2

Owner’s Record

The model and serial numbers are located at the rear.

Record these numbers in the space provided below.

Refer to these numbers whenever you call upon your Sony

dealer regarding this product.

Model No. ____________________

Serial No. ____________________

To reduce the risk of fire or electric shock, do not

expose this apparatus to rain or moisture.

To avoid electrical shock, do not open the

cabinet. Refer servicing to qualified personnel

only.

No modification of this equipment is allowed.

THIS APPARATUS MUST BE EARTHED.

To disconnect the main power, unplug the power

plug.

When installing the unit, incorporate a readily

accessible disconnect device in the fixed wiring,

or connect the power plug to an easily accessible

socket-outlet near the unit.

Do not position the ME equipment where it is

difficult to unplug the power plug.

If a fault should occur during operation of the

unit, operate the disconnect device to switch the

power supply off, or unplug the power plug.

For the customers in the U.S.A.

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide

reasonable protection again harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in

which case the user will be required to correct the

interference at his own expense.

You are cautioned that any changes or modifications not

expressly approved in this manual could void your

authority to operate this equipment.

All interface cables used to connect peripherals must be

shielded in order to comply with the limits for a digital

device pursuant to Subpart B of Part 15 of FCC Rules.

For the customers in Canada

This unit has been certified according to Standard CAN/

CSA-C22.2 No.60601-1.

For the customers in the U.S.A and Canada

Model UP-DF750 is Non-Patient Equipment.

This unit can not be used in the vicinity of patients.

* Patient Vicinity

When you use this product connected to 240 V single

phase, be sure to connect this product to a center tapped

circuit.

Important safeguards/notices for use in the

medical environments

1. All the equipments connected to this unit shall be

certified according to Standard IEC60601-1,

IEC60950-1, IEC60065 or other IEC/ISO Standards

applicable to the equipments.

2. Furthermore all configurations shall comply with the

system standard IEC60601-1-1. Everybody who

connects additional equipment to the signal input part

or signal output part configures a medical system, and

WARNING

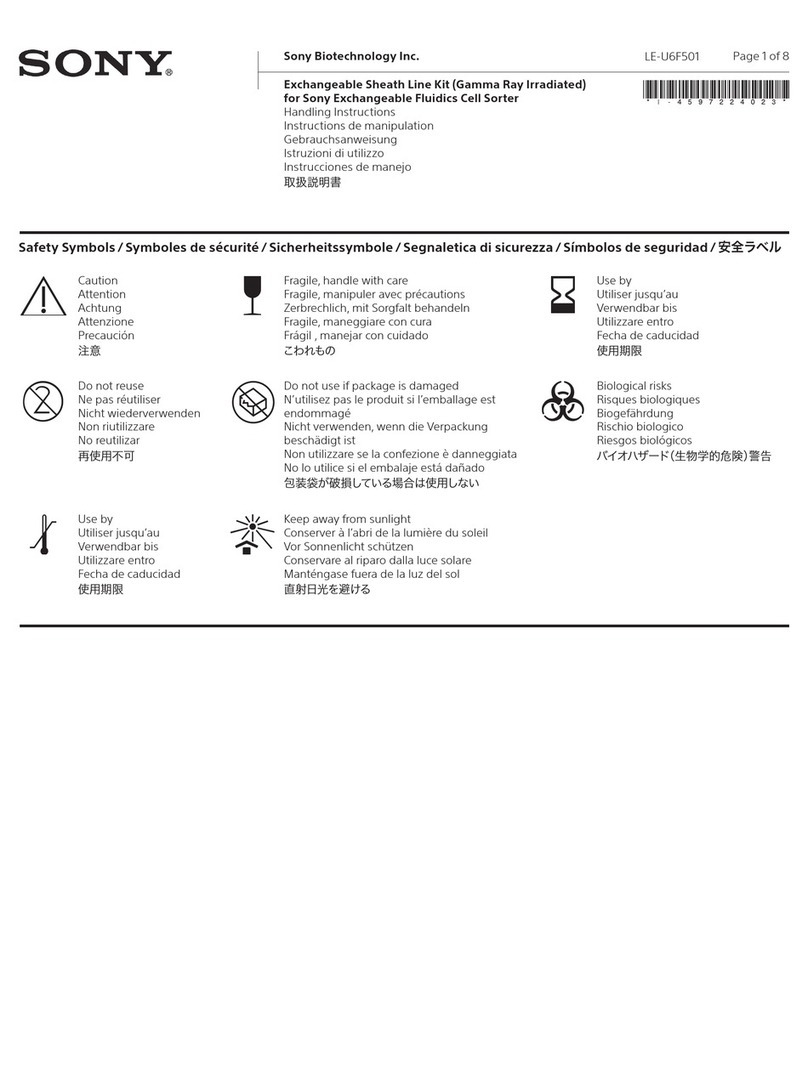

Symbols on the products

This symbol indicates the equipotential

terminal which brings the various parts of a

system to the same potential.

This symbol is intended to alert the user to

the presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

This symbol indicates parts that may be hot.

Take caution when touching parts marked

with this symbol.

This symbol indicates the manufacturer, and

appears next to the manufacturer’s name and

address.

Refer to the operating instructions

Follow the directions in the operating

instructions for parts of the unit on which

this mark appears.

R1.83m

(6 feet)