Lit. No. 44224, Rev. 14 5 August 15, 2011

TABLE OF CONTENTS

Snowplow Owner Data Sheet ...............................3

Preface ..................................................................7

Safety ....................................................................8

Vehicle Application Information...........................15

Ballast Requirements .......................................16

Getting To Know Your Snowplow ........................17

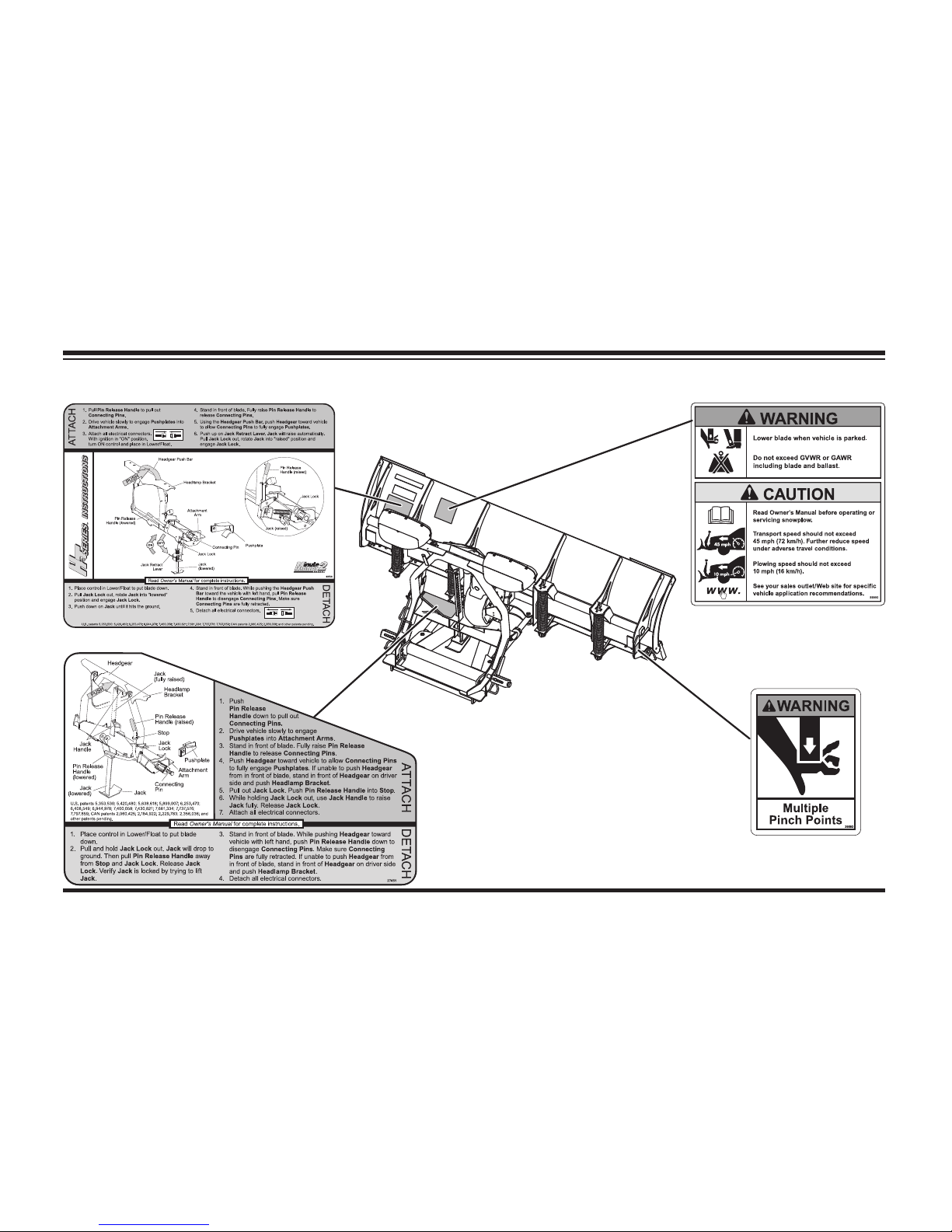

Minute Mount®2 System..................................17

Blades ..............................................................18

HT Series™ Blades.......................................18

SD/HD/XBLADE™ Series ............................19

MC/XtremeV™/XLS™ Series .......................20

A-Frame/T-Frame ............................................21

Straight Blade/HT Series A-Frames .............21

XLS A-Frames ..............................................21

XtremeV T-Frame/Push Assembly................21

Headgear .........................................................21

Weights ........................................................... 22

Mount Kits ........................................................23

INTENSIFIRE™ Snowplow Headlamps...........23

Insta-Act®Hydraulic Units ................................24

System Capacity...........................................26

Pump Motor Specifications ...........................26

Straight Blades ..........................................26

HT Series Blades.......................................26

XtremeV Blades.........................................26

XLS Blades................................................26

Cab Controls .......................................................27

Straight Blade Controls ....................................28

HT Series Controls.......................................... 29

XtremeV & XLS Controls................................. 30

Accessories and Options ....................................31

Attaching Snowplow To Vehicle ......................... 34

Operating Your Snowplow...................................37

Controls............................................................37

Straight Blade Hand-Held Control ................37

Straight Blade Joystick Control.................... 39

HT Series Hand-Held Control.......................41

HT Series Joystick Control .......................... 44

XtremeV/XLS Hand-Held Control ................ 48

XtremeV/XLS Joystick Control......................52

SECURITY GUARD™ System .....................57

XtremeV Blade Positions..................................61

XLS Blade Positions........................................ 64

Snowplow Headlamp Check ............................67

Antiwear Shoe Adjustment.............................. 68

Hydraulic System .............................................70