FISNAR F1300N.2 User manual

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 2 - F1300N.2 Rev 01

Table of Contents

Machine Overview 3

Product Safety Statement 4

Specifications 6

Accessories 6

External Controls 7

•Front

7

•Back

10

HMI Controls 14

•Production Screen

14

•Test Screen

18

•Machine Settings Screen

20

Machine Setup 24

Z-Axis Drive Cylinder Setup 26

Dispense Setup 28

Operation Modes 31

•Standard Mode

31

•Pulse Mode

34

•Index Mode

37

Warning Messages 40

•Emergency Stop

40

•Door Open

41

•Reset Machine

42

•Home Machine

43

•Alarm In

44

•Machine Not In Start Position

45

•Cycle Count Limit

46

External Dispenser Actuation 47

EXT. Connector 48

Safety Connector 49

Internal Safety Relay 50

I/O Connector 51

•Schematic

51

•Output Signal Logic

52

•Input Signal Logic

52

•Output Signal Definition

53

•Input Signal Definition

54

•I/O Timing Diagram

54

Spare Part List 55

Machine Drawings 57

Maintenance & Troubleshooting 60

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 3 - F1300N.2 Rev 01

OVERVIEW

FIG. 1: Model F1300N.2 Rotary Table

The F1300N.2 rotary table provides an efficient method of dispensing a circular pattern on

areas that are difficult to access. The tilting Z-axis allows for controlled rotary dispensing at a

fixed angle.

Used for dispensing adhesives, silicones, greases and lubricants

, the F1300N is fully

adjustable in rotation speed, circle diameter, and dispensing time. Dispense from barrels,

cartridges, or valves mounted on the Z-axis.

The Z-axis tilt is easily adjusted to dispense either on a vertical wall within a cylindrical part

or an outside wall. The system is fully programmable to control dispense delay, degree of

rotation, and wait period before cycling.

Three Operation Modes

Standard mode – For dispensing a continuous arc or circle diameter

Pulse mode – For dispensing multiples arcs over a defined circle diameter

Index mode – For dispensing in multiple fixed positions within a arc or circle diameter

Nine programmable memory slots

Adjustable fluid output pressure (0-100psi) for setting and controlling dispense pressure inside fluid

syringe barrel or cartridge. Alternatively used for actuating connected pneumatic dispense valve.

Touch screen LCD display for easy setup and operation

Fully programmable for accurate dispense results

7 channel I/O circuit for external control

Password-protected operator lock-out mode

Industry standard push-in fitting ensure easy system installation and integration into workplace

environments

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 4 - F1300N.2 Rev 01

General Precautions

Do not operate the machine in excess of its maximum ratings / settings.

Make sure the machine is connected to a properly grounded power source.

Make sure that the input air supply is clean and dry. A 5 micron air filter/regulator

(item number 560567) is supplied and recommended to use, so as to ensure the

input air supply is clean and dry.

If Cyanoacrylates adhesives or other moisture sensitive fluids are being used,

an inline coalescing filter (item number 560779C) must be installed to maintain

dispensing system performance.

The fluid being dispensed may be toxic and / or hazardous. Refer to the Material

Safety Data Sheet for proper handling and safety precautions.

Do not smoke or use near an open flame when flammable materials are being

dispensed.

Do not expose the machine directly to sunlight.

Avoid cleaning the machine with aggressive solvents – neutral detergents are

preferred.

Do not touch any moving parts while the rotary table is running.

Loading and unloading of parts must be done when the rotary table is not

moving.

Changing of tooling must be done with the power source disconnected.

EU & UK Safety Requirement

To meet the conformity requirements of the European Community (CE) Machinery

Safety Directive (2006/42/EC) or UK (UKCA) Machinery (Safety) Regulations 2008 this

machine must be placed in an appropriate safety enclosure prior to production use.

F1300N.2 Malfunction

If the machine malfunctions, shut down the machine immediately. This can be

done by either pushing the power switch at the back of the unit

into the off

position or disconnecting the power cord.

Isolate pneumatic air supply to the controller.

Identify the cause of machine malfunction and fix accordingly before switching

back on.

SAFETY

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 5 - F1300N.2 Rev 01

Inappropriate Use

If the machine is used in a way other than described in this manual, it may cause damage

to self or property.

Do not use any components with the machine other than Fisnar authorized

components.

Do not use incompatible materials.

Do not make any modifications to the machine.

All repairs are to be done using Fisnar specified spare parts.

Do not operate the machine in excess of its maximum ratings / settings.

Do not drop or spill foreign objects or material such as screws or liquids into

the rotary table.

Do not operate the machine where electrical noise is present.

Fire Prevention

Refer to the following instructions to avoid any fire or explosion.

Assess your surroundings and the location of the nearest fire extinguisher and

Emergency Exit.

Do not smoke or use near an open flame when flammable materials are being

dispensed.

Immediately disconnect power if any sparking or smoke appears.

Do not expose the machine directly to sunlight.

Maintenance

The F1300N.2 is generally a maintenance free machine. However, to ensure smooth

operation please follow the below instructions.

Only use non-woven cleaners on the machine.

Periodically inspect pneumatic and fluid tubing for signs of fatigue and replace

as necessary

Ensure that compressed air supply to the machine is clean and moisture free.

Periodically check electrical connections and pneumatic fittings are secure.

SAFETY

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 6 - F1300N.2 Rev 01

ACCESSORIES

Item

Description

Quantity

A23EMOT-EA10681V240

Power Adaptor (Input: 100–240 VAC / Output: 24 VDC)

1

5601888

Foot Pedal Switch

1

0603-25400002

30/55cc Barrel Holder Assembly

1

W122000006

8mm OD x 6mm ID Polyurethane Tubing – 10FT

1

W124000081

Straight 6mm OD Push Connector x 1/4" NPT Male

1

A09WP-1705-1-W24

Aux. Dispenser Cable Assy. – 2 metres

1

A10FBMH-6FR

Safety Connector Socket

1

1705-15910002

Internal Safety Relay Wiring Kit

1

W124000120

6mm OD Push to Connect Air Plug

3

W124000185

Push In Fitting 6mm Stem OD X 4mm Tube OD

1

W124000194

Push In Fitting 8mm Stem OD X 6mm Tube OD

1

A10D-TYPE9MHP2-9CASE

9 Pin D-Sub EXT. Connector Socket

1

A10D-TYPE9MHP2-SHORT

9 Pin D-Sub EXT. Shorted Connector Socket

1

A10D-SUB15FR-15CASER

15 Pin D-Sub I/O Connector Socket 1

SPECIFICATIONS

Dimensions (W x D x H): 13.8” x 19” x 22.6” (350 x 482 x 574 mm)

Weight: 24.3 lbs (11 kg)

Input AC to Power

Supply:

100 – 240 VAC, 50 / 60 Hz

Output DC from Power

Supply:

24 VDC – 1 Amp

Rotation Speed: 0 - 60rpm

Work Load: 2 kg (4.4 lb)

Tool Load: 10 kg (22 lb)

Working Area (Diameter): 300mm (12”)

Vertical Travel 100mm (4”)

Air Input: 70 - 100 psi (5 - 7 bar) max

Air Output: 1 – 100 psi (0.07 – 7 bar)

Standards:

CE Approved, UKCA Approved, EMC Compliant,

RoHS Compliant

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 7 - F1300N.2 Rev 01

EXTERNAL CONTROLS

FIG. 2: External Controls Overview - Front

Item Illustration Item Illustration Item Illustration

1 Purge Button 4 Reset Button 7 HMI Display

2 Vacuum Control Knob 5 Start Button 8 Air Pressure Regulator

3 Emergency Stop Button 6 Air Pressure Gauge 9 Start Button

1

2

3

4

9

7

5

6

8

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 8 - F1300N.2 Rev 01

1. Purge Button

Press the purge button to manually dispense fluid material from the

syringe barrel or cartridge.

Or, if using a pneumatic dispense valve, press the purge button to

manually actuate the dispense valve.

2. Suck Back

Control

This feature is only needed if dispensing a low viscosity fluid directly from

a syringe barrel (I.E. syringe barrel adapter a

ssembly is connected

directly to the “Dispense Air Out” port (Fig.4.9

) on the back of the

machine).

It will keep a negative air pressure in the syringe barrel other than when

carrying out the “Rotation Delay” and “Dispense

Angle” phase of the

program cycle, to prevent low viscosity fluids dripping from the dispense

tip in between program cycles.

3. Emergency

Stop

Press the emergency stop button to immediately stop the machine and

cease a program cycle.

4. Reset Button

If the emergency stop button is pressed, it will be necessary to press the

reset button after releasing the emergency stop button before the

machine can be actuated again.

5. Start Button

Press both start buttons (5) and (9) simultaneously to actuate the machine

and begin the program cycle.

6. Dispense

Pressure Gauge

Shows the amount of pressure being used to pressurize the fluid material

in the syringe barrel or cartridge. Or, if using a pneumatic dispense valve,

then this will show the amount of pressure being used to actuate the valve

during the program cycle.

The pressure gauge value is set and controlled by the pressure regulator

(8).

The set pressure is fed out of the back of the machine from the “Dispense

Air Out” port (FIG.4.9) only during the “Rotation Delay” and “Dispense

Angle” phase of the program cycle. Or when the “Purge” button (1) is

pressed.

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 9 - F1300N.2 Rev 01

7. HMI Display

The HMI display is used to,

- Enter the parameters of the program cycle.

- Manually actuate individual components of the machine.

- Adjust machine settings.

For fu

ll information on the HMI Display functions please refer to “HMI

Controls” section.

8. Pressure

Regulator

Adjusts and sets the amount of pressure being used to pressurize the

fluid material in the syringe barrel or cartridge. Or, if using a pneumatic

dispense valve, then this will set the amount of pressure being used to

actuate the valve during the program cycle.

To reach the desired pressure, turn the knob counterclockwise to a point

below the required pressure, and then turn the knob clockwise to reach

the required pressure.

The regulator can be locked into position by tightening the jam nut behind

the knob against the fitting on the front panel of the machine.

9. Start Button

Press both start buttons (5) and (9) simultaneously to actuate the machine

and begin the program cycle.

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 10 - F1300N.2 Rev 01

EXTERNAL CONTROLS

FIG. 3: External Controls Overview - Back

Item Illustration Item Illustration Item Illustration

1 On / Off Switch 8 Cylinder Out Port 15 Sensor Connector

2 Fuse 9 Dispense Air Out Port 16

Foot Switch

Connector

3 I/O Connector 10 USB Connector 17 Exhaust Port

4 Ext. Control Connector 11 Power Input Connector 18 Main Air In Port

5 Ground Connection 12 RS232 Connector 19 Main Air Out Port

6 Cylinder In Port 13 Dispenser Connector

7 Spray Air Out Port 14 Safety Connector

1

2

3

4

5

6

7

8

9

14

15

16

13

17

11

10

12

18

19

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 11 - F1300N.2 Rev 01

1. On / Off Switch

Used to switch the machine on or off.

2. Fuse

A 2.5A fuse is located here to protect the internal electrical circuit.

3. I/O Connector

Where the external machine I/O input signals and output signals are

connected.

A courtesy 24V + output is also included on the I/O Connector.

4. Ext. Control

Connector

Used in applications where external start and stop controls will be used

and/or when the machine is placed inside a safety enclosure and

connected to an external safety circuit with an

externally fitted safety relay.

The optional remote operation box (F1300AKIT-EXTBOX or F1300AKIT-

EXTBOX-SR) can be used in the instances described above.

If this connection is not utilized, the shorted EXT. Control plug MUST be

inserted.

5. Ground

connection

A safe and secure machine grounding point; to be used when the power

input adapter is not connected directly to a grounding point.

6. Cylinder In Port

(4mm OD)

The pneumatic tubing labelled “Cylinder In” from the z-axis drive

assembly is connected here.

7.

Spray Air Out

Port

(6mm OD)

If a spray valve is being used on the machine, then the atomizing air port

of the spray valve is connected here.

If this connection is not required for use, it is recommended that a blanking

plug be inserted into this port.

8.

Cylinder Out

Port

(4mm OD)

The pneumatic tubing labelled “Cylinder Out” from the z-axis drive

assembly is connected here.

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 12 - F1300N.2 Rev 01

9.

Dispense Air

Out Port

(6mm OD)

At the start of a dispensing cycle, the regulated compressed air set by the

pressure regulator and displayed on the pressure gauge on the machine

will exit this port.

It is used to pressurize and dispense the fluid material from the connected

syringe barrel or cartridge during the program cycle. Or, if using a

pneumatic dispense valve, then this will actuate the valve

during the

program cycle.

If this connection is not required for use, due to an external dispense

controller being used to control the dispensing of fluid material during

the program cycle via the “Dispenser” connector port (13), it is

recommended that the pressure regulator on the machine be set to 0psi

and a blanking plug be inserted into this port.

10. USB Connector

For internal use only.

11. Power Input

Connector

The power input cable from the external power supply is connected here.

12. RS232

Connector

For internal use only.

13 Dispenser

Connector

If an external dispense controller is being used to operate the dispense

valve/syringe barrel mounted on the Rotary Table, the signal wires that

actuate the dispense controller are to be connected here.

14 Safety

Connector

Used in applications when the machine is placed inside a safety enclosure

and connected to a safety circuit with an internally fitted safety relay.

The electrical wires of the safety light curtain or door switch are connected

here when an internal safety relay (F1300AKIT-SR

sold separately) is

fitted inside the machine.

If this connection is utilized, the shorted EXT. Control plug MUST be

inserted into the EXT. Control connector (4) if it is not being utilized.

15. Sensor

Connector

The electrical connector from the z-axis drive

assembly is connected

here.

16 Foot Switch

Connector

The foot pedal switch is connected here.

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 13 - F1300N.2 Rev 01

17. Exhaust Port

(4mm OD)

At the end of a program cycle, pressurized air that was used to control the

program cycle will be exhausted from this Exhaust Port.

18. Main Air In Port

(8mm OD)

External Compressed air 70-100 psi (5-7 bar) is to be connected here.

To prevent damage to internal pneumatic components of the machine,

make sure that the input air supply is clean and dry. A 5-

micron air

filter/regulator (item number 560567) is recommended to be used, to

ensure the input air supply is clean and dry.

19.

Main Air Out

Port

(6mm OD)

The compressed air pressure supplied into the “Main Air In” port will exit

from this port.

It can be used to connect to an auxiliary pressure regulator and gauge

(560779SK) to allow the safe and constant pressurization of the

connected fluid feed system (e.g. syringe barrel, cartridge, fluid reservoir

etc.) in applications when a dispense valve is connected to the machine.

If this connection is not required for use (e.g., a syringe barrel or cartridge

is being directly dispensed from), then a blanking plug MUST be inserted

into this port.

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 14 - F1300N.2 Rev 01

HMI CONTROLS

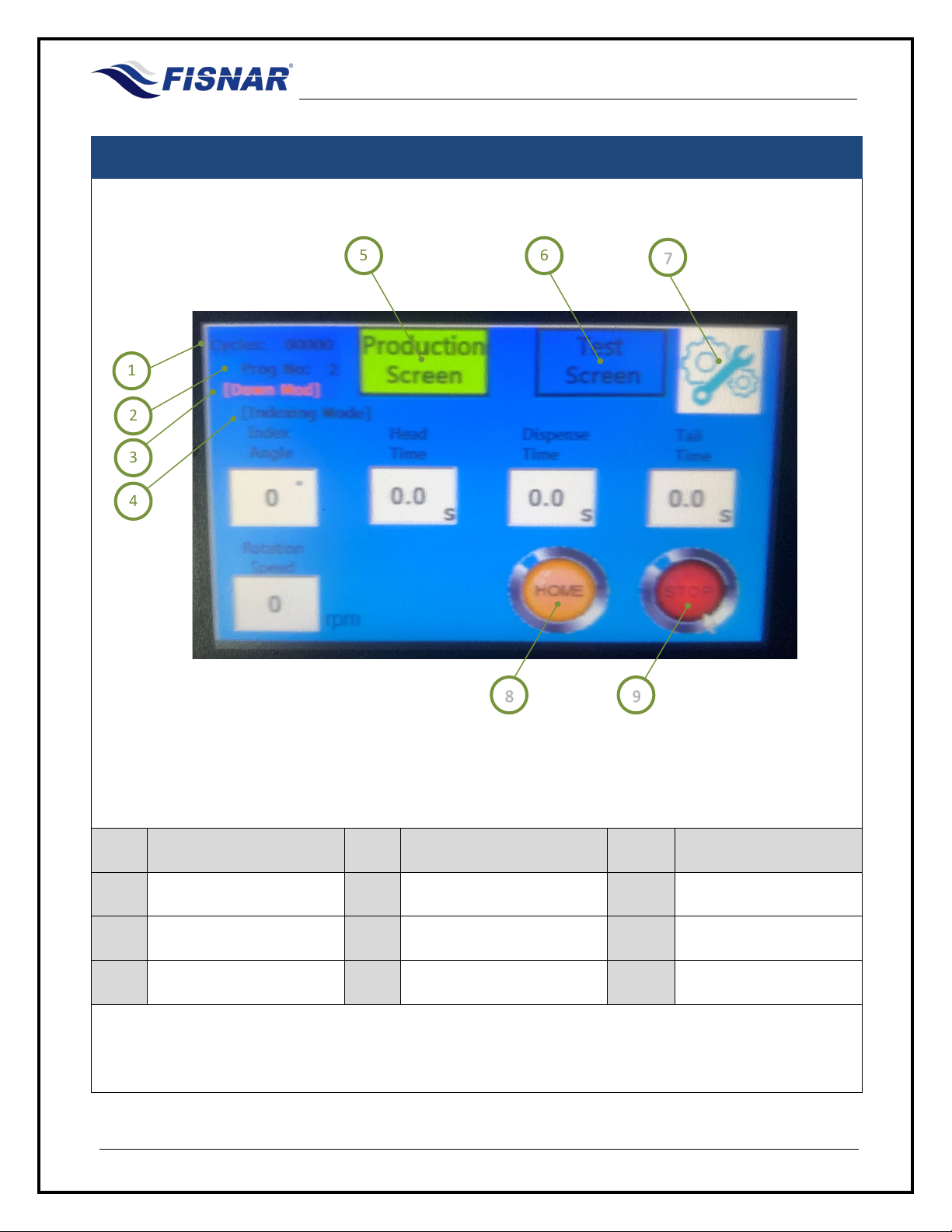

FIG. 4: HMI Controls Overview – Production Screen

Item Illustration Item Illustration Item Illustration

1 Cycle Counter 4 Operation Mode 7 Machine Settings

2 Program Number 5 Production Screen 8 Home Button

3 Static Mode 6 Test Screen 9 Stop Button

1

3

2

4

5

6

7

8

9

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 15 - F1300N.2 Rev 01

1 Cycle Counter

Displays the number of program cycles that have taken place since the

cycle counter was last reset in the Machine Settings screen.

2 Program

Number

Displays the program number the machine is executing.

The program

number is selected in the Machine Settings screen.

3 Static Mode

When the machine has been selected to run in “Static Mode” in the

Machine Settings Screen, the text (Down Mod) will be displayed here.

4 Operation Mode

Displays the operation mode (standard, pulse or index) that the machine

is operating in, which is selected in the Machine Settings screen

5 Production

Screen

Touch this button to display the Production Screen on the HMI.

When the background is highlighted in green color, it confirms that the

Production Screen is being displayed on the HMI.

6 Test Screen

Touch this button to display the Test Screen on the HMI.

Before entering the Test screen a pop-up message will appear requesting

for a password to be entered.

The machine is shipped without a password. Therefore, touch the “Enter”

button to display the Test screen.

If a password has been created by the user of the machine, touch the

empty white box. A pop-up

dialogue window will then automatically

appear allowing the user to type in the password.

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 16 - F1300N.2 Rev 01

Once the password has been entered, touch the “Enter” button on the

dialogue window. The pop-

up dialogue window will then automatically

disappear. The user can then touch the “Enter” button on the original pop-

up message.

When the background is highlighted in green color, it confirms that the

Test Screen is being displayed on the HMI.

7 Machine

Settings

Touch this button to display the Machine Settings Screen on the HMI.

Before entering the machine setup screen a pop-up message will appear

requesting for a password to be entered.

The machine is shipped without a password. Therefore, touch the “Enter”

button to display the Machine Settings screen

If a password has been created by the user of the machine, touch the

empty white box. A pop up dialogue window will then automatically appear

allowing the user to type in the password.

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 17 - F1300N.2 Rev 01

Once the password has been entered touch the “Enter” button on the

dialogue window. The pop-

up dialogue window will then automatically

disappear. The user can then touch the “Enter” button on the original pop-

up message.

8 Home Button

Touch this button to send the motor to its “Home” position.

The “Home” button is only displayed when the production mode has been

set to “Pulse” or “Index” mode.

9 Stop Button

Touch this button to stop the machine in the middle of a program cycle.

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 18 - F1300N.2 Rev 01

HMI CONTROLS

FIG. 5: HMI – Test Screen

Item Illustration Item Illustration Item Illustration

1 Glue Light 4 Cylinder Down Light 7 Motor Button

2 Motor Light 5 Glue Button 8 Home Light

3 Cylinder Up Light 6 Cylinder Button 9 Spray Button

3

1

2

4

7

9

6

5

8

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 19 - F1300N.2 Rev 01

1 Glue Light

When the “Glue” button is in the “ON” position, the Glue Light will light up

green. When the light is green in color the dispense solenoid is active and

the machine is sending the signal to dispense fluid

material from the

syringe barrel/cartridge or actuate the connected dispense valve.

2 Motor Light

When the “Motor” button is in the “ON” position, the Motor Light will light

up green. When the light is green in color the motor on the machine will

be rotating at the speed (rpm) defined in the “Rotation Speed” value on

the production screen.

3 Cylinder Up

Light

When the “Cylinder” button is in the “OFF” position, the Cylinder UP light

will light up green. When the light is green in color it confirms the Z-Axis

drive cylinder is in the “UP” position.

4 Cylinder Down

Light

When the “Cylinder” button is in the “ON” position, the Cylinder Down light

will light up green. When the light is green in color it confirms the Z-Axis

drive cylinder is in the “DOWN” position.

5 Glue Button

This button is used to actuate the dispense

solenoid in the machine.

When in the “ON” position the dispense solenoid is actuated to dispense

fluid material from the syringe barrel/cartridge or actuate the connected

dispense valve.

6 Cylinder Button

This button is used to actuate the Z-Axis drive cylinder on the machine.

When in the “ON” position the Z-Axis cylinder will move to the “DOWN”

position. When in the “OFF” position the Z-Axis cylinder will move to the

“UP” position.

7 Motor Button

This button is used to actuate the motor on the machine. When in the

“ON” position the motor will continuously rotate at the speed (rpm) defined

in the “Rotation Speed” value on the production screen.

8 Motor Home

Light

When the Motor is in its “HOME” position, the Motor Light will light up

green.

9 Spray Button

This button is used to actuate the atomizing air solenoid in the machine.

When in the “ON” position the atomizing air solenoid is actuated to supply

compressed air to the atomizing air port of the connected spray valve.

F1300N.2 Rotary Table Operating Manual

© 2022 Fisnar - 20 - F1300N.2 Rev 01

HMI CONTROLS

FIG. 6: HMI - Machine Settings

Item Illustration Item Illustration Item Illustration

1 E-Stop Condition 8 Change Test Password 15 Cycle Count Limit

2 Firmware Version 9 Change Setup Password 16 Current Cycle Count

3 Total ON Time 10 Operation Mode 17 Reset Count

4 Total Cycles 11 Static Mode 18 Screen Lock

5 Motor Acc. Time 12 Spray Mode 19 Back

6 Motor Rotation 13 Language

7 Auto Cycle Delay 14 Program Select

1

4

9

11

12

10

2

3

5

6

7

8

13

14

15

16

19

17

18

Table of contents

Other FISNAR Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Sony

Sony FilmStation UP-DF750 Setup and user's manual

Drucker Diagnostics

Drucker Diagnostics Horizon 6 FA Service manual

Elster Instromet

Elster Instromet enCore FC1 manual

Haag-Streit

Haag-Streit LI 900 Instructions for use

Linkam Scientific Instruments

Linkam Scientific Instruments FDCS196 user guide

BD

BD CARV II Installation and user guide

Thermo Scientific

Thermo Scientific EASYpure 1164 Series Operation manual and parts list

Gilson

Gilson PIPETMAN Classic P2 user guide

Purelogic

Purelogic R Series user manual

INTELLICYT

INTELLICYT iQue SCREENER Hardware manual

Omni International

Omni International Omni Mixer owner's manual

MRC

MRC MHK 1-6D Operation manual