FKI SDF-22 User manual

0

Instructions for use

Fryer STD

Type Code SDF-22

Version 1.0 –2022

1

Contents

1 Introduction............................................................................................................................................... 3

General .............................................................................................................................................. 4

Appliance description................................................................................................................ 4

Manufacturer............................................................................................................................. 4

Appliance label .......................................................................................................................... 4

Technical specifications and power consumption..................................................................... 4

Modification .............................................................................................................................. 5

2 Safety......................................................................................................................................................... 6

Personal safety equipment................................................................................................................ 6

Potential hazards............................................................................................................................... 6

Safety measures, integrated.............................................................................................................. 7

Safety functions................................................................................................................................. 7

Who may use the appliance .............................................................................................................. 7

Transport/installation/fixation.......................................................................................................... 8

Transport ................................................................................................................................... 8

Installation................................................................................................................................. 9

Fixation .................................................................................................................................... 10

Operation......................................................................................................................................... 10

Cleaning/maintenance .................................................................................................................... 10

Servicing........................................................................................................................................... 10

3 Operation................................................................................................................................................. 11

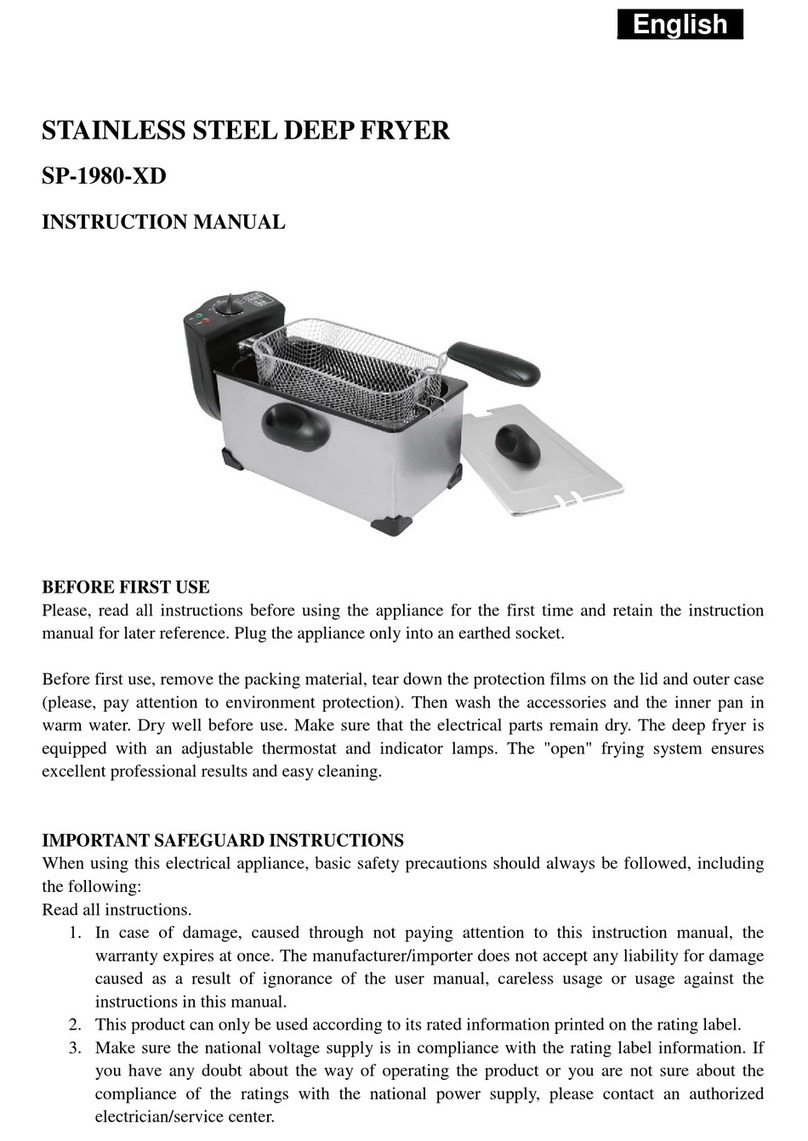

Before first use ................................................................................................................................ 11

Filling with oil................................................................................................................................... 11

Quick start instructions ................................................................................................................... 11

Start-up............................................................................................................................................ 12

Operation......................................................................................................................................... 12

Spare parts....................................................................................................................................... 13

Spare parts list......................................................................................................................... 14

Error codes....................................................................................................................................... 16

4 Electrical diagram .................................................................................................................................... 17

5 Cleaning ................................................................................................................................................... 29

General ............................................................................................................................................ 29

Cleaning during operation............................................................................................................... 29

Daily cleaning................................................................................................................................... 29

2

6 Service ..................................................................................................................................................... 32

7 Disposal.................................................................................................................................................... 34

Packaging......................................................................................................................................... 34

When the appliance is no longer required...................................................................................... 34

8 EU DECLARATION OF CONFORMITY........................................................................................................ 35

3

1Introduction

Original user instructions

These instructions are FKI Fast Food Teknik's original instructions for appliance Fryer STD.

The purpose of these instructions

These instructions are intended to ensure the correct installation, use, handling and maintenance of Fryer

STD.

Important! Read these instructions carefully before use and keep them safe for later use.

Storage of these instructions

You must retain these instructions and make sure that they are easily accessible to users and service techni-

cians.

Understanding these instructions

It is the responsibility of the Appliance's owner to ensure that anyone who will be operating, servicing,

maintaining or repairing FRYER STD has read these instructions and, by way of minimum, the sections that

are of relevance to the work they will perform.

Anyone who will be operating, servicing, maintaining or repairing FRYER STD is required to look up any rele-

vant information in these instructions.

4

General

Appliance description

Fryer STD is an electronic fryer with electronic thermostat. The fryer is easy to maintain and operate. Fryer

STD has deep oil vats to minimize splashes. The powerful heating elements and electronic temperature sen-

sor heat the frying oil very quickly. Fryer STD is easy to clean. The temperature of the frying oil is shown on

a display and can be set in 5°C intervals from 100°C to 180°C.

Manufacturer

FKI Fast Food Teknik a/s

Byghøjvej 5, Verninge

DK-5690 Tommerup

www.fki.dk

Appliance label

Type code: ADF-21

Technical specifications and power consumption

1.1.4.1 Dimensions and weight

Description

Vat

Dimensions

(BxDxH)

Weight

Fryer STD

SINGLE TABLE

16L

352x655x370

32 kg

Fryer STD

SINGLE TABLE SPL

20L

470x655x370

41 kg

Fryer STD

DOUBLE TABLE

2 x 16L

705x655x370

60 kg

Fryer STD

SINGLE FLOOR

16L

352x655x880

44 kg

Fryer STD

SINGLE FLOOR SPL

20L

470x655x880

57 kg

Fryer STD

DOUBLE FLOOR

2 x 16L

705x655x880

99 kg

5

1.1.4.2 Power

Description

Vat

Voltage

Power

Current

MIN. fuse rating

for installation

Fryer STD

SINGLE FLOOR

16L

400V

9kW

13.0A

16A

Fryer STD

SINGLE FLOOR

16L

3x230V

9kW

22.6A

25A

Fryer STD

SINGLE FLOOR

16L

400V

15kW

21.6A

25A

Fryer STD

SINGLE FLOOR

16L

3x230V

15kW

37.6A

40A

Fryer STD

SINGLE FLOOR

16L

400V

21kW

30.3A

32A

Fryer STD

SINGLE FLOOR SPL

20L

400V

10kW

21.6A

25A

Fryer STD

SINGLE FLOOR SPL

20L

3x230V

10kW

37.6A

40A

Fryer STD

SINGLE FLOOR SPL

20L

400V

14kW

30.3A

32A

Fryer STD

DOUBLE FLOOR

2x16L

400V

2x9kW

13.0A

2x16A

Fryer STD

DOUBLE FLOOR

2x16L

3x230V

2x9kW

22.6A

2x25A

Fryer STD

DOUBLE FLOOR

2x16L

400V

2x15kW

21.6A

2x25A

Fryer STD

DOUBLE FLOOR

2x16L

3x230V

2x15kW

37.6A

2x40A

Fryer STD

DOUBLE FLOOR

2x16L

400V

2x21kW

30.3

2x32A

*Actual measured result can be expected to be lower.

The appliance should be connected to its own circuit.

1.1.4.3 Intended use

The fryer is intended for deep frying in oil/fat of defrosted and frozen

products that are suitable for deep frying.

The fryer must never be used for purposes other than deep frying food.

Modification

Fryer STD must never be modified or serviced by unauthorised persons. In the event of non-compliance, FKI

Fast Food Teknik a/s waivers any and all liability.

6

2Safety

General

Read these safety instructions before using the appliance. Keep them near to the appliance for later refer-

ence. These instructions and the appliance itself are provided with important safety information that must

always be read and observed at all times. FKI Fast Food Teknik a/s disclaims any and all liability for non-

compliance with these safety instructions, for inappropriate use of the appliance or the use of incorrect set-

tings.

Fryer STD is designed for continual deep frying of various food products. The appliance can also be used for

other foods that are suitable for frying. To determine optimum temperature and time, a test fry is always

recommended before commencing series production. Note that the nature of the food (thickness, temper-

ature, surface, etc.) will affect the frying result.

When running, the appliance must be continually monitored by staff who have been trained and instructed

in how to use it.

Personal safety equipment

It is recommended that gloves and goggles are worn when working with the fryer and

when emptying the vats as the fryer has hot surfaces and hot grease can be dangerous.

Potential hazards

Surfaces on the fryer’s tabletop and vats are hot and must not be touched when switched on.

Therefore, be careful not to touch them while operating the fryer.

During operation, only buttons on the front may be touched. The food for preparation should be placed in

the basket when it is in the basket retainer. The basket should then be carefully lowered into the oil.

Avoid touching the fryer’s hot surfaces.

7

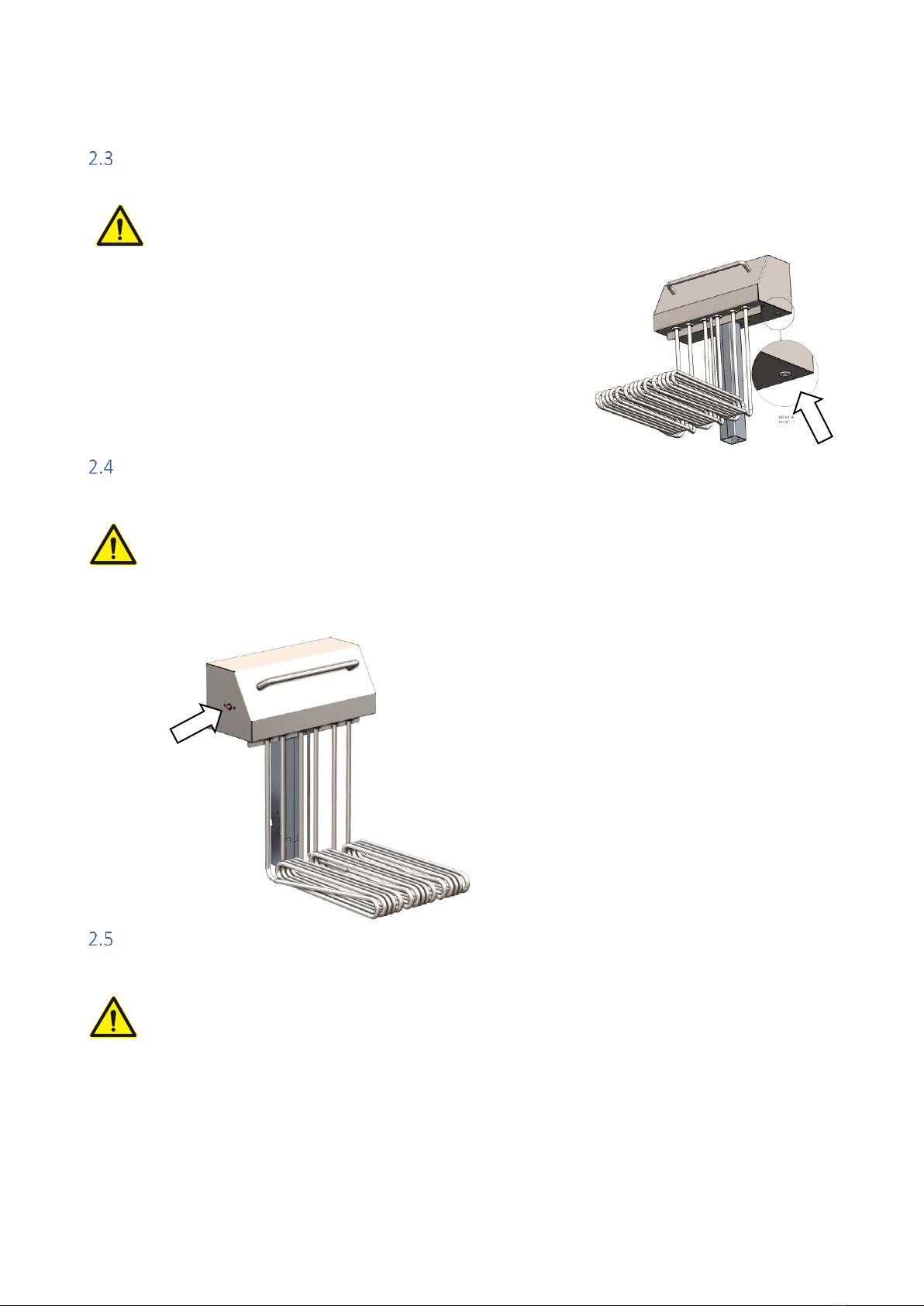

Safety measures, integrated

The heating section has an integrated magnetic contact to cut power to the heating ele-

ments if the heating section is removed from the top panel. There is also a magnetic contact

that cuts off the current at the taps.

Safety functions

The heating section has an integrated safety thermostat that will cut power to the heating

elements if temperatures exceed 230°C. The thermostat can be reset and connected once

the temperature has fallen. To reset the thermostat, press the red button next to the heating

section under the protective cap.

We recommend that the fryer is serviced to find out why the safety thermostat was trig-

gered.

Who may use the appliance

This appliance is not intended for use by children! Neither should it be used by persons with

reduced physical or mental capacity, or who lack appropriate experience and knowledge un-

less they have been trained or instructed in the use of the appliance by someone with re-

sponsibility for their safety.

8

Transport/installation/fixation

Transport

The fryer is delivered secured to a transport pallet and should only be transported in the same way if

moved.

When lifting the appliance into position, lift carefully from the transport pallet by lifting at the front edge of

the table top, allowing it to be carefully rolled into position.

WARNING: Do not lift the appliance at the heating sections.

Moving and setting up the appliance must be performed by two or more peo-

ple due to RISK of injury!

Wear protective gloves and safety footwear during unpacking and installation.

Cut hazard.

9

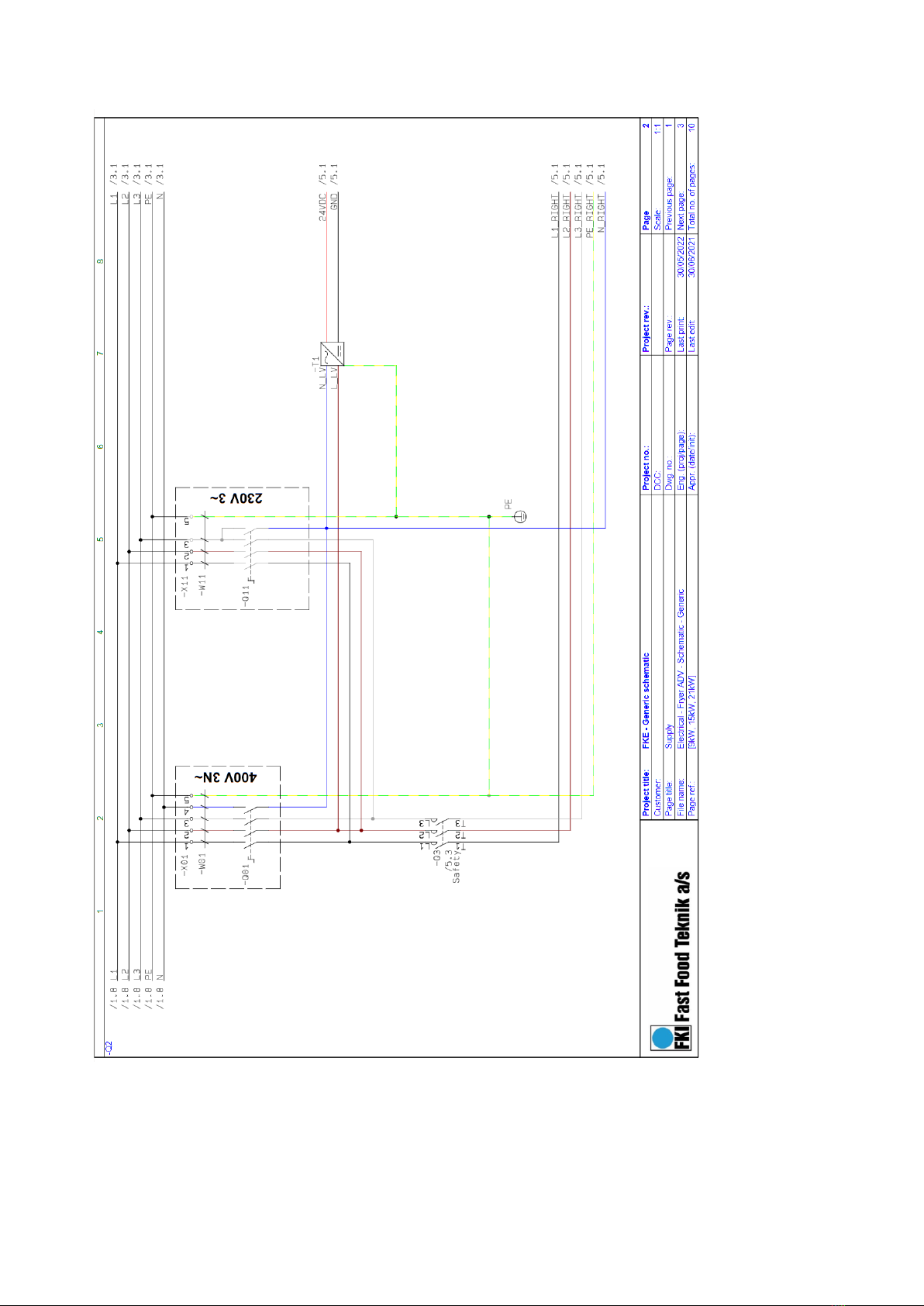

Installation

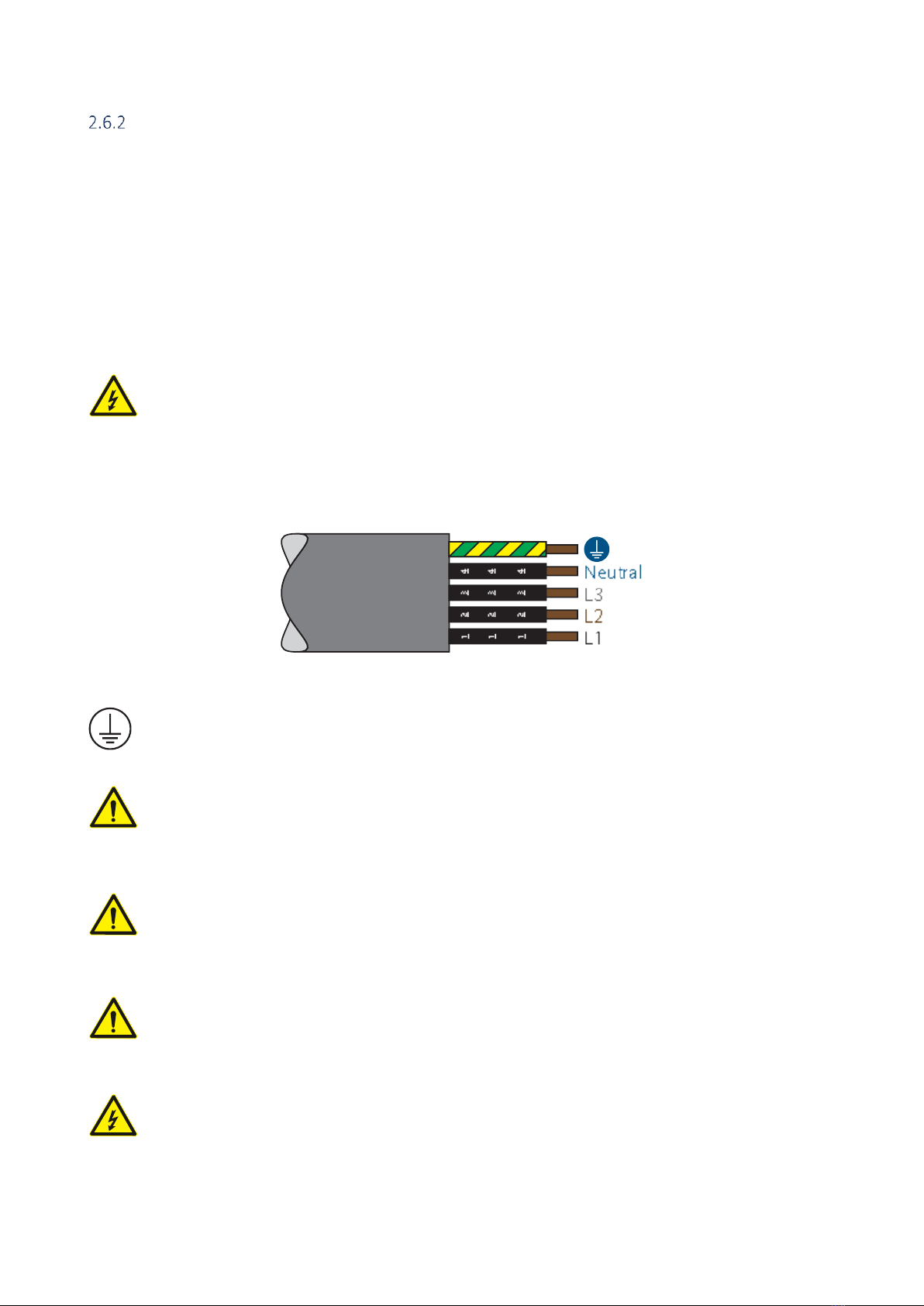

The appliance must be connected to the mains by an authorised electrician.

The fryer must always be connected to ground. Depending on variant, the fryer should be connected to ei-

ther 400V 3N~ or 230V 3~ via an approved supply isolator. Note that each heat section requires a separate

connection.

As standard, floor models are supplied with front legs and fixed wheels at the rear. Space should be left in

front of the fryer so it can be pulled away from the wall when cleaning or performing maintenance tasks.

The fryer must be connected by an authorised electrician and connected to an RCCB circuit

breaker.

See diagram for correct connection:

WARNING: This appliance must be earthed. Failure to do so may cause electric shock and serious

injury.

The appliance must be acclimatised before use. It should therefore not be started up until eight

hours have elapsed.

The power supply must be able to be disconnected, either by unplugging or by means of a freely

accessible multi-pole switch located before the power outlet in accordance with applicable elec-

tricity regulations. The appliance must be grounded in accordance with national safety standards

for electrical appliances.

Do not use extension cords or multi-socket outlets. After installation is completed there must be

no direct access to the electrical components. Never touch the appliance if you are wet or have

bare feet. Do not use this appliance if the power cord or plug is damaged, if the appliance is not

working properly, if it is damaged or if it has been dropped on the floor.

Any replacement of the power cord must be performed by an authorised technician to avoid the

risk of personal injury –RISK of electric shock. Only use oil-resistant cables!

10

Fixation

The appliance does not need to be secured. It is equipped with wheels and/or adjustable legs to

ensure stable and easy installation.

Operation

The appliance must be supervised during use and must be switched off at its main switch if left.

Fryer STD is intended for food preparation only. Never fill the appliance with oil or fat when it is

switched on. Oil/fat can ignite if it contacts the heating elements. It can also produce intense

smoke.

Cleaning/maintenance

CLEANING AND MAINTENANCE WARNING: Turn off the appliance and allow it to cool before per-

forming daily cleaning or maintenance tasks. Do not use products that contain acid as they may

damage the surface of the appliance.

Never use steam/foam cleaners due to RISK of electric shock.

Servicing

WARNING: The appliance has two supply connections, which must both be disconnected before

starting service work on the appliance!

The appliance must always be switched off and disconnected from the power source before com-

mencing repair work.

11

3Operation

Before first use

Before start-up, remove all packaging and protective plastic from the fryer and dispose of it in ac-

cordance with currently applicable regulations (see section 7.1). Carefully read section 2 about

safety before connecting the fryer.

Before start-up, clean the appliance as shown in section 5.

Filling with oil

Turn the fryer off. Never fill the appliance with oil or fat when it is switched on. Oil/fat can

ignite if it contacts the heating elements. It can also produce intense smoke.

Remove the basket. Now fill the fryer with oil/fat to the correct volume. The fryer must

never be switched on unless oil has been filled at least to the minimum level indicator on the

inner side of the vat (at the rear).

Quick start instructions

Before start-up, read section 5.1 under “cleaning”.

Set the desired set point between 100°C-180°C

Press “start” on the display and wait 30 minutes for the fryer to heat up and become ready for use.

The appliance must not be operated unattended.

Remember to use personal safety equipment, see 2.1

12

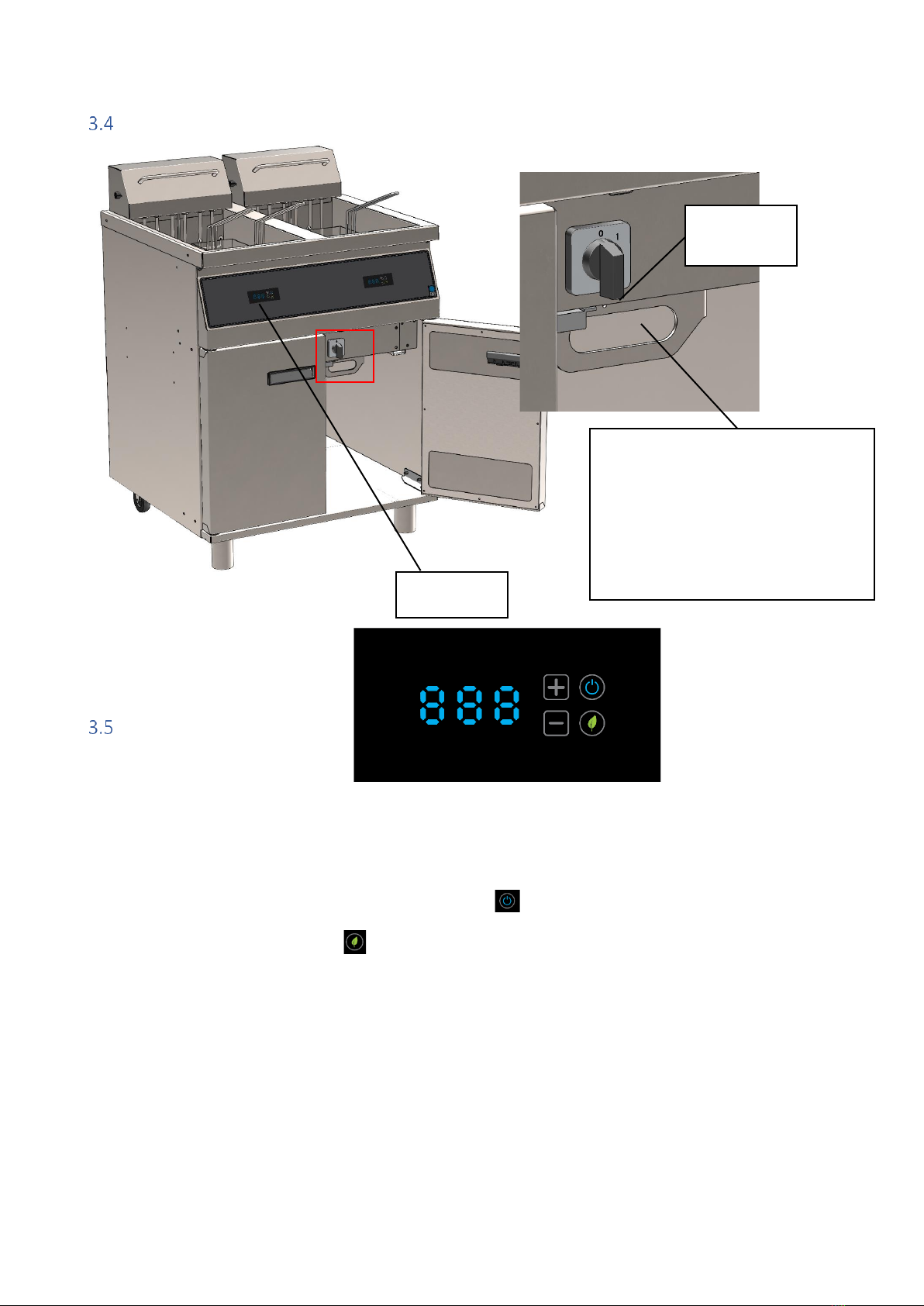

Start-up

Operation

Minimum set point is 100°C

Maximum set point is 180°C

New appliance starts at 100°C but saves the set point setting when power is cut.

When "+" is pressed, the set point will increase by 5°C. Similarly, when "-" is pressed, the set point will de-

crease by 5°C. However, you cannot go higher or lower than the minimum and maximum set point.

When "standby" is pressed, marked with a standby symbol the fryer will turn off the heat.

When "ECO" is pressed, marked with the machine will change the temperature to 100 °C until "ECO" is

pressed again, after which the machine will go back to the desired set point (it takes approx. 7 min from

100°C to 175°C in a fryer with 9 kW).

The display shows the set point, but if you want the current temperature, you can press "+" and "-" at the

same time, after which the current temperature will be displayed for five seconds.

The display flashes until the desired set point is reached.

Breaker

switch

Handle for ball valve (Draining)

Horizontal pos. = closed

Vertical pos. = open

The picture shows floor models, on

table models the handle must be

tilted out towards the user. (Open

state)

Display

13

Spare parts

14

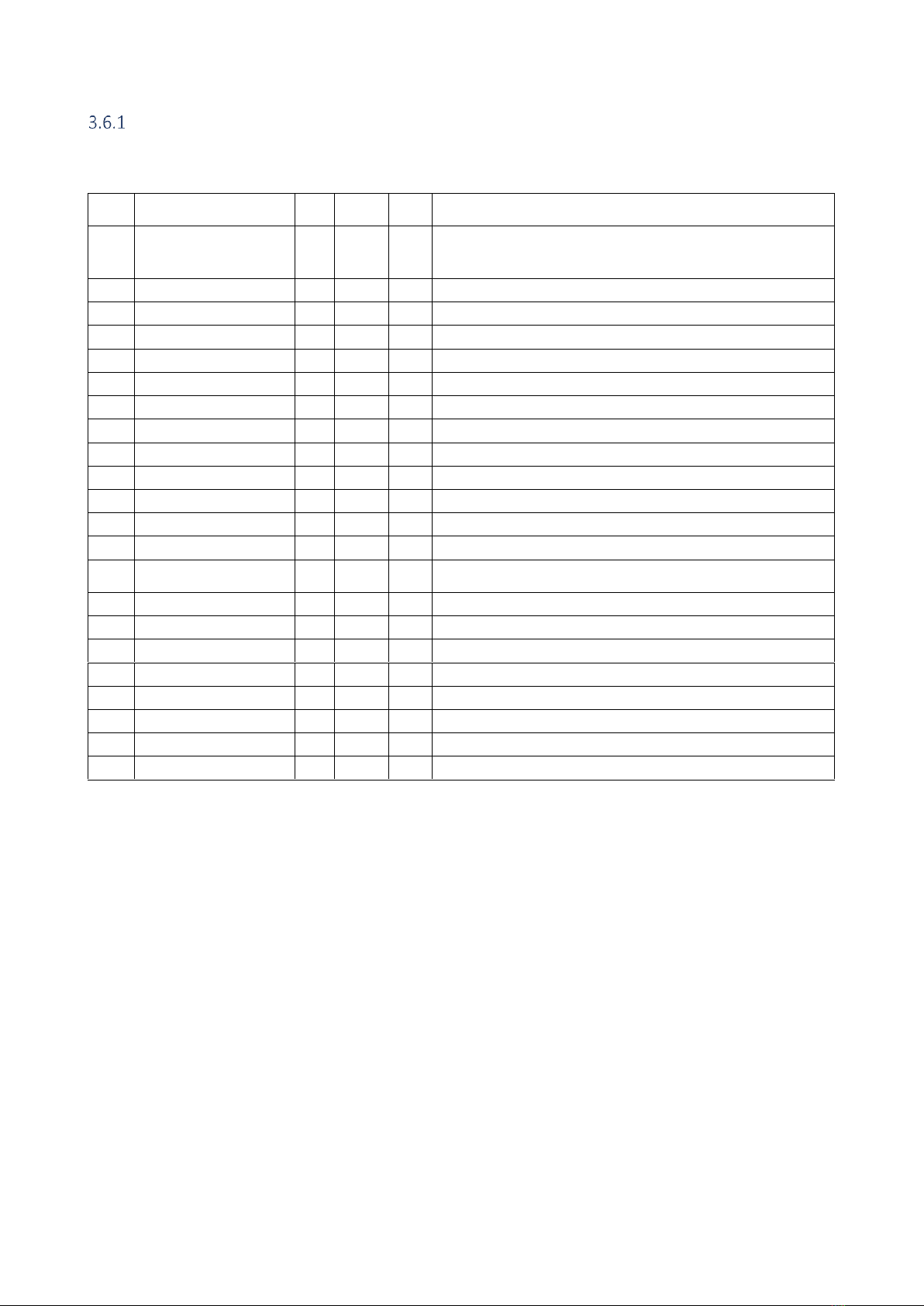

Spare parts list

Fryer STD 400V 3N~

POS

PRODUCT NUMBER

QT

Y

QTY

QTY

DESCRIPTION

Double

Single

Single

Split

1

72-03615

2

1

2

THERMOSTAT LIMITER

2

83-10002

2

1

2

SENSOR PT 100 FLOOR

3

84-00056

6

3

-

Heating element 3 kW, 400V

3

84-00061

6

3

2

Heating element 5 kW, 400V

3

84-00072

6

3

2

Heating element 7 kW, 400V

4

83-41001 (9kW)

2

1

1

CONTACTOR LC1D09P7 9A 230VAC

4

83-41003 (15kW)

2

1

1

CONTACTOR LC1D25P7 25A 230VAC

4

83-41004 (10kW)

2

1

1

CONTACTOR LC1D32P7 32A 230VAC

4

83-41000 (10&14kW)

-

-

2

CONTACTOR B&J 2NO 40A AC1 230VAC

5

72-00143

2

1

1

POWER SUPPLY 240VAC-5VDC RS-15-5

6

72-01324

2

1

2

PRINT ELECTRONIC THERMOSTAT

8

83-10316

4

2

2

SOLID STATE RELAY SSR ctrl 48-660 vac 60A

10

83-41013 (10, 14, 15 &

21kW)

2

1

1

BREAKER, 4-POLE telux 50A, center fitting

10

83-41011 (9kW)

2

1

-

BREAKER, 4-POLE telux 20A, center fitting

11

*** 84-00622

2

1

2

BALL VALVE 1" M/M MS

11

**** 84-00058

2

1

2

BALL VALVE 3/4" WITH T-HANDLE

12

72-05518

1

-

-

FOIL FRYER STANDARD DOUBLE

12

72-05516

-

1

-

FOLIE FRYER STANDARD SINGLE

12

72-05517

-

-

1

FOLIE FRYER STANDARD SPLIT

13

84-00070

1

1*

-

FRY BASKET 1/1 FKE16-

14

84-00071

2

2*

2

FRY BASKET 1/2 FKE16-

* either 2 ½ baskets or 1 1/1 basket per

vat

***FLOOR STANDING

MODELS

***COUNTERTOP

MODELS

15

Fryer STD 230V 3~

POS

PRODUCT NUMBER

QT

Y

QTY

QTY

DESCRIPTION

Double

Single

Single

Split

1

72-03615

2

1

2

THERMOSTAT LIMITER

2

83-10002

2

1

2

SENSOR PT 100 FLOOR

3

84-00057

6

3

-

Heating element 3 kW, 230V

3

84-00062

6

3

2

Heating element 5 kW, 230V

4

83-41003 (9kW)

2

1

1

CONTACTOR LC1D25P7 25A 230VAC

4

83-41004 (15kW)

2

1

1

CONTACTOR LC1D32P7 32A 230VAC

4

83-41000 (10kW)

-

-

2

CONTACTOR B&J 2NO 40A AC1 230VAC

5

72-00143

2

1

1

POWER SUPPLY 240VAC-5VDC RS-15-5

6

72-01324

2

1

2

PRINT ELECTRONIC THERMOSTAT

8

83-10316

4

2

2

SOLID STATE RELAY SSR ctrl 48-660 vac 60A

10

83-41013

2

1

1

BREAKER, 4-POLE telux 50A, center fitting

11

*** 84-00622

2

1

2

BALL VALVE 1" M/M MS

11

****84-00058

2

1

2

BALL VALVE 3/4" WITH T-HANDLE

12

72-05518

1

-

-

FOIL FRYER STANDARD DOUBLE

12

72-05516

-

1

-

FOLIE FRYER STANDARD SINGLE

12

72-05517

-

-

1

FOLIE FRYER STANDARD SPLIT

13

84-00070

1

1*

-

FRY BASKET 1/1 FKE16-

14

84-00071

2

2*

2

FRY BASKET 1/2 FKE16-

* either 2 ½ baskets or 1 1/1 basket

per vat

***FLOOR STAND-

ING MODELS

***COUNTERTOP

MODELS

16

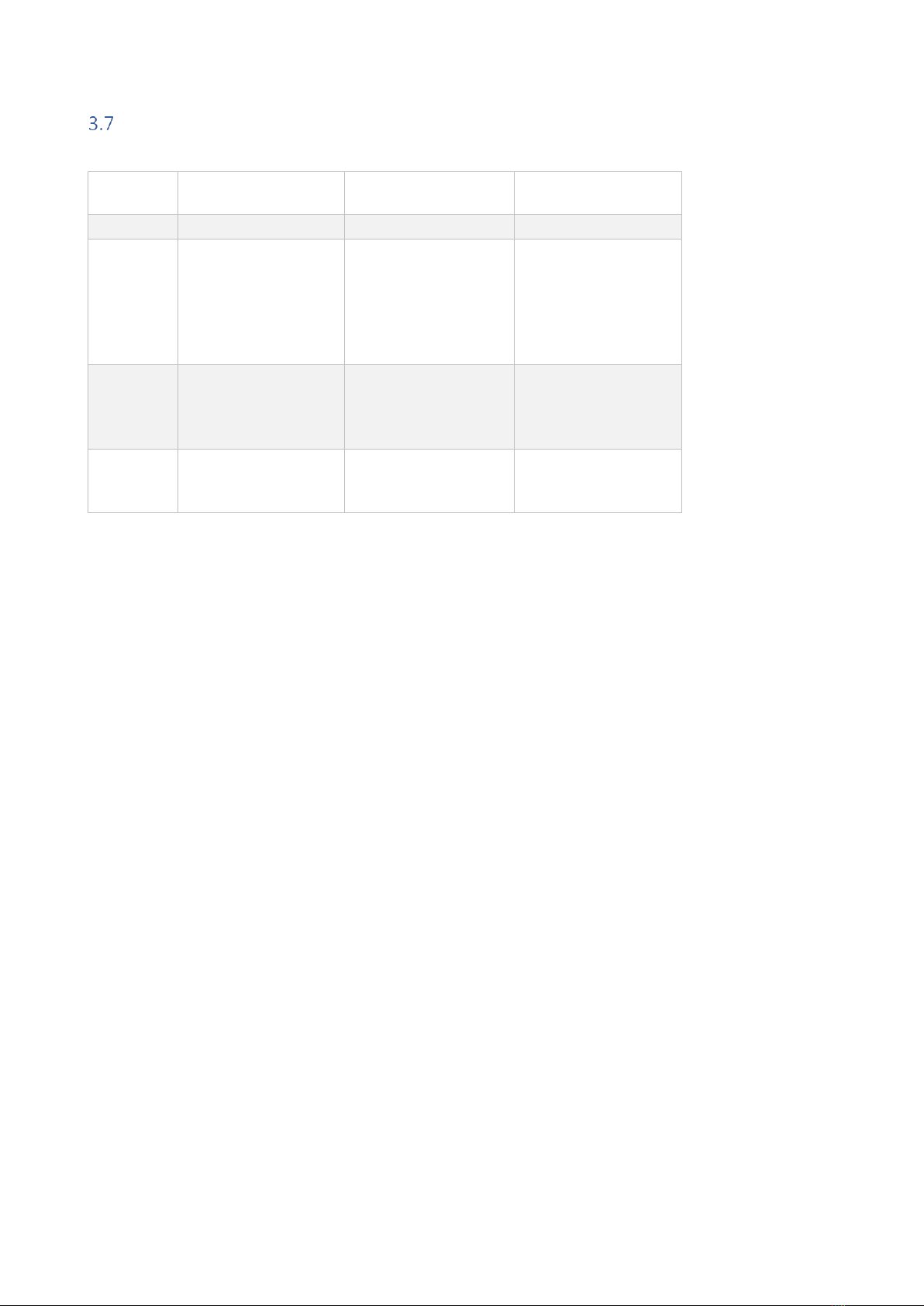

Error codes

ERROR

CODE

ERROR

CAUSE

REMEDY

E00

Undefined error

Unknown

Contact service.

E01

Temperature sensor

error

The measured values

are too low com-

pared to those ex-

pected.

The surroundings are

either too cold or the

sensor is short-cir-

cuited. In the latter

case, service must be

contacted

E02

Temperature sensor

error

The measured values

are too high com-

pared to those ex-

pected.

Sensor is not con-

nected or is defec-

tive.

Contact service.

E88

Oil overheated

The solid state relay

may have short-cir-

cuited.

Contact service.

17

4Electrical diagram

18

19

Table of contents

Other FKI Fryer manuals

Popular Fryer manuals by other brands

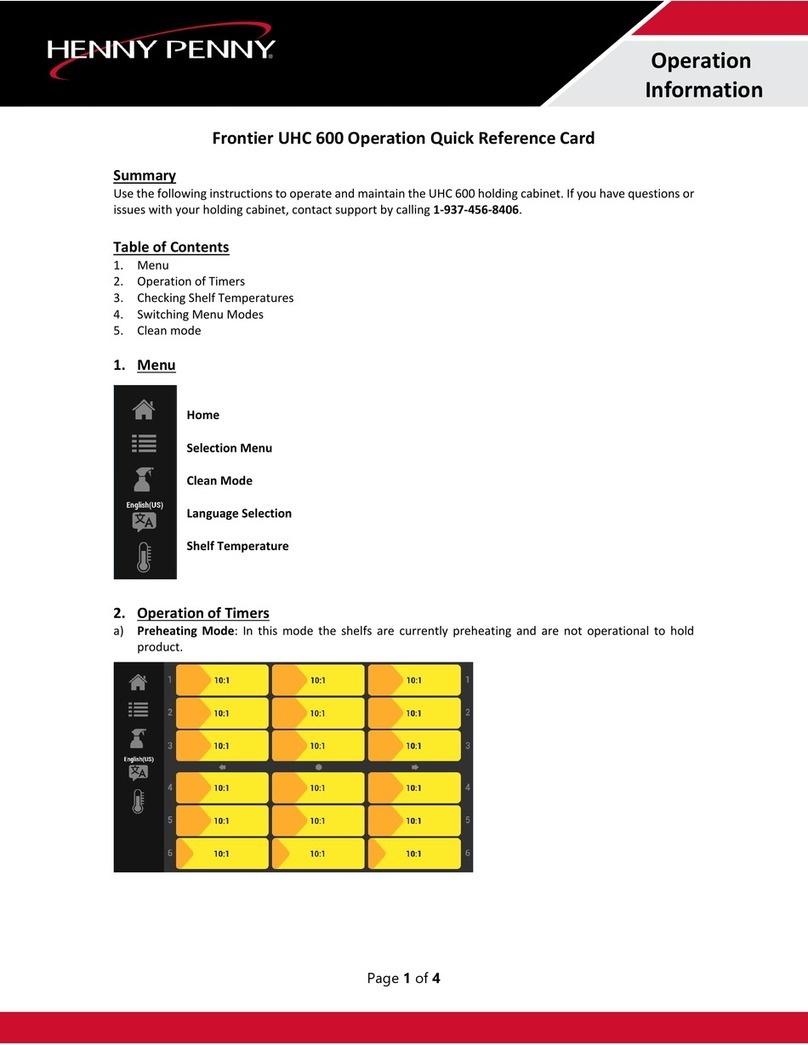

Henny Penny

Henny Penny Frontier UHC 600 Quick reference card

SEVERIN

SEVERIN FR-2439 Instructions for use

Elba

Elba EDF-D2518 owner's manual

TriStar

TriStar TSHEF-15Si Installation and operating instructions

Cosori

Cosori Helio 4-Quart user manual

Tower Hobbies

Tower Hobbies T17006 Safety and instruction manual