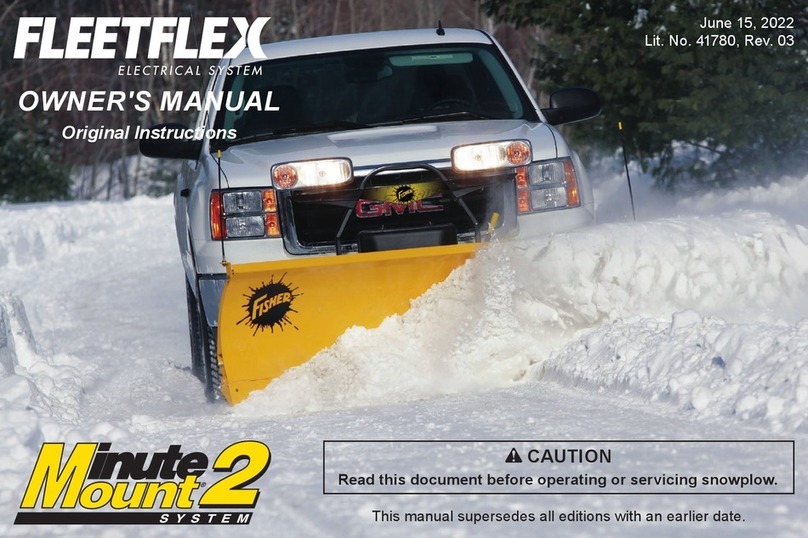

Fisher Engineering EZ-V User manual

SNOWPLOW

MECHANIC'S GUIDE

Fisher Engineering

July 1997

No. 21856

CAUTION: Read this manual before servicing the FISH R® Z-V snowplow.

No. 21856 July 1997

2

PR FAC

This guide has been prepared to

assist the trained mechanic in the

service of FISHER® snowplows. It

also provides safety information and

recommendations. We urge all

mechanics to read this manual

carefully before attempting to service

the FISHER snowplow e uipment

covered by this guide.

Service of your FISHER snowplow

e uipment is best performed by your

local Fisher outlet. They know your

snowplow best and are interested in

your complete satisfaction.

TABL OF CONT NTS

Preface .............................................................................................................2

Safety Information ...........................................................................................3

Tools Re uired ................................................................................................5

Product Specifications ....................................................................................5

Hose Routing ...................................................................................................6

Hydraulic Unit Parts Diagram .........................................................................7

Solenoid Cartridge Valve Identification and Location ..................................8

Relief Valve Identification and Location ........................................................9

Pilot Operated Check Valve Identification and Location ............................10

Vehicle Harness and Vehicle Cable Location .............................................. 11

Operating the Snowplow ..............................................................................12

Theory of Operation ......................................................................................15

Hydraulic and Electrical Schematics ...........................................................17

Electrical Schematic .........................................................................18

Hydraulic Schematic ........................................................................19

Angle Right .......................................................................................20

Angle Left ..........................................................................................22

Right Retract .....................................................................................24

Right Extend .....................................................................................26

Left Retract........................................................................................28

Left Extend ........................................................................................30

Scoop ................................................................................................32

Vee .....................................................................................................34

Raise ..................................................................................................36

Lower .................................................................................................38

Hold in Raise Position Hydraulic ..................................................40

Striking an Object While Plowing Forward Hydraulic.................41

Striking An Object While Back Dragging Hydraulic ....................42

Headlamps Vehicle Only ...............................................................43

High Beam Headlamps With Plow Connected to Vehicle ..............44

Low Beam Headlamps With Plow Connected to Vehicle ...............45

Troubleshooting Guide .................................................................................46

Removable Spring Tool.................................................................................70

No. 21856 July 1997

3

SAF TY INFORMATION

WARNING

Indicates a potentially

hazardous situation that, if not

avoided, could result in death

or serious personal injury .

CAUTION

Indicates a situation that, if not

avoided, could result in minor

personal injury and/or damage

to product or property.

NOTE: Identifies tips, helpful

hints and maintenance

information the owner/operator

should know.

WARNING

Do not exceed GVWR or GAWR

(including blade and ballast) as

found on the driver-side door

cornerpost of the vehicle.

WARNING

Vehicle exhaust contains deadly

carbon monoxide (CO) gas.

Breathing this gas, even in low

concentrations, could cause

death. Never operate a vehicle

in an enclosed area without

venting exhaust to the outside.

WARNING

Hydraulic oil under pressure

could cause skin injection

injury. If you are injured by

hydraulic oil, get medical

treatment immediately.

WARNING

Gasoline is highly flammable

and gasoline vapor is explosive.

Never smoke while working on

vehicle. Keep all open flames

away from gasoline tank and

lines. Wipe up any spilled

gasoline immediately.

WARNING

Remove blade assembly before

placing vehicle on hoist. Failure

to do this could result in

personal injury.

WARNING

Lower blade when vehicle is

parked. Temperature changes

could change hydraulic

pressure, causing the blade to

drop unexpectedly or damaging

hydraulic components. Failure

to do this can result in serious

personal injury.

BEFORE YOU BEGIN

VENTILATION

If you work on the vehicle or

snowplow in a garage or other

enclosed area, be sure to vent

exhaust gas directly to the outside

through a leakproof exhaust hose.

FIRE AND EXPLOSION

Be careful when using gasoline. Do

not use gasoline to clean parts. Store

only in approved containers away

from sources of heat or flame.

Park the vehicle on a level

surface, place shift lever in

PARK or NEUTRAL and set

parking brake.

Leave the snowplow mounted

on the vehicle and lowered for

most service procedures,

unless told otherwise.

PERSONAL SAFETY

Wear only snug-fitting clothing

while working on your vehicle

or snowplow.

Do not wear jewelry or a

necktie, and secure long hair.

Be especially careful near

moving parts such as fan

blades, pulleys and belts.

Wear safety goggles to protect

your eyes from battery acid,

gasoline, dirt and dust.

Avoid touching hot surfaces

such as the engine, radiator,

hoses and exhaust pipes.

Always have a fire extinguisher

rated BC, for flammable li uids

and electrical fires, handy.

HYDRAULIC SAFETY

Always inspect hydraulic

components and hoses before

using. Replace any damaged

or worn parts immediately.

If you suspect a hose leak, DO

NOT use your hand to locate it.

Use a piece of cardboard or

wood.

No. 21856 July 1997

4

SAF TY INFORMATION

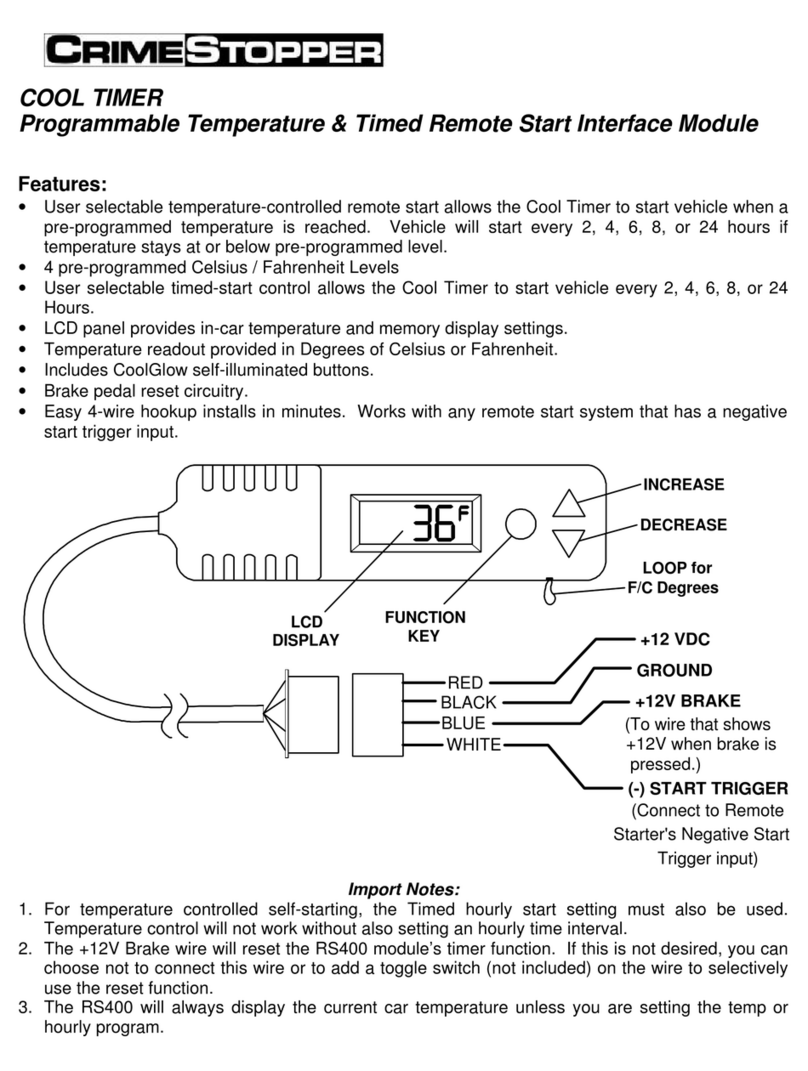

Please bec me familiar with the Safety and Instructi n labels n the back f the blade!

Safety LabelInstruction Label

Instruction Label Safety Label

Pushplate

Attachment

Arm

Jack

Leg

Jack

Stand

Jack Lever

Jack Leg

Connecting Pin

Headgear

Carrying

Chain

Jack Leg (Raised)

Connecting

Pin Withdrawn

Lift Arm

MOUNTING PLOW

U.S. Patent

4,280,062, 4,999,935

5,353,530, 5,420,480

and other patents pending

1. Drive vehicle forward fully engaging

pushplates into attachment arms. 2. Twist connecting pin to release tension.

3. Remove electrical covers on vehicle.

4. Attach electrical connector to

corresponding connector on vehicle.

5. Repeat these steps on passenger side

of vehicle.

6. Release carrying chain and reattach it

leaving plenty of slack.

7. Push headgear upward toward vehicle

until connecting pins snap in place.

8. Pull jack lever outward and raise the

jack leg.

PLOW REMOVAL

1. Position blade in the straight mode

before removing.

2. Place control in Lower mode.

3. Push lift arm down.

4. Pull jack lever outward. ack leg will

adjust to proper height.

5. Disconnect electrical connectors and

cover with protective covers.

6. Insert release rod in lowest possible slot

on jack leg above A-frame.

7. Push down on release rod as you pull

and twist connecting pin.

8. Repeat these steps on passenger side

of vehicle.

9. Remove slack from carrying chain and

reattach.

10. Back vehicle away from plow.

21763

WARNING

CAUTION

LOWER BLADE WHEN VEHICLE IS PARKED.

REMOVE BLADE ASSEMBLY BEFORE PLACINGVEHICLE

ON HOIST.

DO NOT EXCEED GVWR OR GAWR INCLUDING BLADE

AND BALLAST.

READ OWNER'S MANUAL BEFORE OPERATING OR

SERVICING SNOWPLOW.

TRANSPORT SPEED SHOULD NOT EXCEED 45 MPH.

REDUCE SPEED UNDER ADVERSETRAVEL

CONDITIONS.

PLOWING SPEED SHOULD NOT EXCEED 10 MPH.

REMOVE SLACK FROM CARRYING CHAIN BEFORE

TRAVELING.

SEEYOUR FISHER OUTLET FOR APPLICATION

RECOMMENDATIONS.

21793

CAUTION

Batteries normally produce

explosive gases which can

cause personal injury.

Therefore, do not allow flames,

sparks or lit tobacco to come

near the battery. When

charging or working near a

battery, always cover your face

and protect your eyes, and also

provide ventilation.

Batteries contain sulfuric acid

which burns skin, eyes and

clothing.

Disconnect the battery before

removing or replacing any

electrical components.

BATTERY SAFETY

No. 21856 July 1997

5

T ls

TOOLS R QUIR D PRODUCT SP CIFICATIONS

V-Pl w Specificati ns

Electrical System approximate

values:

Solenoid Coil Resistance =

7 Ohms at room temperature

Solenoid Coil Amp. Draw =

1.5 Amp.

Motor Relay Coil Resistance =

16 - 17 Ohms

Motor Relay Amp. Draw =

0.7 Amp.

Maximum Motor Amp. Draw =

190 Amp.

Headlamp Relay Coil

Resistance = 106 Ohms

Headlamp Relay Amp Draw =

0.1 Amp.

Fuse Size

Harness 10 Amp.

(10AFB 3AG)

Circuit Board (2) 5 Amp.

(5AFB SMD)

Mechanical

Fastener Tor ue for :

Pump Bolts = 150160 IN-LB

Motor Bolts = 3040 IN-LB

Reservoir Bolts = 1520 IN-LB

Cartridge Tor ue = 120 IN-LB

Check Valve Tor ue =

120 IN-LB

Coil Nut Tor ue = 4860 IN-LB

Secondary Manifold Block

Assembly Bolt Tor ue =

108 IN-LB

Angle Cylinder

Piston Locknut Tor ue =

100-120 FT-LB

Gland Nut Tor ue =

150-180 FT-LB.

Hydraulic System

Relief valve settings

Pump relief valve = 1750 PSI.

2 1/2 - 2 3/4 turns CCW from

fully seated

Primary relief valve = 3000 PSI.

1 1/2 - 1 3/4 turns CCW from

fully seated

Secondary relief valve = 3500

PSI. 1 1/4 - 1 1/2 turns CCW

from fully seated

Fluid CapacityHydraulic Oil

Unit Reservoir = 1 3/4 Quarts

System Total = 2 1/2 Quarts

Hydraulic Oil

FISHER® High Performance

Fluid to -25°F (-32°C)

Solenoid Valve Spool Travel = 0.07"

for three- and four-way valves

For servicing the electrical and

hydraulic system

Re uired:

Miniature Needle Nose Pliers

Flat Screwdriver

Combination Wrenches: 3/8",

7/16" (2), 1/2", 11/16", 3/4", 7/8"

1/4" Socket or Nut driver

Test Light

Recommended :

Combination Wrenches:

1-1/16", 1-1/8"

Deep Sockets: 11/16", 7/8",

1-1/16", 1-1/8"

Tor ue Wrench ( IN-LB )

Volt/Ohm Meter

Pencil Magnet

3000 PSI Pressure Gauge

For replacing trip springs :

Removable Spring Tool

available from your Fisher

outlet

CAUTION

Do not mix different types of

hydraulic fluid. Some fluids are

not compatible and may cause

performance problems and

product damage.

No. 21856 July 1997

6

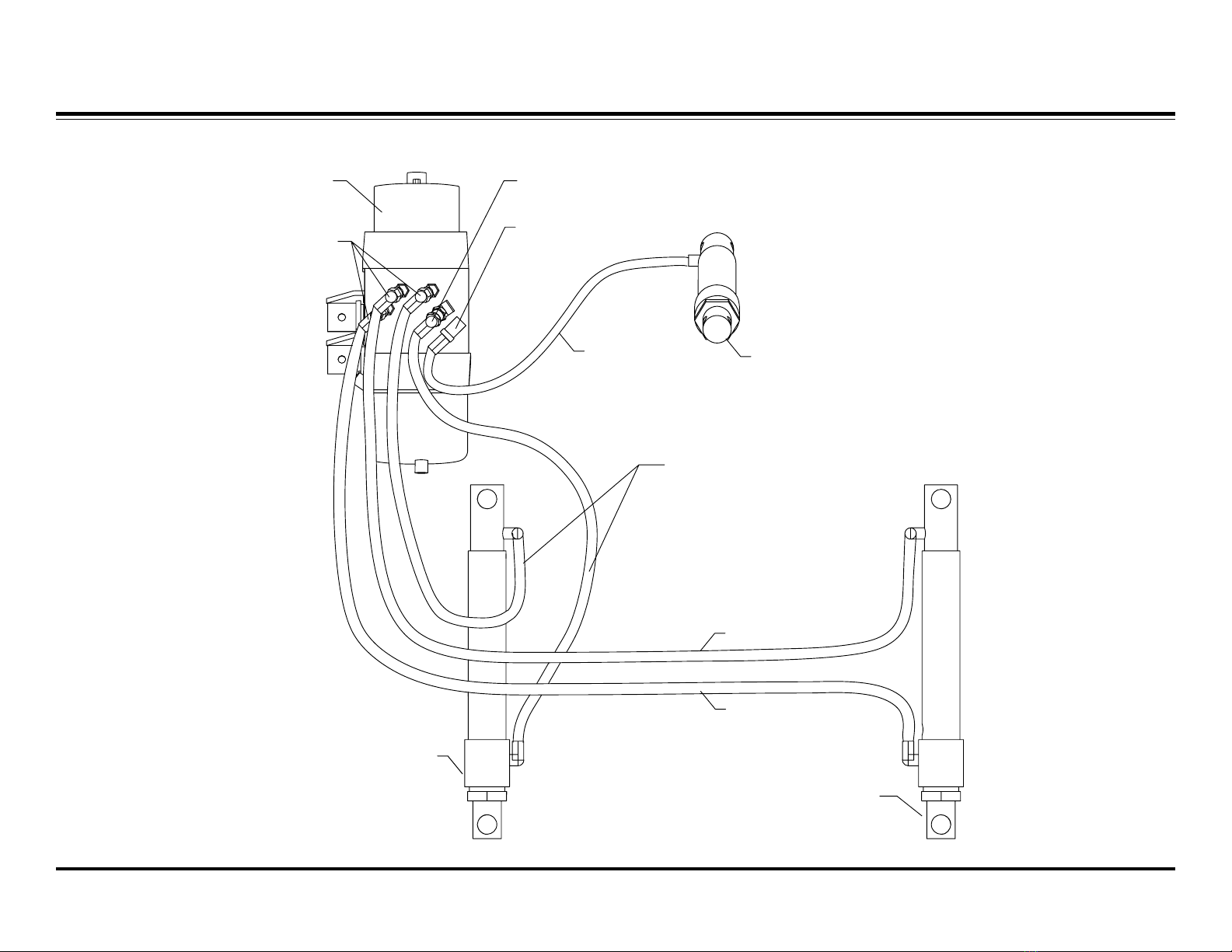

PLOW SIDE

Passenger-Side

Angle Cylinder

(Right Side)

45° Swivel

45° Street Elbow and

Straight Swivel

90° Street Elbow

and Straight Swivel

18" Hose

36" Hose

34" Hose

36" Hoses

Hydraulic

Unit

Driver-Side

Angle Cylinder

(Left Side)

Lift Cylinder

HOS ROUTING

No. 21856 July 1997

7

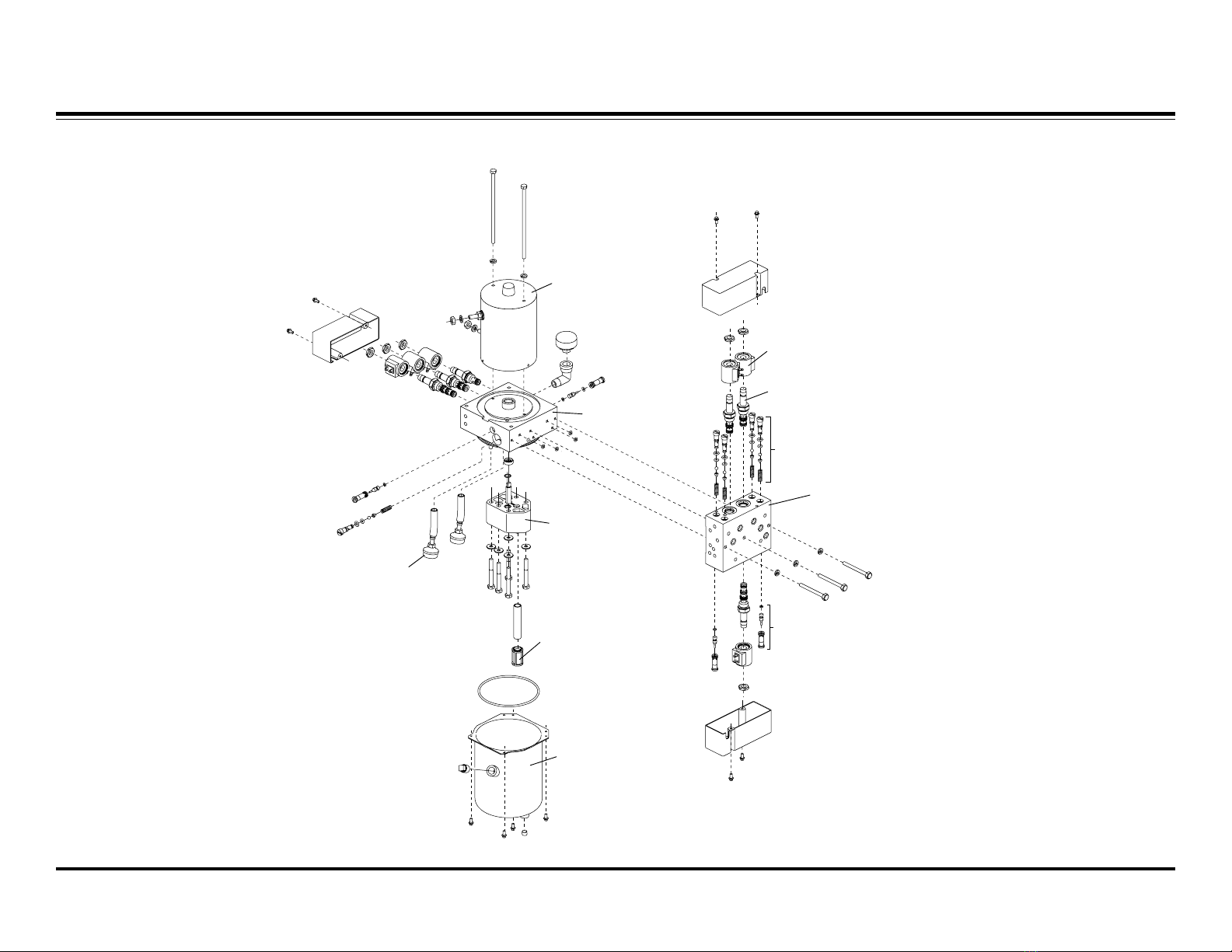

HYDRAULIC UNIT PARTS DIAGRAM

Motor

Primary Valve

Block

Solenoid Valve Coil

Solenoid Valve Cartridge

Relief Valve

Pilot Operated

Check Valve

Reservoir

Pump Filter

Pump

Oil Return Line

Secondary Valve Block

No. 21856 July 1997

8

SOL NOID CARTRIDG VALV ID NTIFICATION AND LOCATION

Solenoid Cartridge

Valve—S1

Solenoid Cartridge

Valve—S6

Solenoid Cartridge

Valve—S4

Solenoid Cartridge

Valve—S5

Solenoid Cartridge

Valve—S3

Solenoid Cartridge

Valve—S2

No. 21856 July 1997

9

R LI F VALV ID NTIFICATION AND LOCATION

RIGHT SECONDARY

RELIEF VALVE

RELIEF VALVE

RIGHT PRIMARY

RELIEF VALVE

LEFT SECONDARY

LEFT PRIMARY

RELIEF VALVE

PUMP RELIEF VALVE

(Passenger Side)

(Passenger Side)

(Driver Side)

(Driver Side)

No. 21856 July 1997

10

PILOT OP RAT D CH CK VALV ID NTIFICATION AND LOCATION

CHECK VALVE C

CHECK VALVE D

CHECK VALVE B

PILOT OPERATED (P/O)

PILOT OPERATED (P/O)

PILOT OPERATED (P/O)

PILOT

OPERATED (P/O)

CHECK VALVE A

No. 21856 July 1997

11

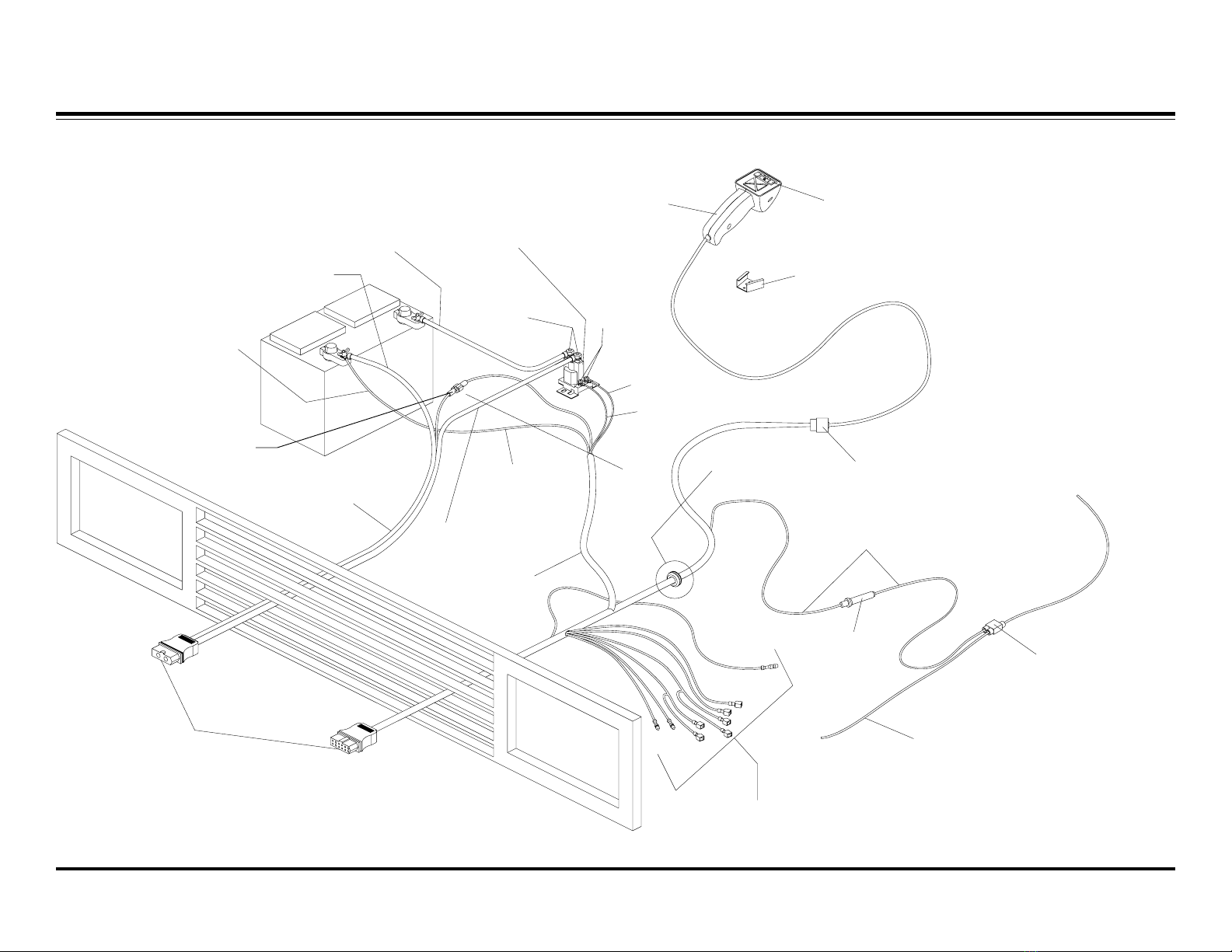

V HICL HARN SS AND V HICL CABL LOCATION

MODE

L

S

/

P

LOWER

C

FLT

R

/

V

E

E

RAISE

PWR

Control ON/OFF

Switch

Control

Bracket

14-pin Connector

(in-cab)

Red Wire

Fuse

Holder Self-Stripping

Connector (Blue)

Vehicle Wire Controlled

by Ignition Switch

Wires to

Headlamp Relays

Grille

Connectors

Vehicle Cable

Assembly

Black Wire

Red Wire

Vehicle

Harness

To Negative

Battery Terminal

22" Red Cable

Secondary

(Large)

Terminals

Motor Relay

Primary

(Small)

Terminals

Brown/Red

Orange/

Black

Firewall

Grommet

+

-

Small Red

Wire

3-pin

12-pin

Faston

Connector

Brown/Green

No. 21856 July 1997

12

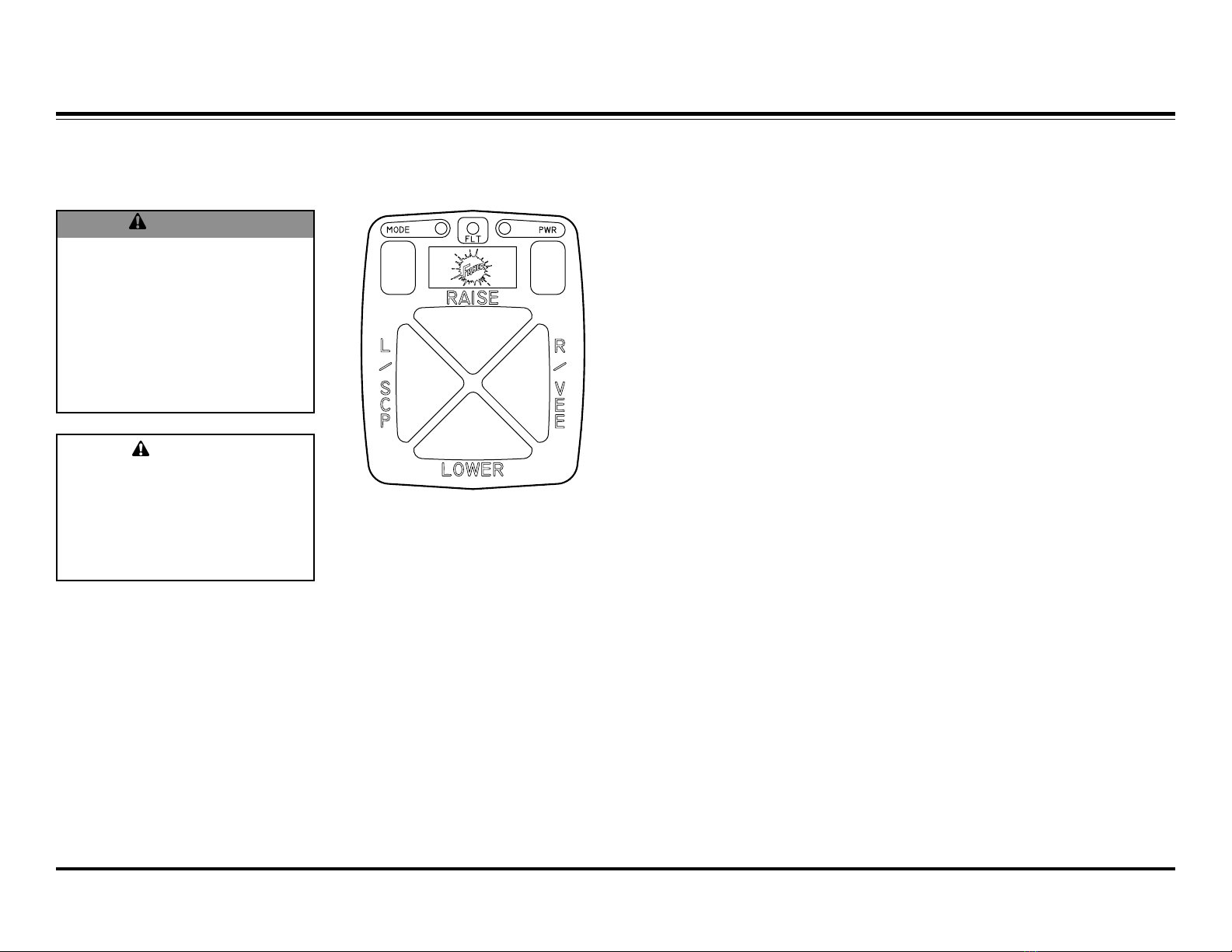

WARNING

OP RATING TH SNOWPLOW

Fish-Stik Hand-Held C ntr l

The driver shall keep

bystanders clear of the blade

when it is being raised, lowered

or angled. Do not stand

between the vehicle and the

blade, or within 8 feet of a

moving blade. A moving or

falling blade could cause

personal injury.

CAUTION

To prevent accidental

movement of the blade, always

turn the ON/OFF switch to OFF

whenever the snowplow is not

in use. The control indicator

light will turn off.

Functi n Time Outs

All control functions, except for

LOWER, automatically time out

stopafter a period of time. This is to

help prolong the battery charge. The

time-out period for the RAISE

function is 2.5 seconds, while all

others are 4.25 seconds.

The control will automatically turn off

after being idle for 20 minutes.

2. Press the PWR button on the

control. The control indicator

light will glow red indicating the

control is on. The control

indicator light will glow red

whenever the control ON/OFF

switch and the vehicle ignition

switch are both ON and the

plow plugs are connected to

the grill connectors.

Sm th St p

The control automatically allows the

blade to coast to a stop. This results

in smoother operation, reduces the

shock to the hydraulic system and

increases hose and valve life.

1. Turn the vehicle ignition switch

to the ON or the ACCESSORY

position.

No. 21856 July 1997

13

Straight Blade M deDefault

Vee/Sc p M de

Quickly press and release the MODE

key to put the control into the vee/

scoop mode. The MODE lamp, near

the upper left corner of the keypad,

will light. Quickly pressing and

releasing the MODE key will toggle

the control between straight blade

mode and vee/scoop mode.

The functions shown at right are

performed in the vee/scoop mode:

OP RATING TH SNOWPLOW

The control automatically defaults to

the straight blade mode when turned

on. The MODE lamp, near the MODE

key in the upper left corner of the

keypad, will not be illuminated or

flashing when the control is in the

straight blade mode.

The functions shown at right are

performed in the straight blade mode:

Button Description of Operation

Raise Press this button to raise the plow and to cancel the float mode.

NOTE: Plow will automatically stop raising after 2.5 seconds. To resume raising the plow, release the button

and press again.

Lower Press this button to lower the plow. NOTE: After reaching the desired height, release the button. Holding the

button down for more than 3/4 second will activate the float mode, indicated by green FLT lamp.

L / SCP Press this button to angle both wings to the left.

R / VEE Press this button to angle both wings to the right.

Button Description of Operation

Raise Press this button to raise the plow and to cancel the float mode.

NOTE: Plow will automatically stop raising after 2.5 seconds. To resume raising the plow, release the button

and press again.

Lower Press this button to lower the plow. NOTE: After reaching the desired height, release the button. Holding the

button down for more than 3/4 second will activate the float mode, indicated by green FLT lamp.

L / SCP Press this button to extend both wings to the scoop position.

R / VEE Press this button to retract both wings to the vee position.

No. 21856 July 1997

14

OP RATING TH SNOWPLOW

Wing M de

To put the control into the wing mode,

press and hold the MODE key for

about two seconds until the MODE

lamp near the upper left corner of the

keypad is flashing. The L / SCP and

R / VEE keys are used to activate the

four functions of the wing mode. The

RAISE and LOWER keys function the

same as in the other modes.

The functions shown at right are

performed in the wing mode:

Button Description of Operation

Raise Press this button to raise the plow and to cancel the float mode.

NOTE: Plow will automatically stop raising after 2.5 seconds. To resume raising the plow, release the

button and press again.

Lower Press this button to lower the plow. NOTE: After reaching the desired height, release the button.

Holding the button down for more than 3/4 second will activate the float mode, indicated by green FLT

lamp.

L / SCP Pressing this button the first time will retract the left wing.

Pressing this button the next time will extend the left wing.

R / VEE Pressing this button the first time will retract the right wing.

Pressing this button the next time will extend the right wing.

No. 21856 July 1997

15

TH ORY OF OP RATION

Pl w Hydraulics

The EZ-V snowplow

hydraulic system performs

10 blade movement

functions.

All functions re uire the

vehicle ignition (key) switch to be in

the run or accessory position and the

power to be activated on the

snowplow cab control.

Nine of the ten hydraulic functions

re uire energizing the electric motor,

shifting of solenoid cartridge spools

or activating p/o check valves. The

tenth function, lower, does not

energize the motor but re uires

shifting of solenoid cartridge spools.

Operation of Electrical Circuit:

The electrical drive circuit that is used

for the EZ-V snowplow hydraulics is

defined as a low side drive system.

MOVEMENT

BLADE RAISE LOWER

ANGLE

RIGHT

ANGLE

LEFT RIGHT

EXTEND

RIGHT

RETRACT LEFT

RETRACT SCOOP VEE

(DEFAULT)

STRAIGHT BLADE

R/VEE L/SCP R/VEE *

R/VEE *

WING

CONTROLLER MODE

CONTROLLER BUTTON

V / SCOOP

L/SCP * L/SCP R/VEE RAISE LOWER

ALL ALL

EXTEND

LEFT

L/SCP *

Low side drive provides a common

live hot (12V) to all of the loads (coils,

relays, etc.). When the cab control is

activated, the ground path is closed

to complete the circuit, energizing the

selected coils and/or relay. The

current flow through the coils

produces a magnetic field which

shifts the spools in the cartridges.

The cartridges direct the fluid flow to

the appropriate passages to produce

the selected blade movement

function. Current flow also energizes

the motor relay, closing the motor

relay contacts connecting the motor

to the battery through heavy electrical

cables. The heavy cables carry a

large current flow which energizes the

motor, which in-turn rotates the

internal pump and creates fluid flow.

(Motor relay does not energize in

lower function).

Testing Low Side Drive Systems:

To test a low side drive system,

connect the negative lead of the test

instrument (volt meter) to ground and

the positive lead to the negative side

of the load (coil, relay, etc.). A

reading of 12 volts should be

indicated when the load is not

activated. A reading of near 0 volts

when load is activated.

No. 21856 July 1997

16

TH ORY OF OP RATION

Pl w Headlamps

The headlamp circuit operates using

a high side drive system. High side

drive provides a hot 12V source to

activate the loads (coils, relays, etc.)

that share a common ground. The

headlamp switching circuit uses two

single pole double throw (SPDT)

relays. When combined with the

snowplow plug-in headlamp harness

and the vehicle harness, the relays

will automatically switch between

plow and vehicle headlamps as the

plow plugs are connected and

disconnected.

The vehicle harness has a brown

wire that is spliced into the vehicle

park lamp circuit. This wire feeds the

plow park lamps through the grill

connector and also powers the coils

of both relays. The other terminal of

the relay coils is connected to the

black/orange ground wire which also

goes to the grill connector. When

both the plow and battery cable plugs

are connected to the grill connectors,

a ground is completed for the relay

coil. When the vehicle park lamps

are turned on and the plugs are

connected, the relay coils will be

activated. This causes the relay

contacts to switch from the normally

closed contacts to the normally open

contacts. The normally closed

contacts power the vehicle

headlamps. The normally open

contacts power the plow headlamps.

Refer to the Headlamp Test Diagram

in the Troubleshooting Guide.

It should be noted that:

The relay with the yellow,

orange and black wires

operates the low beam

headlamps.

The relay with the green, red

and white wires operates the

high beam headlamps.

The parking lamp circuit

provides power to both relays

at the same time.

Both plow plugs (12 pin and

battery cable) need to be

connected and the headlamp

switch must be on for the

relays to activate.

Daytime Running Lights

An additional fused pink wire is used

in place of the brown park circuit wire

to introduce power to the light relays.

The pink wire is connected to a circuit

controlled by the vehicle ignition

switch. When the vehicle ignition is

on and the grill connector plugs are

connected the relay coils will be

activated. This allows the DRLs to be

switched to the plow lights when the

vehicle headlamp switch is off. DRLs

use the same circuit as the regular

headlamps.

Testing High Side Drive Systems:

Connect the negative lead of the test

instrument (voltmeter) to ground and

positive lead to the positive side of

the load. A reading of 12 volts should

be indicated when the load is

activated; zero volts when load is not

activated.

No. 21856 July 1997

17

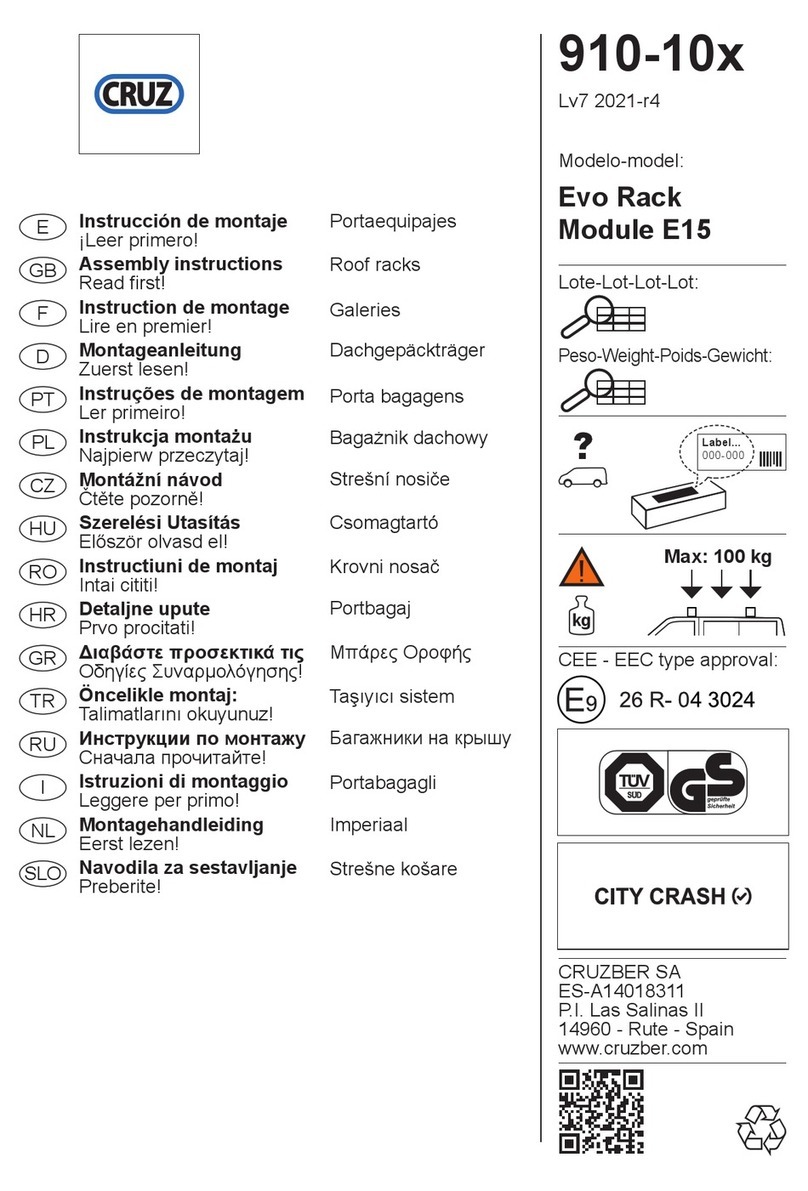

HYDRAULIC AND L CTRICAL SCH MATICS

The following section contains

hydraulic and electrical schematics to

help explain how the hydraulic unit

performs the different functions. A

schematic is an abstract drawing

showing the purpose of each of the

components in the system. Each

component is represented by a

graphical symbol. The hydraulic and

electrical legends list and describe

each of the symbols used in the

schematics for this guide.

The first two schematics show a

general overview of the complete

hydraulic and electrical systems. The

remainder of the schematics have

been altered to highlight flow of

hydraulic oil and electrical current for

each function the hydraulic unit

performs or flow of electrical current

for the snowplow and vehicle lights.

Bold lines represent the circuit

being activated only.

Shaded components are either

activated or shifted from their

normal position.

FILTER,STRAINER

DIFFUSER

COMPONENT ENCLOSURE

ELECTRIC MOTOR

CYLINDER

FIXED DISPLACEMENT

HYDRAULIC PUMP

BELOW FLUID LEVEL

LINE, TO RESERVOIR

LINES CROSSING

LINES OINING

LINE, PILOT (FOR CONTROL)

LINE, WORKING (MAIN)

FLOW, DIRECTION OF CHECK VALVE

SOLENOID, SINGLE WINDING

SPRING

PRESSURE RELIEF

VALVE, AD USTABLE

AD USTABLE-

NON-COMPENSATED

VALVE, FLOW CONTROL,

VALVE, TWO POSITION

TWO CONNECTION

(TWO-WAY)

VALVE, TWO POSITION

THREE CONNECTION

(THREE-WAY)

VALVE, TWO POSITION

FOUR CONNECTION

(FOUR-WAY)

HYDRAULIC LEGEND

CROSSING WIRE

WIRE SPLICE

FUSE

SOLENOID

CIRCUIT GROUND

MOTOR RELAY

BATTERY

MOTOR

ELECTRICAL LEGEND

HYDRAULIC FLUID

IN LINE CONNECTOR

WIRE CONTINUES

ELSEWHERE

LIGHT

PILOT OPERATED (P/O)

COMPONENT ENCLOSURE

No. 21856 July 1997

18

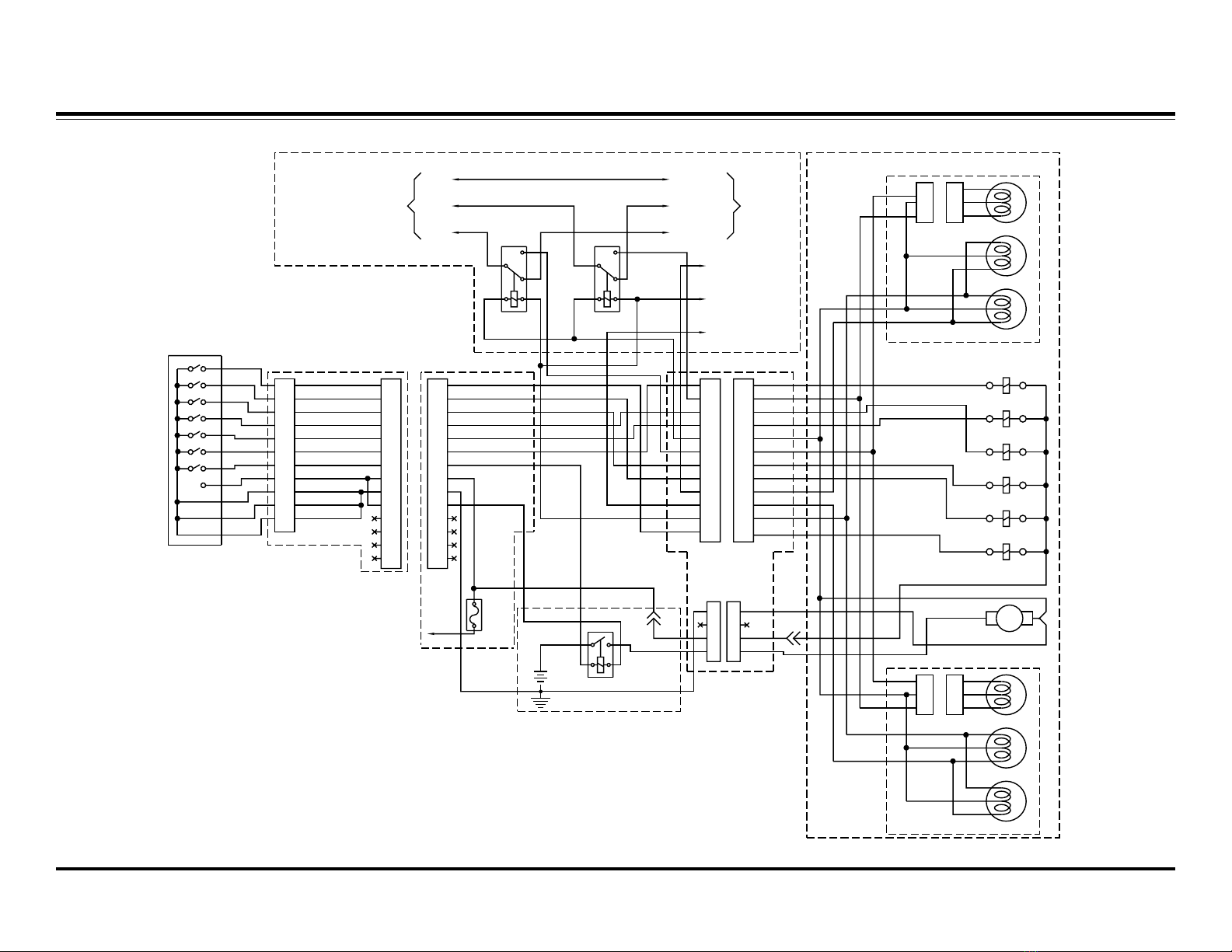

L CTRICAL SCH MATIC

BLK/ORN

HIGH BEAM LOW BEAM

GND

LOW

HIGH GRN

YEL

BLU

BLK

ORN

RED

TO LEFT TURN SIG

M BULLET

TO PARK LAMP

M BULLET

TO RIGHT TURN SIG

M BULLET

GRY

TO VEHICLE

HEADLIGHT CONNECTOR HARNESS

HEADLAMP

COMPONENTS LOCATED FRONT LEFT OF VEHICLE

LEFT SIDE PLOW LAMP

TURN SIG

TURN SIG

HEADLIGHT

CON3 CON3

T

P

T

P

RIGHT SIDE PLOW LAMP

L

H

GRY

PLOW ASSEMBLY

*

CIRCUIT BOARD

OF PRINTED

REPRESENTATION

11

*

8

10

9

7

6

4

5

3

CONTROL

1

2

ORN

11

10

9

7

8

5

6

TAN

BLK

BRN

GRN

RED

BLU

COIL CORD HARNESS

4

3

1

2

WHT

GRY

YEL

VIO

13

14

ORN/BLK

RED

14

13

12V BATTERY

LOCATED AT VEHICLE FRONT RIGHT

#6 RED

MTR RLY

10AFB

LOCATED UNDER DASH

BLU/ORN

LT BLU/ORN

BLK/WHT

LT BLU

LT GRN

BRN/RED

WHT/YEL

11

12

9

10

7

8

5

6

3

4

2

1

12

11

10

9

7

8

5

6

3

4

2

1

RED

BRN/GRN

BRN

BRN

#6 BLK

#6 RED

FASTON

VIO

BLK/ORN

BRN

BLK

WHT

LOCATED AT GRILLE

VIO

WHT

PUMP MOTOR

#6 RED

#6 BLK

+M

-

RED

BLK/ORN

S6 SOLENOID

LT BLU/ORN

BLU/ORN

BLK/WHT

WHT/YEL

LT BLU

LT GRN

IGNITION

BLK (HIGH)

ORN (LOW)

BLU (GND)

1

8

12

11

9

10

4

6

7

5

2

3

8

12

11

9

10

4

6

7

5

2

3

1

4

2

3

11

2

3

4

1

2

33

2

1

L

TURN SIG

CON3

3

CON3

3

TURN SIG

T

P

HEADLIGHT

T

P

2

1

2

1H

S5 SOLENOID

S4 SOLENOID

S3 SOLENOID

S2 SOLENOID

S1 SOLENOID

TO

No. 21856 July 1997

19

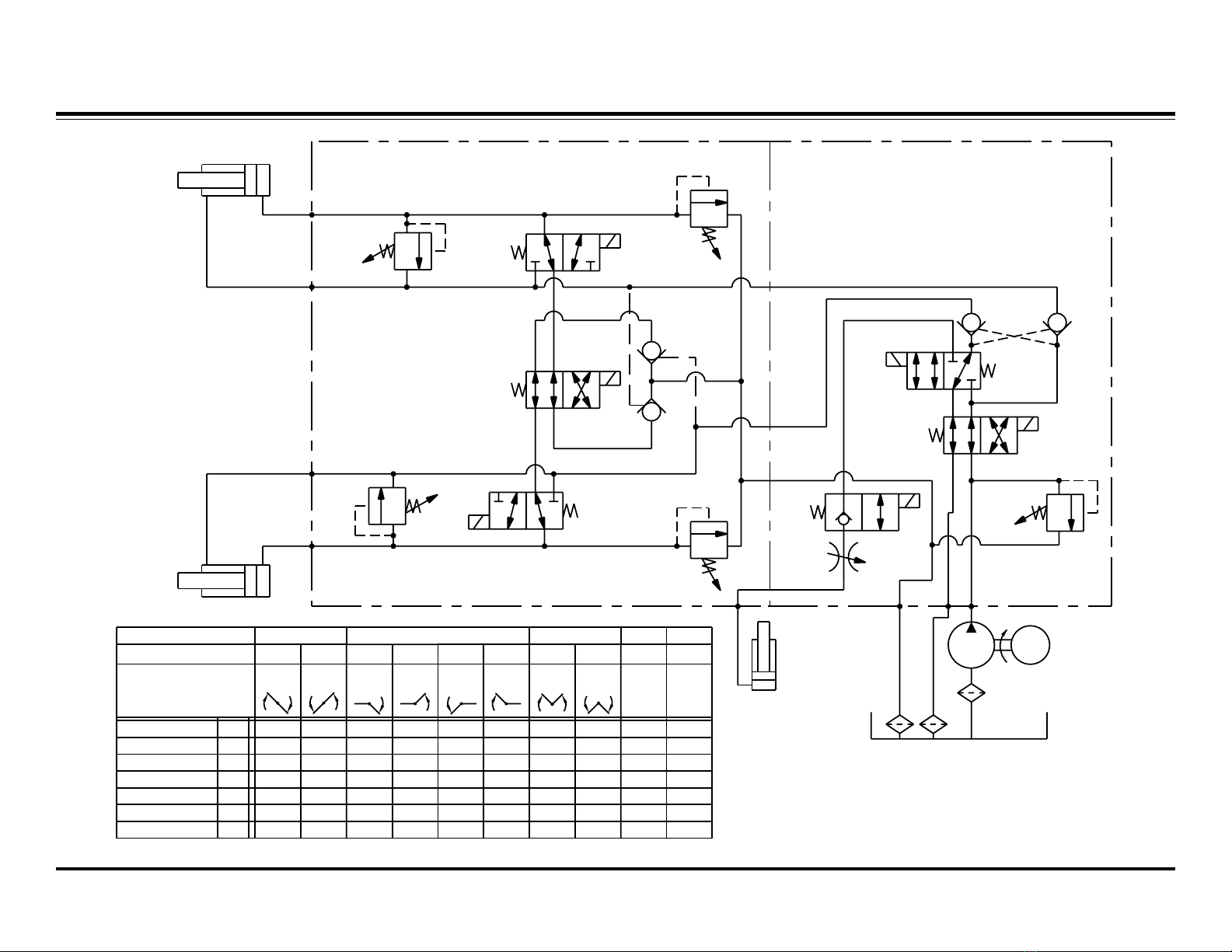

HYDRAULIC SCH MATIC

M

LEFT

RIGHT

3000 PSI

3000 PSI

3500 PSI

3500 PSI

1750 PSI

S6

S3

S1

S5

S4

S2

(C)

(D)

(A) (B)

LIFT

RELIEF VALVE

SECONDARY

RELIEF VALVE

SECONDARY

SECONDARY BLOCK ASSY. PRIMARY BLOCK ASSY.

VALVE

RELIEF

PRIMARY

PRIMARY

RELIEF

VALVE

VALVE

RELIEF

PUMP

MOTOR

SV08-2004

SV08-40

SV08-43

SV08-40

SV08-30 S6

S5

S3

S2

S1

M

S4

SV08-30

ON

ON

ON

ON

ON ON

ON

ON ON

ON

ON

ON

ON

ON

ON ON

ON

ON ON

ON

ON

MOVEMENT

BLADE

RAISE LOWER

ANGLE

RIGHT

ANGLE

LEFT

RIGHT

EXTEND

RIGHT

RETRACT

LEFT

RETRACT SCOOP VEE

(DEFAULT)

STRAIGHT BLADE

R/VEE L/SCP R/VEE *

R/VEE *

WING

CONTROLLER MODE

CONTROLLER BUTTON

V / SCOOP

L/SCP * L/SCP R/VEE RAISE LOWER

ALL ALL

* NOTE - SEE BLADE MOVEMENT TEXT

FOR BUTTON OPERATION

EXTEND

LEFT

L/SCP *

ON

ON

ON

P/O CHECK

VALVE

P/O

CHECK

VALVE

P/O

CHECK

VALVE

P/O

CHECK

VALVE

No. 21856 July 1997

20

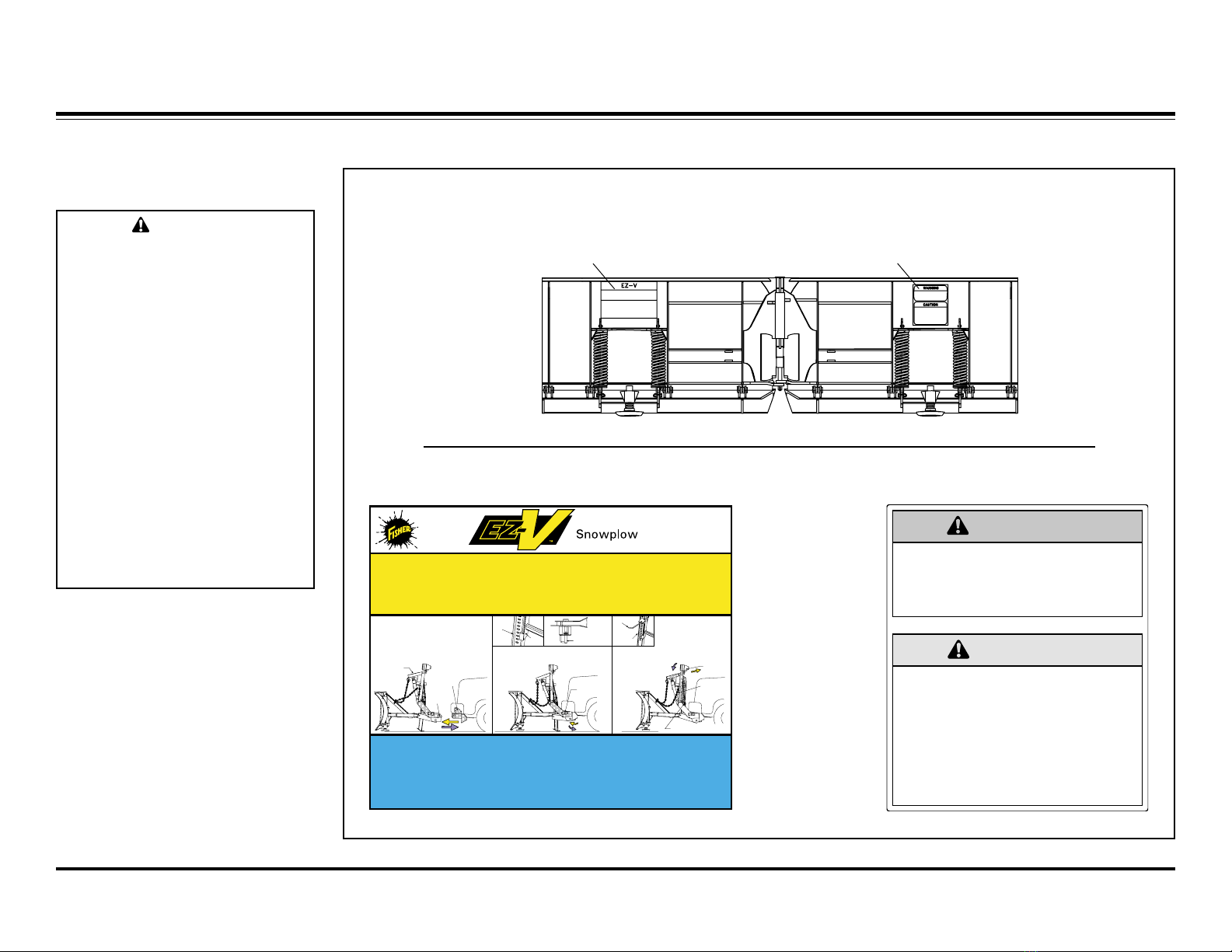

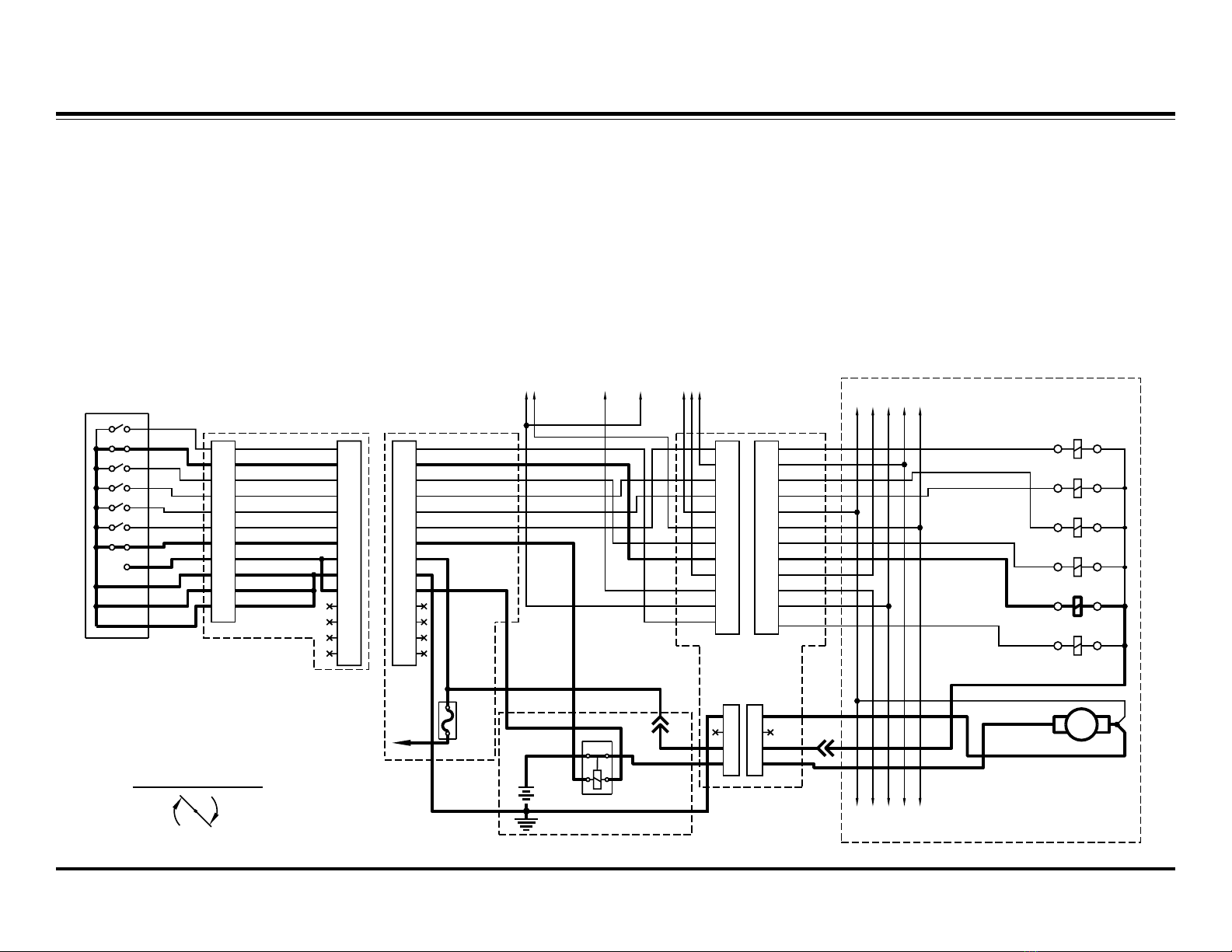

ANGL RIGHT L CTRICAL

COMPONENTS LOCATED FRONT LEFT OF VEHICLE

LEFT SIDE PLOW LAMP

RIGHT SIDE PLOW LAMP

GRY

PLOW ASSEMBLY

*

CIRCUIT BOARD

OF PRINTED

REPRESENTATION

11

*

8

10

9

7

6

4

5

3

CONTROL

1

2

ORN

11

10

9

7

8

5

6

TAN

BLK

BRN

GRN

RED

BLU

COIL CORD HARNESS

4

3

1

2

WHT

GRY

YEL

VIO

13

14

ORN/BLK

RED

14

13

12V BATTERY

LOCATED AT VEHICLE FRONT RIGHT

#6 RED

MTR RLY

10AFB

LOCATED UNDER DASH

BLU/ORN

LT BLU/ORN

BLK/WHT

LT BLU

LT GRN

BRN/RED

WHT/YEL

11

12

9

10

7

8

5

6

3

4

2

1

12

11

10

9

7

8

5

6

3

4

2

1

RED

BRN/GRN

BRN

BRN

#6 BLK

#6 RED

FASTON

VIO

BLK/ORN

BRN

BLK

WHT

LOCATED AT GRILLE

VIO

WHT

PUMP MOTOR

#6 RED

#6 BLK

+M

-

RED

BLK/ORN

S6 SOLENOID

LT BLU/ORN

BLU/ORN

BLK/WHT

WHT/YEL

LT BLU

LT GRN

IGNITION

1

8

12

11

9

10

4

6

7

5

2

3

8

12

11

9

10

4

6

7

5

2

3

1

4

2

3

11

2

3

4

S5 SOLENOID

S4 SOLENOID

S3 SOLENOID

S2 SOLENOID

S1 SOLENOID

BLADE MOVEMENT

ANGLE RIGHT

Blade Movement: Angle Right

Controller Mode: Straight Blade

Mode (Default)

Controller Button: R/VEE

System Response:

1) By pressing the controller button,

the circuit board within the cab

control completes the ground

path for the electrical circuit.

2) Electrical current flows through

the motor relay, activating the

pump motor, and solenoid

cartridge valve S5, shifting its

spool.

3) Hydraulic oil from the pump flows

through solenoid cartridge valve

S2, P/O check valve (B) and into

the rod end of the right cylinder

causing it to retract.

4) Pressure within the hydraulic

circuit causes P/O check valves

(A) & (D) to open.

5) The retracting right cylinder

pushes the hydraulic oil out of its

base end, through solenoid

cartridge valves S6 & S5 & S4

and into the base end of the left

cylinder causing it to extend.

6) The extending left cylinder

pushes the hydraulic oil out of its

rod end, through P/O check valve

(A), solenoid cartridge valves S3

& S2 and back to the reservoir.

Table of contents

Other Fisher Engineering Automobile Accessories manuals