FISNAR F1300N User manual

F1300N

Rotary Table Operating Manual

Rev A, February 2018

F1300N

ROTARY TABLE

OPERATING MANUAL

F1300N

Operating Manual

Rev A, February 2018

2

THIS PAGE INTENTIONALLY LEFT BLANK

F1300N

Operating Manual

Rev A, February 2018

3

Table of Contents

SECTION 1: Introduction 5

1. Safety Precautions 6

2. Package contents 7

3. Connector and switch location 9

3.1. Front View 9

3.2. Back View 10

SECTION 2: Setup 11

1. Unpacking the Rotary Table 12

2. Removing the Rotary Table 12

3. Setup 13

3.1. Drive Cylinder Setup 15

SECTION 3: Teaching Overview 16

1. Teaching Overview 17

2. Rotary Table Menu Summary 18

2.1. Production Screen 18

2.2. Test Screen 20

2.3. Setup Screen 22

SECTION 4: Programming Example 24

1. Programming examples 25

1.1. Glue Timings 25

1.2. Motor Timings 26

1.3. Cylinder Timings 26

1.4. Example Program 27

2. Optimizing Dispense Cycle 29

2.1. Dispense Pressure 29

2.2. Rotation Speed 29

2.3. Dispense Angle 29

2.4. Tail Angle 29

2.5. Rotation Delay 29

2.6. Dispense Delay 29

3. Changing the Program Number 30

SECTION 5: Error Messages and Specification 32

1. Error Messages 33

1.1. Door Error 33

1.2. Emergency 33

1.3. I/O Alarm 33

2. I/O Specifications 34

2.1. I/O Pin Assignment 34

2.2. I/O System Specification 35

2.3. Ext. Control Pin Assignments 36

3. System Specification 37

4. Machine Dimensions 38

4.1. Work Table Dimensions 39

F1300N

Operating Manual

Rev A, February 2018

4

SECTION 6: Maintenance and Periodic Inspection 40

1. Check Cycles and Methods 41

1.1. General Considerations 41

1.2. Check Cycles and Points 41

1.3. Check Methods 41

2. Mechanical Parts List 44

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

5

SECTION 1:Introduction

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

6

1 Safety Precautions

1.1 In order to meet the requirements of the European Community (CE) safety

directives, the rotary table must be placed in an enclosure supplied by Fisnar Inc.

distributors. The enclosure will prevent the operator from entering the rotary table work

area and will generate an emergency stop signal if the enclosure’s door switch is opened

while the rotary table is running.

1.2 Make sure the rotary table and accessories are connected to a properly grounded power

source.

1.3 Do not drop or spill foreign objects or material such as screws or liquids into the rotary

table.

1.4 Do not touch any moving parts while the rotary table is running.

1.5 Loading and unloading of parts and material must be done when the rotary table is not

running.

1.6 Changing of fixtures or tooling must be done with the power source disconnected.

1.7 The F1300N Rotary Table should only be operated in an environment of 0 to 40 degrees

centigrade and humidity of 20 to 95 percent with no condensation.

1.8 Do not store or install the rotary table in an area where it is exposed to direct sunlight.

1.9 Do not operate the rotary table where electrical noise is present.

1.10 Only use a neutral detergent for cleaning. Do not use alcohol, benzene or thinner.

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

7

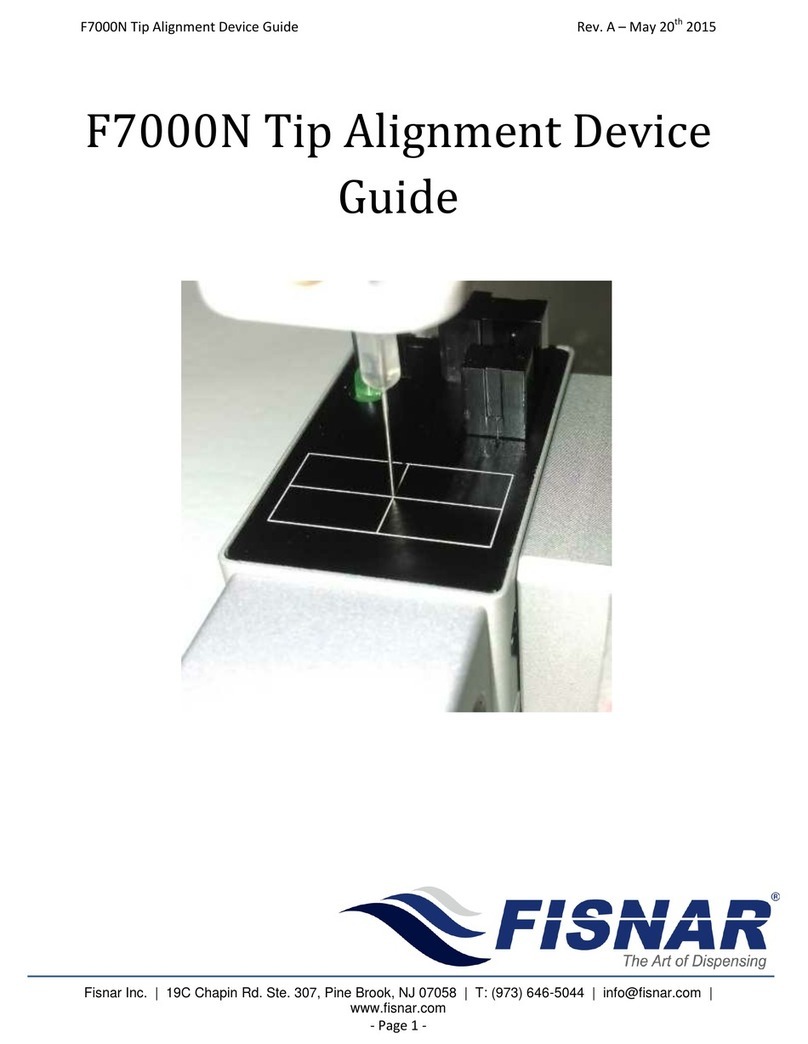

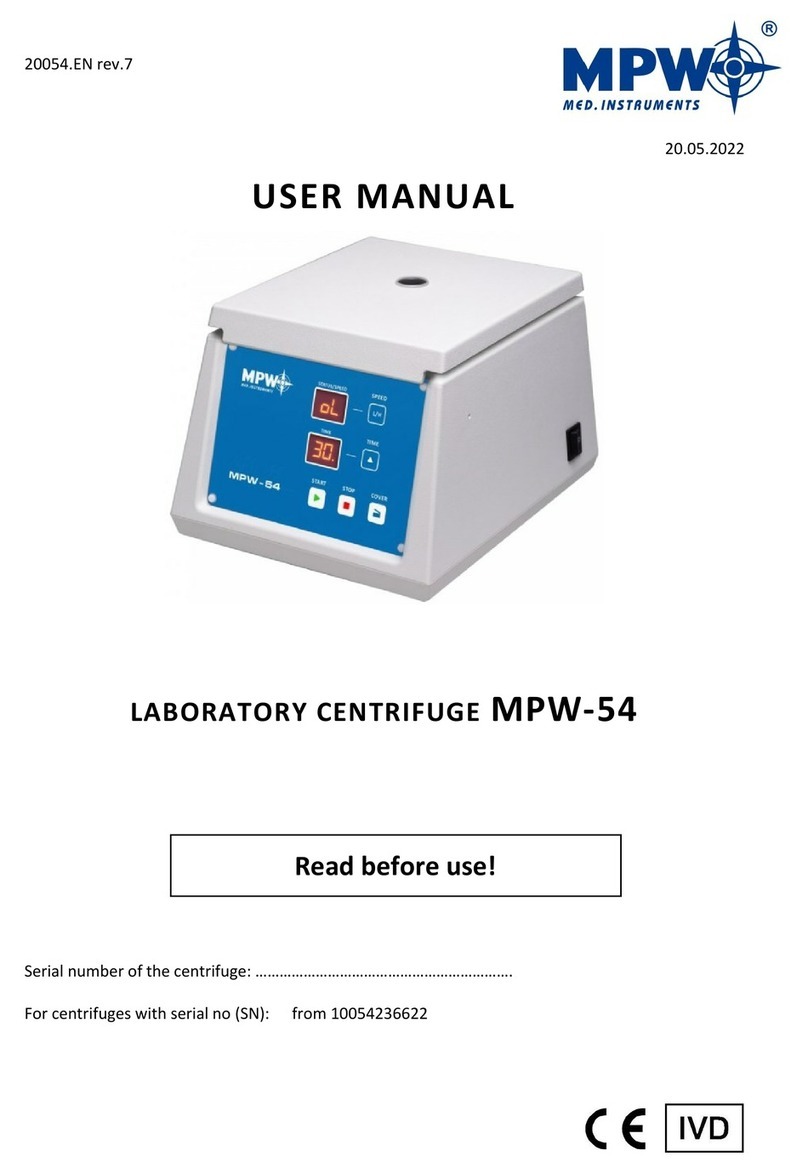

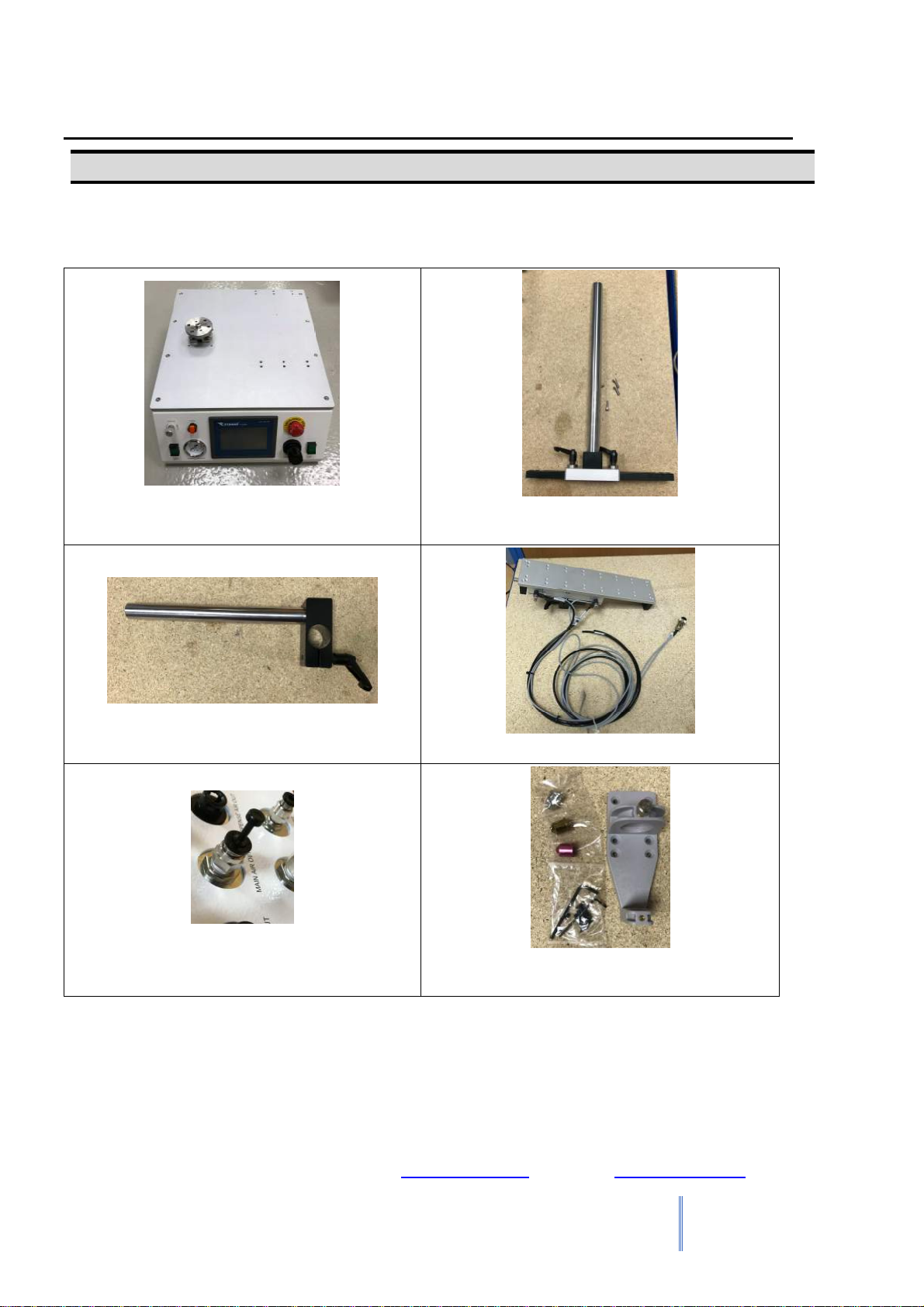

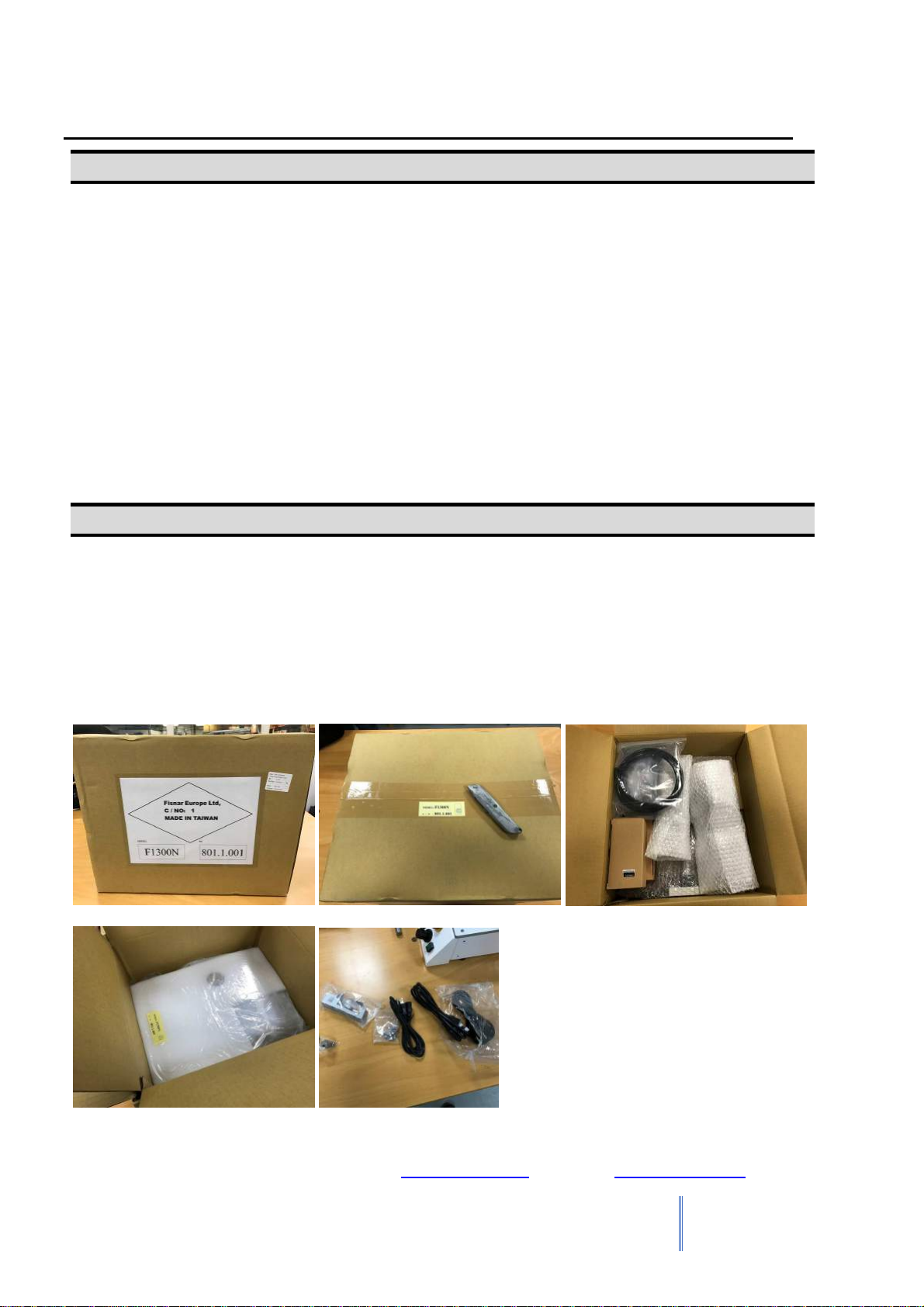

2 Package Contents

In addition to this operating manual, the following items should be included with the rotary

table:

Main Unit Moveable Post Y axis

(mounting screws)

X Axis Post Drive Cylinder Z axis

6mm Mains air out Plug

Barrel Holder

(holder accessories)

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

8

Mains Air Piping 8mm

Power Cables

Shorted Ext. Connector Plug

Open Ext. Connector Plug

Foot Pedal

I/O Port Connector

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

9

3 Connector and Switch Locations

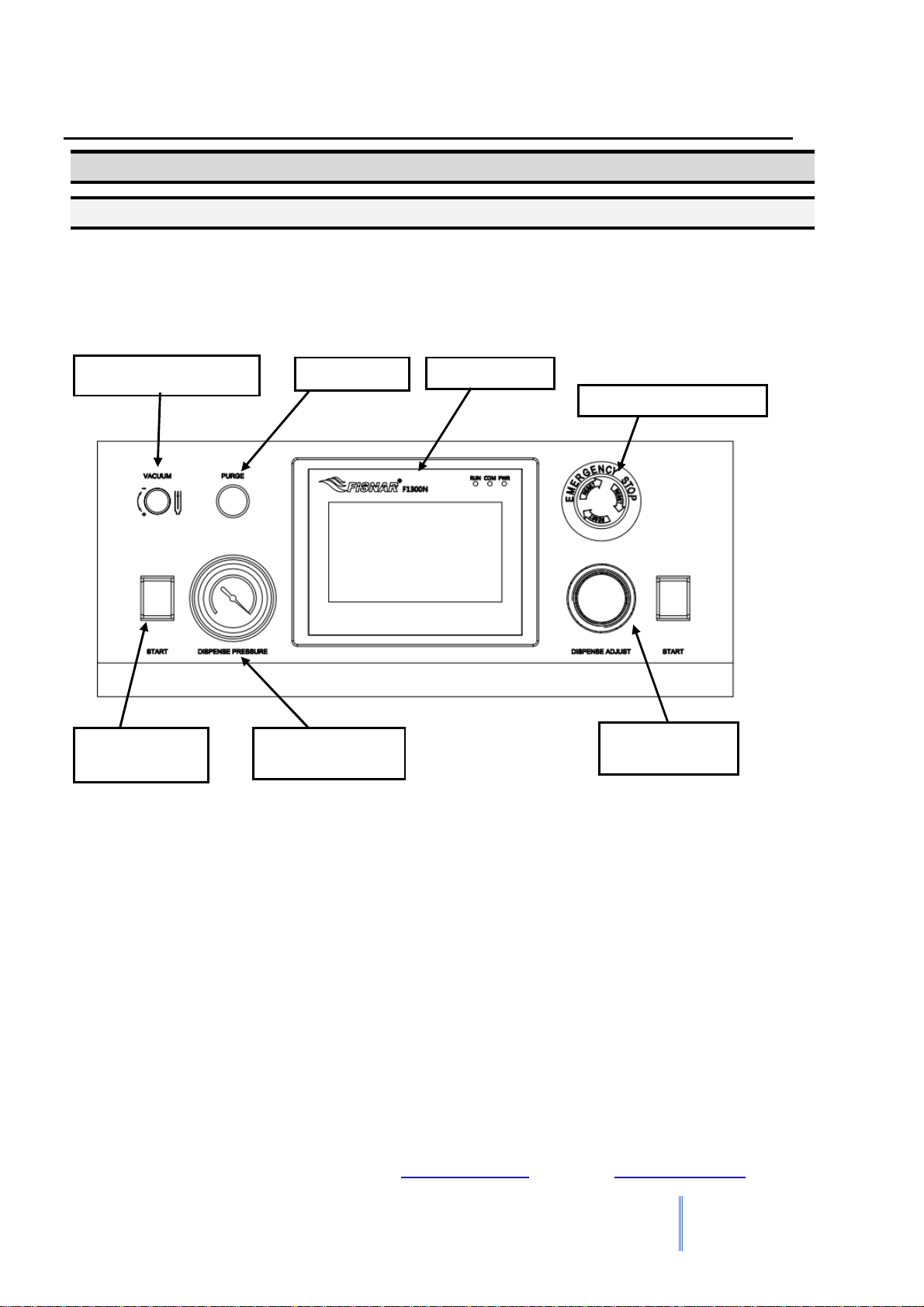

3.1 Front View

Vacuum adjusting knob Purge button

Dispense adjust

knob

Emergency stop button

HMI screen

Dispense pressure

gauge

Start Button

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

10

3.2 Back View

Sensor

connector

Cylinder in

I/O port

Power

switch

Ext. Control

Fuse

RS232 port

Cylinder out

Serial plate

Dispense air out

Exhaust out port

USB port

Mains air in

Foot switch

24Vdc

power inlet

Mains air out

Spray out

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

11

SECTION 2:Setup

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

12

1 Unpacking the Rotary table

•Unpacking the rotary table will require a minimum of two people. Do not attempt to lift the

rotary table without assistance.

•Always lift the rotary table from the base.

•Remove all accessories from the shipping package before attempting to remove the rotary

table.

•Place the rotary table on a stable workbench.

•Do not discard the packing material or the robot’s shipping bracket as these items may be

needed if the rotary table is shipped or moved in the future.

2 Remove

All units are shipped from the factory with Foaming Covers installed. The shipping Foaming

Covers secure the worktable to Y Axis and X/Z head to prevent movement and damage

during shipment.

Remove the shipping Foaming Covers removing the secured tapes.

Keep the Foaming Covers and packages in a safe place for future use.

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

13

3 Setup

The F1300N Rotary tables are available in many different configurations. The configuration of

each machine and the accessories used with each system will depend on the customer’s

application.

The steps required to setup a system using a 30 cc or 55 cc barrel are listed below.

3.1. If the system is being used in the European Community, the rotary table must be

placed in an enclosure supplied by Fisnar Inc. distributors. The enclosure will prevent

the operator from entering the rotary tables work area and will generate an emergency

stop signal if the enclosure’s door switch is opened while the rotary table is running.

Connect the external start / stop box and door switch or light curtain to the Ext. Control

connector on the main unit. For further information, see Error! Reference source not

found. Ext. Control Connector.

If an enclosure is NOT being used, the enclosure door switch can be bypassed by

connecting the plug labeled SHORTED (included in the rotary table accessories

box) to the Ext. Control Connector.

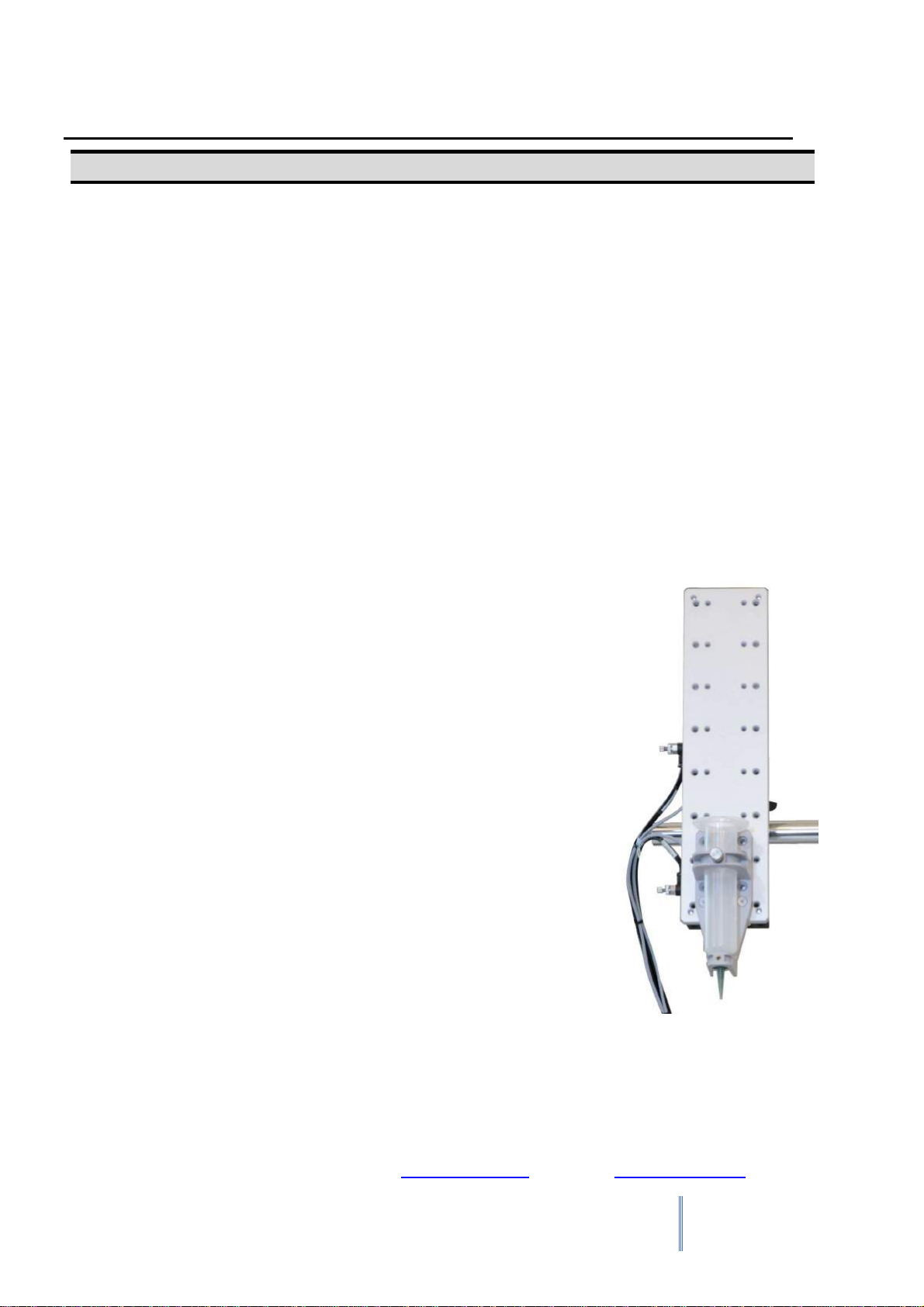

3.2. Standard systems are shipped with a barrel holder, which

must be mounted on the Z head of the rotary table. The

barrel holder will hold a 30 cc or 55 cc barrel on the rotary

tables head. An optional valve / cartridge bracket assembly

may be used as a replacement for the barrel holder if the

application so requires.

3.3. Mount the barrel holder or valve bracket assembly on the Z

axis head as shown, using two screws. The barrel holder

has several sets of mounting holes to allow it to be

mounted at different heights. Choose mounting holes which

give maximum work piece clearance but allow the tip to

reach all areas on the work piece where dispensing is

required.

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

14

3.4. When the Rotary table base is set on a secure work table, take the X axis mounting

post and fix it to the mounting table top, use the M5 x 25 cap head screws supplied

with the post.

3.5. Mount the secondary Y axis post to the X axis post at an appropriate height for the

application. The post’s height is locked in place using the threaded locking handle and

slotted mounting bracket.

3.6. Mount the air cylinder Z axis moving plate onto the Y axis mounting post, the mounting

bracket will slide on the post into position based on the application specified. The air

cylinder’s Y axis position and dispense angle can be locked in place using the

threaded locking handle. The “cylinder in” must be at the bottom of the drive cylinder or

the Z axis will travel in the wrong direction.

3.7. Connect the pneumatic pipes to the matching labelled tube to tube fittings. I.e. pipe

labelled “cylinder out” to back panel 4mm push connector labelled “cylinder out”.

Connect the cylinder in pipe to the cylinder in 4mm push connector. The Z axis drive

cylinder sensors connector to the back panel 4 pin connector labelled “sensor”

3.8. Connect the extras from the accessary box. Pneumatic plug into mains air out. Shorted

ext. connector to link the emergency stop signal. Mains air in, 6mm air fitting. Connect

the power plug to a 230vac mains power plug.

3.9. Check all connections are secure, and none of the pneumatic connections are leaking

air.

3.10. Tie back all cables and air lines so that they will not interfere with the rotary tables

motion when the rotary table is operating. Be sure that the cables and air lines do not

restrict the motion of the rotary tables, Z axis drive cylinder and of the rotary tables

motor and make sure that they cannot become jammed as the rotary table moves in

the work area.

3.11. The mounting posts can but moved and slid into place and aligned with the area of

dispense of the specified part.

3.12. It is recommended to setup the flow control valves that regulate the drive cylinder

before positioning the dispense tip to the application. This can be done when driving the

cylinder in the “test screen”. Set the flow control to drive the cylinder at a controlled speed

that meets application requirements.

Note that this unit ships with a Shorted External Control Connector. This is not

connected when shipped. Unless this is plugged in, the unit will display an EMG

ERROR (Emergency Stop). Please insert the Shorted Connector.

F1300N Rotary Table Operating Manual

Section

2: Setup

Rev A, February 2018

15

3.1 Drive cyclinder Setup

To correctly set up the drive cylinder for application usage:

After plumbing in the mains air supply to the 8mm fitting on the back of the rotary table,

and the 4mm cylinder in and clyinder out pipes into the correct flow relugator fittings.

Use and dummy program to set up the cylinder movement speeds

Fully close both flow regulators before beginning.

Start the Dummy program to actuate the pneumatics and being to move the drive

cylinder.

Slowly open the “Cylinder In” flow regulator to release the air pressure in the drive

cylinder and begin the movement down towards the dispesne location

When the cylionder is moving at a speed appropriate for the application use the locking

nut to set the flow regulator parameter.

After the Cylinder in flow regulator is set, then repeat the above to set the “Cylinder

Out” flow regulator the same way, by opening until the required speed is set and lock it

in place

The flow regulators are pneumatic dampeners, meaning they act as slow air release air

cushions to control the movement speed of the drive cylinder.

Cylinder out flow regulator,

showing locking nut and adjustable

knob for flow rate.

F1300N Rotary Table Operating Manual

Section 3: Teaching Overview

Rev A, February 2018

16

SECTION 3:Teaching Overview

F1300N Rotary Table Operating Manual

Section 3: Teaching Overview

Rev A, February 2018

17

1 Teaching Overview

A program consists of a series of parameters stored in the main unit memory. Each parameter

is stored in a numbered program memory. The programs consist of motor rotation angle,

speed and control delays.

When the program is executed, the rotary table will actuate the Z axis drive cylinder to travel

to dispense position set mechanically during set up. When the cylinder reaches travel

distance the delay timers start and begin the parameter set dispense sequence.

The rotary table applications are for full circular dispensing applications. Being internal

gaskets or external gaskets on a rounded object. Or an application for a rounded dispense

less than a full circle.

F1300N Rotary Table Operating Manual

Section 3: Teaching Overview

Rev A, February 2018

18

2 Rotary Table Menu Summary

2.1 Production Screen

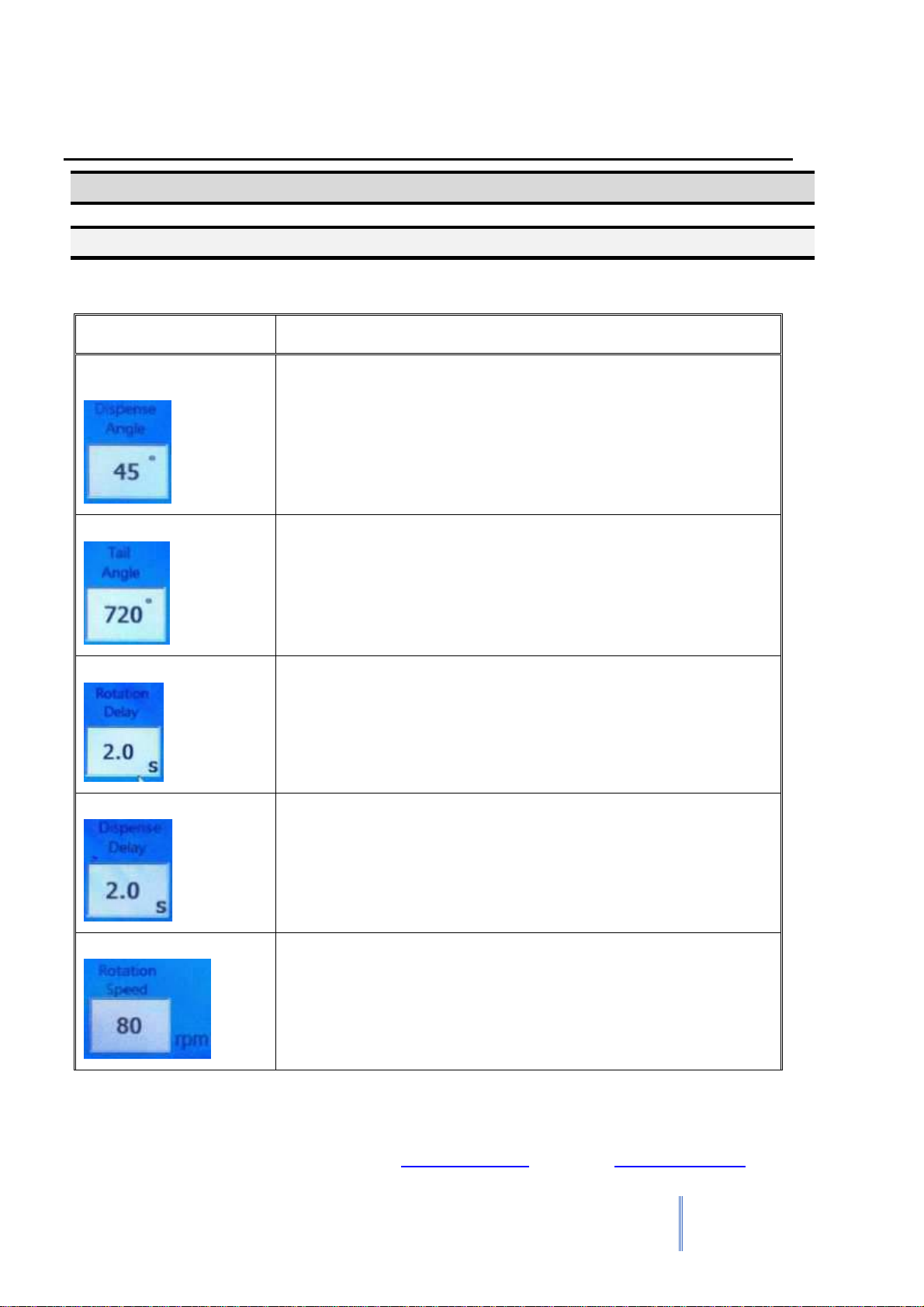

Below is a list of functions, which are found under the Production Screen:

Function

Description

Dispense Angle

Sets the parameter for the angle of rotation of the motor

during the dispense cycle

Tail Angle

Sets the parameter for the angle of rotation for after the

dispense angle is complete (no material is dispensed on this

angle)

Rotation Delay

This is a time in seconds to create a delay before beginning

the dispense angle rotation. This time starts once the drive

cylinder moves into place.

Dispense Delay

This is a time in seconds to create a delay before the start of

material dispense. This time starts once the drive cylinder

moves into place.

Rotation Speed

This is the speed of motor rotation during the dispense cycle.

Measured in RPM.

F1300N Rotary Table Operating Manual

Section 3: Teaching Overview

Rev A, February 2018

19

Function

Description

setup screen

This button opens the settings menu on the HMI touch

screen. This menu is password protected.

Test Screen

This button opens the Test screen on the HMI touch screen.

This menu is password protected.

F1300N Rotary Table Operating Manual

Section 3: Teaching Overview

Rev A, February 2018

20

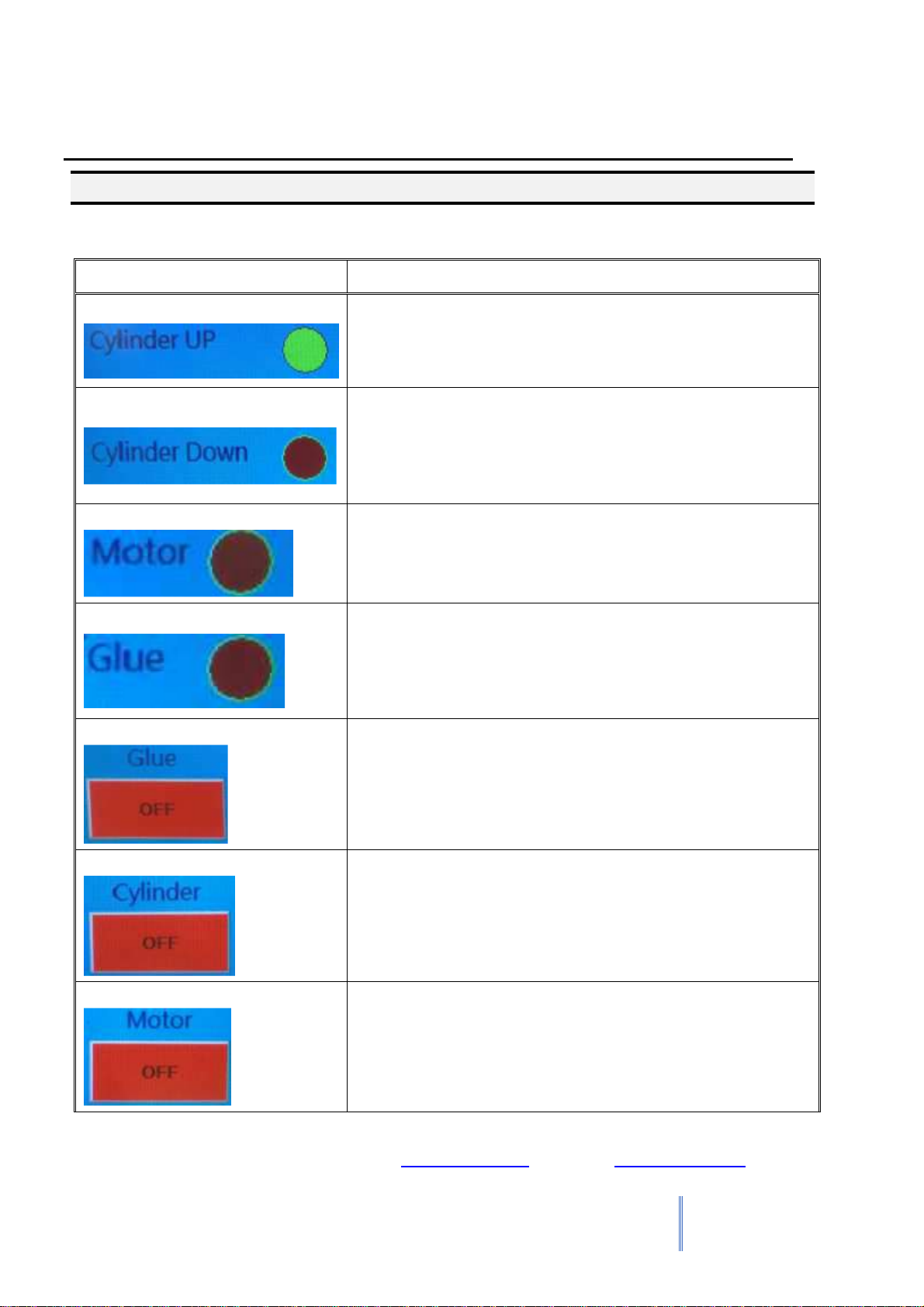

2.2 Test Screen

Below is a list of functions, which are found under the Test Screen:

Function

Description

Cylinder Up

Shows a red or green light to show when this function is

active or in active. When active it shows the drive

cylinder is at the top of its location.And when inactive it

shows the cylinder isn’t at the top of its location.

Cylinder Down

Shows a red or green light to show when this function is

active or in active. When active it shows the drive

cylinder is at the bottom of its location.And when

inactive it shows the cylinder isn’t at the bottom of its

location.

Motor

Shows a red or green light to show when this function is

active or in active. When active it shows the motor is

rotating at the speed set in the production screen. And

when inactive it shows the motor isn’t moving.

Glue

Shows a red or green light to show when this function is

active or in active. When active it shows the dispense

solenoid is active and the rotary table is dispensing fluid.

When inactive the solenoid is close and no fluid is being

dispensed.

Glue On/Off

This button actuates the dispense solenoid in the rotary

table system to test if it is functioning correctly. On,

opens the solenoid to dispense fluid. Off, closes the

solenoid and stops fluid from being dispensed.

Cylinder On/Off

This button actuates the drive cylinder to move from its

top position, to its bottom position. On, drives the

cylinder from its top position to its bottom position. Off,

drives the cylinder from its bottom position to its top

position.

Motor On/Off

This button activates the motor to rotate at the speed set

in the production screen. On, starts the motor rotation.

Off, stops the motor rotation.

Table of contents

Other FISNAR Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Oxford Instruments

Oxford Instruments ANDOR Sona 4.2B-6 Hardware guide

Helmer Scientific

Helmer Scientific TCR Operation and service manual

Grant

Grant GLS Aqua Plus operating manual

Caiman

Caiman NITEHOG TIR-M50 manual

Metrohm

Metrohm 940 Professional IC Vario ONE/LPG manual

ProteinSimple

ProteinSimple Maurice S user guide