Lit. No. 74916, Rev. 02 3 August 1, 2020

95150, 95160, 95180-3, 95190-3

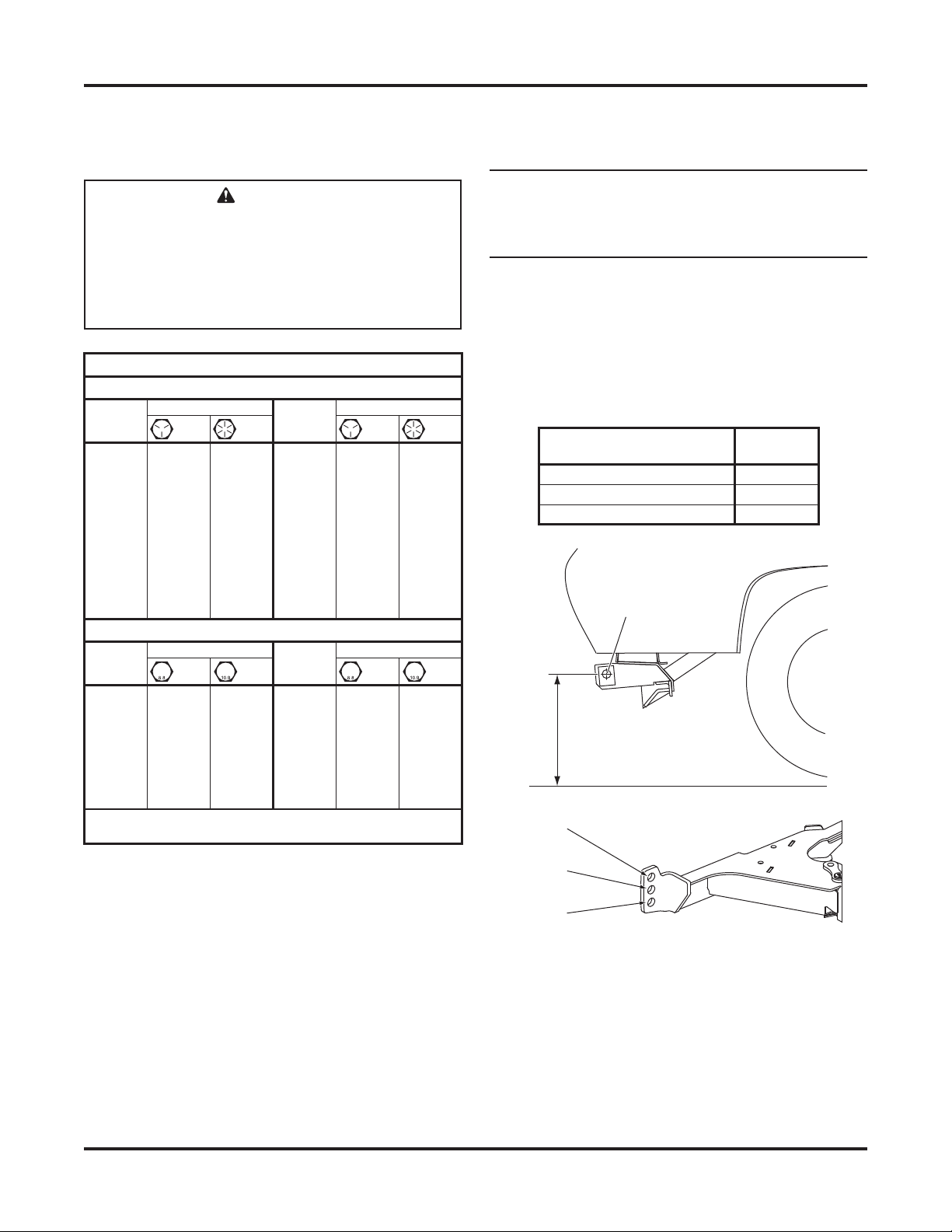

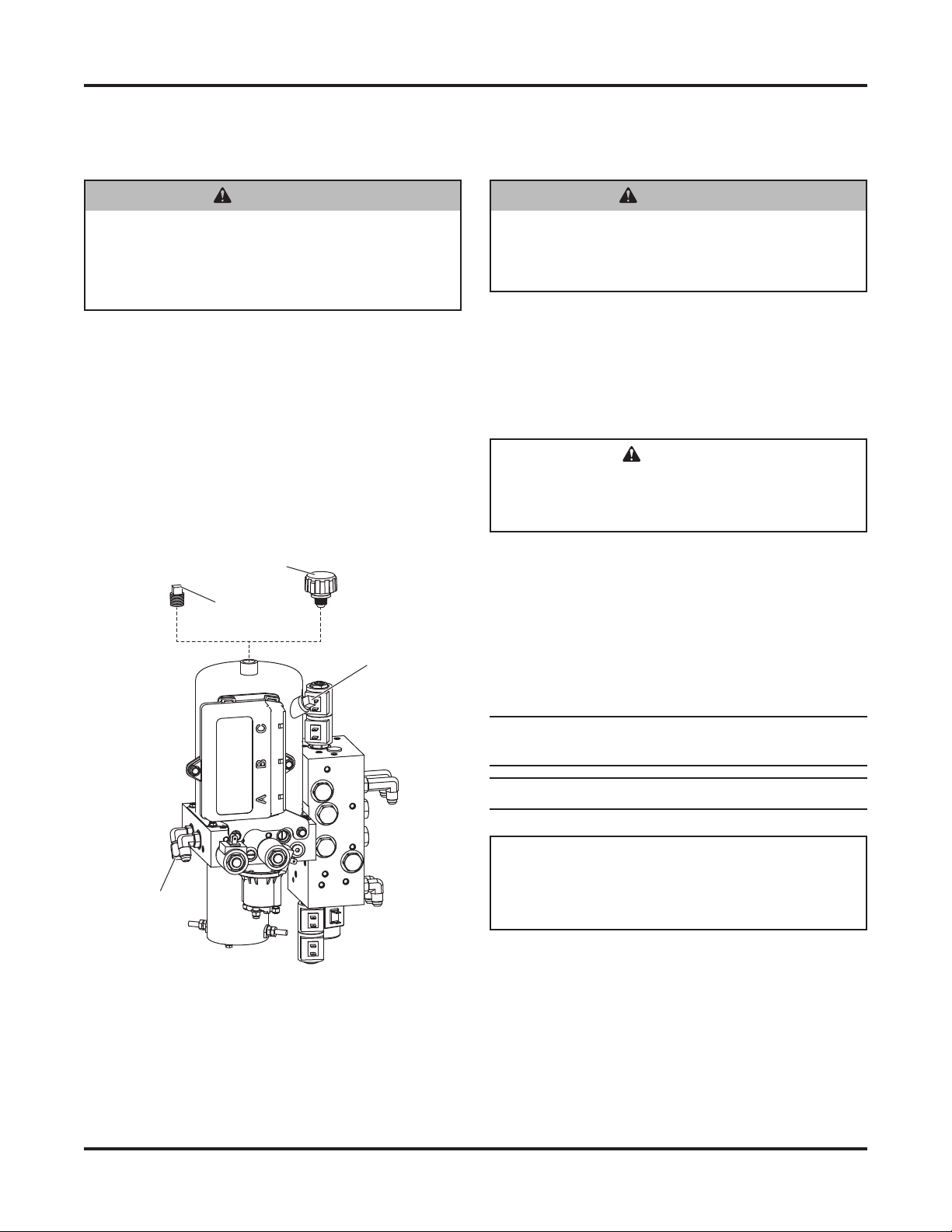

HYDRAULIC SAFETY

• Always inspect hydraulic components and hoses

before using. Replace any damaged or worn parts

immediately.

• If you suspect a hose leak, DO NOT use your

hand to locate it. Use a piece of cardboard or

wood.

FUSES

The FISHER®electrical and hydraulic systems

contain several automotive-style fuses. If a problem

should occur and fuse replacement is necessary,

the replacement fuse must be of the same type and

amperage rating as the original. Installing a fuse with

a higher rating can damage the system and could start

a fire. Fuse Replacement, including fuse ratings and

locations, is located in the Maintenance section of the

Owner's Manual.

PERSONAL SAFETY

• Remove the ignition key and put the vehicle in

PARK or in gear to prevent others from starting

the vehicle during installation or service.

• Wear only snug-fitting clothing while working on

your vehicle or snowplow.

• Do not wear jewelry or a necktie, and secure long

hair.

• Wear safety goggles to protect your eyes from

battery acid, gasoline, dirt, and dust.

• Avoid touching hot surfaces such as the engine,

radiator, hoses, and exhaust pipes.

• Always have a fire extinguisher rated BC handy,

for flammable liquids and electrical fires.

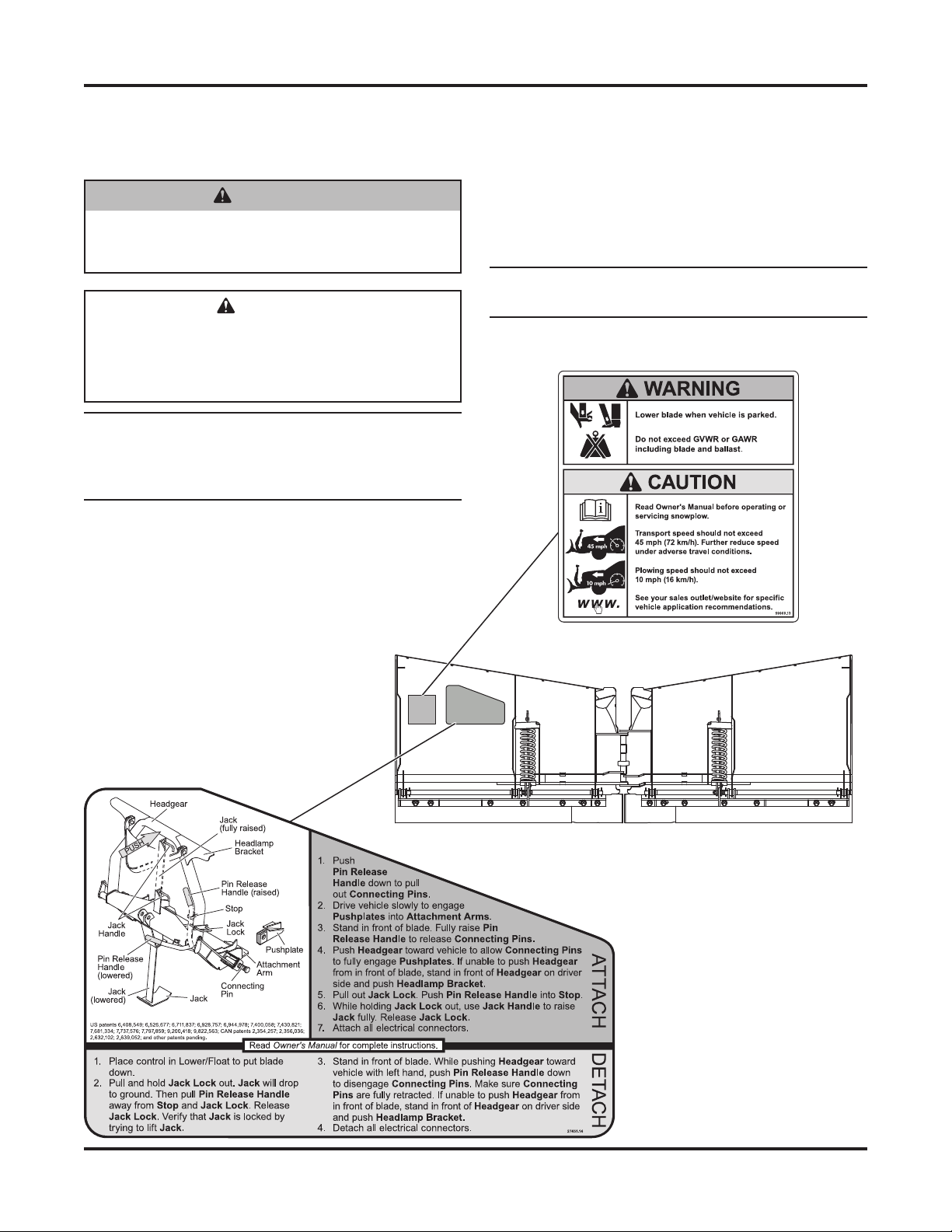

WARNING

Hydraulic fluid under pressure can cause skin

injection injury. If you are injured by hydraulic

fluid, get medical attention immediately.

SAFETY PRECAUTIONS

Improper installation and operation could cause

personal injury and/or equipment and property damage.

Read and understand labels and the Owner's Manual

before installing, operating, or making adjustments.

WARNING

Lower the blade when vehicle is parked.

Temperature changes could change

hydraulic pressure, causing the blade to

drop unexpectedly or damaging hydraulic

components. Failure to do this could result in

serious personal injury.

WARNING

Remove blade assembly before placing

vehicle on hoist.

WARNING

The driver shall keep bystanders clear of the

blade when it is being raised, lowered, or

angled. Do not stand between vehicle and

blade or within 8 feet of a moving blade. A

moving or falling blade could cause personal

injury.

WARNING

Do not exceed GVWR or GAWR, including

blade and ballast. The rating label is found on

driver-side vehicle door cornerpost.

WARNING

To prevent accidental movement of the blade,

always turn the control OFF whenever the

snowplow is not in use. The power indicator

light will turn OFF.

WARNING

Keep hands and feet clear of the blade and

T-frame when mounting or removing the

snowplow. Moving or falling assemblies could

cause personal injury.

CAUTION

Refer to the current eMatch selection system

for minimum vehicle recommendations and

ballast requirements.