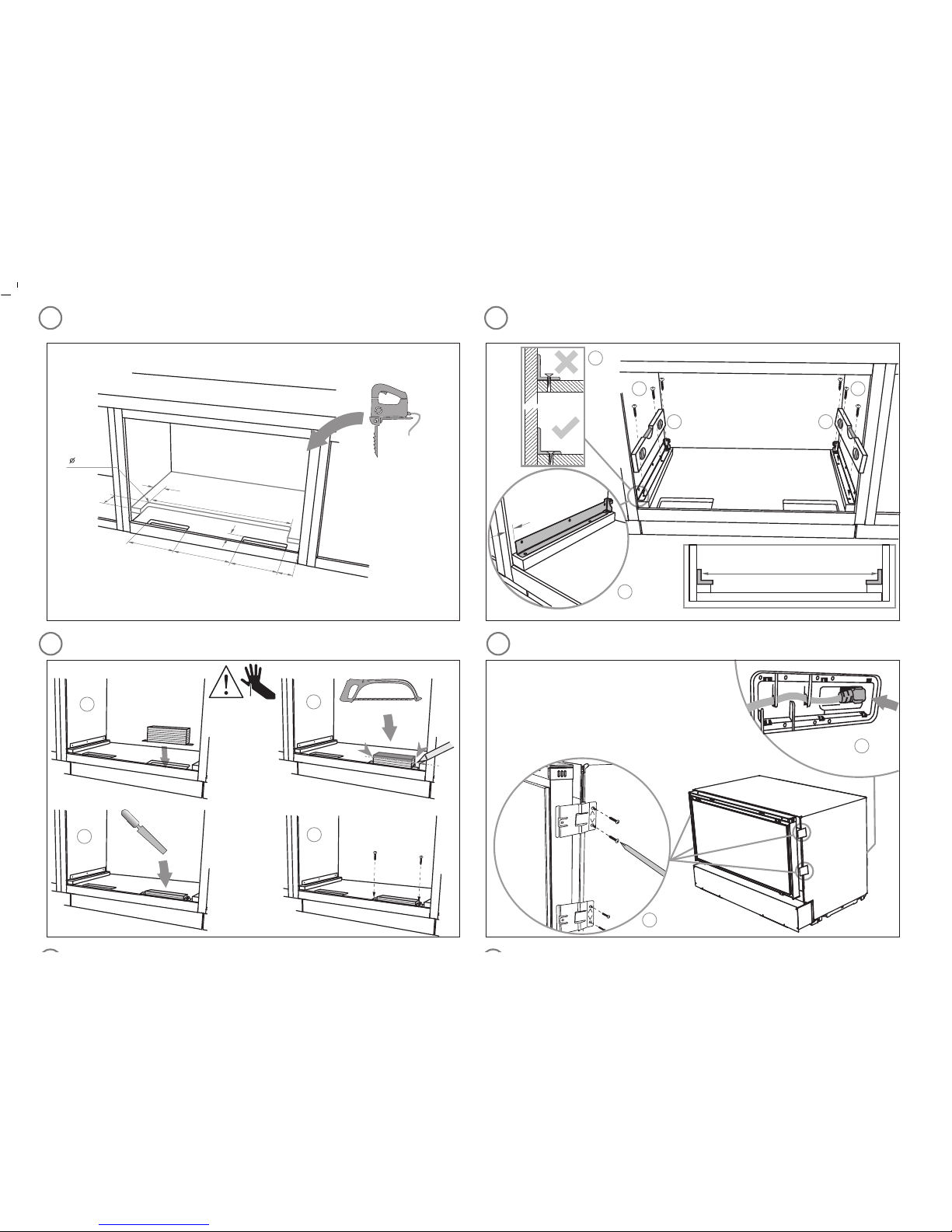

Important!

Disconnect power to surrounding appliances before preparing cavity.

Recommended to allow the vertical removal of the refrigerator bins.

WARNING!

Electrical shock hazard

Disconnect product from main power supply before installing appliance.

Failure to do so may result in electrical shock or death

Important safety precautions!

Installation of the CoolDrawer requires competent mechanical and electrical skills.

Be sure to leave these Instructions with the Customer.

Installation must comply with your local building and electricity regulations.

At the completion of the CoolDrawer installation, the Installer must perform the Final Check List.

Remove all packaging materials supplied with the CoolDrawer.

The CoolDrawer is manufactured for indoor use only.

Important!

SAVE THESE INSTRUCTIONS

The models shown in this document may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country, please go to our

website www.fisherpaykel.com or contact your local Fisher & Paykel dealer.

SAFETY AND WARNINGS

WARNING!

Cut hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

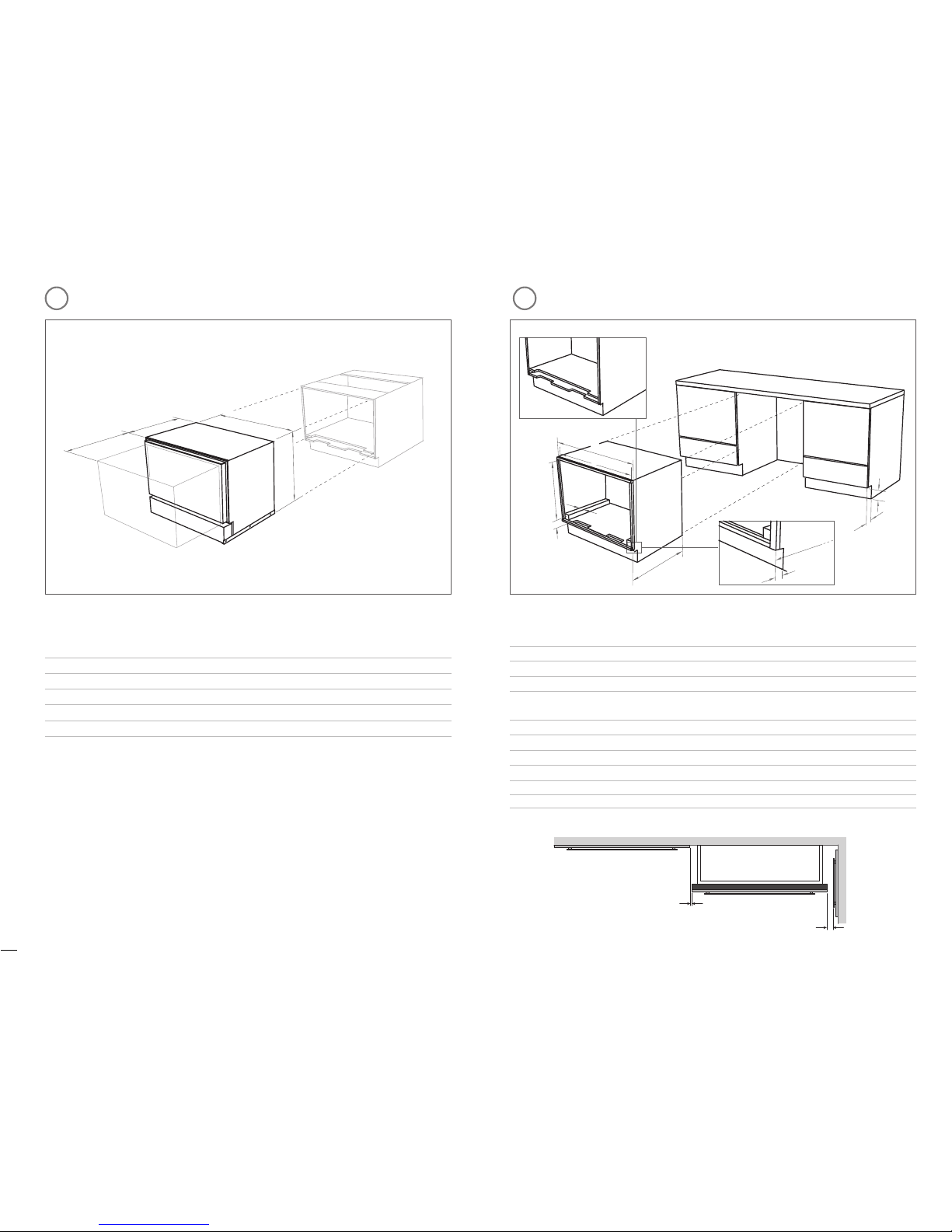

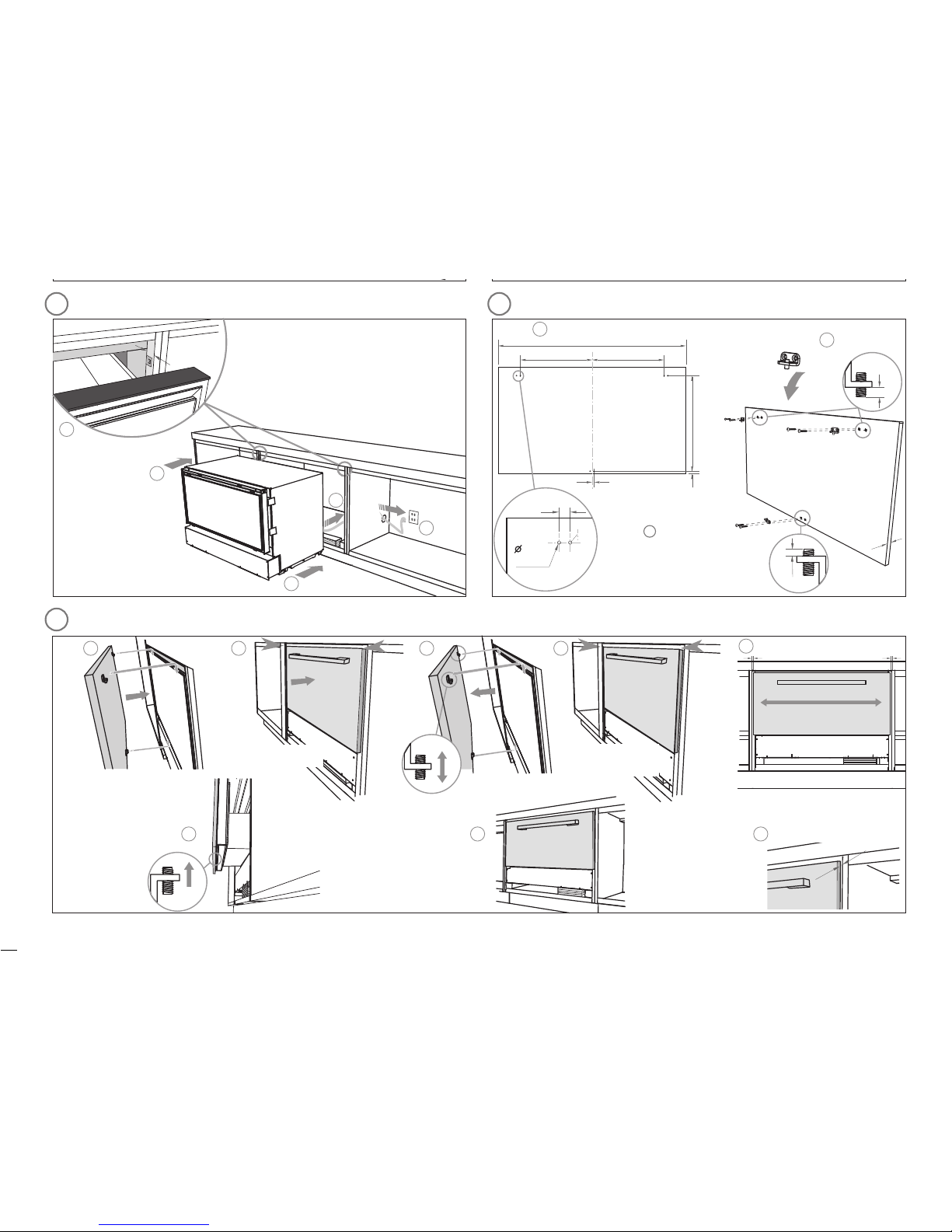

1

2

The CoolDrawer MUST be installed to allow for future removal from the enclosure if service is required.

Do not seal the CoolDrawer into the cabinetry with silicone or glue. Doing so will make future servicing

difficult. Fisher & Paykel will not be liable for any costs associated with removing or replacing a sealed-in

product, nor for repairing any damage that may be incurred by doing this.

Care should be taken when the appliance is installed or removed to reduce the likelihood of damage to the

power supply cord.

Failure to install the CoolDrawer correctly will invalidate any warranty or liability claims.

If the power supply cord is damaged, it must be replaced. Parts are available from your Authorised

Fisher & Paykel dealer.

Cabinetry must be sufficiently robust to support a combined product and food load of 220 lb (100 kg).

Bearers may be required to support the internal shelf.

Before you install the CoolDrawer, please make sure that

The switched power outlet must be outside the refrigerator drawer cavity so that it is accessible after

installation.

The switched power outlet must be located outside the cavity, within 55” (1400 mm) from the CoolDrawer

cavity if situated on the left-hand side of the cavity and within 33” (840 mm) if situated on the right-hand

side of the cavity.

The services hole in the refrigerator cavity needs to be large enough for the power supply plug to fit

through.

PRODUCT DIMENSIONS

PARTS SUPPLIED

4

5CAVITY PREPARATION

IZONA CoolDrawer

Installation instructions

FRAMED CABINETRY

WARNING!

Tipping hazard

Do not operate this apppliance until it has been securely anchored inside the

cabinetry. The cabinet must be securely anchored to the floor.

Failure to use caution could result in injury or cuts.

Product dimensions (inches [mm])

CoolDrawer

RB36S

RB90S

Aoverall height of product (inc. installation brackets) 25 /” (640)

Boverall width of product 33 /” (855)

Coverall depth of product (excl. drawer panel; inc. power cord) 21 /” (557)

Ddepth of drawer (open) (excl. handle) 20 ½” (520)

Installation diagrams for illustration purposes only

A

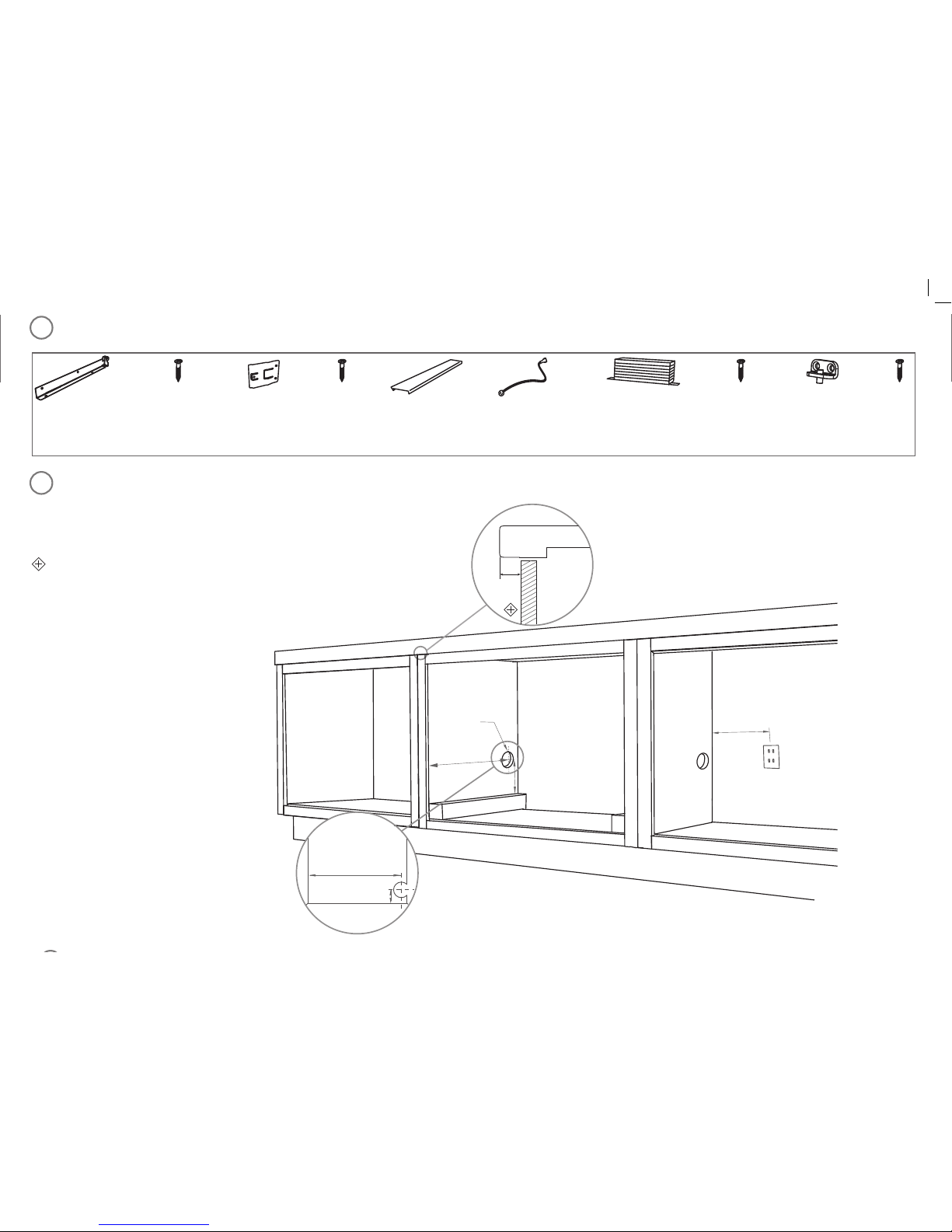

Cabinetry dimensions (inches [mm])

CoolDrawer

RB36S

RB90S

Aoverall width of cabinetry frame 36” (914)

Bminimum inside width of cabinetry frame 34” (864)

Cheight from frame inner face to top of spacer block 25 /” (644)

Dheight below top of spacer block to frame inner*

(to allow for outlet duct height)

max. 4 /” (120)

min. /” (21)

Eminimum height of toe kick 3” (75)

Fminimum depth** of toe kick 1 /” (40)

Gminimum distance from front of cabinetry to rear wall 22 /” (560)

Hwidth of spacer blocks 1 /” (50)

*Minimum internal height of cabinetry frame can be 25 /” (644mm) if outlet duct is not used.

**All depth measurements are taken from the front face of the cabinetry frame (not drawer panel)

Minimum clearances (inches [mm])

/” (2 mm)

½” (13 mm)

E

Installation diagrams for illustration purposes only

B

C

D

G

F

F

C

D

H

G

A

B

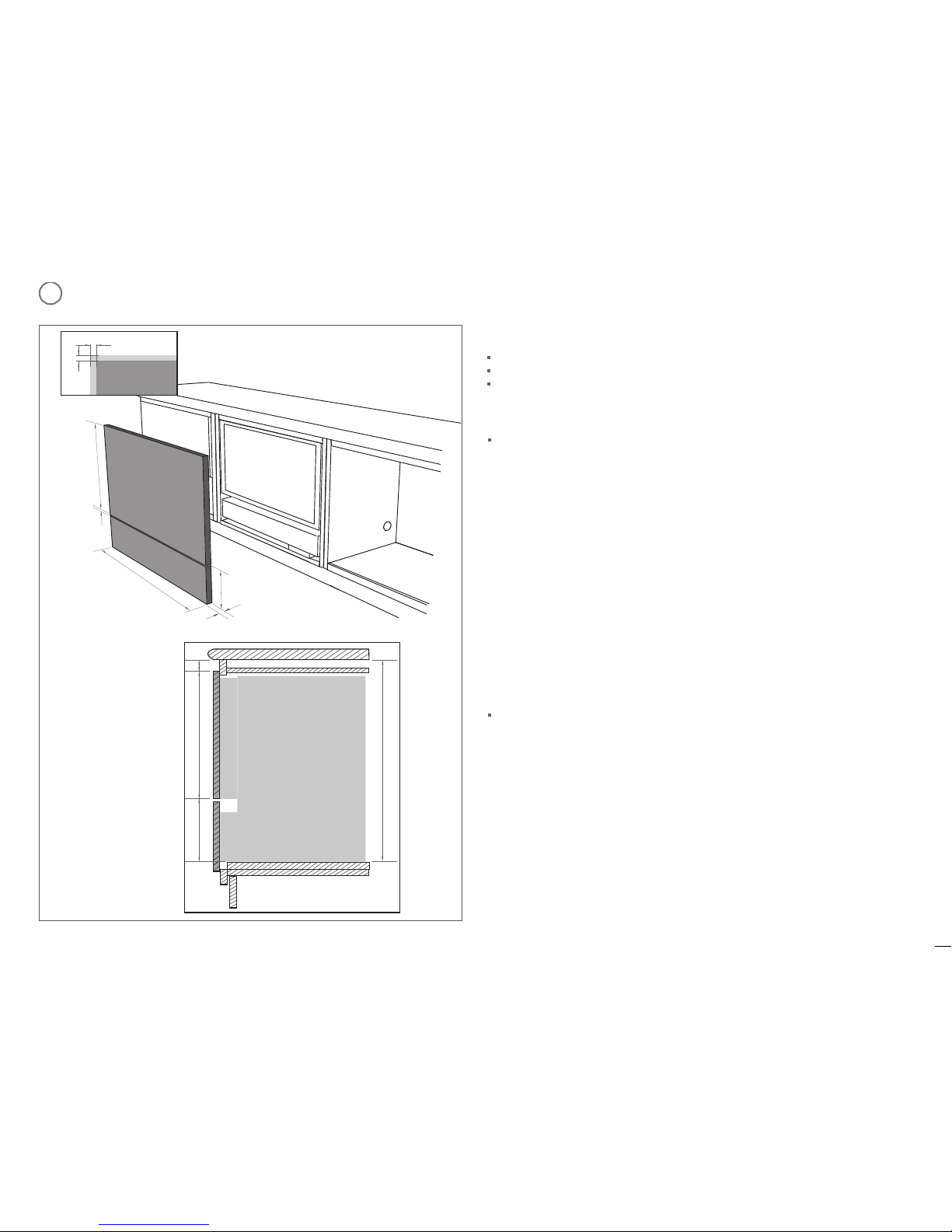

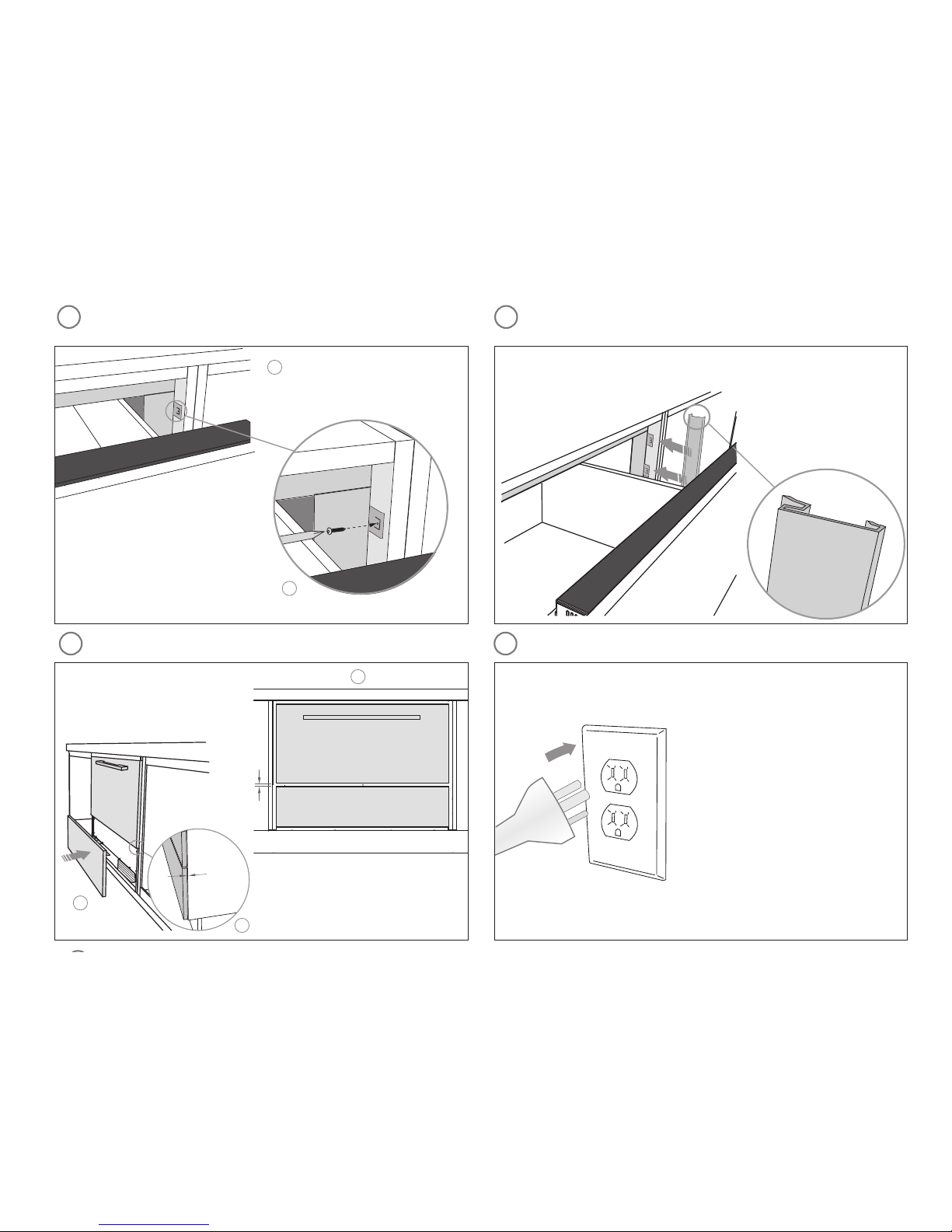

6PANEL PREPARATION

Integrated Panel material

/

-

/”

(16 - 20 mm) panel thickness (

¾”

[18 mm] recommended).

Maximum weight of 15.5 lb (7 kg).

Adequately sealed to withstand moisture (122

O

F/50

O

C @ 80% RH)

max.

¾” (20 mm)

max.

33”

(840

mm)

min. ø

1 /” (

50 mm)

Benchtop

Panel

min. 21”

(

535 mm)

Height of Drawer Panel

The following information is required to correctly define your drawer panel height:

Dimension Data Source

AReveal dimension Your kitchen designer

BHeight between top of spacer block and Your kitchen designer

underside of benchtop

CBottom face of Drawer panel to top of spacer block Your kitchen designer

(Min. 6” [152 mm])

(Max. 7

¼

” [184 mm])

DDrawer panel height Calculated from A, B & C

To calculate D complete the following equation:

D = B - A - C

i.e. For the F&P prefinished panel with a

¼

“ (6 mm) reveal:

18

¾

” (476 mm) = 26

¼

” (666 mm) -

¼

” (6 mm)

-

7

¼

” (184 mm)

Height of the False Panel

Determine the height of the false panel according to your individual kitchen cabinetry

requirements maintaining a

/

” (4 mm) gap between panels.

F&P prefinish panel width is 35

¼

” (896 mm)

F&P prefinish panel height (D) is 18

¾

” (476 mm)

Installation diagrams for illustration purposes only

Drawer Panel

/

-

/”

(16 - 20mm)

height of False

Panel

A

A

False Panel

width of Panels

D

height of

Drawer Panel

min.

5” (

130 mm)

/”

(4 mm)

An internal shelf can be used as an alternative to spacer blocks to

position the product at the correct height. In this case additional

cutouts will be required. Refer to Step 7.

Installation

trims (2)

Installation brackets

(left-hand and right-

hand side) (2)

Outlet duct (1)Trim brackets (4) Drawer Panel

attachment

hooks (3)

Power

cord (1)

Phillips 16 mm

(

/” )

wood

screw (6)

Pan Head

16 mm (

/” )

screw (12)

Pan Head

16 mm (

/” )

screw (2)

Phillips

16 mm

(

/” )

wood

screws (6)

3CABINETRY DIMENSIONS

Note: Services can be located

either side of CoolDrawer.

min.

21” (

535 mm)

min.

5” (

130 mm)

SIDE VIEW

Benchtop

Drawer panelFalse panel

A

D

C

B

Shows cutout if cabinetry

depth at

21 /” (

550 mm)

RB36S & RB90S models