FISCHER FISCHERSCOPE X-RAY 4000 Series User manual

OPERATOR’S MANUAL

Coating Thickness Material Analysis Microhardness Material Testing

FISCHERSCOPE® X-RAY 4000 Series

Operator’s Manual

FISCHERSCOPE®X-RAY 4000 Series

X-ray fluorescence (EDXRF) measuring system

For coating thickness measurements and materials analysis according to the energy

dispersive X-ray fluorescence method

On our home page www.helmut-fischer.com you will find the addresses of our sole agen-

cies and subsidiary companies around the globe.

© 2012 by Helmut Fischer GmbH Institut für Elektronik und Messtechnik, Germany.

This operator’s manual remains the copyrighted property of Helmut Fischer GmbH. All

rights reserved. This manual may not be reproduced by any means (print, photocopy,

microfilm or any other method) in full or in part, or processed, multiplied or distributed to

third parties by electronic means without the written consent of Helmut Fischer GmbH.

Subject to correction and technical changes.

Document order number: 952-597

Issue date: October 10, 2012

Manufacturer

Helmut Fischer GmbH Phone: +49 (0) 70 31 3 03 - 0

Institut für Elektronik und Messtechnik Fax: +49 (0) 70 31 3 03 - 710

Industriestraße 21 www.helmut-fischer.com

Quality Assurance System of the Helmut Fischer GmbH

DIN EN ISO 9001:2008 Management system certified by Germanischer Lloyd

Systems Certification

DIN ISO/IEC 17025 Calibration lab accredited for certified mass per unit area

standards

FISCHERSCOPE®X-RAY 3

Table of Contents

Table of Contents

1 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2 Safety of the Electrical Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.3 Maintenance and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4 X-Radiation Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

1.5 Requirements for the Operating Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.6 X-Radiation Safety Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2 Instrument Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Areas of Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.2 X-Ray Fluorescence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.3 Functional Principle of the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.4 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3 Switching the Instrument on and off. . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Switching on the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.2 Switching off the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3.3 Communication between Instrument and WinFTM. . . . . . . . . . . . . . . . . . . . . .20

4 Manual Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 Deleting Measurement Readings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5 WinFTM File Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 Def.MA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.2 Measurement Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.3 Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6 User Interface of the WinFTM Software . . . . . . . . . . . . . . . . . . . . . . 29

6.1 WinFTM Main Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.2 Video Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.3 Statistics Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.4 Measurement Value Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4FISCHERSCOPE®X-RAY

Table of Contents

6.5 Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.6 mq Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.7 Limited Operating Mode - Short menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.8 The Spectrum Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7 Product Administration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1 Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.2 Setting up a new product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7.3 Importing a product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

7.4 Modifying a product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7.5 Deleting a product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7.6 Assigning a new measurement application to a product . . . . . . . . . . . . . . . . .48

7.7 Modifying a measurement application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

7.8 Copying a measurement application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

7.9 Deleting a measurement application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

7.10 Viewing the Def.MA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

7.11 Importing a Def.MA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

7.12 Backing up product or Def.MA files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.13 Reference samples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

7.14 Base material in Def.MA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

7.15 Monitoring the measurement devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

8 Handling of Measurement Data and Statistical Evaluations . . . . . . 55

8.1 Saving / not saving measurement data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

8.2 Overwriting Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8.3 Closing a Block (Order no. / Operator) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

8.4 Block evaluation (statistics) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

8.5 Variable and fixed block size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

8.6 Deleting a block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

8.7 Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

9 Setting Up the Print Form Using PDM. . . . . . . . . . . . . . . . . . . . . . . . 61

9.1 Statistical Evaluation and Documentation Using the

Supplementary Software PDM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

9.2 Editing Print Form Templates Using PDM . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

9.3 Inserting Variables for Print Form Templates. . . . . . . . . . . . . . . . . . . . . . . . . .63

9.4 Variables Available for Block Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

9.5 Variables Available for the final Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . .68

FISCHERSCOPE®X-RAY 5

Table of Contents

9.6 Products with a variable or fixed block size . . . . . . . . . . . . . . . . . . . . . . . . . . .71

9.7 Special Features for SPC Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

9.8 Printing the Print Form Using the Supplementary Software PDM . . . . . . . . . .74

10 Measurement Uncertainty and Measuring Ranges. . . . . . . . . . . . . . 75

10.1 Meaning of the measurement uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

10.2 Random Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

10.3 Systematic Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

10.4 Display of the measurement uncertainty . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

11 Task programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

11.1 Starting a Task . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

11.2 Programming Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

11.3 Getting started with task programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

11.4 Syntax of Task Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

11.5 List of Task Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

11.6 Example Specification Limit Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

12 Data back-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12.1 Extent of the data back-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

12.2 Target path for data back-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

12.3 Back-up cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

13 Mass per unit area and geometric coating thickness . . . . . . . . . . . 90

13.1 Correlation between mass per unit area and coating thickness . . . . . . . . . . . .92

13.2 Calibration standards from FISCHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

13.3 Setting the density in the Def.MA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

14 Measurement device monitoring for the Fischerscope X-RAY . . . . 96

14.1 Calibration of X-ray fluorescence measuring instruments . . . . . . . . . . . . . . . .96

14.2 Why monitor measurement devices? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

14.3 Variation of measurement readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

14.4 Trueness of measurement readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

14.5 Random and systematic deviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

14.6 Trueness and precision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

6FISCHERSCOPE®X-RAY

Table of Contents

14.7 Practical monitoring of the measurement devices . . . . . . . . . . . . . . . . . . . . .105

14.8 When and how to carry out corrections? . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

14.9 Wouldn’t it be better to re-calibrate? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

14.10 Pre-run for determining the control limits . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

14.11 Long-term monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

15 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

16 Measurement Data Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

16.1 Starting the Measurement Data Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

16.2 Export Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

16.3 Setting up an Export Template . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

17 Addendum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

17.1 Description of the Characteristic Statistical Parameters. . . . . . . . . . . . . . . . .131

17.2 Periodic Table of the Elements with X-Ray Properties. . . . . . . . . . . . . . . . . .139

Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

WinFTM Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I

FISCHERSCOPE®X-RAY 7

Intended Use Safety Information

1 Safety Information

When used as intended, the FISCHERSCOPE®X-RAY is safe in its operation. When you

use the instrument as intended and observe the safety information, the instrument does

not pose any risks.

Please read and follow these instructions and observe the safety information. Please also

note the generally applicable regulations concerning safety and accident prevention.

1.1 Intended Use

The FISCHERSCOPE X-RAY is used for coating thicknesses measurements and for

materials analysis. The measurement method conforms to DIN 50 987, ASTM B568 and

EN ISO 3497.

The specifications of the instrument and of the accessories are described in the data sheet

in the Attachment to this Operators Manual.

Only accessories recommended and approved by FISCHER may be connected to this

instrument.

Modifications, repairs, maintenance and service work on the FISCHERSCOPE X-RAY and

its accessories must be performed by authorized FISCHER service personnel only.

There is no other intended use. The risk for damage from unintended use lies solely with

the user.

1.2 Safety of the Electrical Equipment

The FISCHERSCOPE X-RAY is designed as a Protection Class I instrument according to

the IEC 348 / VDE 0411 standard. The instrument contains components under line voltage

and under high voltage. Observe the directives and standards IEC 348, VDE 0411.

1.3 Maintenance and Repair

Repair, maintenance and service work on the FISCHERSCOPE X-RAY and its accesso-

ries must be performed by authorized FISCHER service personnel only.

Exceptions are described in the operator’s manual, as replacing the line fuse.

8FISCHERSCOPE®X-RAY

Safety Information X-Radiation Safety

1.4 X-Radiation Safety

The design as a fully protected instrument and the functions of several integrated protec-

tive devices protects the operating personnel and the surroundings fully from x-radiation.

Two devices that work independent of each other ensure that x-radiation can be generated

only when the measurement chamber is closed. For the safe operation of the instrument

please also note the intended use; ref. Chap. 1.1. on Page 7.

Observe the laws and regulations of the country where the FISCHERSCOPE X-RAY

is operated. The responsible government authority must possibly be informed or

consulted about the commissioning of the FISCHERSCOPE X-RAY.

In addition, we would like to point out the following:

Operate the instrument according to the instructions in this manual and the online help.

Do not attempt any structural alterations on the instrument.

Maintenance and service work on the instrument may be performed only by FISCHER

or by companies authorized by FISCHER for this purpose.

1.4.1 Repeat Inspection

FISCHER recommends to check the instrument by an expert in intervals of no longer than

five years. Observe the laws and regulations of the country where the instrument is oper-

ated.

If you prefer to perform the repeat inspection yourself, contact the responsible authority

for the expert responsible for your area.

During the repeat inspection, the expert must be provided with the Certificate of Approval.

Store the Certificate of Approval in a manner that it will be available at the time of the

inspection.

The responsible authority must be notified of the result of the repeat inspection without

being requested to do so.

1.4.2 Safety Devices

Safety devices are absolutely necessary to protect the operating personnel and the

surroundings fully from x-radiation. Two micro switches observe the opening condition of

the protective hood. If the protective hood is opened, the x-ray escape will be closed

(shutter closed).

FISCHERSCOPE®X-RAY 9

Requirements for the Operating Personnel Safety Information

No Alterations to the Instrument!

Only specialized service personnel, as a rule the Service of FISCHER, is authorized to

carry out alterations to the measuring instrument.

1.5 Requirements for the Operating Personnel

1.5.1 Operators with Introductory Training

Operators with introductory training can work with the instrument efficiently and safely.

For this purpose, the instrument is prepared such that all settings for the measuring appli-

cation are made by trained specialists. Then, the software’s scope of functions is

restricted such that only the functions required for carrying out the measuring application

remain accessible (Short menu). This provides operators with introductory training with a

clear workspace and the instrument is protected from interventions and changes in the

software.

Operators with introductory training should have the following knowledge:

Fundamental knowledge about the use of Microsoft®Windows®

Knowledge of the safety information described in this manual

Operators with introductory training must be instructed in the proper use by a person that

has the requisite qualifications.

1.5.2 Trained Specialists

Trained specialists can utilize the full bandwidth of the technical capabilities of the

FISCHERSCOPE X-RAY.

In addition, trained specialists have the following knowledge:

Knowledge of the physical principle of x-ray fluorescence and of the functional prin-

ciple of the FISCHERSCOPE X-RAY instrument

The aforementioned physics knowledge is important for defining the measuring application

and for other settings. Only the most important facts are explained in this

Operators Manual. This does not replace detailed training.

The practice-oriented seminars of FISCHER are a worthwhile opportunity for obtaining the

required knowledge. Several times a year, user seminars that provide insights into the

physical fundamentals of x-ray fluorescence and prepare users for their work with the

measuring instruments are conducted at various locations.

Seminar dates can be found on our website www.helmut-fischer.com.

DANGER

X-radiation and high voltage

Carrying out alterations to the instrument can lead to death or serious inju-

ries and legal consequences.

Do not carry out any alterations to the instrument.

10 FISCHERSCOPE®X-RAY

Safety Information X-Radiation Safety Details

1.6 X-Radiation Safety Details

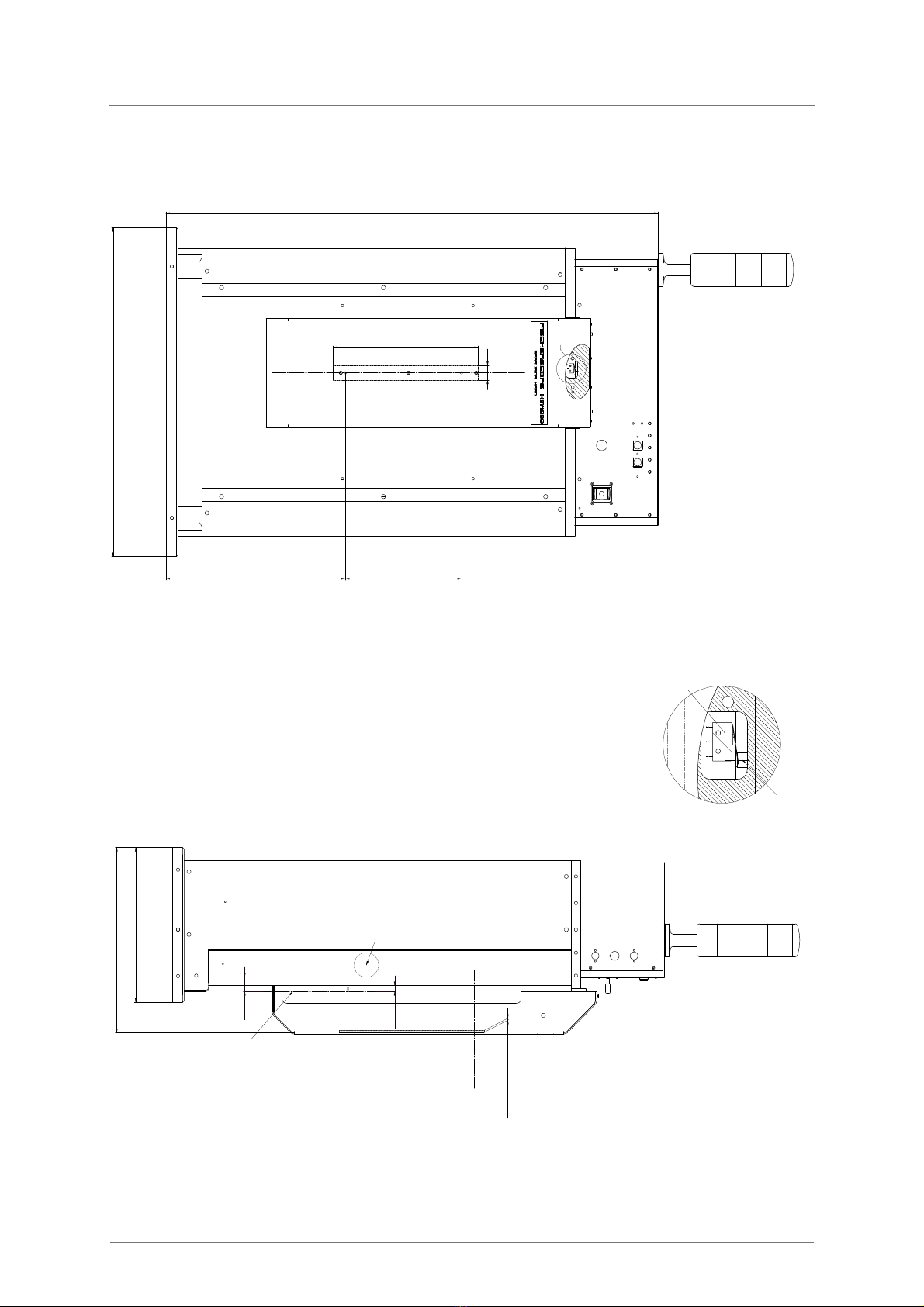

+RPH3RVLWLRQ

7UDYHO=$[LV

=

PPPHWDOVKHHW

3&7XEH

;5D\%HDP

$[LV

PHVXULQJSODQH

;5D\

6RXUFH3ODQH

;5D\%HDP

$[LV

]D[LVPLQ

]D[LVPD[

=

0LFURVZLWFKHV

$FWXDWLQJ3LQ

FISCHERSCOPE®X-RAY 11

Areas of Application Instrument Overview

2 Instrument Overview

The FISCHERSCOPE®X-RAY is a high performance energy dispersive x-ray fluores-

cence (EDXRF) spectrometer.

The WinFTM®(Fischer Thickness Management Software for Windows®) software

controls the instrument and handles the evaluation of the signals supplied by the

instrument.

The measured values (coating thickness, material compositions, mass per unit area) are

stored and displayed on the monitor. Using WinFTM, you can conveniently design the

measurement results as a print form for printout and export them to other applications.

WinFTM runs under Windows®.

2.1 Areas of Application

The instrument is suited for the following measurement applications:

Analysis of solid materials

Measurement of the composition and coating thicknesses of complex multi-layered

systems

Continuous in-line measurement in production processes

12 FISCHERSCOPE®X-RAY

Instrument Overview X-Ray Fluorescence

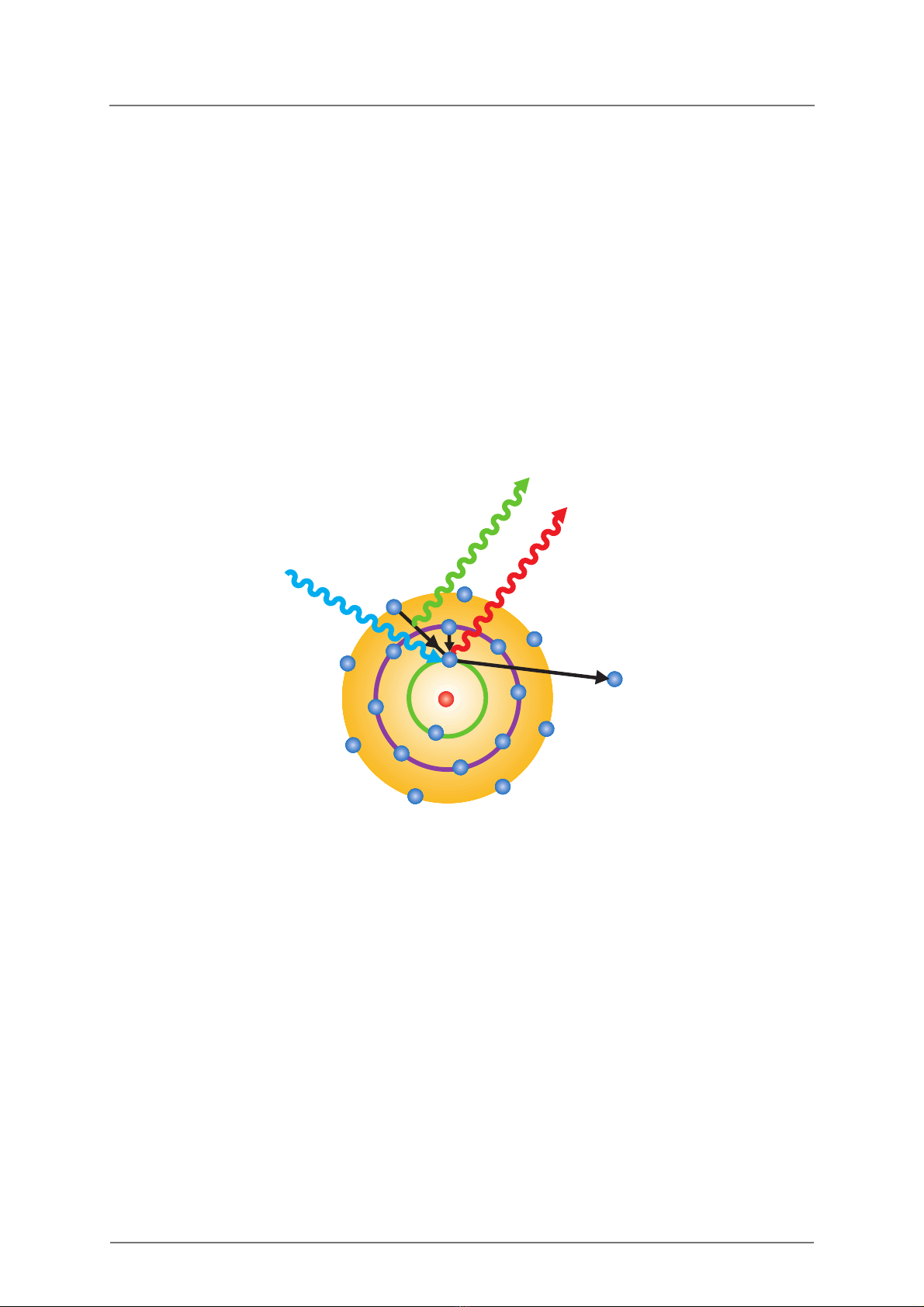

2.2 X-Ray Fluorescence

The specimen is excited with the primary x-radiation. In the process electrons from the

inner electron shells are knocked. Electrons from outer electron shells fill the resultant

voids emitting a fluorescence radiation that is characteristic in its energy distribution for a

particular material. This fluorescence radiation is evaluated by the detector.

The generation of the x-ray fluorescence radiation is shown simplified in Fig. 2-1. One

electron from the K shell is knocked. The resultant void is filled by either an electron from

the L shell or an electron from the M shell. In the process the Kand Kradiation is

generated, which is characteristic for the particular material.

Fig. 2-1: Generation of the x-ray fluorescence radiation

Primary X-radiation

X-ray fluorescence radiation

Shell K

L

M

K

K

Electron

FISCHERSCOPE®X-RAY 13

Functional Principle of the Instrument Instrument Overview

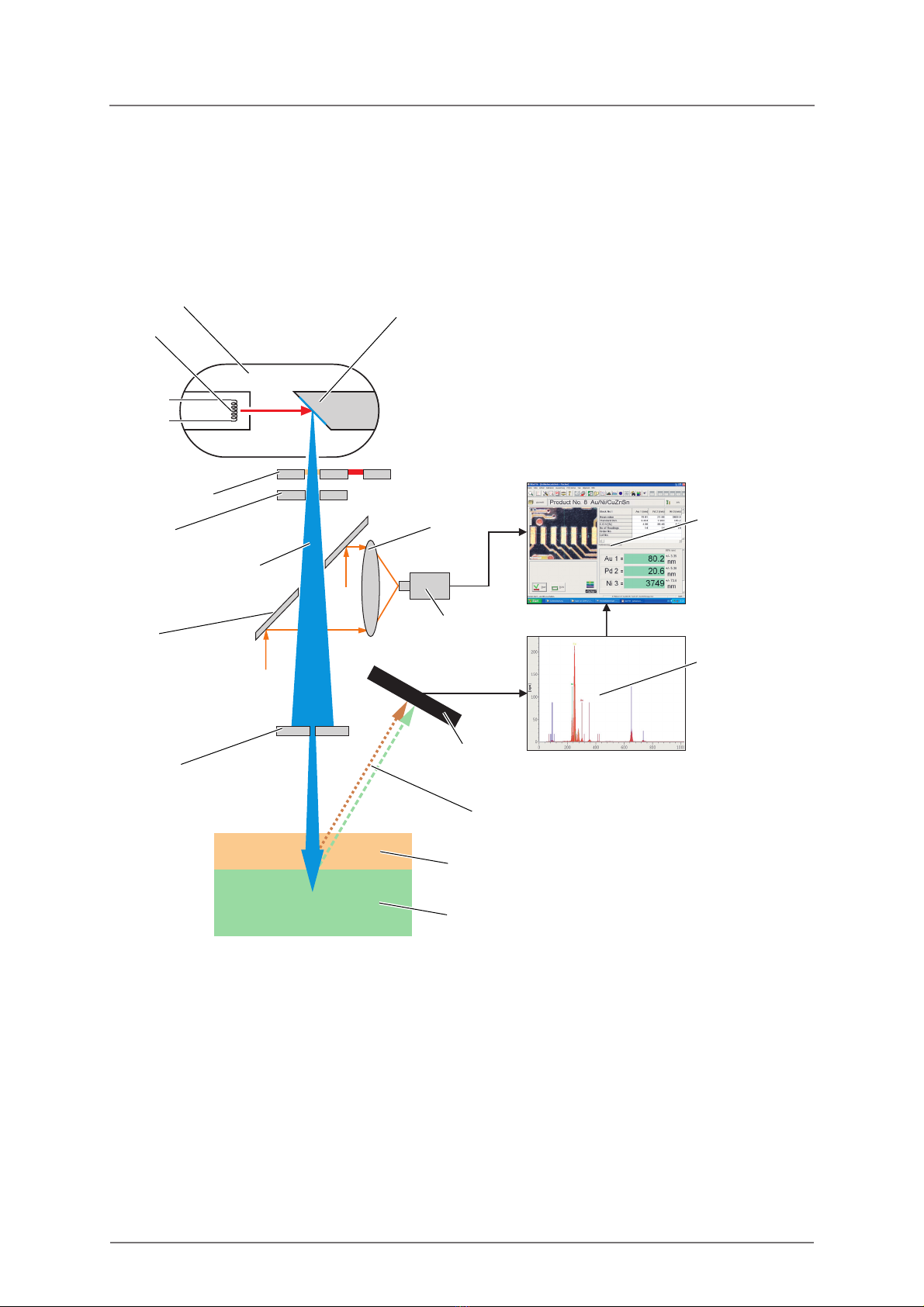

2.3 Functional Principle of the Instrument

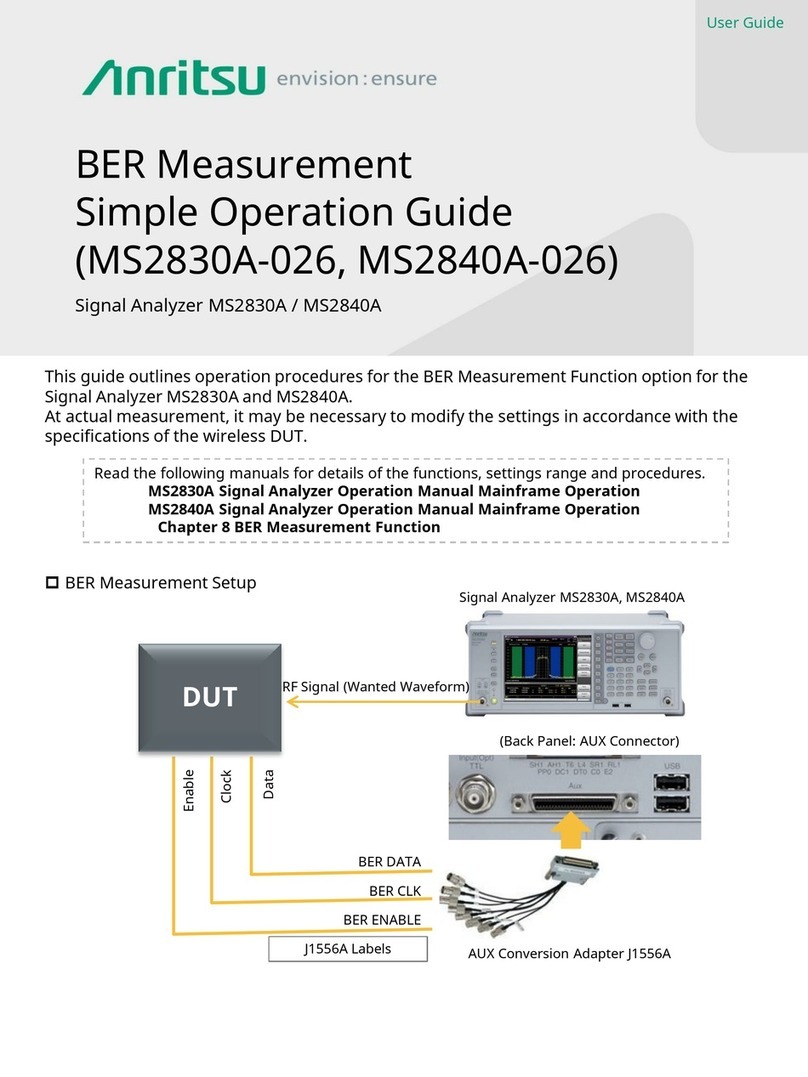

The following figure shows the principle structure of the instrument:

Fig. 2-2: Functional principle of the instrument

Functional principle

1. The x-ray tube generates the primary x-radiation (primary radiation). The electrically

heated cathode emits electrons. Accelerated by the applied high voltage to very high

speeds, the electrons bombard the anode material. This generates the primary

x-radiation.

2. The primary filter optimizes the energy distribution of the primary x-radiation.

3. The shutter serves as a safety device and closes the access of the primary x-radiation

to the measurement chamber, if needed.

X-ray tube

Cathode Anode

Primary x-radiation

Mirror

Lens

Video camera

Aperture

Coating layer

Base material

X-ray fluorescence radiation

Spectrum

WinFTM

main window

Detector

Shutter

Primary filter

14 FISCHERSCOPE®X-RAY

Instrument Overview Functional Principle of the Instrument

4. A light source (not shown in Fig. 2-2) illuminates the sample. A mirror and lens direct

the image of the measurement location to a color video camera. The mirror has a hole

in its center for the primary radiation to pass through.

5. The aperture (collimator) limits the cross-section of the primary beam in order to excite

a measurement spot of a defined size.

6. The primary x-radiation impacts the atoms on the sample surface (coating layer and

base material) and in the process knocks electrons from the inner electron shell.

Electrons from outer electron shells fill the resultant voids emitting a fluorescence

radiation that is characteristic in its energy distribution for a particular material.

7. The energy dispersive detector measures the energy distribution of the fluorescence

radiation. A multistage electronics circuit processes the measurement signals.

8. The measured spectrum shows lines or peaks that are characteristic for the chemical

elements in the sample.

9. The WinFTM Software computes the thickness of the coating(s) and/or the analysis

result. The video image of the sample is shown in the WinFTM window. The precise

position of the measurement location and the measurement spot is possible due to the

special design of the optical and the x-ray guidance systems.

FISCHERSCOPE®X-RAY 15

Components

2.4 Components

2.4.1 Aperture (Collimator)

The aperture is used to limit the size of the primary x-ray beam to a defined diameter or

cross-section.

The aperture is a borehole with defined geometries (rectangular or round) and sizes,

through which part of the primary x-ray beam passes. Thus, a fraction of the primary radi-

ation is suppressed.

A reproducible, controlled and defined primary x-ray beam geometry is an important

prerequisite for good measurement accuracy.

To create ideal excitation conditions for every measurement, the instrument is equipped

with several electrically changeable apertures, see the Technical Data Sheet in the

addendum of this document. Using the software, you can select the optimum aperture for

the respective measurement application.

To select the aperture:

1. In the WinFTM main window select Product > Modify….

The window Modify product appears.

2. Select the tab Application.

3. Click Collim..

4. Select the collimator and click OK.

2.4.2 Shutter

The shutter is used to keep the primary x-rays from entering the measurement chamber

and the environment.

The shutter is part of the safety system. The shutter closes immediately, when a malfunc-

tion occurs. X-rays can then no longer reach the measurement chamber and the environ-

ment.

2.4.3 Specimen Lighting

The specimen lighting ensures good visibility of the specimen in the video window. The

lighting elements are white LEDs that are located in the area of the aperture.

Use the slide control in the video window to adjust the intensity of the illumination.

16 FISCHERSCOPE®X-RAY

Components

2.4.4 Primary filter (Optional)

The primary filter consists of a thin foil made of nickel or aluminum, which is located

between the x-ray tube and the specimen to be measured.

By using a primary filter, the composition of the primary X-radiation can be influenced such

that it is optimally suited for the excitation of the respective specimen for x-ray fluores-

cence. Thus, undesirable components of the fluorescence spectrum can be avoided from

the outset.

Using a primary filter is useful for certain applications, however, it is not required in most

cases. The user requires special physical knowledge for a case-by-case evaluation of this

question.

The primary filter can be controlled using the software, if the WinFTM extension SUPER

is installed.

To change the primary filter:

1. In the WinFTM main window select Product > Modify….

The window Modify product appears.

2. Select the tab Application.

3. Click Def.MA (local).

The window Definition of measuring conditions… appears.

4. In the upper right field select the desired primary filter and click OK.

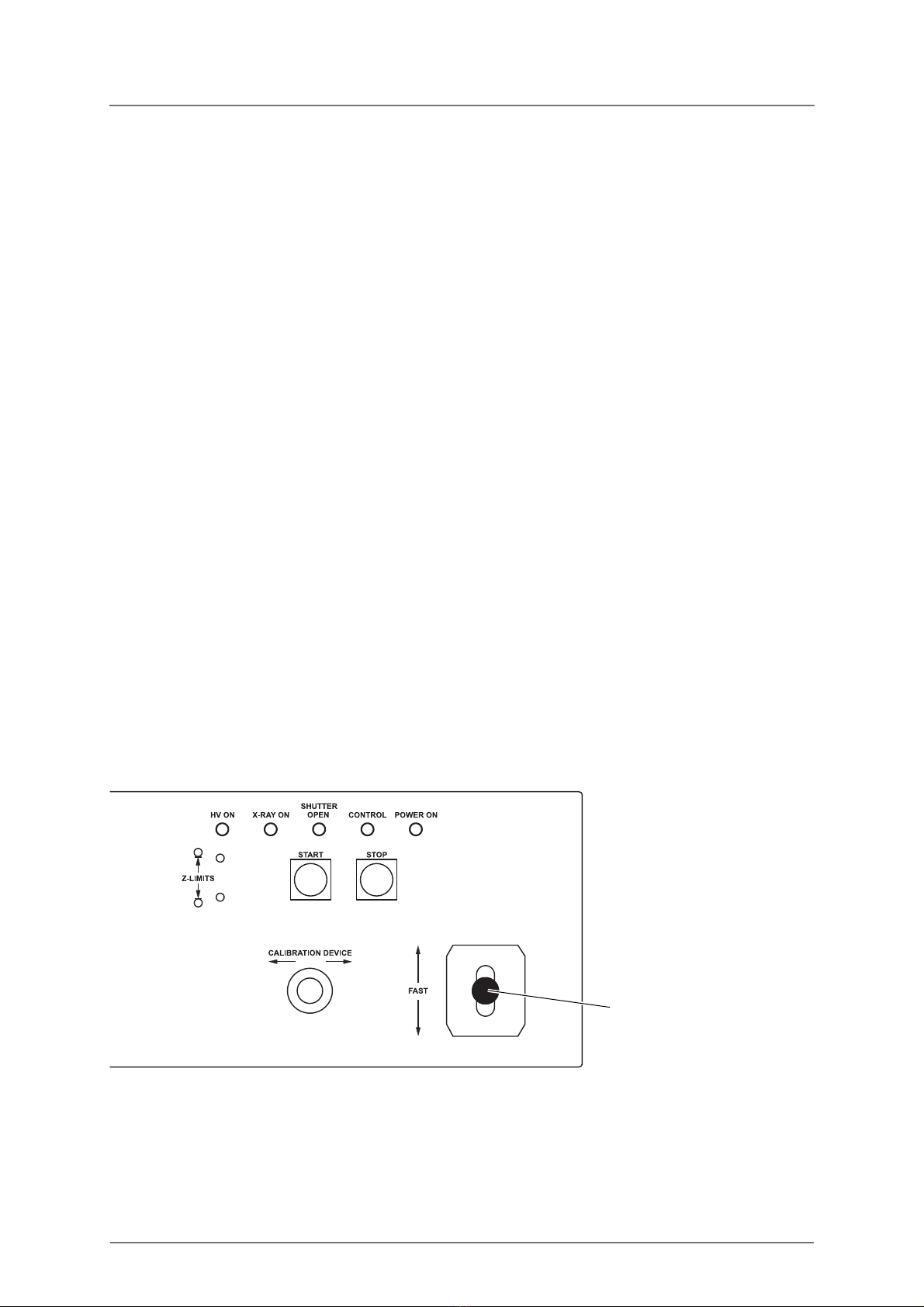

2.4.5 Control Panel

You can use the control panel to control certain functions of the instrument.

Fig. 2-3: Control panel of the instrument

Joystick

FISCHERSCOPE®X-RAY 17

Components

Table 2-1: Function of the operating controls

Operating control Function

Joystick Controls the measuring stage movement.

START Starts a single measurement.

STOP Stops a measurement.

Table 2-2: Function of the LEDs

LED Function

HV ON Lights yellow when the high voltage is turned on.

X-RAY ON Lights red when the X-radiation is ready.

SHUTTER OPEN Lights yellow when a measurement is in progress.

CONTROL Flashes red when the safety system discovers an error or when

the cover is not fully closed, measurements are not possible.

No malfunction message of the safety system is present if the

LED does not light.

POWER ON Lights green when the instrument is switched on.

18 FISCHERSCOPE®X-RAY

Components

FISCHERSCOPE®X-RAY 19

Switching on the Instrument Switching the Instrument on and off

3 Switching the Instrument on and off

3.1 Switching on the Instrument

The following section describes how to switch on the X-RAY measuring head and the PC.

Always pay attention to this section, when you need to switch on the measuring head, e.g.

after an emergency shut-off.

To switch on the instrument and the PC

1. Switch on the instrument by using the Off/On rocker switch at the rear of the instru-

ment.

2. Plug the FISIM (Fischer Software Identification Module) into an USB port of the

computer.

3. Switch on the PC and the monitor.

Windows will be started.

4. Wait for at least 2 minutes.

The sensor located in the instrument needs this time to reach its operating

temperature.

5. To start WinFTM, double click the WinFTM icon .

6. In the WinFTM start window click OK.

The software will open in the ready-to-measure mode (Communication on). The

product that had been selected prior to powering off will be called automatically.

What you can do next

You can now perform measurements.

CAUTION

Wrong measurement readings

If you don‘t follow the steps described in the following section, the measurement

readings may be wrong.

Follow the steps described below when switching on the measuring head.

The following activities must not be performed immediately after power up, but

only after about half an hour of measuring time:

Calibration and normalization

Monitoring measurement devices including corrective measures

20 FISCHERSCOPE®X-RAY

Switching the Instrument on and off Switching off the Instrument

3.2 Switching off the Instrument

To switch off the instrument and the PC

1. Switch off the instrument by using the Off/On rocker switch at the rear of the instru-

ment.

2. To terminate WinFTM, select File > Exit.

3. To shut down the PC, select Start > Shut down.

4. Switch off the monitor and the printer, if present.

3.3 Communication between Instrument and WinFTM

Communication between instrument and WinFTM is necessary to obtain measurements

with the instrument.

Determining the current communication condition

If the communication is enabled, the measurement distance appears in the status bar.

If the communication is disabled, XRAY Communication OFF appears in the status

bar of the WinFTM window.

It is not possible to make measurements when the communication is disabled, that is,

when WinFTM is in demo mode.

To enable the communication

In the WinFTM main window select General > Communication ON.

To disable the communication

In the WinFTM main window select General > Communication OFF.

Table of contents

Other FISCHER Analytical Instrument manuals