www.Fisher.com

Fisher™846 Current-to-Pressure Transducer

Contents

Introduction

Scope of Manual 2.............................

Description 2.................................

Specifications 2...............................

Educational Services 5.........................

Installation 6..................................

Hazardous Area Classifications and Special

Instructions for Safe‐Use and Installation

in Hazardous Locations 7.....................

Mounting 8..................................

Pressure Connections 8........................

Supply Pressure 10.........................

Output Pressure 14........................

Electrical Connections 14.......................

Venting Ports 15..............................

Signal Interruption 15..........................

Calibration 16..................................

Standard Performance:

Full Range Input, Direct Action 18.............

Multirange Performance:

Full Range Input, Direct Action 18.............

Standard Performance:

Split Range Input, Direct Action 19.............

4 to 12 mA Input Signal 19..................

12 to 20 mA Input Signal 19.................

Standard Performance:

Full Range Input, Reverse Action 20............

Multirange Performance:

Full Range Input, Reverse Action 20............

Standard Performance:

Split Range Input, Reverse Action 21...........

4 to 12 mA Input Signal 21..................

12 to 20 mA Input Signal 21.................

Transporting the Module Final Assembly 22.......

Principle of Operation 22........................

Electronic Circuit 22...........................

Magnetic Actuator 23..........................

Pilot Stage 23.................................

Booster Stage 24..............................

Troubleshooting 25.............................

Diagnostic Features 25.........................

Stroke Port 25.............................

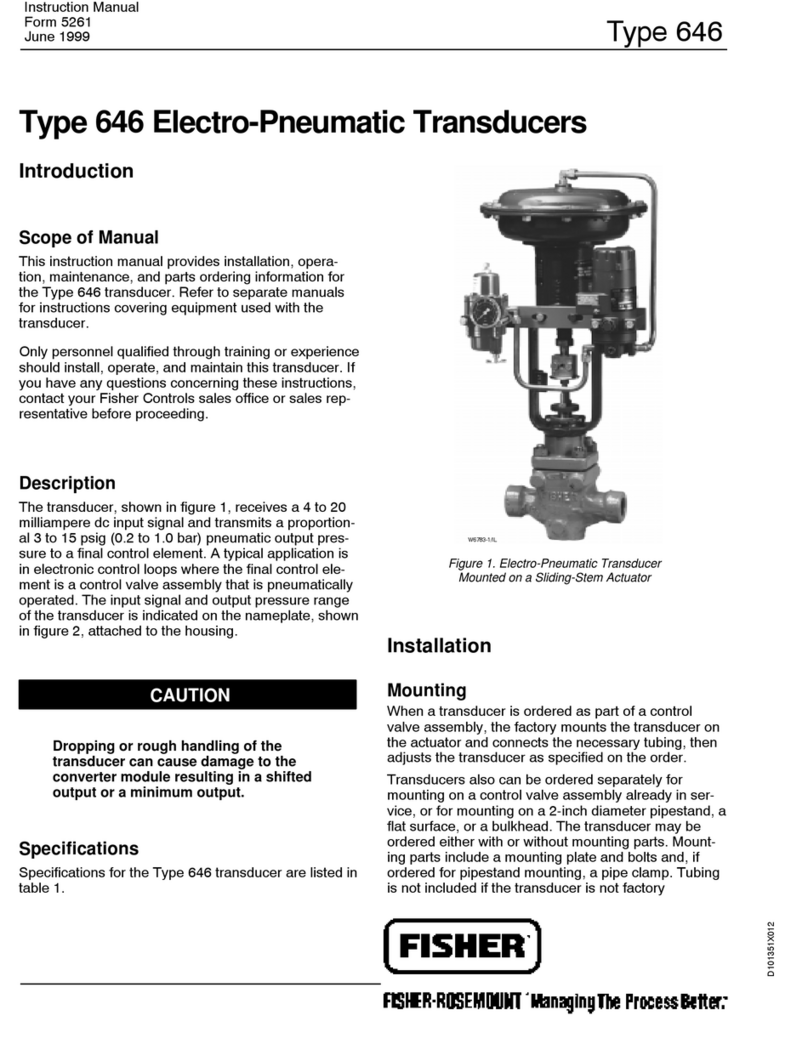

Figure 1. Fisher 846 Current‐to‐Pressure Transducer

X0234

Remote Pressure Reading (RPR) 25...........

Using a Frequency Counter to read the

RPR Signal 25.........................

In‐service Troubleshooting 26...................

Troubleshooting in the Shop 29.................

Maintenance 31................................

Module Final Assembly 32......................

Removing the Module Final Assembly 34......

Replacing the Module Final Assembly 35.......

Electronic Circuit Board 36......................

Remote Pressure Reading (RPR) Jumper 36.....

Range Jumper 37..........................

Action 37.................................

Removing the Electronic Circuit Board 37......

Replacing the Electronic Circuit Board 38......

Pilot/Actuator Assembly 38.....................

Action 38.................................

Removing the Pilot/Actuator Assembly 39.....

Replacing the Pilot/Actuator Assembly 39.....

Module Subassembly 40........................

Terminal Compartment 40.....................

Exhaust and Stroke Port Screens 41..............

Parts 42......................................

Instruction Manual

D102005X012

846 Transducer

June 2017