FITOP CTS Series User manual

To

Our Customer;

We

appreciate your purchase of our products and look forward to a

lasting relationship.

You

are now the owner of a new

FITOP

Electric Chain Hoist.

We

believe that our hoist products have many advanced features that will

minimize your maintenance requirements and bring you many years of

trouble free service.

We

recommend that you read this manual thoroughly prior to

installation of your new hoist or trolley. This manual has been provided

to assist you in the proper installation and operate of your new host or

trolley and will provide you with important safety and operation tips.

The safe operation of your new hoist is your most important concern.

Proper operation of your hoist will increase its longevity and minimize

your maintenance requirements.

Please study this manual thoroughly before installing your new hoist or

trolley.

CONTENT

CONTENT

CONTENT

CONTENT

1. Attention! Before Installation ...............................

1

2. Caution! Before Operating .................................

2

3. Examination and Maintenance ..............................

5

4.Troubles hooting and m aintenance ...........................

7

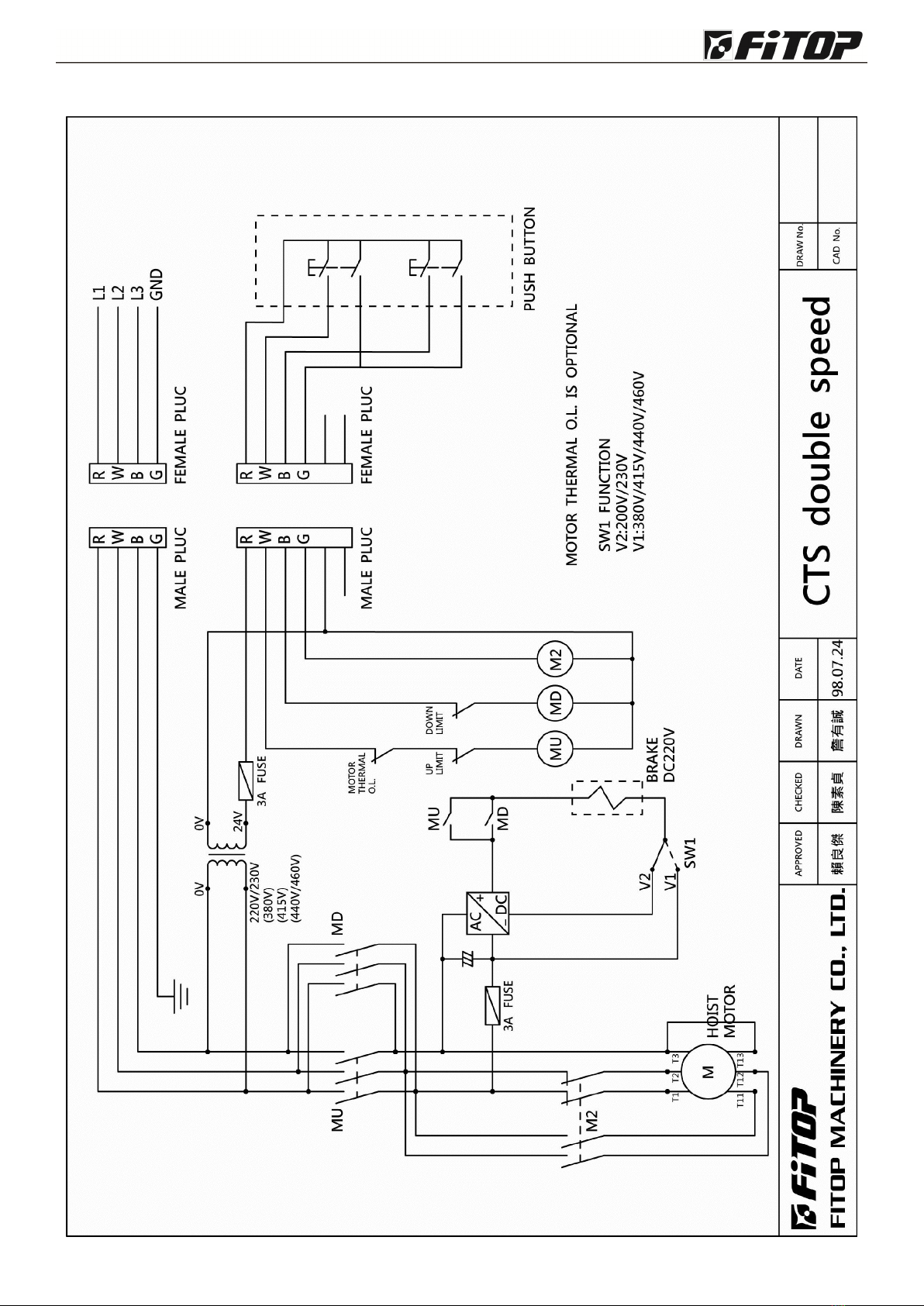

5.Circuit diagram ..........................................

9

- 1 -

1.

1.

1.

1. Attention!

Attention!

Attention!

Attention! Before

Before

Before

Before Installation:

Installation:

Installation:

Installation:

1.1

1.1

1.1

1.1 Check

Check

Check

Check Your

Your

Your

Your Shipment

Shipment

Shipment

Shipment for

for

for

for Damage:

Damage:

Damage:

Damage:

1.1.1 Check to see that the hoist or trolley (unit) h as bee n

delivered in good condition and that there are no v isibl e signs

of damage. Prior to shipment from the manufacturer e v ery

hoist and trolley is subjected to a strict quality control check.

However, unseen damage could occur during handling so it is

recommended that the customer perform the following tests.

1.1.2 Check the plug-in power cable to the hoist and/or trolley

with an Ohmmeter. The minimum resistance should be one

million Ohms as measured to ground.

1.1.3 Please check the plug-in push button and/or trolley motor

cable in the same manner.

1.2

1.2

1.2

1.2 Check

Check

Check

Check the

the

the

the Hoist

Hoist

Hoist

Hoist Load

Load

Load

Load Chain:

Chain:

Chain:

Chain:

1.2.1 Is the load chain twisted or damaged? Check to see that

the chain links that are 90 °to the lifting sprocket have the

We l ds facing ( away) out.

1.2.2 Is the load chain oiled? If not, please oil it.

1.2.3 See Picture 1 for proper chain bag installation.

1.3

1.3

1.3

1.3 Electrical

Electrical

Electrical

Electrical Hookup:

Hookup:

Hookup:

Hookup:

1.3.1 The plug-in power input cable is a four wire (R, S, T&E) “SO ”type cable equipped with a four-

conductor plug for your convenience. Connect the wires marked R, S and T the incoming power

source. If one of the three phases of the power source is connected to ground (Grounded Delta),

the wire marked S should be connect with the phase which is grounded.

1.3.2 The Green or E wire is the unit ground and must be securely connected to a clean-grounded

surface.

1.3.3 When installing a trolley care must be taken to see that the rail is properly grounded and the

contact surface (rail to wheel) is clean to minimize resistance.

1.4

1.4

1.4

1.4 After

After

After

After installation:

installation:

installation:

installation:

1.4.1 Check to see that the unit is phased properly. Depress the Up button, if the hook is lowered stop

immediately; disconnect the power and change phase, i.e., switch the R and T wires.

1.4.2 Test, does the hoist sound quite? If it is growling or sluggish stop immediately and disconnect the

incoming power! Check to see that the voltage is correct for this unit.

1.4.3

Test

the upper and lower limit with the hoist unloaded.

1.4.4 Instruct operators to perform these three testes at the beginning of each shift.

PICTURE 1

- 2 -

PICTURE 5PICTURE 4PICTURE 3

Hook Safety Patch

O

O

O

O X

X

X

X

PICTURE 7PICTURE 6

2.

2.

2.

2. Caution!

Caution!

Caution!

Caution! Before

Before

Before

Before Operating:

Operating:

Operating:

Operating:

2.1

2.1

2.1

2.1 Qualified

Qualified

Qualified

Qualified Operator:

Operator:

Operator:

Operator:

2.1.1 Only qualified personnel should be allowed to operate hoisting equipment.

2.1.2 Read this manual thoroughly (ref. Picture 2)

2.2

2.2

2.2

2.2 Correct

Correct

Correct

Correct Operation:

Operation:

Operation:

Operation:

2.2. 1 Never exceed the rated capacity of the hoist or trolley

2.2.2 It is required that you clearly mark the capacity of the hoist on the monorail or bridge beam

(ref. Picture 3) for the operator ' s reference.

2.2. 3 Use this and all hoisting equipment in a safe and proper manner. Improper or negligent use of this

equipment could result in bodily injury or death to the operator or surrounding personnel

(ref. Picture 4).

2.2.4 Do not remove the safety latch from the top or bottom hooks. The safety latch is designed to

secure the hook to the lifted load. It can prevent the load from slipping off the hook (ref. Picture 5).

Furthermore, local and national safety laws require all hoists to be equipped with safety latches.

2.2.5 Always center the hoist over the load to be lifted. Attempting to lift loads off center can result in

damage to the hoist or injury to the operator.

2.2.6 Before lifting a load examine it to insure that it is rigged properly and that it will not spill or topple

over causing damage or injury (ref. Picture 6).

2.2.7 Make sure the load to be lifted is free of any attachments such as chains, bindings or clamps.

While lifting the load (ref. Picture 7) take care that it does not snag or catch on stationary objects.

PICTURE 2

- 3 -

2.2.8 While operating two hoists in tandem, please note that the center of gravity must be equal.

(Ref.Picture 8). Never use three hoists simultaneously!

2.2.9 Never stand under the lifted load (ref. Picture 9)!

2.2.10 Never lift, support or otherwise transport people or suspend loads over people (ref. Picture 9)!

2.2.11 Caution! Always release the push button under the hoist. Do not release the button from a

distance, it could swing and injure someone (ref. Picture 10).

2.2.12 Frequently inspect all below hook lifting devises such as cable or chain slings for signs of

e xcessive wear, stretching or open hooks, replace any damaged slings immediately.

2.2.13 Do not pull the hoist by the push button cable (ref. Picture 11) instead push the lifted load.

2.2.14 Do not run the hoist into the end stops this could result in damage to the hoist and possible loss

of the load (ref. Picture 12).

2.2.15 While operating the push button, please push the buttons firmly excessive jogging (tapping) of

the push button causes high inrush currents and can result in motor overheating or premature

brake wear.

2.2.16 The Upper and lower limit switches are emergency safety stops and are not to be used as

automatic stop positions. Even though your hoist is equipped with an overload clutch do not

remove the limit switches (ref. Picture 13). If the limit switches do not function properly please

ask the maintenance department to repair or replace them immediately.

PICTURE 10PICTURE 9PICTURE 8

PICTURE 11 PICTURE 12 PICTURE 13

- 4 -

2.2.17 Your

FITOP

FITOP

FITOP

FITOP

hoist is furnished with grade #80 Super Alloy load chain. Corrosion will make the

load chain bind-up when passing over the load sprocket (ref. Picture 14). Keep the load chain

clean, free of rust and well oiled for proper operation and maximum life.

• The weld point of the chain link should be on the inside when it passes over the idler sprocket

(ref. Picture 15-A).

• With 2-fall hoist, care should be taken so as not to flip the hook 360 ° back through it and twist

the load chain (ref. Picture 1 5-B )

• Do not operate the hoist with twisted or damaged load chain.

2.2.18 Never side pull with your hoist, non-vertical lifts can damage your hoist limit switches, chain

guides and/or load chain (ref. Picture 16).

2.2.19

To

extend the service life of machine, please check the hoist periodically.

2.2.20 Please be aware of the position of the electric current switch. Shot down the switch if there ' s any

Emergency.

2.3

2.3

2.3

2.3 Safety

Safety

Safety

Safety Inspection

Inspection

Inspection

Inspection before

before

before

before Operation:

Operation:

Operation:

Operation:

To

To

To

To

insure

insure

insure

insure operator

operator

operator

operator safely

safely

safely

safely and

and

and

and extend

extend

extend

extend the

the

the

the service

service

service

service life

life

life

life of

of

of

of the

the

the

the hoist

hoist

hoist

hoist please

please

please

please perform

perform

perform

perform the

the

the

the

following

following

following

following safety

safety

safety

safety checks

checks

checks

checks listed

listed

listed

listed below.

below.

below.

below.

2.3.1 Check if the push button operates properly, Up is Up Down is down, etc.(ref. Picture 1 7 )

2.3.2 Check for proper operation of both the upper and lower limit switches with an unloaded (empty)

hook . (ref. Picture 1 8 )

2.3.3 Does the hook stop immediately when loaded? If not, check to determine whether the h o ok

drift(brake slip) is not more than 1/2 of 1% of the hoisting distance as traveled in one minute .

(ref. Picture 19)

2.3.4 Others Safety Checks: Listen for unusual noises such as squealing or grinding? Does the lower

hook swivel freely? Doe the hook show signs of overload, is the safety latch working? Is the load

chain twisted or damaged? Is the load chain lubricated? Are there any signs of excessive wear or

damage? Is the push button or cable damaged?

The

The

The

The regular

regular

regular

regular examinations

examinations

examinations

examinations can

can

can

can prevent

prevent

prevent

prevent accidents

accidents

accidents

accidents and

and

and

and prolong

prolong

prolong

prolong the

the

the

the life

life

life

life of

of

of

of your

your

your

your hoist.

hoist.

hoist.

hoist.

Same direction

Wrong direction

PICTURE 16A

PICTURE 17

PICTURE 15

PICTURE 18

B

PICTURE 19

PICTURE 14

Weld Point

Wrong direction

- 5 -

3.

3.

3.

3. Examination

Examination

Examination

Examination and

and

and

and Maintenance:

Maintenance:

Maintenance:

Maintenance:

3.1

3.1

3.1

3.1 Daily

Daily

Daily

Daily examination:

examination:

examination:

examination: Each

Each

Each

Each day

day

day

day perform

perform

perform

perform the

the

the

the following

following

following

following maintenance

maintenance

maintenance

maintenance checks

checks

checks

checks listed

listed

listed

listed below

below

below

below :

:

:

:

3.1.1 Is the up and down operation of the hoist correct?

3.1.2 Listen for any unusual noises?

3.1.3 Do the limit switches and the holding brake work correctly?

3.1.4 Does the hook rotate freely and is the latch working?

3.1.5 Is the load chain twisted or damaged?

3.1.6 Is the load chain clean, free of corrosion and well lubricated?

3.2

3.2

3.2

3.2 Monthly

Monthly

Monthly

Monthly examination:

examination:

examination:

examination:

3.2.1 Examination of load chain:

• Your FITOP electric chain hoist has been furnished with special calibrated grade #80 load chains

t hat a re available through FITOP authorized dealers only.

• The load chain must be replaced if it is stretched or worn beyond allowable, refer to diagram 20

f or proper chain specifications.(ref. Picture 20 )

• Do not use worn, damaged or stretched

load chain or attempt to repair it.

• Use the chain limit gauge (ref. Picture 21)

to test if the chain is within allowable limits,

if it is not it must be replaced immediately!

d .

Diameter

P.

Pitch

a .

Inside width

b .

Outside width

φ5.6 17.0 7.0 18.6

φ

7.1 20.2 8.9 23.2

φ

10.0 30.0 12.5 33.2

φ11.2 34.0 14.0 37.2

PICTURE 20

UNIT: mm Diagram: 20

PICTURE 2 1

- 6 -

3.2.2 Examination of the hoist holding brake is essential to the safe operation of your electric chain

hoist .

T

o check your brake for proper operation follow the instructions listed below (ref. Picture 22).

1Nut, Ny i stop type 4pcs

2

Nut, Ny i stop type 4pcs

3

Brake Coil Assembly

4Spring Closing

5

Feeler gap(Standard: 1~1.5mm)

6

Feeler gauge(1mm thick)

7Lock P l at e 1pcs

8

Nut Nyistop type 1pcs

• The method of adjust feeler gap :

(1)

To

open the brake end cover of hoist.

(2)

To

remove the feeler gauge ⑥f ro m the brake coil assembly ③.

(3) The feeler gauge

⑥

has been provided to measure the distance of feeler gap

⑤

. If the gap is larger

than 1.5mm, you need to adjust your brake.

(4)

To

adjust the nut ②which is on the brake coil assembly ③down to the appropriate seat .

(5) After adjusting, please to lock the nut

①

on the brake coil assembly

③

.

(6) Then put the feeler gauge ⑥into the feeler gap ⑤to adjust the gap around 1mm-1.5mm.

(7) After finish the above procedure, please put the feeler gauge ⑥back to the brake coil assembly ③.

(8) Closing the brake end cover of the hoist.

If there is slide situation after operating, please to adjust as picture 22 (Mark:

To

avoid

adjustment without authorization)

• The method of adjust load limiter :

(1)

To

open the brake end cover of hoist.

(2)

To

stretch the lock plate ⑦.

(3)

To

turn the nut

⑧

clockwise into the anchor stud then turning it counter clockwise so that will

increase the load about 1.25 times.

(4) Bending the lock plate ⑦to fix the nut ⑧.

(5) Closing the brake end cover of the hoist.

PICTURE 22

- 7 -

3.2.3 Examine the push button station (pendant):

• Is the push button case or cover broken or damaged in any way?

• Is the pendant cable cut or damaged?

• Does the pendant operate correctly?

• Any problems with the electrical operation such as intermittent contact?

• Is the plug clean and undamaged?

3.2.4 Examination of limit switches:

• Does the limit paddle move (rock) freely? If not check for damage or corrosion, possibly it needs

to be lubricated.

• Do the upper and lower limits operate correctly?

3.2.5 Examination of hoist hook . (ref. Picture 2 3 )

• Is the hoist hook bent or distorted? If so, it must be replaced. .

• If the hook saddle thickness (H) is reduced by 5 % of the hook thickness (ref Digraph 23) then the

hook must be replaced.

• If the shape of the width of edge changes (L), please change the hook immediately for safety

reason.

3.2.6 Examination of the chain container:

• Does the hoist hook or load chain catch on the container?

• Is the bag ripped or the frame bent or damaged?

• Any other object in the container except the chain?

3.2.7 Examination of the power cord and other electrical cables:

• Are any of the electrical cables pulled out?

• Are the cables damaged or cut?

• Are the plugs in good order and tight?

3.2.8 Examine all screws in insure a good tight connection.

4.

4.

4.

4. Troubles

Troubles

Troubles

Troubles hooting

hooting

hooting

hooting and

and

and

and maintenance:

maintenance:

maintenance:

maintenance:

4.1

4.1

4.1

4.1 Maintenance:

Maintenance:

Maintenance:

Maintenance:

4.1.1 Disconnect the power source and lock the box out prior to performing maintenance.

4.1.2 Do not leave any tools or parts on the trolley, hoist or rail.

PICTURE 23

- 8 -

4.2

4.2

4.2

4.2 Mechanism:

Mechanism:

Mechanism:

Mechanism:

Trouble Possible Cause Troubleshooting

Motor will

Not run.

1. Blown fuse or tripped circuit 1. Check your power source for blown(open)

breaker. fuses. With motorized trolley option check for

tripped circuit breaker in the trolley control box.

2. Motor has overheated. 2. Check the motor brake, is it releasing? Measure

the motor amperage, does it match the motor

name plate data? Note: Overloading or excessive

Jogging will cause high current draw, which in

turn will cause the motor to overheat.

3. Contactor malfunctions. 3. Replace the contactor.

4. Low Voltage. 4. Check the incoming voltage, is it correct?

5. Control circuit is off. 5. Check the control transformer output voltage is

the fuse blown (open)?

Examine for loose connections, broken switches

or damage to the cable or plug.

Motor

makes loud

growling or

buzzing noise

1. Wrong voltage. 1. Confirm that the voltage of your hoist matches

your power supply voltage.

2. Single phase condition. 2. Check your power source for blown (open)

fuses. Check the hoist contactor for loose wires

or burnt (open) contact point.

3. Motor has overheated. 3. Check the motor brake, is it releasing? Measure

the motor current draw, is it correct? Note:

Overloading or excessive jogging will cause high

current draw, which in turn will cause the motor

to overheat.

4. Damaged motor. 4. Check the motor windings, are they grounded?

Hoist

operates in

Only one

direction

1. Hoist Up motion only? The 1. Check the motor brake, is it releasing? Measure

motor O.L. has tripped(opened)

the motor current draw, is it correct? Note:

due to excessive overheating. Overloading or excessive jogging will cause high

current draw, which in tum will overheat the

motor

2.

Limit switch is tripped because

2. Side pulling will cause the limit paddle to trip,

side pulling. always center the hoist over the lifted load.

3. Limit paddle is bent or 3. Repair, lubricate or replace limit paddle.

corroded and sticking

4. Push button switch or cable is 4. Examine for loose connections, broken switches

broken. or damage to the cable or plug.

5. Contact point of magnetic 5. Install new magnetic contactor.

contactor burned (open)

Hoist brake

will not hold.

1. The distance between the 1. Adjust the brake according to the directions, air

brake magnet and armature Gap=1mm minimum to 1.5mm maximum.

Plate (air gap) is too large.

2. The brake is worn out. 2. W hen the lining wear is 50% the thickness of the

brake lining(3.5mm), the brake discs (pads)

must be replaced.

Remarks:

Remarks:

Remarks:

Remarks: Hoist

Hoist

Hoist

Hoist Motor

Motor

Motor

Motor has

has

has

has Class

Class

Class

Class H

H

H

H Insulation,

Insulation,

Insulation,

Insulation, Trolley

Trolley

Trolley

Trolley Motor

Motor

Motor

Motor has

has

has

has Class

Class

Class

Class E

E

E

E Insulation

Insulation

Insulation

Insulation

- 9 -

- 10 -

- 11 -

Table of contents

Popular Winch manuals by other brands

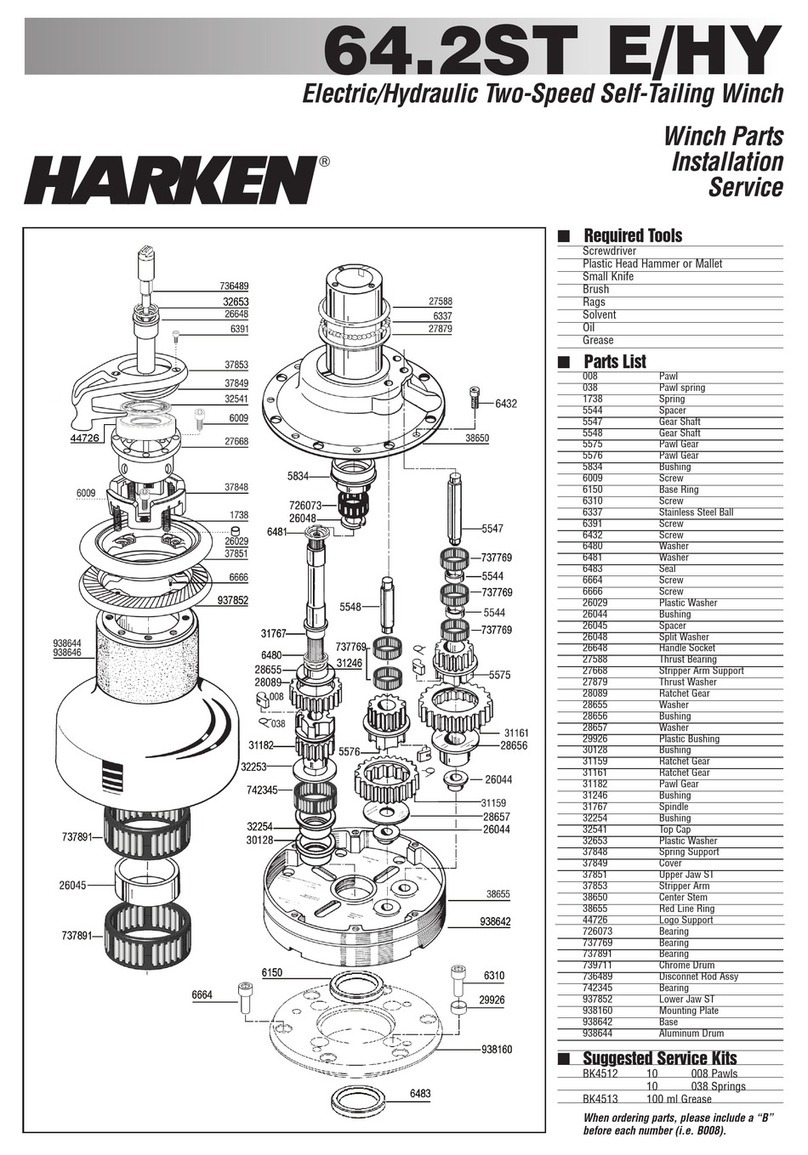

Harken

Harken 50.2 PTBBB Installation and maintenance manual

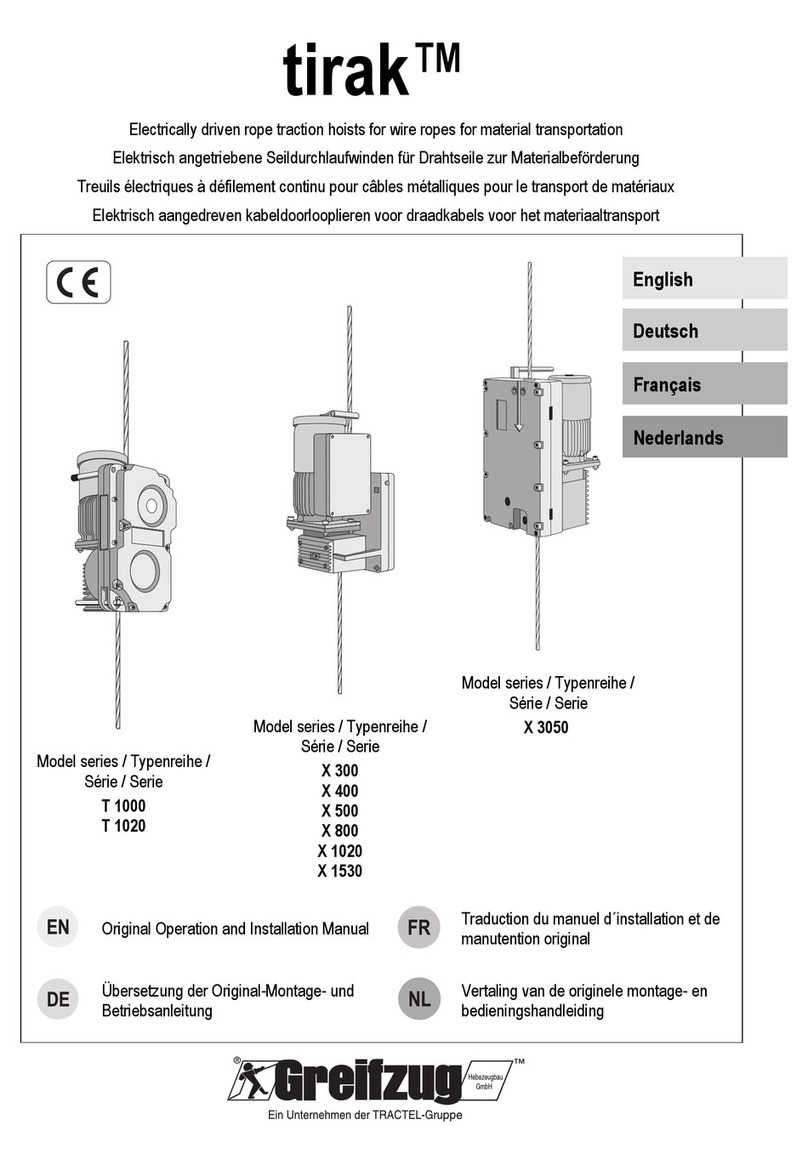

Greifzug

Greifzug Tirak T 1000 series Operation and installation manual

Comeup

Comeup Baby Winch CWS-300 manual

Harken

Harken Performa Winch 60.2 STP Installation and maintenance manual

Ingersoll-Rand

Ingersoll-Rand Force 5i Series Product Maintenance Information

Solid

Solid SW-V4012 user guide