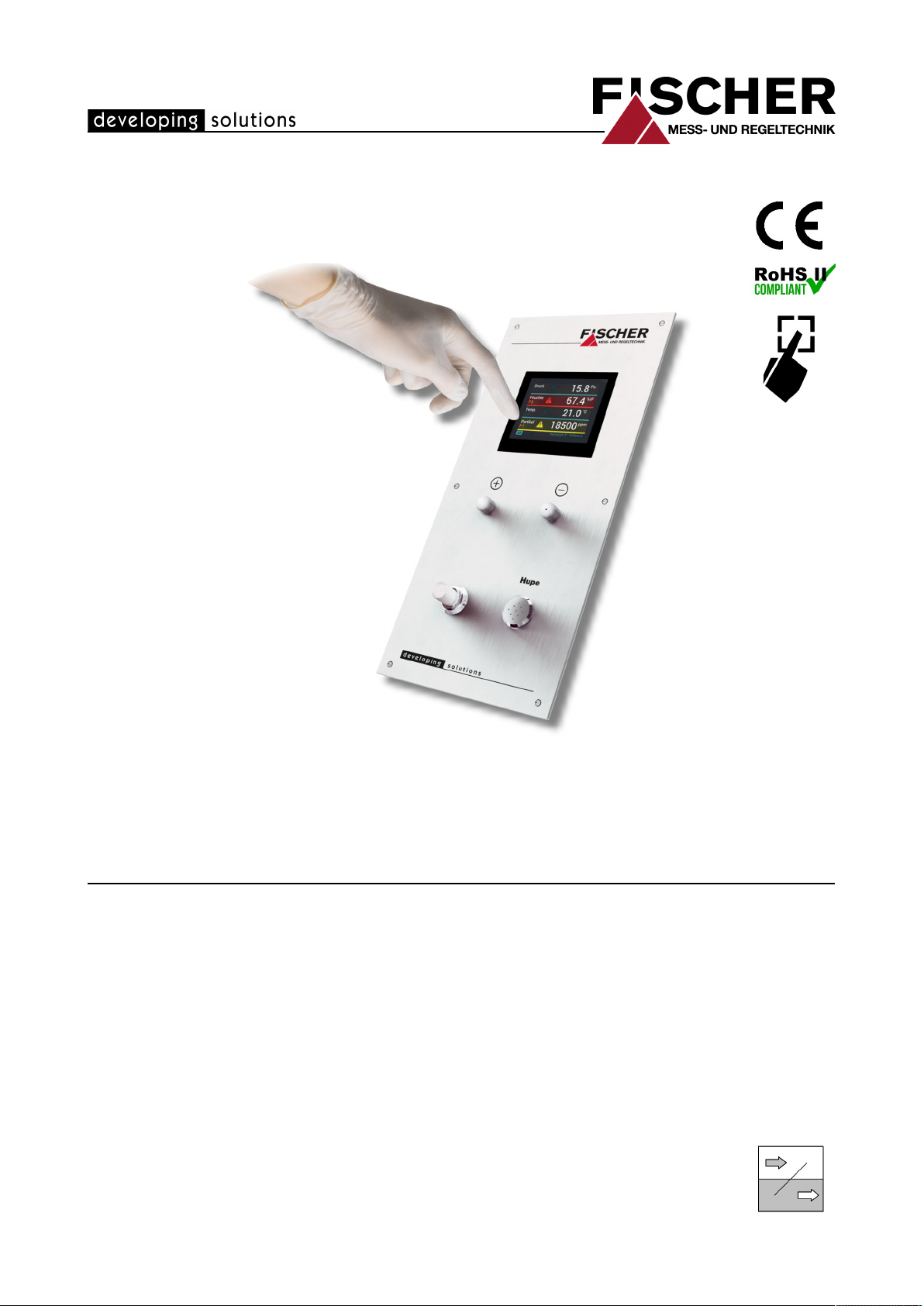

FISCHER EA16 Series User manual

Operating manual

EA16

Measured value display

Component for panel installation

09005809 • BA_EN_EA16 • Rev. ST4-B • 01/19

*09005809*

| Masthead FISCHER Mess- und Regeltechnik GmbH

2 / 88 BA_EN_EA16

Masthead

Manufacturer: FISCHER Mess- und Regeltechnik GmbH

Bielefelderstr. 37a

D-32107 Bad Salzuflen

Telephone: +49 5222 974 0

Telefax: +49 5222 7170

eMail: [email protected]

web: www.fischermesstechnik.de

Technical editorial team: Documentation representative: T. Malischewski

Technical editor: R. Kleemann

All rights, also those to the translation, reserved. No part of this document may

be reproduced or processed, duplicated or distributed using electronic systems

or any other form (print, photocopy, microfilm or another process) without the

written consent of the company FISCHER Mess- und Regeltechnik GmbH, Bad

Salzuflen.

Reproduction for internal use is expressly allowed.

Brand names and procedures are used for information purposes only and do

not take the respective patent situation into account. Great care was taken

when compiling the texts and illustrations; Nevertheless, errors cannot be ruled

out. The company FISCHER Mess- und Regeltechnik GmbH will not accept any

legal responsibility or liability for this.

Subject to technical amendments.

© FISCHER Mess- und Regeltechnik GmbH

Version history

Rev. ST4-A 03/16 Version 1 (first edition)

Rev. ST4-B 01/19 Version 2 (new versions)

FISCHER Mess- und Regeltechnik GmbH Table of Contents

BA_EN_EA16 3 / 88

Table of Contents

1 Safety guidelines ............................................................................................................................................5

1.1 General .....................................................................................................................................................5

1.2 Personnel Qualification.............................................................................................................................5

1.3 Risks due to Non-Observance of Safety Instructions ...............................................................................5

1.4 Safety Instructions for the Operating Company and the Operator............................................................5

1.5 Unauthorised Modification ........................................................................................................................5

1.6 Inadmissible Modes of Operation .............................................................................................................6

1.7 Safe working practices for maintenance and installation work .................................................................6

1.8 Pictogram explanation ..............................................................................................................................6

2 Product and functional description ..............................................................................................................7

2.1 Use as intended........................................................................................................................................7

2.2 Function diagram ......................................................................................................................................7

2.3 Design and mode of operation..................................................................................................................8

3 Installation and assembly..............................................................................................................................9

4 Commissioning.............................................................................................................................................10

4.1 General ...................................................................................................................................................10

4.2 Measured value display ..........................................................................................................................11

4.2.1 Tile view ...................................................................................................................................... 11

4.2.2 List view ...................................................................................................................................... 13

4.2.3 Presentation variants .................................................................................................................. 15

4.3 Control elements.....................................................................................................................................16

5 Parameterization...........................................................................................................................................18

5.1 General Information ................................................................................................................................18

5.2 Navigation in the menu tree....................................................................................................................18

5.3 Value input..............................................................................................................................................19

5.3.1 Input of number values ............................................................................................................... 19

5.3.2 Text input .................................................................................................................................... 19

5.3.3 Select parameter values ............................................................................................................. 20

5.3.4 Dialogue box ............................................................................................................................... 20

5.4 Main menu [Level 1] ...............................................................................................................................21

5.4.1 Menu: History [Level 2] ............................................................................................................... 22

5.4.1.1 Graphic display ........................................................................................................... 22

5.4.2 Menu: Event log [Level 2] ........................................................................................................... 29

5.4.3 Menu: Log on / log off [Level 2]................................................................................................... 30

5.4.4 Menu: Configuration [Level 2] ..................................................................................................... 31

5.4.4.1 Menu: Display [Level 3] ............................................................................................... 32

5.4.4.2 Menu: Switch outputs [Level 3] ................................................................................... 33

5.4.4.3 Menu: Inputs [Level 3] ................................................................................................. 40

5.4.4.4 Menu: Outputs [Level 3] .............................................................................................. 68

5.4.4.5 Menu: Datalogger [Level 3] ......................................................................................... 72

5.4.5 Menu: Language [Level 2] .......................................................................................................... 76

Table of Contents FISCHER Mess- und Regeltechnik GmbH

4 / 88 BA_EN_EA16

5.4.6 Menu: System [Level 2] .............................................................................................................. 76

5.4.6.1 Menu: Configuration [Level 3] ..................................................................................... 77

5.4.6.2 Menu: Overview inputs/outputs [Level 3] .................................................................... 77

5.4.6.3 Menu: System info [Level 3] ........................................................................................ 78

5.4.6.4 Menu: Firmware update [Level 3]................................................................................ 79

5.4.6.5 Menu: Date/Time [Level 3] .......................................................................................... 79

5.4.6.6 Menu: Unmount SD card [Level 3] .............................................................................. 80

5.4.6.7 Menu: Data transfer SD->USB [Level 3] ..................................................................... 81

5.4.6.8 Menu: Convert log data [Level 3] ................................................................................ 81

5.4.6.9 Menu: Delete SD card [Level 3] .................................................................................. 82

5.4.6.10 Menu: Change passwords [Level 3]............................................................................ 82

6 Technical data...............................................................................................................................................83

6.1 Generalities.............................................................................................................................................83

6.2 Input variables ........................................................................................................................................83

6.2.1 Analogue inputs A1 ... A4 ........................................................................................................... 83

6.2.2 Digital inputs I/O1 ... I/O4............................................................................................................ 83

6.3 Output parameters..................................................................................................................................83

6.3.1 Analogue outputs A1 ... A4 ......................................................................................................... 83

6.3.2 Digital outputs I/O1 ... I/O4.......................................................................................................... 84

6.3.3 Switching outputs K1 ... k4.......................................................................................................... 84

6.4 Measurement accuracy ..........................................................................................................................84

6.5 Digital interfaces .....................................................................................................................................85

6.6 Display and operating interface ..............................................................................................................85

6.7 Auxiliary energy .....................................................................................................................................85

6.8 Application conditions .............................................................................................................................85

6.9 Construction design ................................................................................................................................85

7 Order Codes..................................................................................................................................................86

8 Attachments..................................................................................................................................................87

8.1 EU Declaration of Conformity .................................................................................................................87

FISCHER Mess- und Regeltechnik GmbH Safety guidelines | 1

BA_EN_EA16 5 / 88

1 Safety guidelines

1.1 General

WARNING

This operating manual contains instructions fundamental to the installation, op-

eration and maintenance of the device that must be observed unconditionally. It

must be read by the assembler, operator and the specialized personnel in

charge of the instrument before it is installed and put into operation.

This operating manual is an integral part of the product and therefore needs to

be kept close to the instrument in a place that is accessible at all times to the re-

sponsible personnel.

The following sections, in particular instructions about the assembly, commis-

sioning and maintenance, contain important information, non-observance of

which could pose a threat to humans, animals, the environment and property.

The instrument described in these operating instructions is designed and manu-

factured in line with the state of the art and good engineering practice.

1.2 Personnel Qualification

The instrument may only be installed and commissioned by specialized person-

nel familiar with the installation, commissioning and operation of this product.

Specialized personnel are persons who can assess the work they have been

assigned and recognize potential dangers by virtue of their specialized training,

their skills and experience and their knowledge of the pertinent standards.

1.3 Risks due to Non-Observance of Safety Instructions

Non-observance of these safety instructions, the intended use of the device or

the limit values given in the technical specifications can be hazardous or cause

harm to persons, the environment or the plant itself.

The supplier of the equipment will not be liable for damage claims if this should

happen.

1.4 Safety Instructions for the Operating Company and the Operator

The safety instructions governing correct operation of theinstrument must be

observed. The operating company must make them available to the installation,

maintenance, inspection and operating personnel.

Dangers arising from electrical components, energy discharged by the medium,

escaping medium and incorrect installation of the device must be eliminated.

See the information in the applicable national and international regulations.

Please observe the information about certification and approvals in the Tech-

nical Data section.

1.5 Unauthorised Modification

Modifications of or other technical alterations to the instrument by the customer

are not permitted. This also applies to replacement parts. Only the manufacturer

is authorised to make any modifications or changes.

1 | Safety guidelines FISCHER Mess- und Regeltechnik GmbH

6 / 88 BA_EN_EA16

1.6 Inadmissible Modes of Operation

The operational safety of this instrument can only be guaranteed if it is used as

intended. The instrument model must be suitable for the medium used in the

system. The limit values given in the technical data may not be exceeded.

The manufacturer is not liable for damage resulting from improper or incorrect

use.

1.7 Safe working practices for maintenance and installation work

The safety instructions given in this operating manual, any nationally applicable

regulations on accident prevention and any of the operating company's internal

work, operating and safety guidelines must be observed.

The operating company is responsible for ensuring that all required mainten-

ance, inspection and installation work is carried out by qualified specialized per-

sonnel.

1.8 Pictogram explanation

DANGER

Type and source of danger

This indicates a direct dangerous situation that could lead to death or serious

injury (highest danger level).

a) Avoid danger by observing the valid safety regulations.

WARNING

Type and source of danger

This indicates a potentially dangerous situation that could lead to death or ser-

ious injury (medium danger level).

a) Avoid danger by observing the valid safety regulations.

CAUTION

Type and source of danger

This indicates a potentially dangerous situation that could lead to slight or seri-

ous injury, damage or environmental pollution (low danger level).

a) Avoid danger by observing the valid safety regulations.

NOTICE

Note / advice

This indicates useful information of advice for efficient and smooth operation.

FISCHER Mess- und Regeltechnik GmbH Product and functional description | 2

BA_EN_EA16 7 / 88

2 Product and functional description

2.1 Use as intended

The EA16 is a measuring value display unit for measuring transducers with out-

put signals for current and voltage acc. to IEC 60381. Up to four measuring

transducers in two or three-conductor versions can be connected.

Typical applications

• Measured value display in clean room

Important features

• 3.5" (8.9 cm) TFT Touch LCD colour display

• Configurable colour switching

• 2 or 4 channel mode with …

– 2 or 4 configurable analogue inputs

for uniform signals (0/4 … 20 mA, 0 … 10 V) acc. to IEC 60381

(signal ranges ca be selected freely within the limits; see Technical

Data)

– 2 or 4 configurable analogue outputs

with possibility of characteristic curve spread and reversal with any off-

set

– 2 or 4 configurable switching outputs

with potential-free relay contacts or semiconductor switches

• USB interface

• Optional Modbus RTU interface

• Optional data logger function with data storage on Micro SD card

• Configuration of all parameters and a measuring point protocol(1) are pos-

sible via PC software

2.2 Function diagram

1E

2E

3E

4E

USB

SD

A

D A

DA1

A2

A3

A4

K1

K2

K3

K4

CPU

21

3

4

5

6

Modbus RTU

7

Fig.1: Function diagram

1 Analogue inputs 2 Analogue outputs

3 Touch colour display 4 Switching outputs

5 Micro SD memory card 6 Micro USB interface

7 Modbus interface (option)

(1) parameter profile

2 | Product and functional description FISCHER Mess- und Regeltechnik GmbH

8 / 88 BA_EN_EA16

2.3 Design and mode of operation

The measuring signals of up to four connected measuring transducers can be

analysed simultaneously by the microcontroller electronics. The configurable

3.5" touch display can display up to four measuring values at the same time. A

configurable colour switch serves to present specific operating modes. Option-

ally, the device can be delivered with a data logger function.

The processed input signals are converted into the following output signals:

• 2 or 4 configurable switching outputs. Parameters, such as activation and

deactivation points, switching function or delay, are available for this pur-

pose. The switching states are displayed with symbols on the display.

• 2 or 4 analogue outputs with configurable output range. Every output signal

can be set freely within the signal limits (see Technical Data). The charac-

teristic curve change can be made in a linear, rooted, tabular or mathematic

form proportional to the displayed value.

The unit also has a Modbus interface and can be connected to a Modbus RTU

network as a slave. For more information about this topic, please reference the

product user manual and the Modbus reference manual.

(http://www.fischermesstechnik.de/en/downloads/manuals)

All parameters can also be set on the device via the touch display or (optionally)

via a PC software. The measuring value display unit has a USB interface to

which a USB stick can be connected. For instance, the USB stick can be used

to allow simple configurations to be exported to other devices. The PC software

also allows a measuring point protocol (2) .

(2) parameter profile

FISCHER Mess- und Regeltechnik GmbH Installation and assembly | 3

BA_EN_EA16 9 / 88

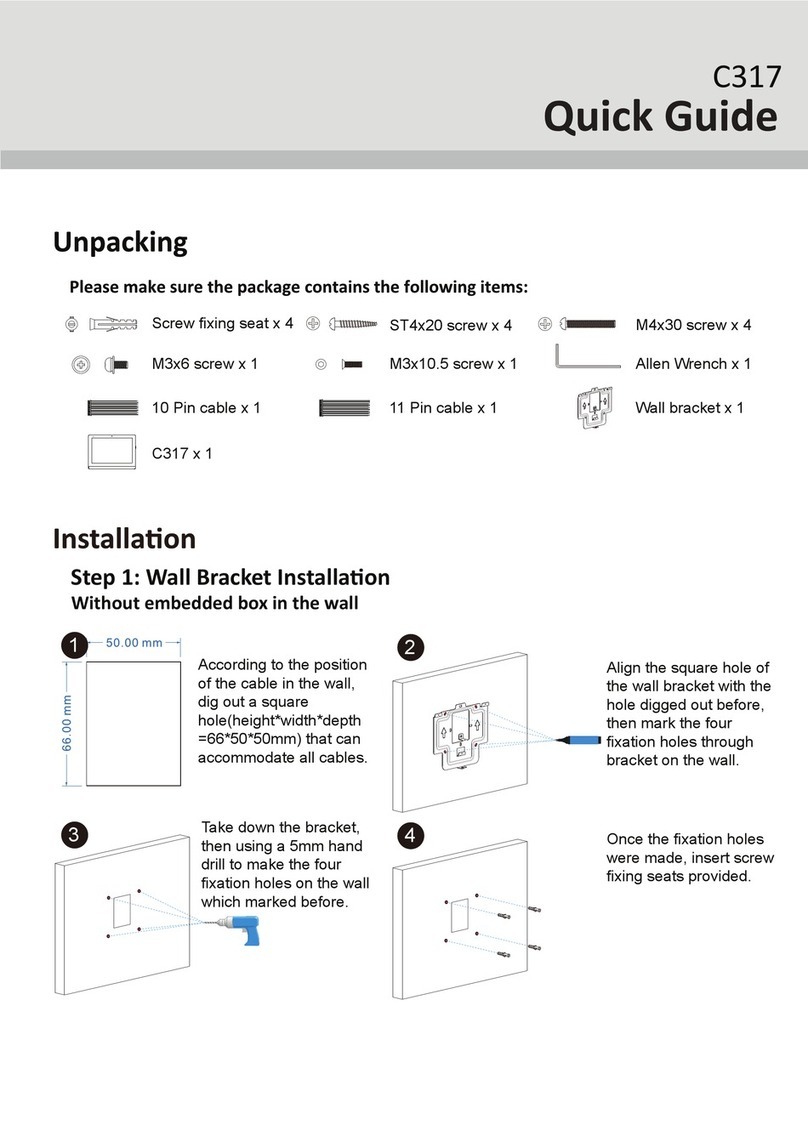

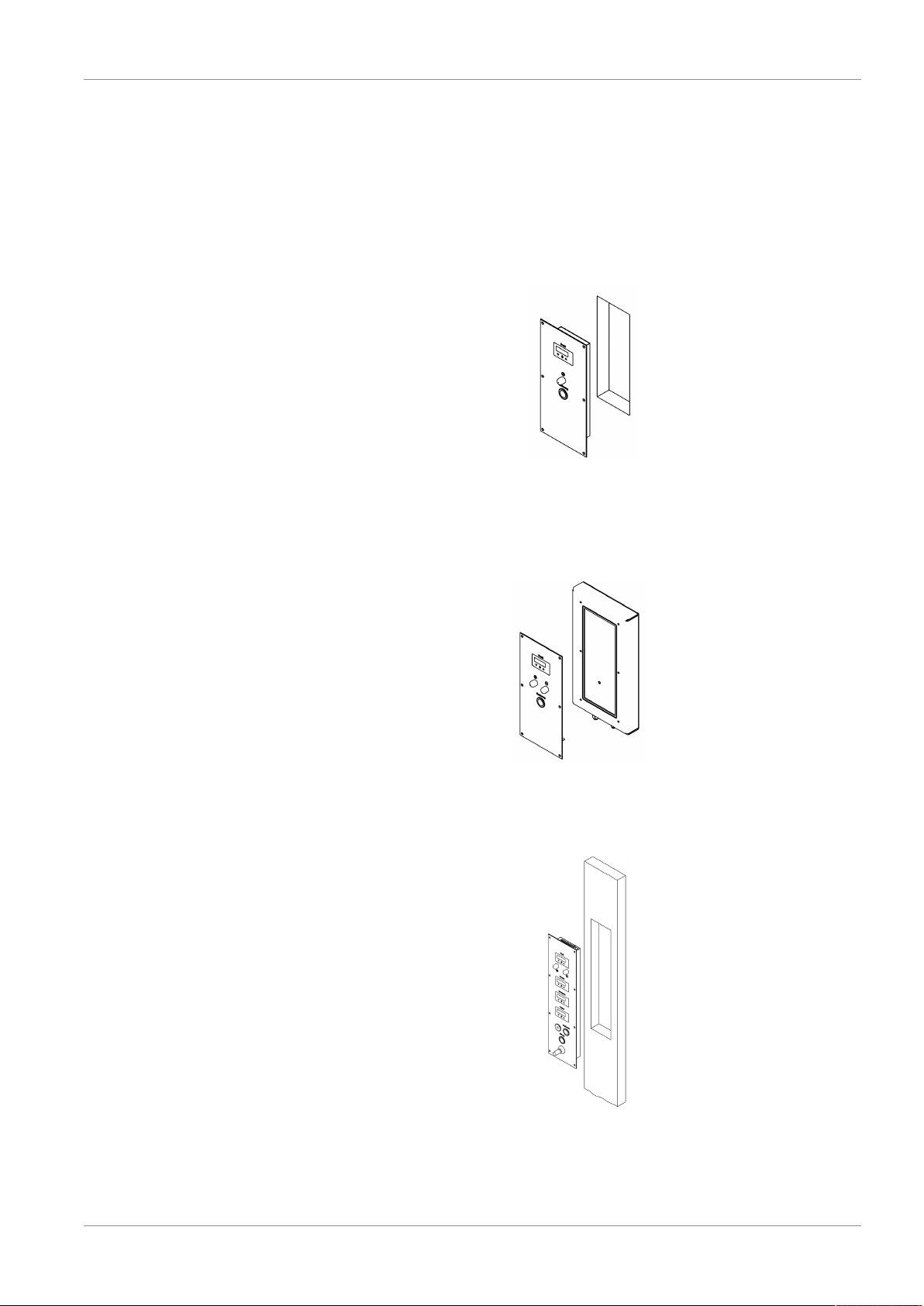

3 Installation and assembly

The EA16 is designed for panel installation and is supplied fully assembled.

Please see the supplied electro-technology documents for the dimensional

drawings and information about the electrical connection of the panel. Panels

can always be supplied in the following mounting types.

Wall-mounting

Via a recess in the wall in the clean room. The minimum installation depth is 49

mm. The panel is attached with sunk-head screws.

Fig.2: Wall-mounting

Surface installation

Via surface-mounted housing on the wall of the clean room. The minimum in-

stallation depth is 52 mm. The panel is attached to the surface-mounted hous-

ing with sunk-head screws.

Fig.3: Surface installation

Channel assembly

Via a cut-out in the channel The minimum installation depth is 49 mm. The

panel is attached with sunk-head screws.

Fig.4: Channel installation

4 | Commissioning FISCHER Mess- und Regeltechnik GmbH

10 / 88 BA_EN_EA16

4 Commissioning

4.1 General

All electrical supply, operating and measuring lines, and the pressure connec-

tions must have been correctly installed before commissioning.

NOTICE

Illustrations

All illustrations are examples to demonstrate a certain situation. The contents of

the screen may vary greatly on the unit. For instance, the names of the input

channels can be freely selected; the status displays for the switch outputs can

be hidden and lots more.

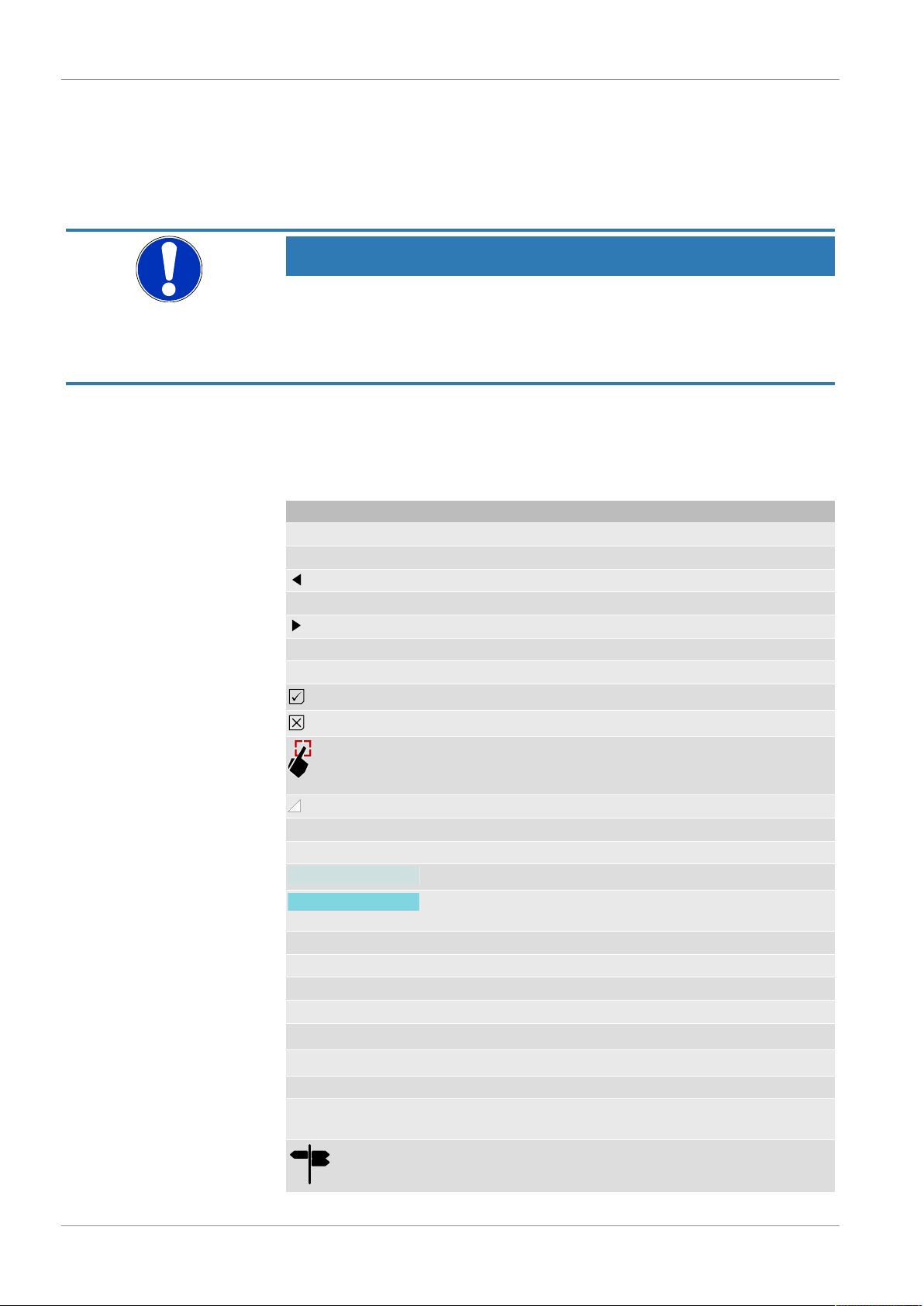

Pictogram explanation

This table explains how the different objects (menu, parameters, etc.) are

shown in the text of these operating instructions. Due to modifications to the

background colour, the colour of the presentation of some symbols on the

screen may vary.

Symbol Description

Operating keys

þ

Increasing

W

Left

û

OK

X

right side

ÿ

decreasing

Esc

Cancel

yes on

N/a Off

Touch the screen (with your hand or stylus

pen), the symbol may be in a different col-

our

Paging symbol

Menu

Parameters

Menu name (button)

Parameters

Menu and/or parameter not valid under cer-

tain conditions.

File Parameter name

<Value> System parameter value

Access Rights

T

No access

V

read only

NOTICE!Swipe function Important comments

e.g. only swipe function

Further left

FISCHER Mess- und Regeltechnik GmbH Commissioning | 4

BA_EN_EA16 11 / 88

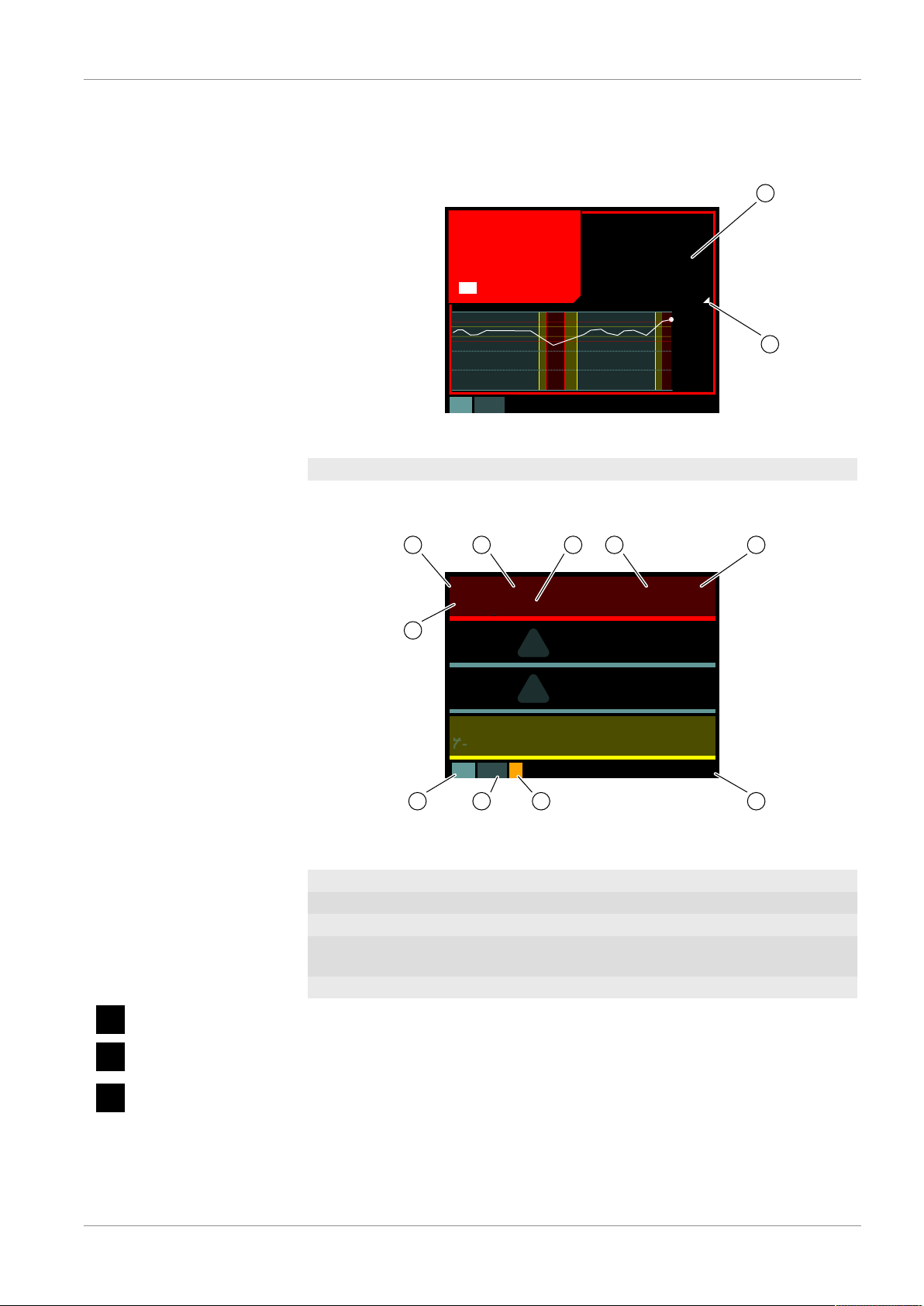

4.2 Measured value display

There are two options for the measured value display presentation.

• Tile view

• List view

The colour of the individual chapters can be changed depending on the respect-

ive input signal. To do this, certain thresholds are configured for each colour in

the menu

Colour change

. The associated colours represent the respective

operating statuses.

In the list view, the background shadowing and the warning symbol assume the

function of the tiles. The colours are controlled depending on the input signal

like the tiles.

Depending on the unit model (2-channel/4-channel), there are different present-

ation variants [}15] for the measured value display.

4.2.1 Tile view

Pressure Pa

35.8

E1O2

O4

O3

Humidity %rF

55

Temp °C

24.7

Particle ppm

12803

PQ

2

3

1

4

5 6

Monitoring sluice 1

7

Channel 1 Channel 2

Channel 4Channel 3

O-

Status bar T

8

Fig.5: Measured value display

1 Channel name 2 Einheit

3 Measurement 4 Status switch output

5 Status SD card 6 Status USB

7 Unit designation

or Date / Time

8 Login symbol

S1

R1

Contact switched

Contact not switched

R-No contact assigned

Fig.6: Status display

The example of a switch output demonstrates how the status display works.

1. The symbol for the switch output lights up, if the contact is switched.

2. The backlighting disappears, if the contact is not switched. The contact

symbol is shown in grey.

NOTICE!Back lighting

The backlighting colour is usually white. However the backlighting for a yellow

tile is black.

In the status displays for the SD card and USB interface, access to the medium

is symbolised by orange backlighting. The green backlighting shows that a unit

is connected. The backlighting is grey, if no unit is connected.

A logged-in user is shown by the login symbol. If the user is inactive, he will be

automatically logged out after a timeout time has expired.

4 | Commissioning FISCHER Mess- und Regeltechnik GmbH

12 / 88 BA_EN_EA16

Detail view channel 1

Fig.7: To detail view

Tip the respective tile to go to the detail view of a channel. Return to the meas-

ured value screen in the same way. The following uses the detailed view of the

first channel to demonstrate all channels.

Pressure Pa

35.8

E1O2

PQMonitoring sluice 1

50.00

0.00

-50.00

Warning:

Alarm: 30.00 Pa

25.00 PaWarning:

Alarm:

15.00 Pa

10.00 Pa

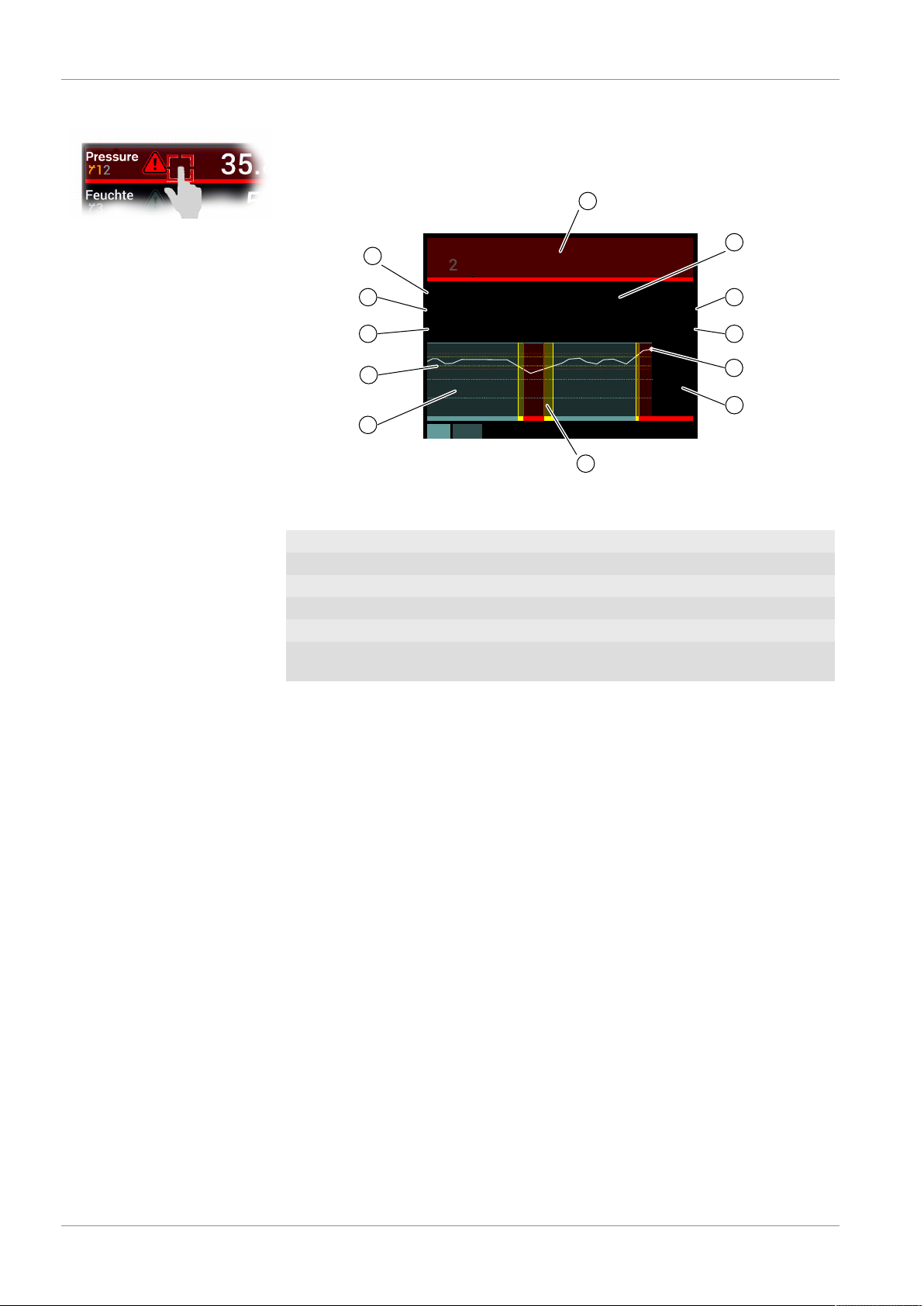

1

2

3

2.1

2.2

2.3

2.4

3.1

3.4

3.2

3.3

Fig.8: Detailed view

1 Measurement data display

2 Status display 3 Trend display

2.1 Alarm: Threshold value high - red 3.1 Current measured value

2.2 Warning: Threshold value high - yellow 3.2 Measuring range

2.3 Warning: Threshold value low - yellow 3.3 Colour change

2.4 Alarm: Threshold value low - red 3.4 Limit lines of the

thresholds

Status display

The page symbol shows that there are more screen pages in the status dis-

play. Touch anywhere on the status display to show the next page.

Pressure Pa

35.8

E1O2

PQMonitoring lock 1

50.00

0.00

-50.00

Warning:

Alarm: 30.00 Pa

25.00 PaWarning:

Alarm:

15.00 Pa

10.00 Pa

1

2

Fig.9: Status display

1 Status display 2 Paging symbol

FISCHER Mess- und Regeltechnik GmbH Commissioning | 4

BA_EN_EA16 13 / 88

The second page of the status display appears. Touch anywhere on the status

display to show the next page. At the end, you automatically return to the first

page.

Pressure Pa

35.8

E1O2

PQMonitoring sluice 1

50.00

0.00

-50.00

Pressure too high

1

2

Fig.10: Detail view alarm message

1 Message high - red (input 1) 2 Paging symbol

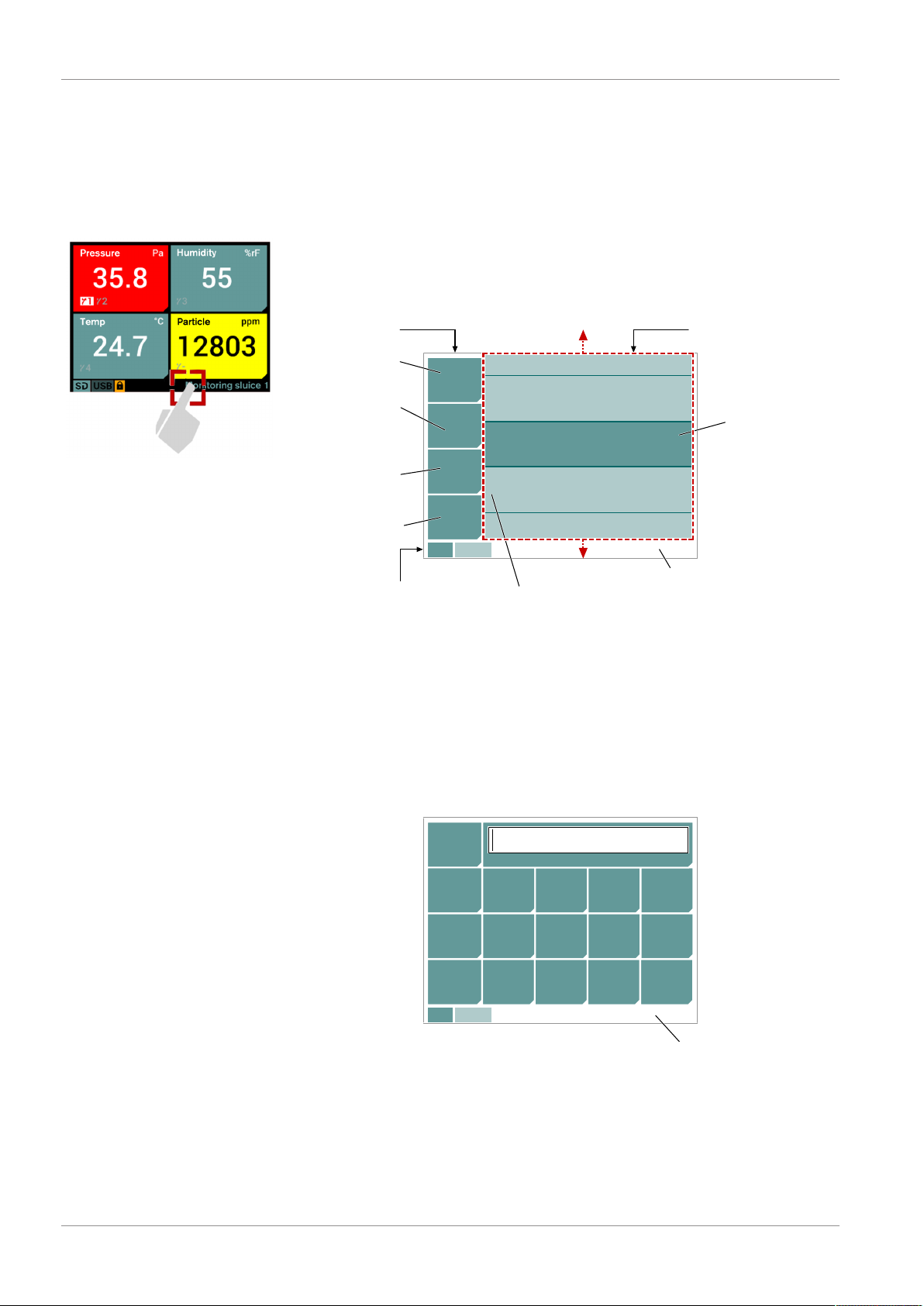

4.2.2 List view

Pressure

S135.8Pa

2

Humidity

S355%rF

Temp.

S424.7°C

Particle 12803ppm

PQMonitoring sluice 1

S-

Channel 1

Channel 2

Channel 3

Channel 4

1 23

4

5 6 7

89

Status bar T

10

C

B

C

B

C

B

C

B

C

Fig.11: Measured value display

1 Channel name 2 Einheit

3 Measurement 4 Status switch output

5 Status SD card 6 Status USB

7 Unit designation

or Date / Time

8 Warning signs

9 Background shadowing 10 Login symbol

S1Contact switched

Contact not switched

R1

No contact assigned

R-

Fig.12: Status display

The example of a switch output demonstrates how the status display works.

1. The symbol for the switch output goes orange, if the contact is switched.

2. The symbol for the switch output goes grey, if the contact is idle.

NOTICE!Back lighting

In the status displays for the SD card and USB interface, access to the medium

is symbolised by orange backlighting. The green backlighting shows that a unit

is connected. The backlighting is grey, if no unit is connected.

A logged-in user is shown by the login symbol. If the user is inactive, he will be

automatically logged out after a timeout time has expired.

4 | Commissioning FISCHER Mess- und Regeltechnik GmbH

14 / 88 BA_EN_EA16

Detail view channel 1

Fig.13: To detail view

Tip the respective list entry to go to the detail view of a channel. Return to the

measured value screen in the same way. The following uses the detailed view

of the first channel to demonstrate all channels.

Pressure

S135.8 Pa

2

PQMonitoring sluice 1

50.00

0.00

-50.00

Pressure too high

Warning:

Alarm: Alarm:

Warning:15.00 Pa

10.00 Pa

25.00 Pa

30.00 Pa

1

2

2.1

2.3 2.2

2.12.4

3

3.4 3.1

3.2

3.3

C

B

C

Fig.14: Detailed view

1 Measurement data display

2 Status display 3 Trend display

2.1 Alarm: Threshold value high - red 3.1 Current measured value

2.2 Warning: Threshold value high - yellow 3.2 Measuring range

2.3 Warning: Threshold value low - yellow 3.3 Colour change

2.4 Warning: Threshold value low - red 3.4 Limit lines of the

thresholds

FISCHER Mess- und Regeltechnik GmbH Commissioning | 4

BA_EN_EA16 15 / 88

4.2.3 Presentation variants

The unit is available in a 2-channel and 4-channel version. This setting is made

ex-works.

The detail views are identical to the detail views of the 4-channel version.

The analogue inputs on both versions can be switched off individually. This

status is indicated by OFF in the respective tile (or list). If two analogue outputs

are switched in the 4-channel version, the presentation variant of the 2-channel

model is shown on the measured value display.

2-channel tile view

PQMonitoring sluice 1

Channel 1

Channel 2

Status bar T

Temperature error °C

24.7

O1

Humidity %rF

55

O2

Fig.15: 2-channel measured value display

2-channel list view

Humidity

S255%rF

Temp.

S124.7°C

PQMonitoring sluice 1

Channel 1

Channel 2

Status bar T

Warning

Alert

°C20.0

15.0 °C

Warning

Alert

°C20.0

15.0 °C

Warning

Alert

%rF35,000

20,000 %rF

Warning

Alert

%rF55,000

70,000 %rF

B

C

C

B

C

Fig.16: 2-channel measured value display

4 | Commissioning FISCHER Mess- und Regeltechnik GmbH

16 / 88 BA_EN_EA16

4.3 Control elements

The unit is equipped with a TFT Touch LCD colour display. It is operated via a

list menu and the input interfaces that depend on the functions.

The touch function is not explained because so many devices have this state-

of-the-art function.

We recommend using a stylus pen.

Fig.17: Menu input

Example: Password input

Touch anywhere on the status bar to go to the menu. The following menu ap-

pears on the screen:

P

Esc

K

J

I

Log-in

Event log

History

Parameterization

Sprache (language)

T

T

T

QMain menu/

Menu bar

Escape button

OK button

Arrow button

upwards

Arrow button

downwards

Operating keys

Status bar

Menu path

Menu item

selected

Access rights

T

Fig.18: Main menu

The dotted red line marks the picture section. This can be moved using the ar-

row keys

þ

ÿ

, the arrow shows the respective direction.

The menu entry in the centre of the screen is always selected and opened by

pressing the OK button

û

. Alternatively, a menu entry can also be touched to

open it.

In this example, the screen opens when a password is entered. The menu path

shows where you are in the menu tree.

P

Esc

W

J

X

QMain menu/login/

DEL

1230

4 5 6 -

789

Please enter your password

Menu path

Fig.19: Main menu/login

FISCHER Mess- und Regeltechnik GmbH Commissioning | 4

BA_EN_EA16 17 / 88

Enter the password and complete the input by pressing the OK button

û

. A

message appears on the screen stating which user you have logged in with.

Once you have acknowledged the message, you return to the main menu.

The following user profiles are used:

User Rights

View The user only has read rights for the configuration options.

Expert The user may change some of the configuration options. The

user has no access to the passwords.

Admin The user may change all the configuration options. However the

user only has access to the passwords of the subordinate user

levels.

Supervisor This user has full access to all parameters and passwords.

5 | Parameterization FISCHER Mess- und Regeltechnik GmbH

18 / 88 BA_EN_EA16

5 Parameterization

5.1 General Information

The EA16 is a highly complex measured value display with a control system

that can be learned intuitively. Due to its complex structure and the possibility of

supplementing functions by means of a firmware update, it is not possible to

present all functions in details in these operating instructions.

The following describes the basic functions of the unit and how they are used.

NOTICE

Value ranges

The presented value ranges of the parameters correspond to the default values

of the factory configuration. If certain parameters are changed (e.g. measuring

range), the value ranges of the dependent parameters (e.g. thresholds) are

automatically adjusted. For this reason, the actually displayed value ranges may

differ from the value ranges shown in these instructions. The latter only serves

as a typical example.

5.2 Navigation in the menu tree

The menu can have up to six levels. There are several user profiles with various

read/write rights are filed in the user administration. Access to the menus and

parameter settings depends on the user.

The menu tree is navigated based on the following scheme:

P

Esc

K

J

I

Log-in

Event log

History

Configuration

Language

T

QMain menu/

V

V

P

Esc

K

J

I

Inputs

Switch outputs

Display

Outputs

Data logger

T

QMain menu/Configuration/

V

V

P

Esc

K

J

I

Configuration

Log off

Event log

Language

System

QMain menu/

V

V

Level 1 Level 2 Level 1

(a) Level change by direct tapping

(b) Level change by positioning the screen section

P

Esc

K

J

I

Log-in

Event log

History

Configuration

Language

T

QMain menu/

V

V

P

Esc

K

J

I

Configuration

Log off

Event log

Language

System

QMain menu/

V

V

P

Esc

K

J

I

Inputs

Switch outputs

Display

Outputs

Data logger

T

QMain menu/Configuration/

V

V

Level 2Level 1 Level 1 Level 1

P

Esc

K

J

I

Configuration

Log off

Event log

Language

System

QMain menu/

V

V

Fig.20: Navigation menu tree

FISCHER Mess- und Regeltechnik GmbH Parameterization | 5

BA_EN_EA16 19 / 88

5.3 Value input

The following provides a description of the input interfaces that are used to

enter the values. A differentiation is made between the input of numbers and

the input of texts. The screens shown are examples only and may vary in terms

of their layout and presentation.

Their functionality can be learned intuitively and is always based on the same

principle.

5.3.1 Input of number values

P

ESC

W

J

X

QInput signal.../Signal min./

DEL

1230

4 5 6 .

789

min.: 0.000V max.: 10.5000V

Menu path

allowed value range

Input field

10-digit keypad

Cursor

Navigation

-

changes to a

minus sign

0

Fig.21: Number input

Negative integers can be entered by deleting the number value (0 in the ex-

ample) in the display. The decimal point then changes to a minus sign and can

be used.

5.3.2 Text input

P Q Analogue input.../Designation/

... Pressure

A

N

B C D E F G H I J

K L M N O P Q R S T

U V W X Y S J

Menu path

Input fieldCursor

Keyboard Layout

Back button

Space button OK button

Fig.22: Text input

The key … is used to change the assignment of the key pad, and lower case

letters, numbers and special characters can be used.

5 | Parameterization FISCHER Mess- und Regeltechnik GmbH

20 / 88 BA_EN_EA16

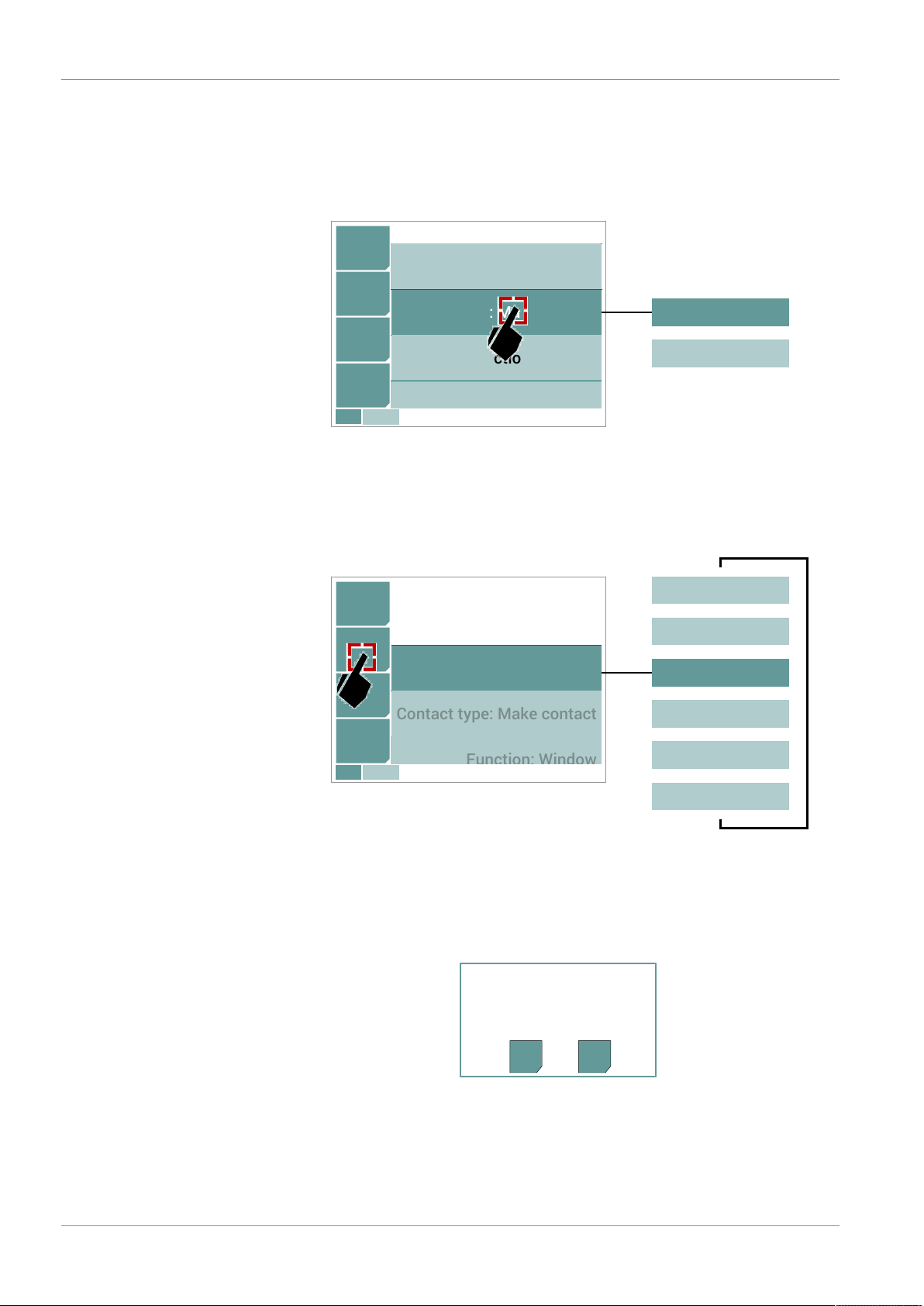

5.3.3 Select parameter values

Some inputs are made by selecting defined parameter values. This occurs

either by switching the button or by selection from a list.

Changeover button

ESC

K

J

I

Contact type: Make contact

Function: Window

Window max.

Switch out.../Switch output 1/

P Q

Assignment: Input 1

Button

Make contact

Break contact

g f

Fig.23: Select parameter values

Touch the button to change the parameter value. The set value is saved with

the button

û

.

Selection list

Touch the button to open the parameter. A screen as shown appears.

ESC

K

J

I

Assignment: Input 1

Contact type: Make contact

Function: Window

Switch out.../Switch output 1/

P Q

f

g

Value list

Input 3

Input 4

Input 1

Input 2

Colour change

Input -

f

g

f

f

g

g

f

Fig.24: Select parameter values

You can navigate the value list using the buttons

þ

and

ÿ

. The set value is

saved with the button

û

.

5.3.4 Dialogue box

YES

Accept

changes?

NO

Fig.25: Dialogue box

This or a similar dialogue box appears, if the user needs to confirm something.

Parameter changes are accepted after they have been confirmed with Yes, and

are logged in the activated event log. If rejected with NO, the changes are can-

celled.

Table of contents

Other FISCHER Monitor manuals