tirak™

G932.1 - 06/2010 EN-DE-FR-NL–III

DE

FR

NL

ENEN

tirakTM

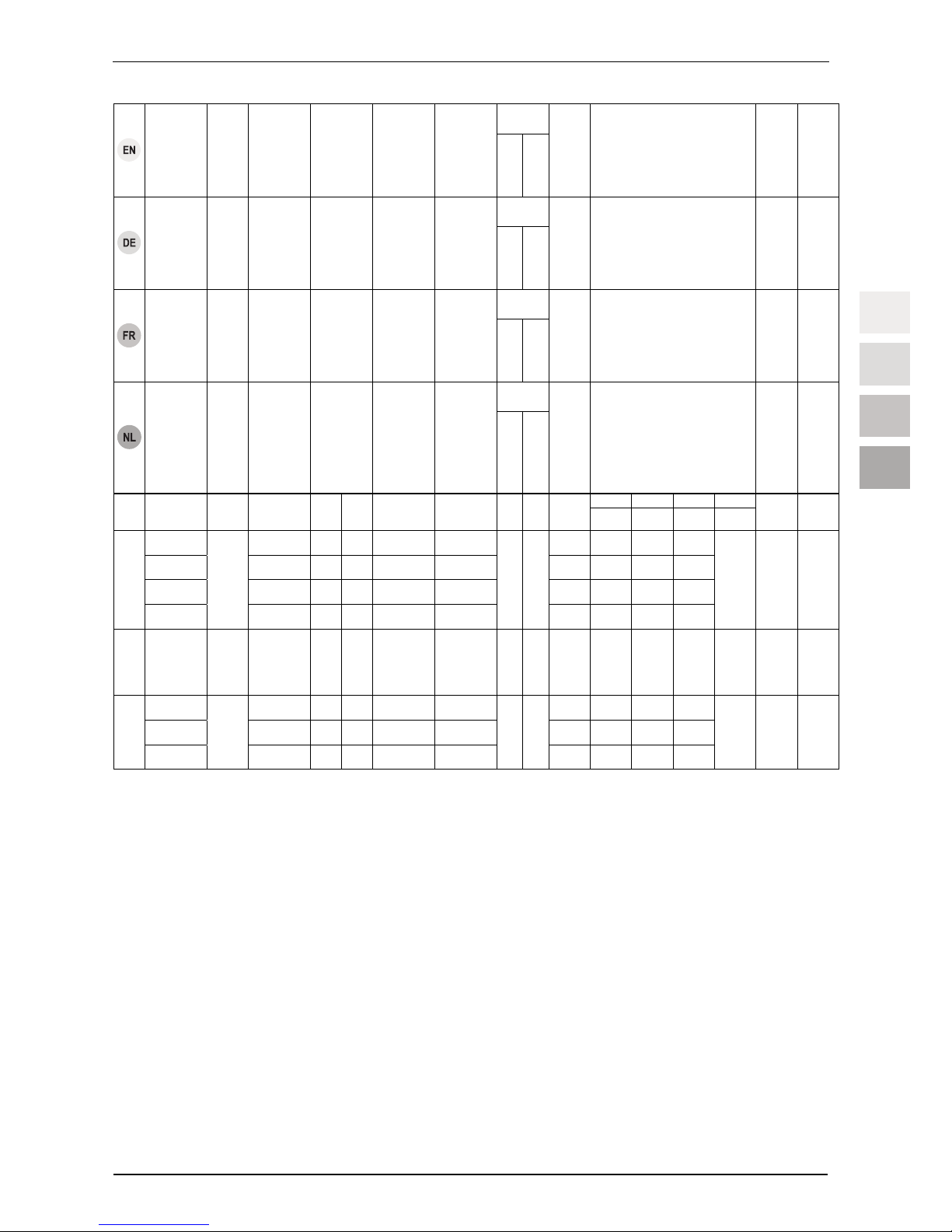

rope

Hoist

Load-carrying

capacity4)

Wire rope speed6)

Connection

Power

Nominal

current

Diameter

Minimum

breaking load5)

Weight

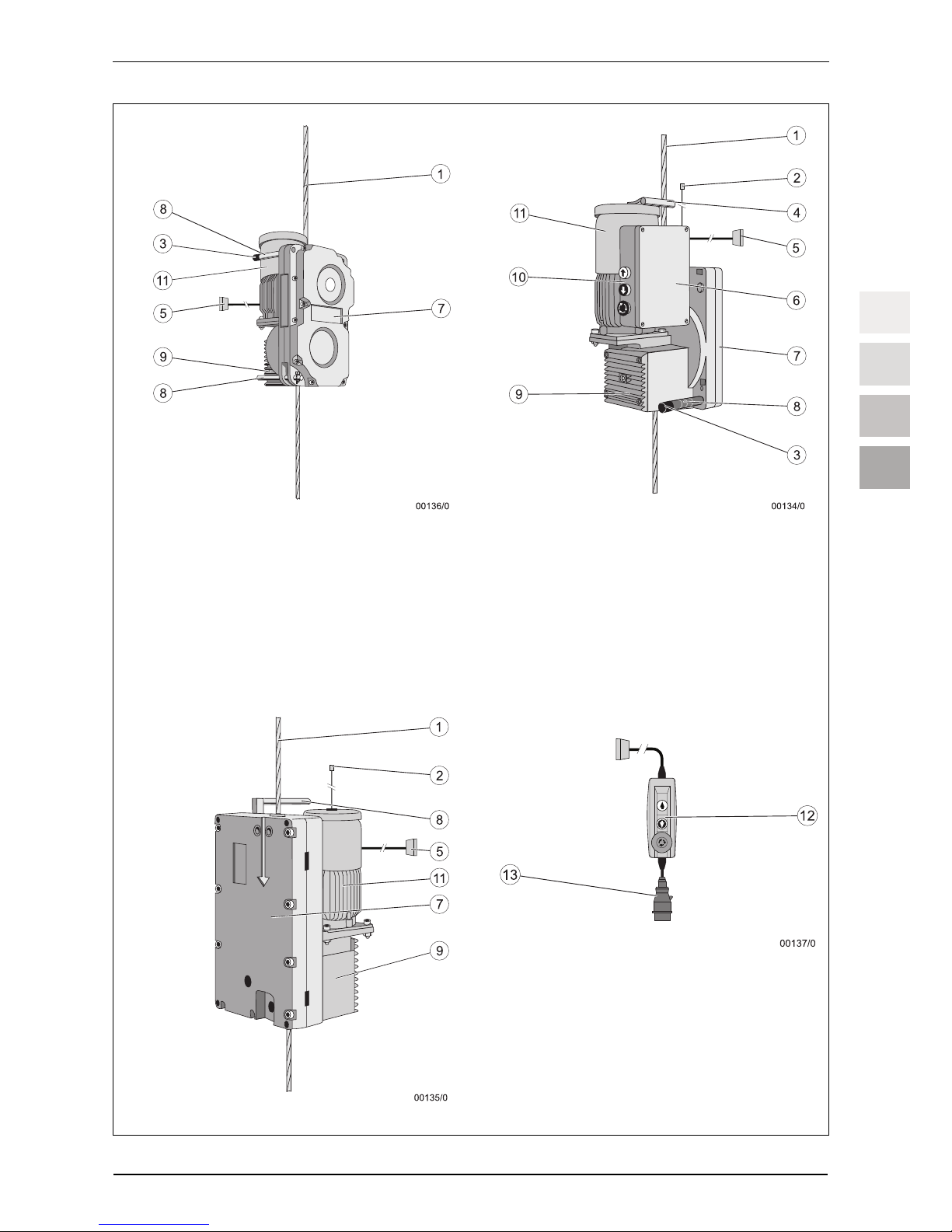

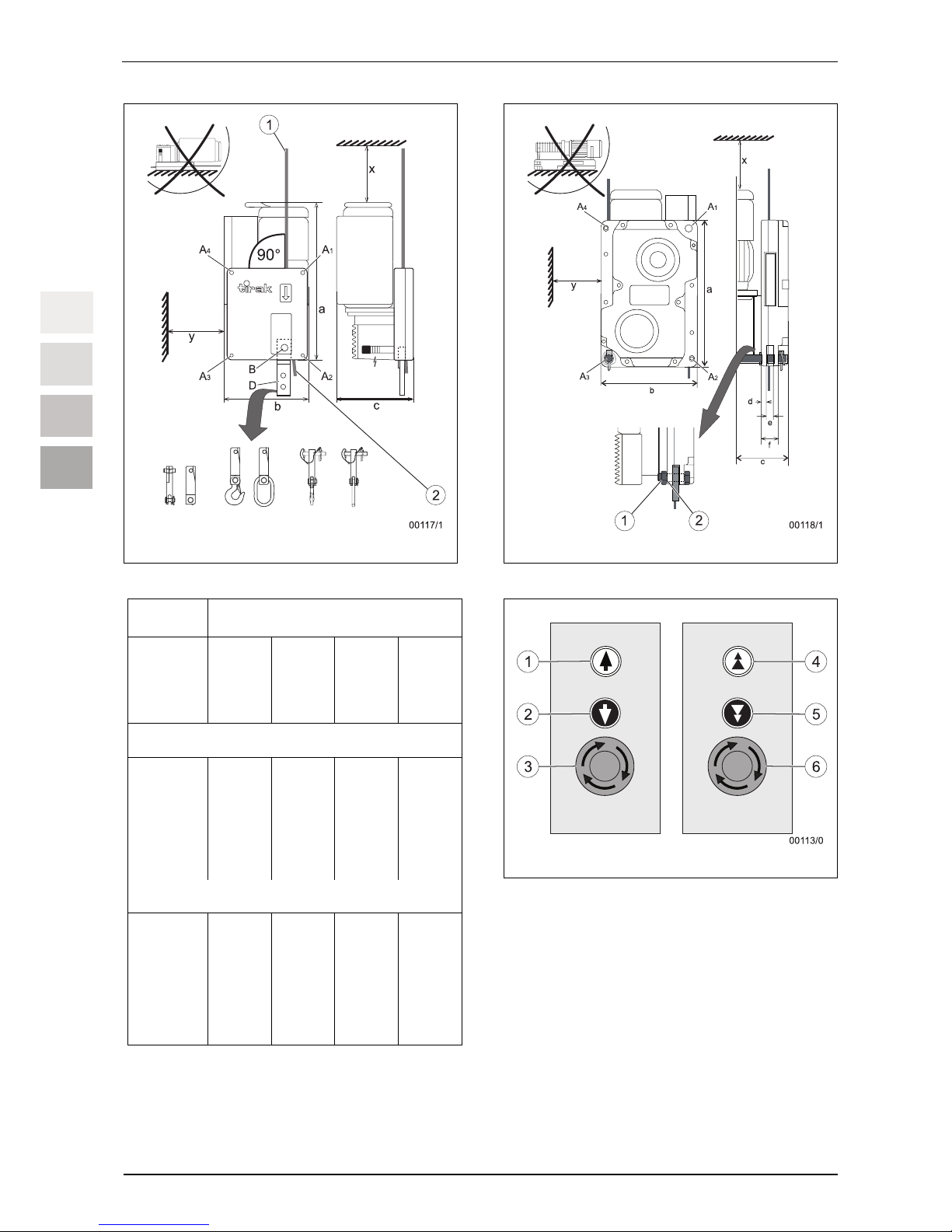

Dimensions / unit size

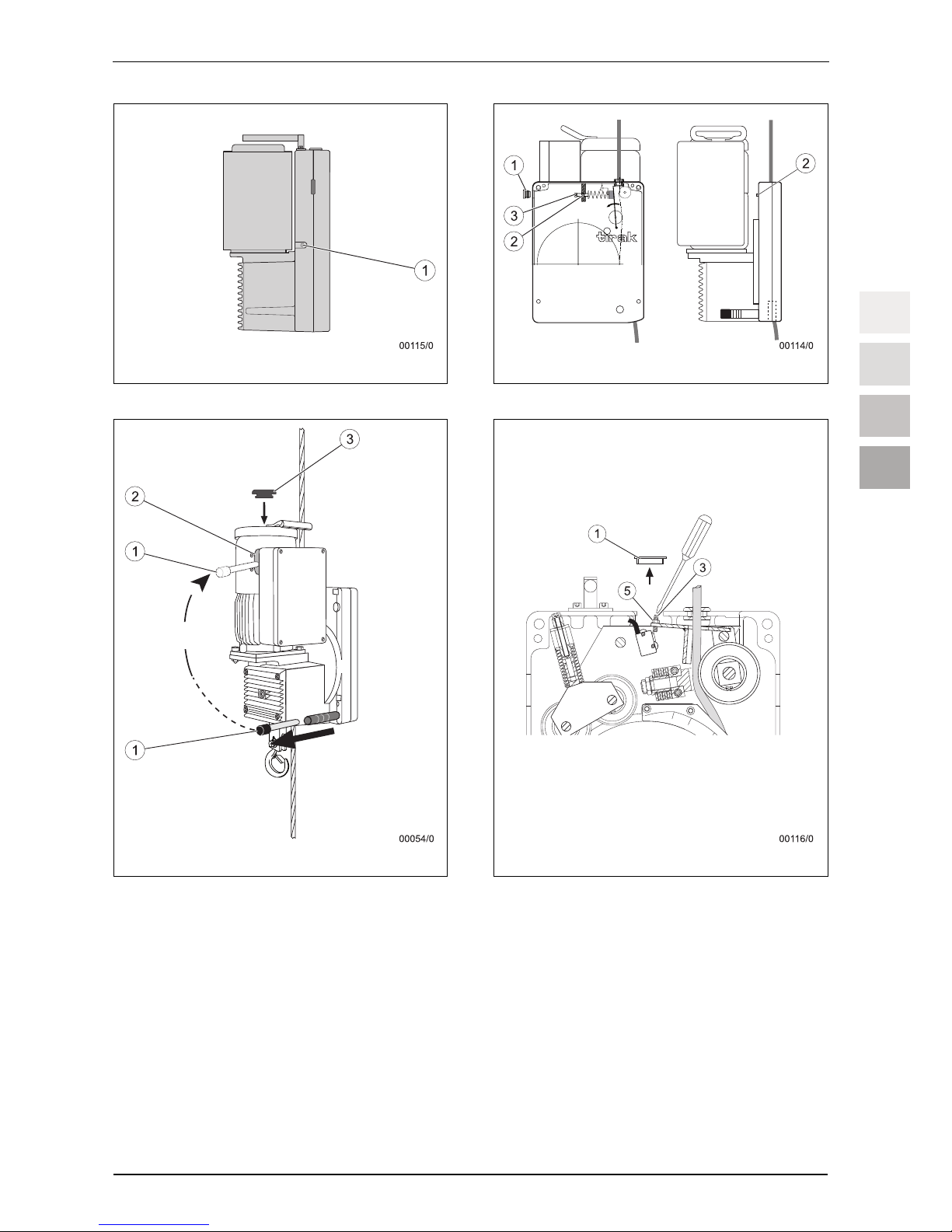

(see Fig. 2 and 3)

Temperature

range3)

Noise2)

tirakTM

Seil

Winde

Tragfähigkeit4)

Seilgeschwind-

igkeit6)

Anschluss

Leistung

Nennstrom

Durchmesser

Mindest-

bruchkraft5)

Gewicht

Abmessungen /

Einbaumaße

(siehe Abb. 2 und 3)

Temperatur-

bereich3)

Geräuschent-

wicklung2)

tirakTM

câble

Treuil

Capacité de

charge4)

Vitesse du câble6)

Branchement

Puissance

Courant

nominal

Diamètre

Effort de rupture

minimal5)

Poids

Dimensions /

Cotes de montage

(cf. Fig. 2 et 3)

Plage de tempé-

rature3)

Emission so-

nore2)

tirakTM

kabel

Lier

Draagvermogen4)

Kabelsnelheid6)

Aansluiting

Vermogen

Nominale stroom

Diameter

Min. breukkracht5)

Gewicht

Afmetingen/inbouwmaten

(zie Afb. 2 en 3)

Temperatuurbereik3)

Geluidsont-

wikkeling2)

Table/Tabelle/Tableau/Tabel 1

4) X-model series from 1000 kg load carrying capacity: with mechanical load limiting device; X-model series from

1000 kg load carrying capacity: mechanical or electric load limiting device can be supplied as an option. T

Model series: electric load limiting device can be supplied as an option.

X-Typenreihe ab 1000 kg Tragfähigkeit: mit mechanischer Hubkraftbegrenzung; X-Typenreihe bis 1000 kg

Tragfähigkeit: mechanische oder elektronische Hubkraftbegrenzung optional lieferbar. T-Typenreihen:

elektronische Hubkraftbegrenzung optional lieferbar.

Série X à partir d'une capacité de charge de 1000 kg : avec limitation mécanique de la force de levage; série X

jusqu'à une capacité de charge de 1000 kg : limitation mécanique ou électronique de la force de levage dispo-

nible en option. Séries T : limitation électronique de la force de levage disponible en option.

X-type serie vanaf 1000 kg draagvermogen: met mechanische hefkrachtbegrenzing; X-type serie tot 1000 kg

draagvermogen: mechanische of elektronische hefkrachtbegrenzing optioneel leverbaar. T-type series:

elektronische hefkrachtbegrenzing optioneel leverbaar.

1) expanded temperature range on request / erweiterter

Temperaturbereich auf Anfrage / extension de la plage de

température sur demande / uitgebreid temperatuurbereik op

aanvraag

2) at a distance of 1m / in 1 m Abstand / à 1m de distance / op 1 m

afstand

3) Depending on the ambient conditions (ambient temperature,

sunrays, etc.) as well as the possible thermal discharge (dirt, ac-

cumulated heat, etc.)

Abhängig von den Umgebungsbedingungen (Umgebungs-

temperatur, Sonneneinstrahlung, etc.) sowie der möglichen Wär-

meabfuhr (Schmutz, Stauwärme, etc.)

En fonction des conditions ambiantes (température ambiante,

rayonnement solaire etc.) et de l'éventuelle évacuation de la cha-

leur (saleté, accumulation de chaleur etc.)

Afhankelijk van de omgevingsvoorwaarden (omgevings-

temperatuur, zonbestraling, etc.) en van de mogelijke

warmteafleiding (vuil, warmteopstopping, etc.)

a b c x/y

kg m/min

230 V

50 Hz

400 V

50 Hz

kW A

mm

kN

kg mm mm mm mm °C dB

(A)

X 1020 9 – x 1,9 4,6 45 525 297 265

X 1023 9/18 – x 1,9/3,8 4,5/8,5 56 563 307 315

X 1025 4,5/9 – x 0,9/1,9 3,5/4,8 55 563 307 285

X 1020

X 1026

980

4,5/18 – x 0,9/3,8 4/9,6

9

48,1

71 605 332 315

∼250 / 250

-15

…

+70

70

X 1530

X 1530 1500 9 – x 2,8 7

10

73,6

49 522 297 285

∼250 / 250

-15

…

+70

70

X 3050 6 – x 3,8 9,9 105 669 400 372

X 3052 12 – x 7,5 17 117 681 403 372

X 3050

X 3053

3000

6/12 – x 3,8/7,5 9,9/19

14

147,2

156 786 428 442

∼250 / 250

-15

…

+70

78,5