ASSEMBLY MANUAL XAIR April, 04, 2006 MANUEL DE MONTAGE XAIRF 2 Juin 2006 Page 2 / 72

IMPORTANT ADVICE

FOR THE ASSEMBLY OF YOUR X-AIR F ULTRALIGHT.

Your

X-AIR F

is delivered in kit form

with many pre-assembled units

.

Hence, assembly in considerably simplified; however, a few elements remain to be assembled with utmost care.

We urge you to read the following

carefully and thoroughly

before you start work on your ultralight. We insist you follow the

assembly schedule of this manual, which is based on our own, considerable experience and makes best use of it.

Please return your warranty sheet to us promptly, bearing the stamp of your dealer, and send us the address of any subse uent

buyer so that we may keep him posted on the latest, often vital information about the

X-AIR F

.

Make a c mplete invent ry f the kit, checking f r any missing part

.

When in doubt during assembly, before any damage is done, call:

-your favorite dealer who will be happy to help

-our company at the following numbers:

phone: +33 (0)2 40 64 2 66

fax.: +33 (0)2 40 64 5 22

email: xair-info@randkar.fr

Web site: http://www.randkar.fr

you can too join the e-group dedicated to X-AIR on the internet:

http://www.egroups.com/group/X-Air_Ultralight_Aircraft

We welcome any criticism or suggestions sent by mail: they help us improve the uality of our product and service. Thank you

for writing.

We wish you a pleasant, easy assembly,

and many enjoyable flights

A few ti s from a friend:

Apart from the nuts securing the rubber silent blocks, Loctite thread Locker or e uivalent should be applied on all

screws and nuts before tightening. This kind of nut with nylon ring must be used only once and have to be replaced if

taken out.

Tor ueing norms for the airframe are:

-6mm screws 1kgm

-8mm screws 2,5kgm

E cept screws going through tubes, in this cases, just torque to apply surfaces in contact and take care to

never put the tubes out of shape.

For the engine, refer to the manufacturer’s manual.

References to the parts are of two kinds:

with three digits, they refer to a pre-assembled unit ex:

2

main axle

with six digits, they refer to a sub-unit ex:

2 . 86

mounting strap for gear leg

Screws, pins and axles fitted vertically are installed with their heads up

those fitted horizontally, parallel to the keel axis are installed from front to back (head forward).

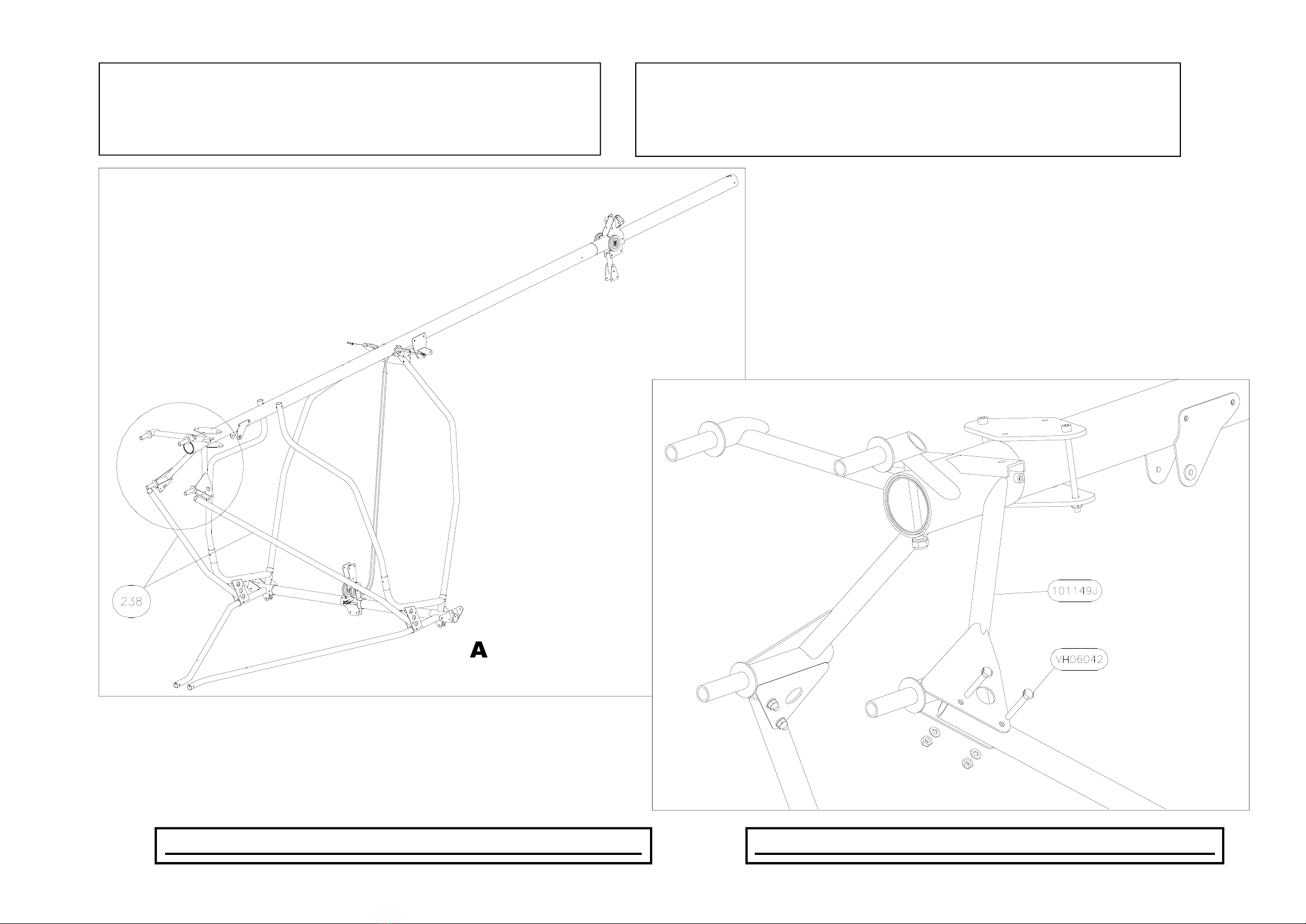

refer to the drawing sheets to visualize the stages of assembly.

Paragraph A 11 Plan A11

Paragraph C 3 Plan C3

Tools needed:

Open-, ring- or socket-wrenches: 7 / 10 / 13 / 14 / 17 / 19

Allen wrenches: 3 / 4 / 5 / 6 / 8

Nylon-tipped hammer

Pop rivet tool

Drill with 4/5/6mm bits

Tor ue wrench (advisable, but not strictly necessary)

Products needed

Blue Loctite

Silastic silicone or e uivalent

Silicone grease