Type 846

2–1

Section2 Installation

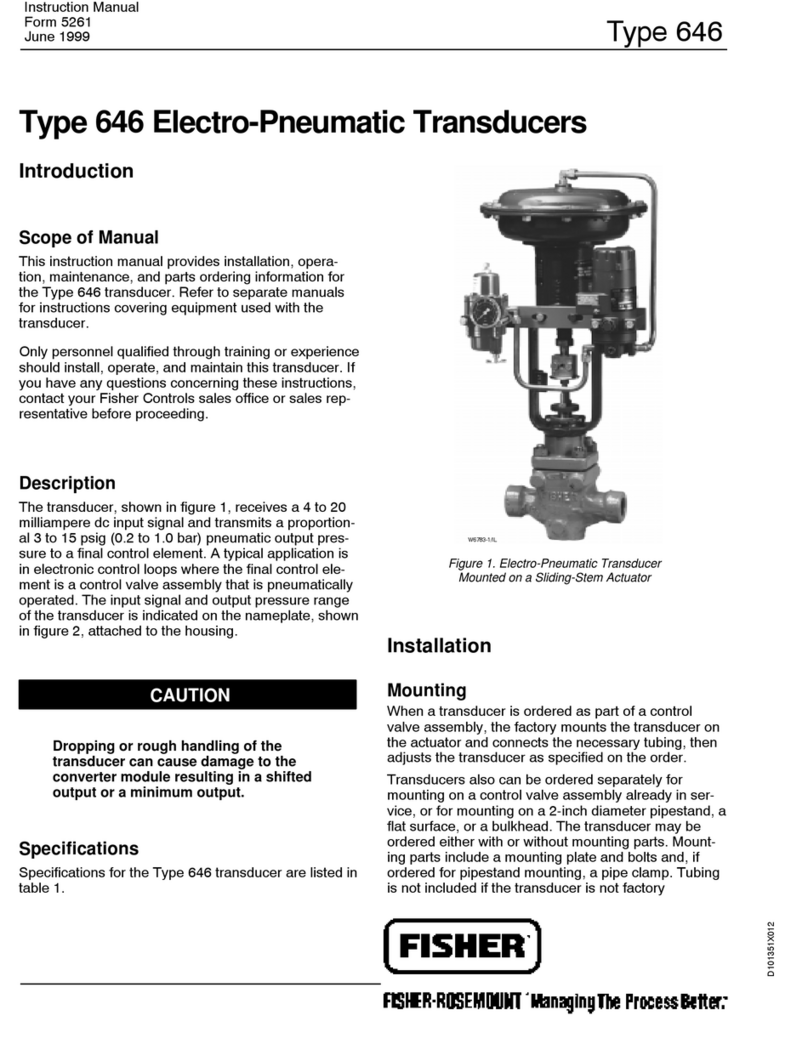

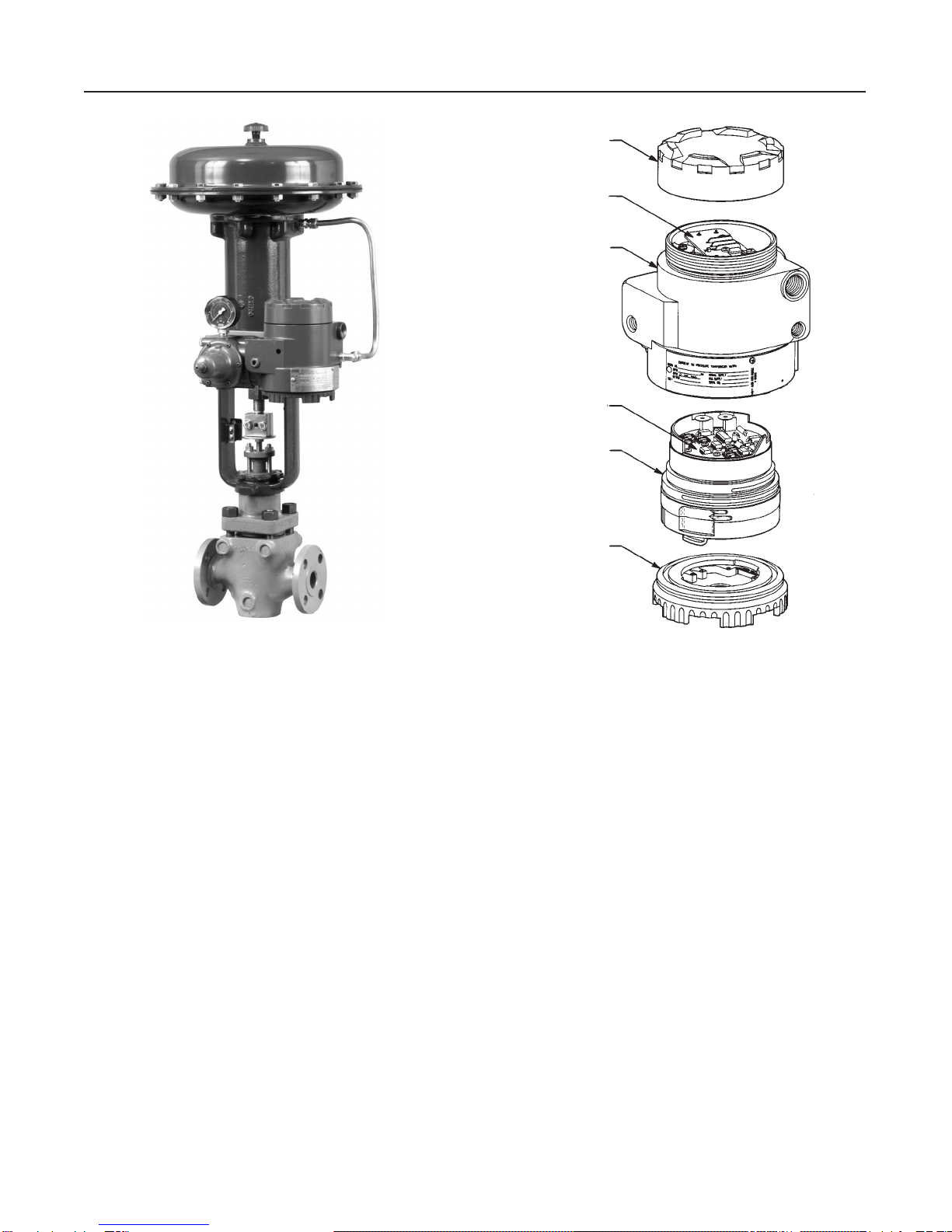

When a control valve is ordered with a Type 846 trans-

ducer specified to be mounted on the actuator, the

factory-mounted transducer is connected to the actua-

tor with the necessary tubing and calibrated to the

specifications on the order.

If the transducer is purchased separately for mounting

on a control valve already in service, all the necessary

mounting parts are furnished, if ordered. This includes

the appropriate bracket for attaching the unit to an ac-

tuator boss (with tapped holes) or for attaching it to the

diaphragm casing.

If preferred, mounting parts can be supplied for mount-

ing the transducer on a 2-inch (51 mm) diameter pi-

pestand, a flat surface, or a bulkhead.

Mounting

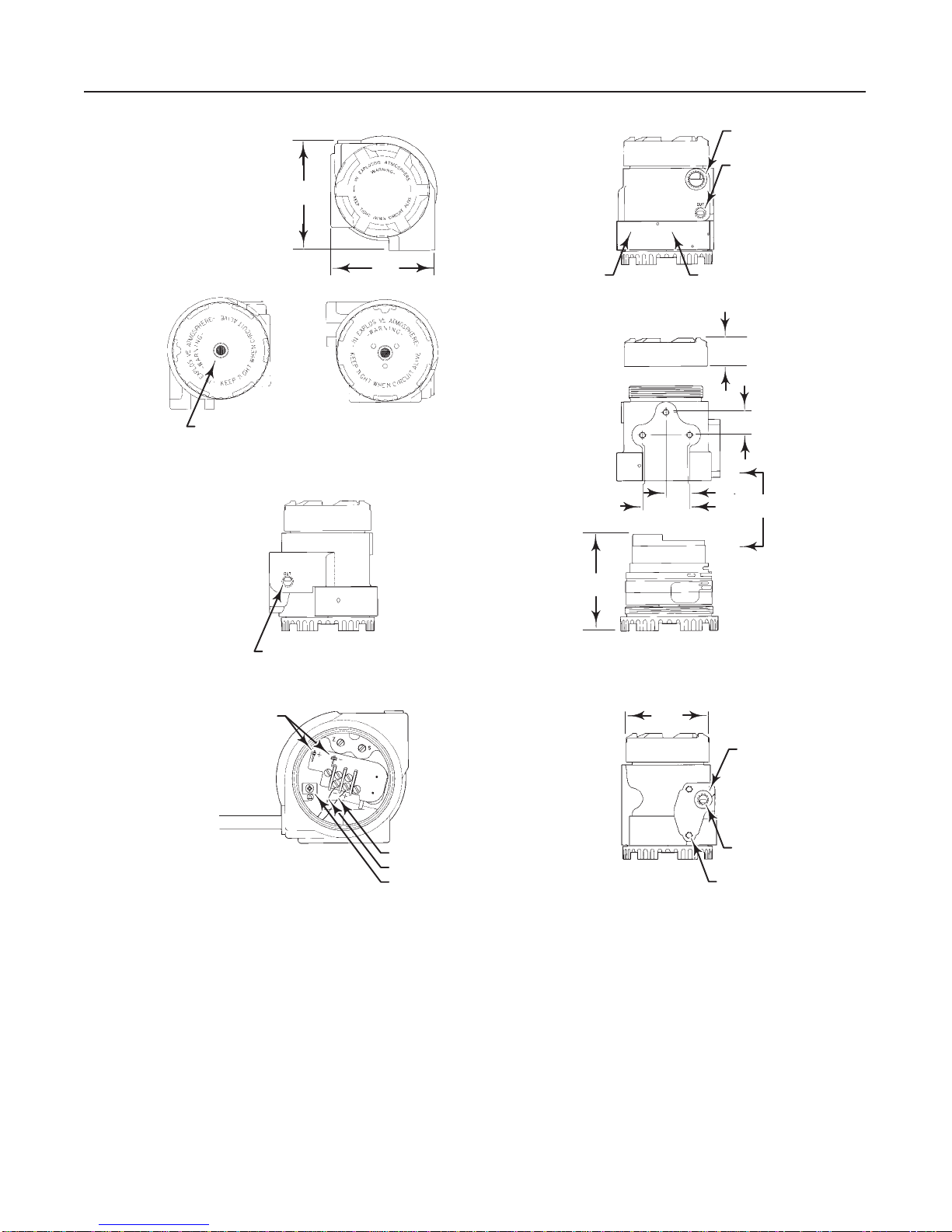

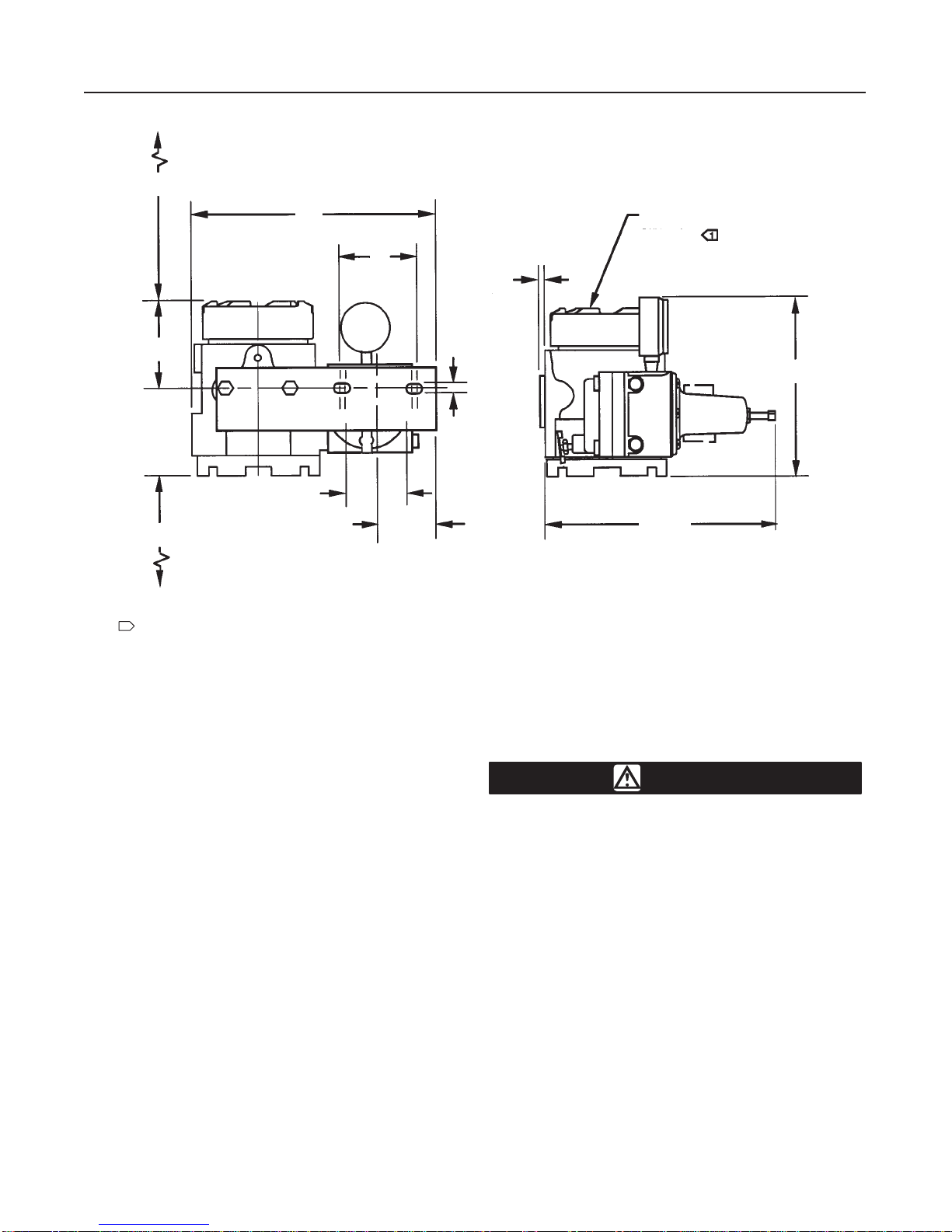

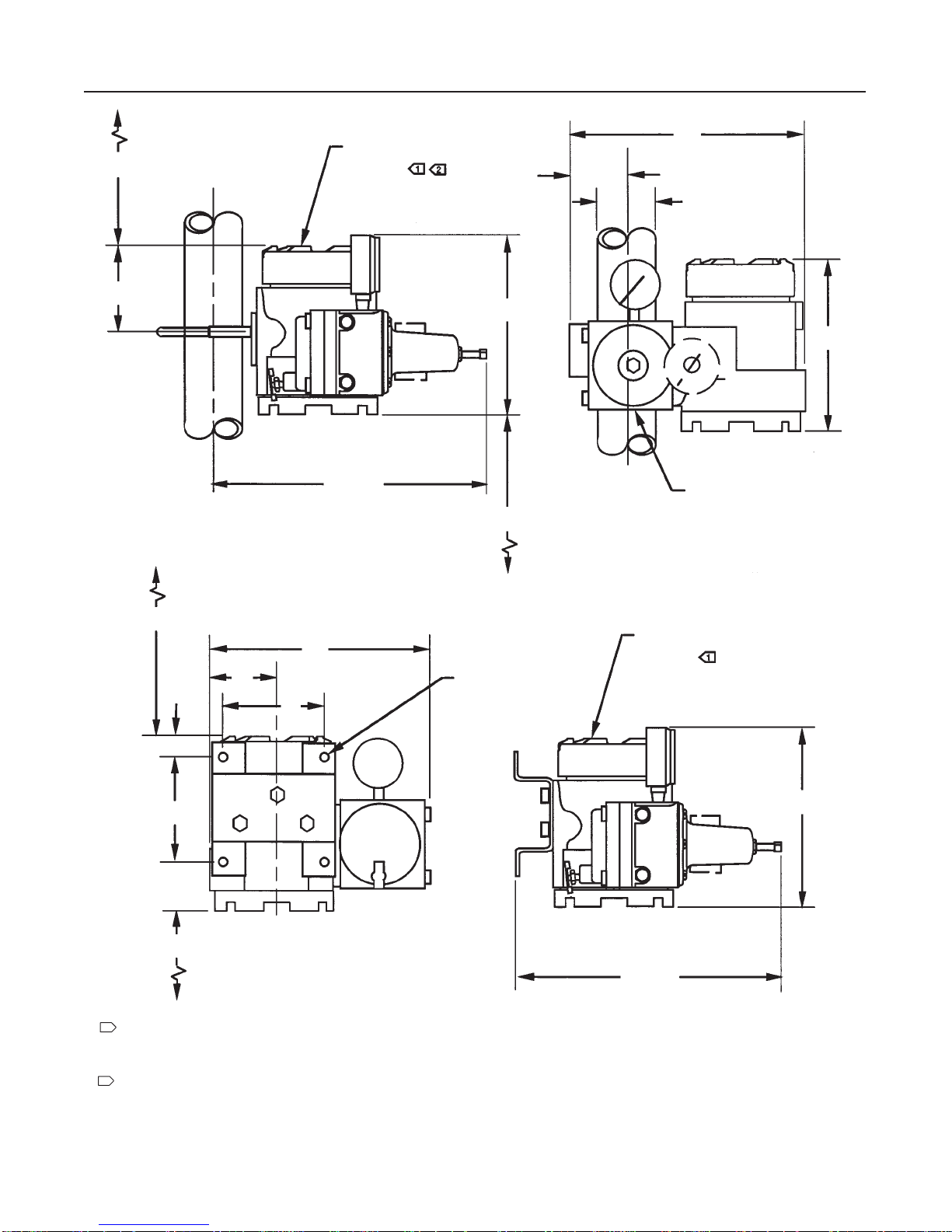

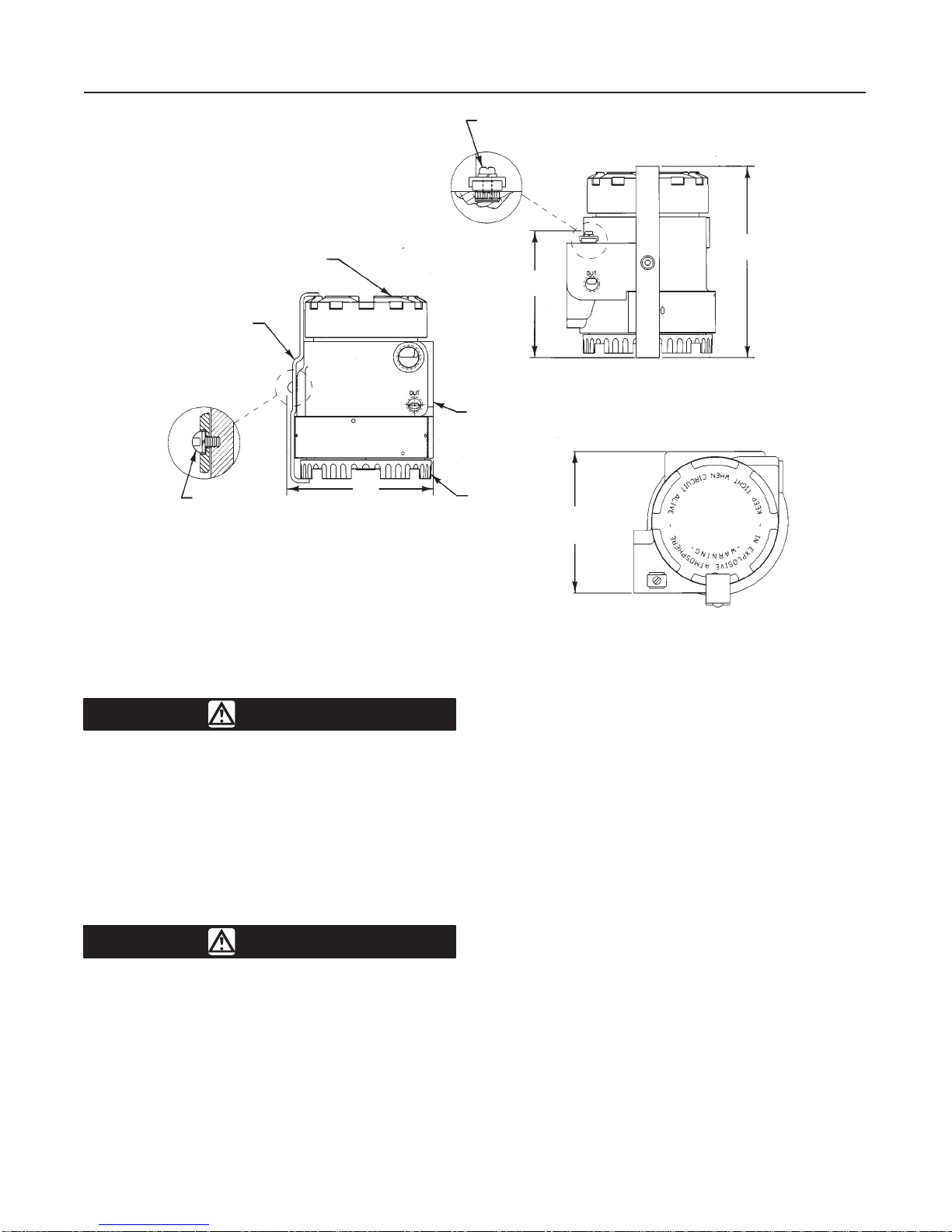

Figures 2-1, 2-2, and 2-NO TAG show the mounting

dimensions. Mount the unit with the stroke port down.

This allows any moisture buildup in the terminal

compartment to drain to the signal wire conduit en-

trance. Any moisture in the pilot stage area will be ex-

pelled through the stroke port without affecting pilot

stage operation. As an alternative, the Type 846 may

be mounted horizontally. However, it must be mounted

so that the flat bracket-mounting surface is down. In

applications with excessive moisture in the supply air,

vertical mounting allows the most effective drainage

through the stroke port.

Before mounting the Type 846, note the following rec-

ommendations:

DEnsurethatall bolts arefullytightened. The recom-

mended torque is 16 lbfSft (22 NSm).

DBolts that connect to the Type 846 and to a valve

actuator should have thelock washer placeddirectly be-

neath the bolt head and the flat washer placed between

the lock washer and bracket. All other boltsshould have

the lock washer next to the nut, and the flat washer

placed between the lock washer and bracket.

DDo not mount the Type 846 in a location where for-

eign material may cover the stroke port or exhaust port.

See the descriptions of the stroke port and exhaust port

later in this section.

Pressure Connections

As shown in figure 2-1, all pressure connections are

1/4-18 NPT female connections. Use 3/8-inch (9.5

mm) outside diameter tubing for the supply and output

connections.

Supply Pressure

WARNING

Personal injury or property damage may

occur from an uncontrolled process if

the supply medium is not clean, dry, oil-

free, or non-corrosive gas. Industry

instrument air quality standards de-

scribe acceptable dirt, oil, and moisture

content. Due to the variability in nature

of the problems these influences can

have on pneumatic equipment, Fisher

Controls has no technical basis to rec-

ommend the level of filtration equipment

required to prevent performance degra-

dation of pneumatic equipment. A filter

or filter regulator capable of removing

particles 40 microns in diameter should

suffice for most applications. Use of

suitable filtration equipment and the es-

tablishment of a maintenance cycle to

monitor its operations is recommended.

WARNING

Explosions may cause death or serious

injury. Do not operate the Type 846 with

the CENELEC flameproof options at a

supply pressure in excess of 20 psi (1.4

bar). Doing so invalidates the CENELEC

flameproof certifications and could al-

low flames to spread from the unit po-

tentially igniting and causing an explo-

sion.

The supply medium must be clean, dry air or noncor-

rosive gas that meets the requirements of ISA Stan-

dard S7.3-1975 (R1981). An output span of 3 to 15

psig (0.2 to 1.0 bar) requires a nominal supply pres-

sure of 20 psig (1.4 bar) and a flow capacity not less

than 4 SCFM (0.11 m3/min). For multirange perfor-

mance units with higher output spans, the supply pres-

sure should be at least 3 psig (0.2 bar) greater than

the maximum calibrated output pressure, but should

not exceed 35 psig (2.4 bar).

The air supply line can be connected to the 1/4–18

NPT supply port, or to the supply port of a filter-regula-

tor mounted directly to the transducer.

The mounting boss for the air supply connection con-

tains two 5/16–18 UNC tapped holes that are 2-1/4

inches apart. The tapped holes allow direct connection

of a filter-regulator having a matching through-bolt pat-

tern. A filter-regulator with mounting hardware is avail-

able. The mounting hardware consists of two 5/16–18

x 3-1/2 inch grade 5 bolts and one O-ring. See Table

6-1 for the O-ring size. The O-ring is positioned in the