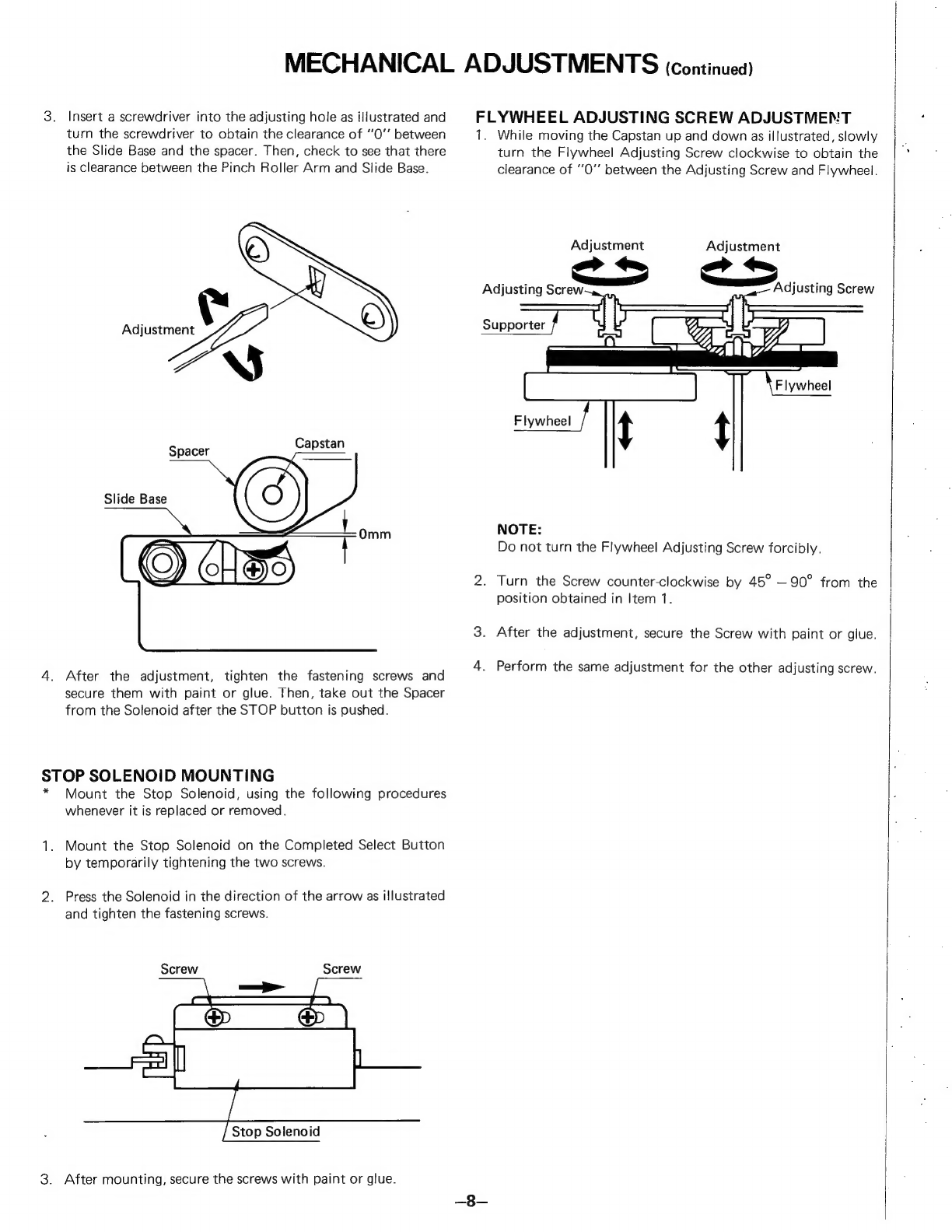

Fisher CR-5125 User manual

Other Fisher Stereo Receiver manuals

Fisher

Fisher RS-1060 User manual

Fisher

Fisher 400 User manual

Fisher

Fisher 4020 User manual

Fisher

Fisher RS-560 User manual

Fisher

Fisher Studio-Standart 504 User manual

Fisher

Fisher 800-C Installation guide

Fisher

Fisher Studio-Standart 504 User manual

Fisher

Fisher 800-C Installation guide

Fisher

Fisher 500-T Installation guide

Fisher

Fisher RS-3030 User manual

Popular Stereo Receiver manuals by other brands

Pioneer

Pioneer SX-1000TA operating instructions

Yamaha

Yamaha MusicCast TSR-5B3D owner's manual

Sony

Sony STR-DE335 - Fm Stereo/fm-am Receiver operating instructions

Sony

Sony STR-DG500 - Multi Channel Av Receiver Service manual

Panasonic

Panasonic AJSD955B - DVCPRO50 STUDIO DECK Brochure & specs

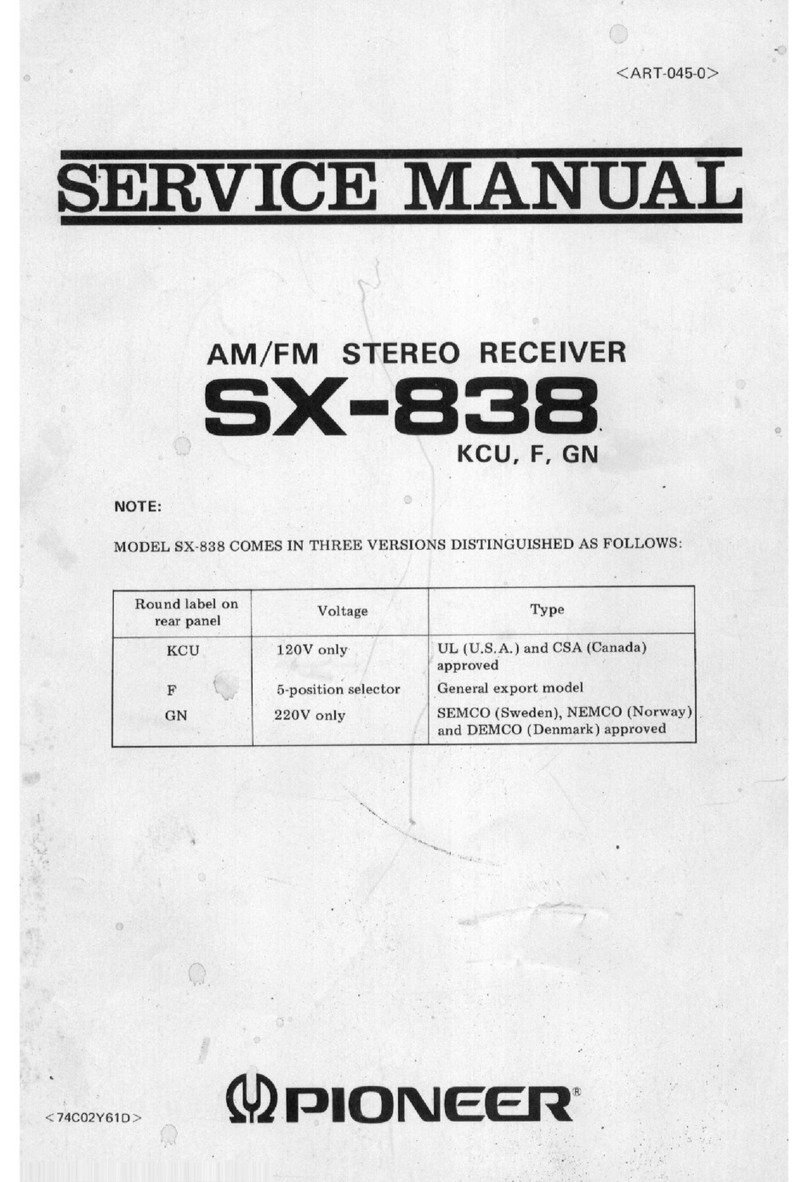

Pioneer

Pioneer SX-838 Service manual