a Chlorine tablet. Remember to wait 72 hours

following the chlorine tablet before adding the blue dye as

the Chlorine tablet is extremely concentrated.

Important: Do not fill past the calibration mark as indi-

cated on the tank level sticker or water spillage may occur.

See tank filling/water treatment page for details.

Long term water treatment and basic operation

Resistance:

Warning:

Use two hands when either raising or lower-

ing the control arm as pictured.

Removing hands or feet before the crank

comes to a complete stop while training can

cause injury. The crank is direct drive so as

to allow both forward and reverse rotation

during training.

10

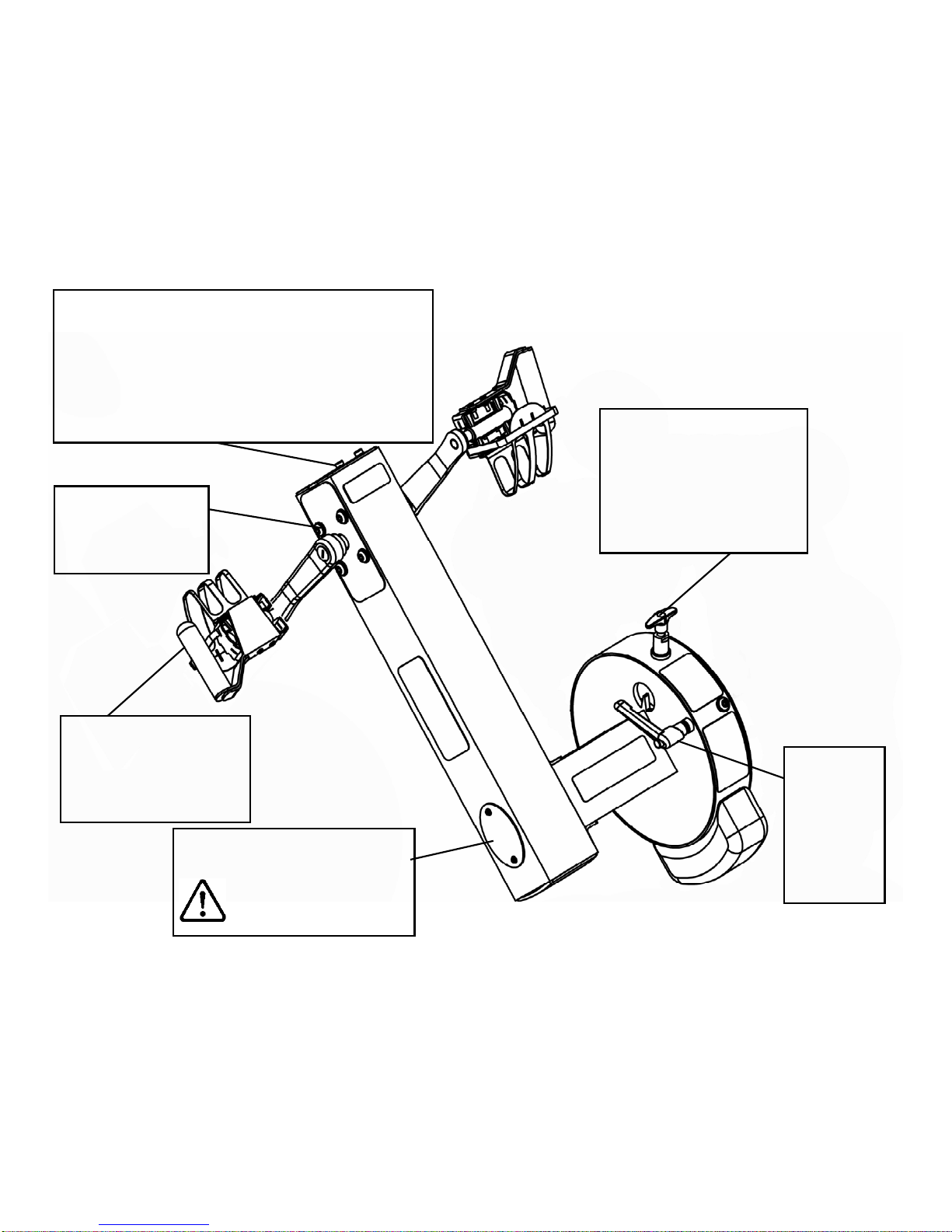

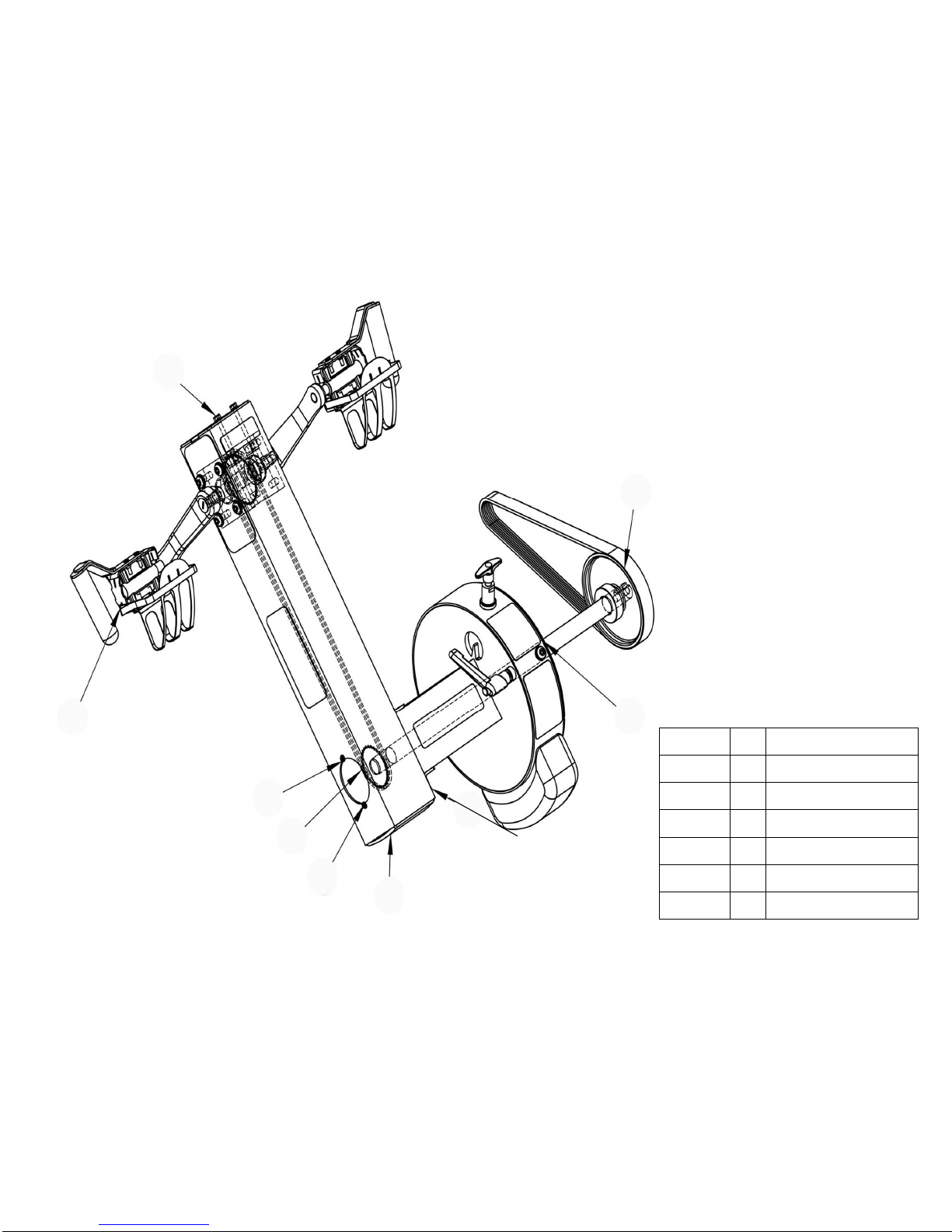

Chain tensioning bolts: Allows for tightening the chain or

adjustment from side to side. Make sure when tightening

only to adjust the same amount for both bolts, otherwise the

sprocket will be misaligned.

Note: Tightening the right bolt only will pull the right side of

the crank assembly toward you, tightening the left will pull the

left side toward you. Use this feature to realign the rear with

the front sprocket if needed or when changing to a new chain.

The E720 Pedal: This pat-

ented design allows for usage

in both the recumbent posi-

tion and for sitting/standing

upper body workouts.

L-pin: Loosen

when rotating

the control arm

and tighten

(snug only)

once the de-

sired position

has been

reached.

T-pin: The T-pin locks the con-

trol arm in any one of 72 different

positions throughout its 360 de-

gree range of motion. Pull up

the T-pin to allow the control arm

to rotate while supporting the

control arm with the other hand.

Crank arm bolts:

Loosen all 8 bolts

slightly before adjusting/

tightening chain.

The E720 Control Arm

Inspection plate: Open to check

chain tension.

Warning: Do not check

chain tension by hand!

11

Item Timeframe Instructions Notes

Seat and Frame. Weekly. Wipe down weekly with lint free

cloth or more often with heavy club

use.

PK belt tension. Monthly. Check monthly for signs of slippage.

Adjust/tighten as required.

Tank and water treatment. 12 months to 2 years. Follow instructions as specified in

the “Water Treatment” section of

this manual.

Chain drive. Check every 100 hours for correct

tension. Open the inspection plate and check

tension using a screwdriver or other

tool. Tighten as required using

chain tensioning bolts located at the

end of the control arm.

E720 pedals. Tighten weekly using 15mm box

wrench (supplied) The pedals should be checked on a

regular basis. A loose pedal can

cause damage to the crank arm alu-

minum threads, requiring replace-

ment.

Maintenance chart.

12

Fault Probable Cause Solution

Water changes color or becomes

cloudy. Rower is in direct sunlight or has

not had water treatment.

Change rower location to reduce direct exposure to sunlight.

Add water treatment and blue dye or change tank water as

directed in the water treatment section of this manual.

Knocking noise from inside the control

arm while training, especially when

changing directions.

Chain requires tightening or ad-

justment. Open inspection plate located on front of control arm and

check tension using a screwdriver or other tool. Use the

chain tensioning bolts located at the rear of the control arm

to tighten or adjust as needed. The chain should have

approx 3mm of slack when properly adjusted. See P.10 for

details.

Pedals slip during hard training. PK tank belt requires tightening. Remove large inspection plate next to the tank, insert a long

tool to push the rear end cap out from the inside, exposing

the tank belt tensioning bolt. Loosen tank bolts slightly. Re-

move upper rubber belt cover to expose the PK belt.

Tighten the tank tensioning bolt until the belt is too tight to

be twisted from side to side more than 45 degrees by hand.

See P.14 for details

Pedal is loose (either left or right) and

cannot be retightened. Aluminum crank arm threads are

stripped.

Contact service center for replacement. Then check weekly

as recommended.

Computer screen illuminates, but does

not register when rowing.

Loose or failed connection/

Sensor gap too wide (see erratic

computer display).

Check that the computer lead is connected properly. If con-

nected properly check sensor gap. Contact your local ser-

vice center if this fails to address the problem.

The E720 computer does not illuminate

after battery installation. Batteries installed incorrectly or

need replacing. Reinstall batteries in correct position and try again. If the

LCD screen fails to illuminate, try rotating the batteries

slightly in the computer. If this fails, contact your local ser-

vice center.

The E720 computer display is erratic/

slow while displaying RPM and WATTS Gap between sensor and mag-

netic ring is too wide. Remove inspection plate and check sensor gap and that

magnetic ring is not wobbly.

Troubleshooting guide:

13

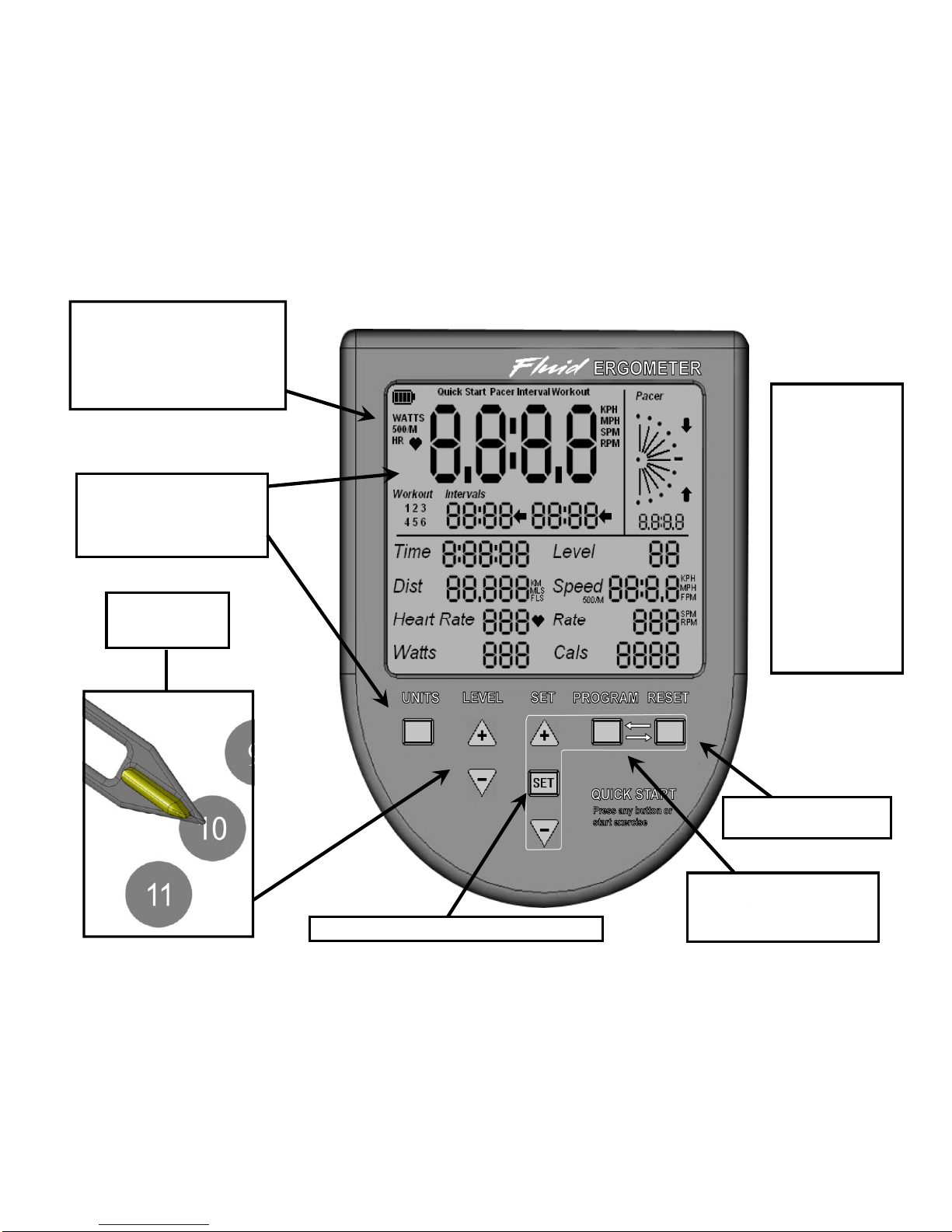

E720 Ergometer

Quick start provides instant

workout information. Just start

training to activate. You can

choose to change UNITS dis-

played.

UNITS displays

WATTS, RPM, HR, MPH,

Level Adjustable

from 1-20

Set Changes Time, Distance parameters

Program Clears current exer-

cise program

Note: For complete

operational instruc-

tions, please refer

to the computer

manual, which is

included with your

E720.

Reset Clears data

14

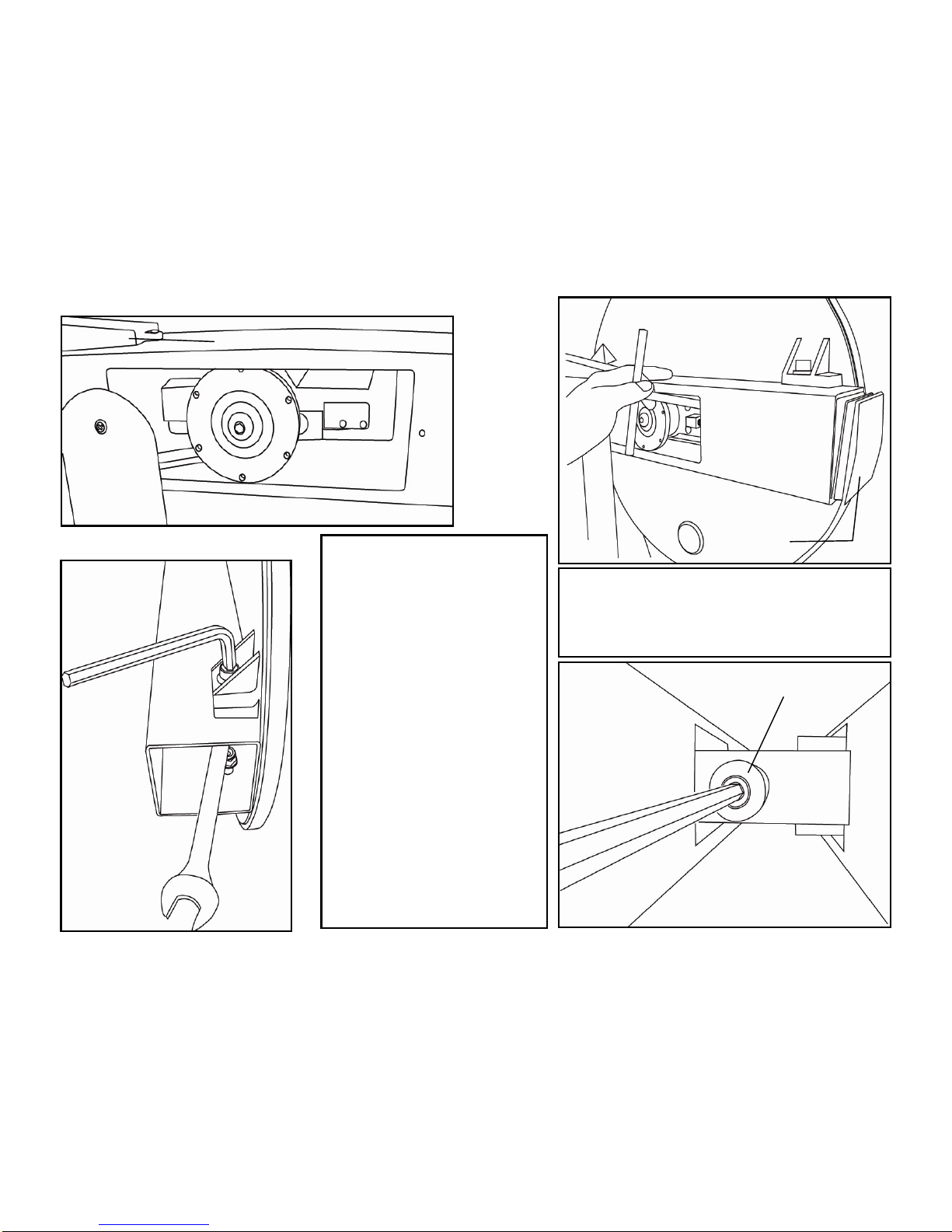

Step 1

Step 1: Remove large metal in-

spection plate as shown above

right.

Step 2: Using a long tool, push out

the rear end cap as pictured above

right. This will give you access to

the tank tensioning bolt (shown bot-

tom right).

Step 3: Loosen both the rear and

front tank bolts slightly as shown

left. Remove front rubber belt

cover.

Step 4: Using a 6mm Allen key,

tighten the belt using the tank ten-

sioning bolt until the belt no longer

slips during hard rowing.

Note: Do not over tighten tank

bolts.

Step 2

Step 3 Step 4

Tank Belt Adjustment

Tank tensioning bolt

End Cap

Rubber belt cover

Tip: Twist the belt by hand to gauge tightness. Cor-

rect tension should be obtained when no longer able

to twist more than 60 degrees.

15

P/N QTY Description

33100 1 Main Frame Assembly

20008 1 End Cap 75x75

10040 1 Bolt M12x140

10043 6 Washer M12

10066 3 End Cap 100x100mm

10067 2

Rubber Cover for Large PK

Pulley

10072 2

Small Steel Side Cover

100mm

10170 6 Washer M4

10070 18 Screw M4x10

20163 2 Semi Circle Cover

20850 1 Tension Adjustment

10082 5 Washer M10

10041 4 Nut M10 Nylock

71025 2

M10x25mm Main Shaft Rear

Bracket Bolt

10139 2 Spring Washer Flywheel Shaft

33915 1 Oil Bushing

23045 1 L Pin M10x35

33913 1 Plastic Spacer 10x25x4T

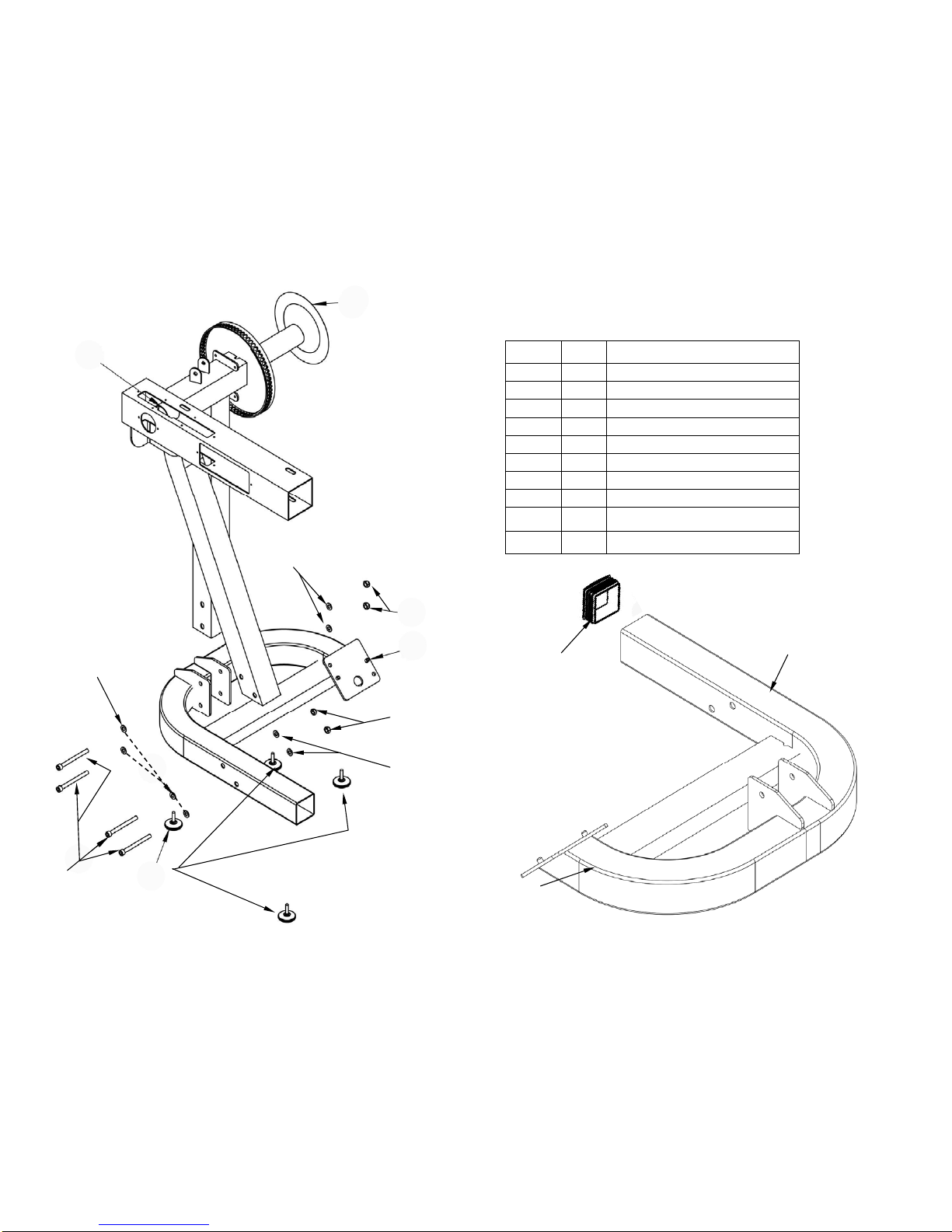

E720 Exploded Diagram:

10066

33100

10170

Refer to Control

Arm Assembly

Refer to A010

Tank Assembly

20850

Refer to Computer

Assembly

10040

10043

10067

20163

10070

10072

10082

10041

20008

71025

10139

33915

Refer to Seat Frame

Assembly

23045

33913

Refer to A037/A038

Left & Right Pedal

Assembly

Refer to Seat

Frame Assembly

16 P/N QTY Description

20101 1 Upper Main Frame

10082 8 Washer M10

20024 1 Number Decal

33101 1 Lower Main Frame

73016 4 Foot Levelers M8x30 PVC

10041 4 Nut M10 Nylock

20009 4 Bolt M10x100

20014 1 Right Bottom Frame

30010 1 Left Bottom Frame

23008 1 End Cap 75x75 Rubber

20014

30010

10082

20024

33101

73016

20009

10041

20101

Upper/Lower Mainframe:

10041

10082

10082

23008

17

Refer to Crank Arm

Assembly

20850

20163

10066

Refer to Control Arm

Assembly

10170

30012

10070

Refer to Main Drive

Assembly

Control Arm (external) Assembly:

P/N QTY Description

30012 1 DID-25 Chain 178

10066 1 End Cap 100mm

10170 2 Washer M4

10070 2 Screw M4x10

20163 2 Semi Circle Cover

20850 1 Tension Adjustment

18

10080

10081

30014

20008

33910

30002

20115

20117

10080

10081

P/N QTY Description

20115 1 Seat LS-622

20117 1 Seat Back LS-622

10080 8 Bolt M6x20

10081 8 Washer M6

20008 1 End Cap 75x75 PVC

30014 2 End Cap

30002 2 Handle Grip

33910 1 Rotating Seat Frame Upper

73016 1 Foot Levelers M8x30 PVC

33902 1 Seat Lower Frame

73016

33902

Seat Frame Assembly:

19

P/N QTY Description

13112 1 Computer Mounting Arm

10114 4 Bushing 20x16x13x10

10082 4 Washer M10

10116 1 Bolt M10x60

10097 2 Nut Dome Head M10

10117 1 Computer Wiring 1200

10096 1 Bolt M10x70 for Aluminum Rail

30903 1 Computer

30903

10096

10117

10097

10116

10082

10114

13112

10114

10082

20068

10083

10041

20125

20045

30013

20170

10083

10082

20151

20020

20151

20064 20174

20151

10120 20170

20170

20170

20151

20032 20033

20036

20291

Computer Assembly

P/N QTY Description

20291 1 Rotating Arm

20064 1 Weight Block

10083 2 Bolt M10x20

20151 4 Washer M10

20020 1 Bolt M10x35

10082 1 Washer M10

20174 1 Eccentric Bushing

10041 1 Nut M10 Nylock

10120 1 Screw M6x15

20125 1 Plastic Washer 30*6*6

20068 1 T-Pin

20045 1 L-Pin M12x40

20170 4 Chain Protection Decal

30013 1 CXT Decal

20032 1 Warning Decal

20033 1 Arm Moving Decal

20036 1 Small Warning Decal Control Arm Assembly

20

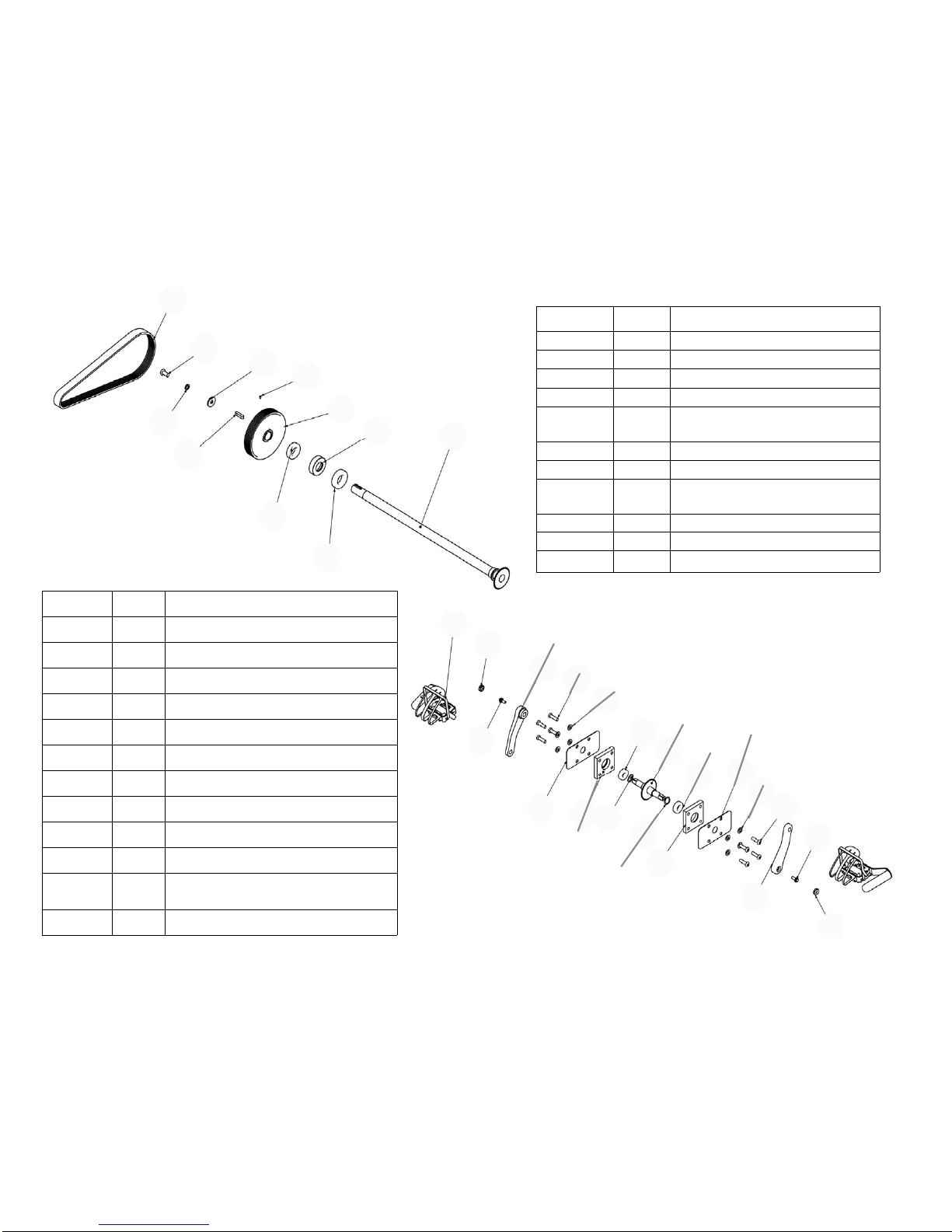

P/N QTY Description

20157 1 Shaft+Sprocket

10146 1 Ball Bearing NSK6006ZZ

10011 1 Bearing Housing

10012 1 NSK 6005ZZ Bearing

10015 1

Large PK Transmission Pulley

150mm

10017 1 Key way 7x7x32

10052 1 Grub Screw M4x6

10138 1

Shaft Washer 30x10.2x3t for Fly-

wheel, Stainless

10139 1 Spring Washer M10 for Impeller

10109 1 Belt 7PK 926mm HUTCHINSON

10083 1 Bolt M10x20

P/N QTY Description

30611 1 Right Pedal Assembly

30610 1 Cycle Axle + Cog

20052 2 Side Bearing Cover

10082 8 Washer M10

20020 8 Bolt M10x35

20134 1 Crank-Left

20135 1 Crank-Right

20132 2 France Screw M8x20xP1.0

20133 2 Crank End Cap

20190 2 Aluminum Block Bearing Housing

20193 2

NSK 6004ZZ Aluminum Block Hous-

ing Bearing

20196 2 Wave Washer 20mm

10083

10109

10139

10138 10052

10017

10015

10012

10011

10146

20157

Main Drive Assembly

20133

30611

20135

30610

20196

20193

20190

20052

20020

10082

20132

20134

20196

20193 20052

20190

20020

10082

20132

20133

Crank Arm Assembly

Table of contents

Other First Degree Fitness Equipment manuals

Popular Fitness Equipment manuals by other brands

BERGER

BERGER VP Body Slim Manual instruction

Gratz Pilates

Gratz Pilates HALF CADILLAC CONVERSION Assembly instructions

Keys Fitness

Keys Fitness Leg Press Hack Squat KF-LPHS owner's manual

Stamina

Stamina 1690 POWER TOWER owner's manual

TKO

TKO 823NVR-SM owner's manual

York Fitness

York Fitness 45072 owner's manual