FKI Friomat FKE 169 EG User manual

1

User Manual for Friomat fryer

Floor model

Version 6.0 –OKT 2016

2

Table of contents

1Introduction........................................................................................................... 3

2In general.............................................................................................................. 3

2.1 Manufacture .....................................................................................................3

2.2 The name of the machine...................................................................................4

2.3 Machine tag .....................................................................................................4

3Outline and utilization .............................................................................................4

3.1 General description ...........................................................................................4

3.2 Purpose og the machine and intended utilization...................................................4

3.3 Warning of foreseeable mistreatment ..................................................................4

3.4 Technical specifications and consumption.............................................................5

4Safety and risk.......................................................................................................6

4.1 Safety instructions, built in.................................................................................6

4.2 Precaution........................................................................................................ 6

5Operation .............................................................................................................. 7

5.1 Start-up...........................................................................................................7

5.2 Fryer equipped with automatically lift system .......................................................7

5.3 Fryer equipped with oil cleaning system...............................................................7

5.4 Encoding.......................................................................................................... 8

5.4.1 Encoding of times for deep frying .................................................................. 8

5.4.2 Encoding the temperature ............................................................................8

5.5 Factory settings ................................................................................................9

6Storage, transportation and installation ..................................................................... 9

6.1 Installation....................................................................................................... 9

6.2 General ...........................................................................................................9

6.3 Fixing ..............................................................................................................9

7Maintenance, troubleshooting and repair.................................................................. 10

7.1 Cleaning ........................................................................................................ 10

7.2 Trouble shooting ............................................................................................. 12

8Termination ......................................................................................................... 12

8.1 Destruction .................................................................................................... 12

9Specifications for spare parts ................................................................................. 13

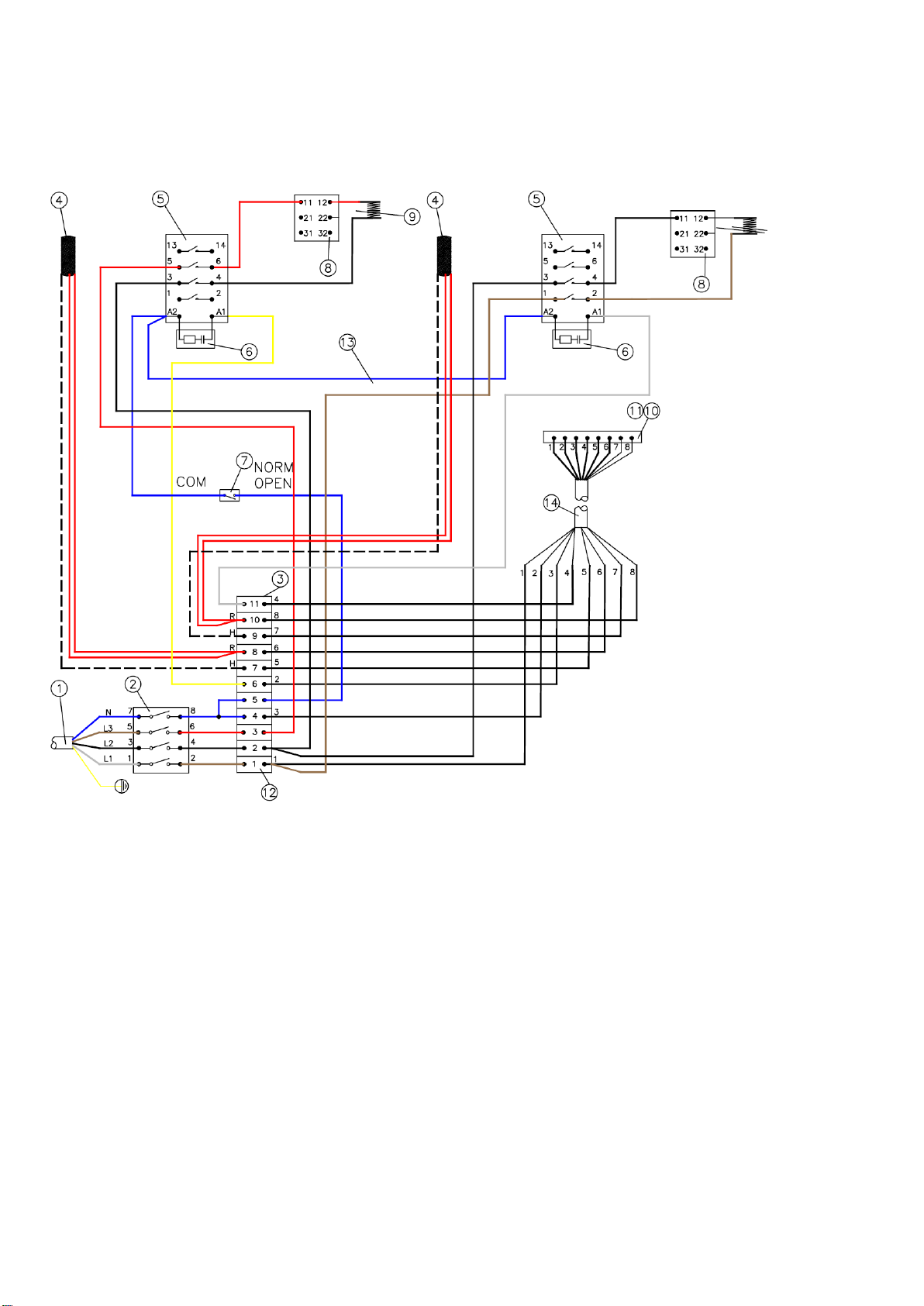

10 Wire diagram .................................................................................................... 15

11 EC Declaration of Conformity............................................................................... 21

3

1 Introduction

Original instruction manual

This guide is a translation of the original instructions manual of FKI for the Friomat Fryer

- Floor model.

Purpose

The purpose of this manual is to ensure proper installation,use, handling and

maintenance of the fryer.

Accessibility

The instruction manual must be kept - to the staff - in a well-known place which is easy to access

for electricians and personnel who maintain.

Knowledge

The employer is obligated to ensure that people who operate, serve and maintain the fryer, has

read the instruction manual or as a minimum are familiar with the parts which are relevant to

their job.

Furthermore everybody who operates, serve and maintain the fryer is obligated to seek.

information in the operation instructions manual.

2 In general

2.1 Manufacture

The fryer is produced by:

FKI Fast Food Teknik A/S

Byghøjvej 5, Verninge

DK - 5690 Tommerup

4

2.2 The name of the machine

The name of the Friomat fryer is FKE followed by 3 or 4 digits and 2 letters. The first and the

second digit marks the size of the vessel (contents of oil) in litres. The third and the forth digit

marks the power in each heat section in kW.

The letters mark model EG = single floor and DG - double floor.

Furthermore each heat section is called VSFK followed by digit which is equal to the

description of the fryer.

2.3 Machine tag

The machine tag is placed on the back og the machine.

3 Outline and utilization

3.1 General description

The Friomat fryer is the full electronic programmable fryer which is easy to operate and maintain.

It has deep vessels which make splash screens unnecessary. The powerful heat elements and

the electronic heat sensor cause the oil immediately to warm up. The Friomat fryer is easy to

clean. The temperature of the oil is shown on a display which has up to 6 different programmable

frying times. Furthermore a lift system and an oil cleaning system can be installed as part of the

fryer.

3.2 Purpose og the machine and intended utilization

The fryer is designed for deep-frying defrosted as well as frosted products minded for deep-

frying in oil/deep fat.

3.3 Warning of foreseeable mistreatment

The Friomat fryer must not be used for anything other than deep-frying food products.

5

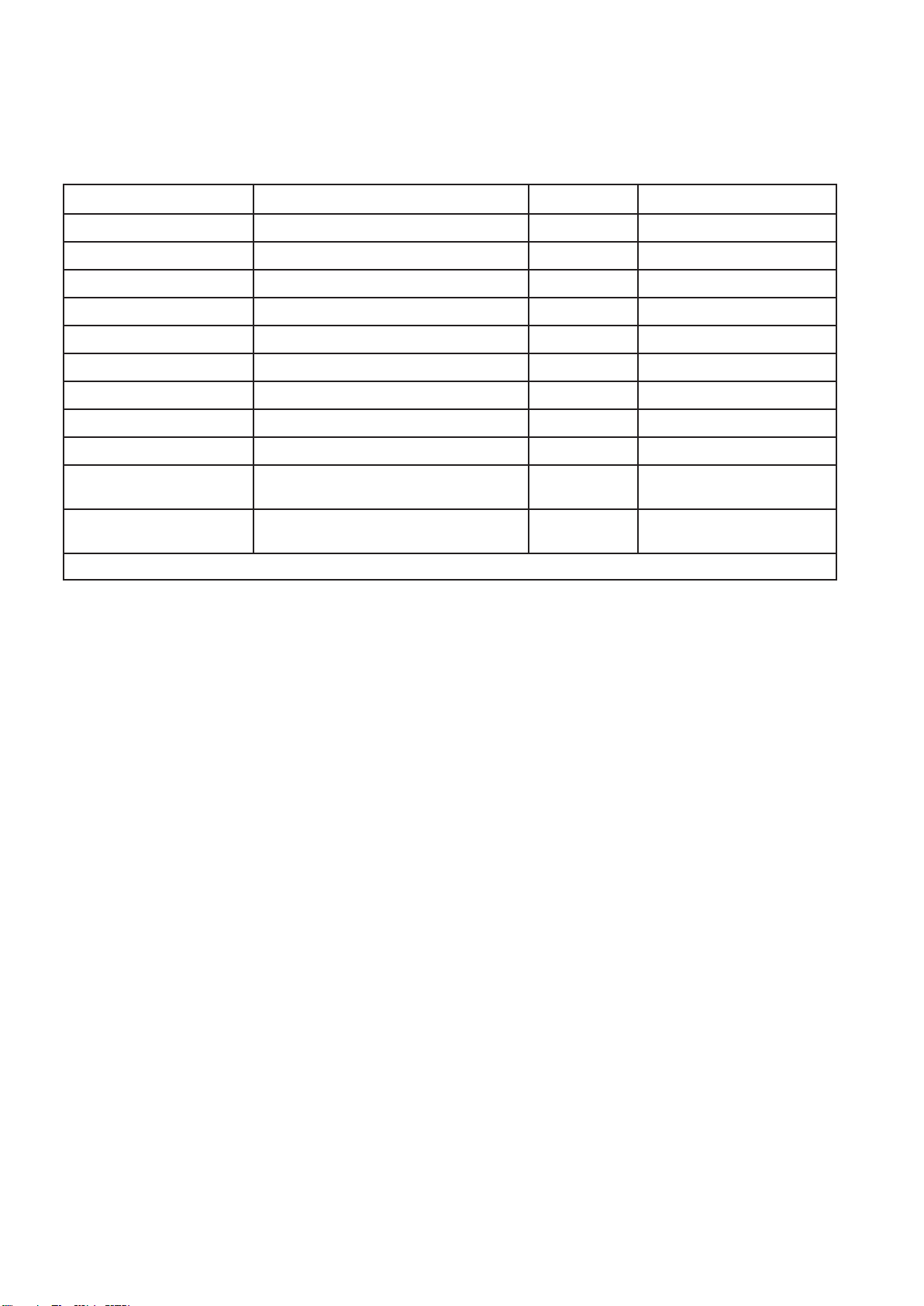

3.4 Technical specifications and consumption

Fysiske dimensioner

Model

Width x Depth x Height

Liter

Weight in kilo

FKE 169 EG

350 x 650 x 880 mm

16

53

FKE 1615 EG

350 x 650 x 880 mm

16

53

FKE 2515 G

500 x 650 x 880 mm

25

80

FKE 2521 G

500 x 650 x 880 mm

25

80

FKE 2010 G

415 x 650 x 880 mm

2x10*

80

FKE 2014 G

415 x 650 x 880 mm

2x10*

80

FKE 169 DG

700 x 650 x 880 mm

2x16

80

FKE 1615 DG

700 x 650 x 880 mm

2x16

80

FKE 1621 DG

700 x 650 x 880 mm

2x16

80

FKE 3629 TG

760 x 650 x 880 mm

1 x 16

2 x 10*

95

FKE 3619 TG

760 x 650 x 880 mm

1 x 16

2 x 10*

95

*seperate vessels

Electricity

The Friomat fryer must be connected and ground fault current through connector.

Power: 3 x 400 V AC or 3 x 230 V AC (Norway) Frequency:

50/60 Hz

Interference

Airborne interference caused by the friomat fryer:

Measured sound pressure level dB(A): < 45

6

Absorbed power

Typebetegnelse

Varmesektion

Tilslutnings-

spænding

Optagen

effekt

Optagen

strøm

Min. sikring

i installation

FKE 169 EG

VSFK 169 G

400 V

9kW

13,0 A

16 A

FKE 169 EG

VSFK 169 G

3 x 230 V

9kW

22,6 A

25 A

FKE 1615 EG

VSFK 1615 G

400 V

15kW

21,6 A

25 A

FKE 1615 EG

VSFK 1615 G

3 x 230 V

15kW

37,6 A

40 A

FKE 1621 EG

VSFK 1615 G

400 V

21KW

30,3 A

32 A

FKE 2515 G

VSFK 2515 G

400 V

15kW

21,6 A

25 A

FKE 2515 G

VSFK 2515 G

3 x 230 V

15kW

37,6 A

40 A

FKE 2521 G

VSFK 2521 G

400 V

21kW

30,3 A

32 A

FKE 2010 G

VSFK 2010 G

400 V

10kW

21,6 A

25 A

FKE 2010 G

VSFK 2010 G

3 x 230 V

10kW

37,6 A

40 A

FKE 2014 G

VSFK 2014 G

400 V

14kW

30,3 A

32 A

FKE 169 DG

VSFK 169 G

400 V

2x9kW

13,0 A

16 A

FKE 169 DG

VSFK 169 G

3 x 230 V

2x9kW

22,6 A

25 A

FKE 1615 DG

VSFK 1615 G

400 V

2x15kW

21,6 A

25 A

FKE 1615 DG

VSFK 1615 G

3 x 230 V

2x15kW

37,6 A

40 A

FKE 1621 DG

VSFK 1621 G

400 V

2x21KW

30,3 A

32 A

FKE 3629 TG

VSFK 1615 G

VSFK 2014 G

400 V

1x15KW

1x14KW

21,6 A

30,3 A

25 A

32 A

FKE 3619 TG

VSFK 169 G

VSFK 2010 G

400 V

1x9KW

1x10KW

13 A

21,6 A

16 A

25 A

Please notice that Friomat fryers in double version are equipped with two heat sections.

4 Safety and risk

4.1 Safety instructions, built in

The heat section has a built-in magnet switch which cuts off the power to the heat elements when

the heat section is raised from the worktop.

The electronically control is equipped with an acoustics alarm which is activated, if any

temperature above 250°C is recorded.

4.2 Precaution

The heat section has a built-in mechanical safety thermostat which disconnects the power, if the

7

temperature exceeds 245°C. The thermostat is reconnected when the temperature drops. Press

the red button which is placed on the side of the heat section. The electroni- cally control is

equipped with a fuse which protects the control from overload. The fuseis placed under the front

panel which contains the display.

5 Operation

Adding oil

Turn off the fryer. Never add oil or deep fry fat when the fryer is switched on. The oil/deep

fry fat can be ignited if it hits the heat elements. Heavy smoke can also occur.

Remove the lid and the basket. Add oil or deep fry fat to the MAX-tick. Yet as a minimum to

the tick inside the vessel (at the back).

NB! If the fryer is equipped with a pump for oil cleaning, it is only allowed to use oil

- NEVER deep fry fat.

5.1 Start-up

The main switch which is placed on the back of the heat section is turned to ON. A dot will

occur in the lower right corner of the display which indicates that the power is on.

Press ON at the keyboard to activate the fryer. The fryer will start in Standbymode

and heat up to the pre-set Standby temperature.

As long as the temperature is below 50°C, tree dashes will be shown in thedisplay. When

the temperature is above 50°C the actual temperature will be measured by the heat sensor

in the oil and shown in the display.

Press + to change to normal mode and the fryer will continue to heat to the pre-set

operation temperature. When the temperature is reached the fryer is ready.

Place the baskets on the bracket atthe heat section. Place the requested products in the basket

and steady lower it into the oil.

Press a key 1-6 depending on the requested deep-frying time. The display will show the chosen

time in minutes and 1/10 minutes. The time will be counted backwards which means that the

remainingtime is shown at any time.

When time expires an acoustic alarm will sound in approx. 2 sec., and the basket is

removed from the oil. Leave it hanging in the bracket, so the excess oil/deep fry fat can

drain.

A program in progress can be stopped by pressing the Reset button.

5.2 Fryer equipped with automatically lift system

See separate guide.

5.3 Fryer equipped with oil cleaning system

See separate guide.

8

5.4 Encoding

All encoding must be done in Standby mode. Raise the heat section,so the heat elements

are disconnected by the magnetic switch before the fryer is activated by pressing ON.

5.4.1 Encoding of times for deep frying

Press [2] and hold for more than 6 sec. The programming menu 2 will appear in the display.

Press the number of the program (1-6) on which you want to modify thetime.

The time is changed by pressing [+] or[-].

The program returns to menu after 5 seconds, and the modified time issaved.

Toexit the menu, press RESET.

5.4.2 Encoding the temperature

Press [3] and hold for more than 6 sec. The programming menu 3 will appear in the display.

Press [1] to change the Standbytemperature.

Press [2] forthe change in operatingtemperature.

Tochange the temperature press [+] or[-].

The program returns to menu after 5 seconds, and the modified timesaved.

Toexit the menu, press RESET.

9

5.5 Factory settings

6 Storage, transportation and installation

6.1 Installation

The machine must be wired by a certified electrician.

Be aware that the installation is done properly with adequate security size andprotection against

fault currents and earth. The fryer must be connected 400V + 0 + J or 3 x 230V in Norway.

Please notice that there must separate connection to each heat section.

6.2 General

Floor models are standard equipped with front legs and fixed wheels at the rear. There should be

space in front of the fryer, so it is possible to pull it out from the wall for cleaning and maintenance.

Alternatively: fryer also available with 4 wheels, wher the front wheels can be locked (optional).

6.3 Fixing

For ships the fryer can be delivered with fixed legs and bracket for attachment to the floor.

Program 1

3 min.

Program 2

12 min.

Program 3

15 min.

Program 4

3 min.

Program 5

12 min.

Program 6

15 min.

Standby temperature

130°C

Operating temperature

180°C

10

7 Maintenance, troubleshooting and repair

7.1 Cleaning

The fryer should be cleaned daily.

Sluk frituren og lad den køle af. Hvis er er

hæv/sænk på frituren sættes aktiveres stand

by, hvorved kurvene kører ned. Åben

aftapshanen og lad olien løbe ned i

aftapsspanden.

Remove the baskets and the brackets. These

can be cleaned e.g. in a dishwasher

Lift the heat section and tip it back

Ensures that the heating sector hangs

properly

11

Never use cleaners on the parts that are in

contact with food. If it is still necessary, make

sure the parts are thoroughly rinsed and dried.

Dry the heat section with a damp cloth.

Pay special attention to the area around the

micro switch. It is important to clean

thoroughly here.

Wipe the edges of the fryer with a damp

cloth

Place the baskets into place again.

Open the door, pull the drawer out and clean

the filters and bucket

12

7.2 Trouble shooting

The electronically control of the fryer is equipped with a fault reporting which can be read

in the display if any malfunctions of the heat sensor should occur.

In that case the fryer will not start when pressing ON and a code will appear in the display.

1. Code ”1”: The sensor for the temperature is short-circuited.

2. Code ”2”: The sensor for the temperature is not connected or has been cut off.

Call upon service.

.

8 Termination

8.1 Destruction

The machine is marked with the above recycling symbol

(EC Directive 2002/96/EC) and must be disposed in

accordance with your country order.

This means that when the product becomes obsolete, you

should dispose it after the local municipality’s rules, e.g.

in unsorted waste stream.

13

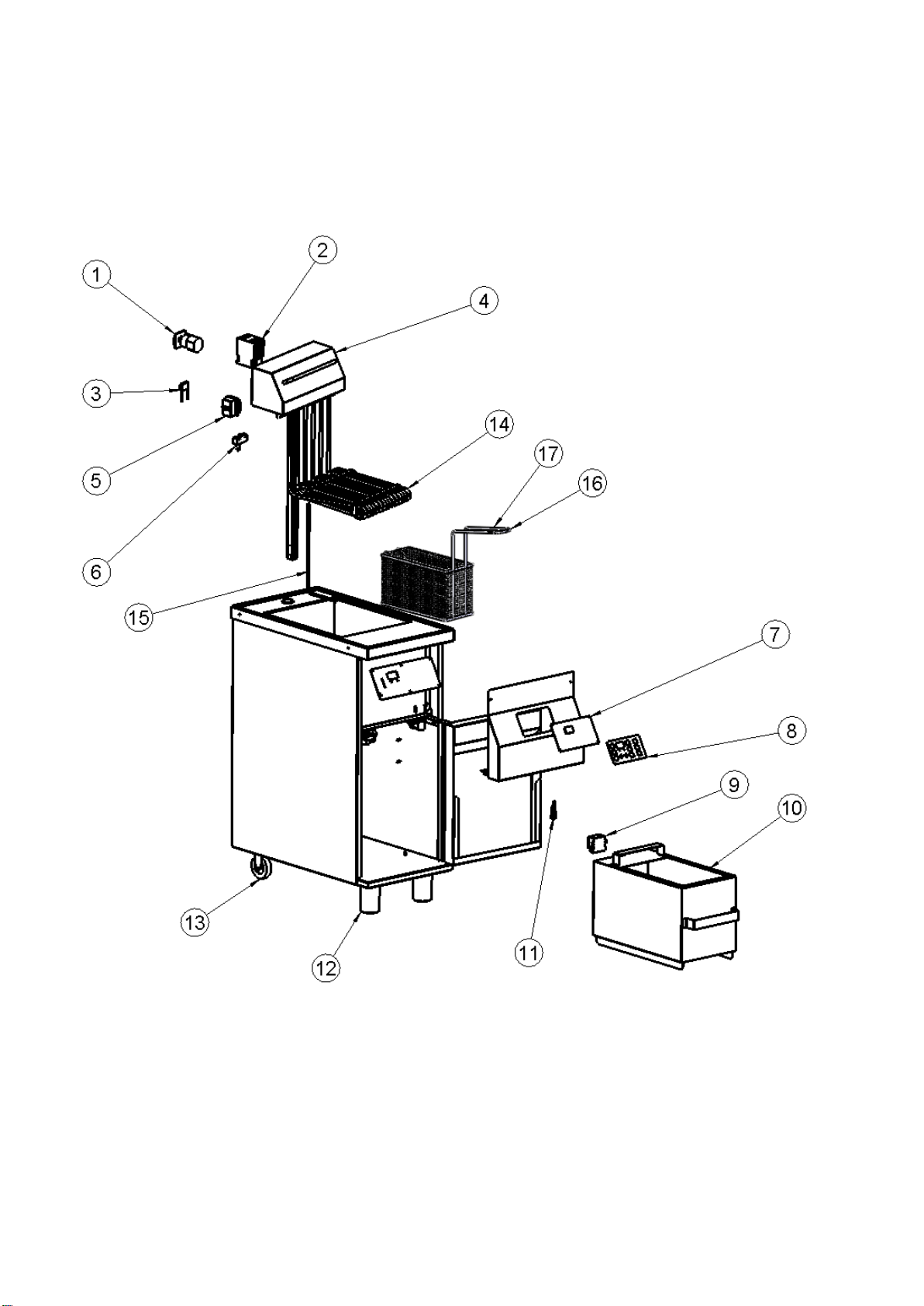

9 Specifications for spare parts

FKE 16/20/25/36

14

Pos.

Item number

Description

1

84-00068

POWER SWITCH 4-POL CA20 25A

1

84-00067

POWER SWITCH 4-POL CA20 32A

2

88-00080

CONTACTOR 3-POL 230V 20A

2

88-00066

CONTACTOR 3-POL 230V 32A

3

84-00288

KONDENSATOR

4

84-16901

HEAT SECTION FKE 169/3619 230V COMPLET

4

84-16902

HEAT SECTION FKE 169/3619 400V COMPLET

4

84-16974

HEAT SECTION FKE 1615/3629 230V COMPLET

4

84-16905

HEAT SECTION FKE 1615/3629 400V COMPLET

4

84-16908

HEAT SECTION FKE 1621G 400V COMPLET

4

84-16914

HEAT SECTION FKE 2010G 400V COMPLET

4

84-16915

HEAT SECTION FKE 2014G 400V COMPLET

4

84-16907

HEAT SECTION FKE 2515G 400V COMPLET

4

84-06906

HEAT SECTION FKE 2521G 400V COMPLET

5

72-03615

SAFETY THERMOSTAT

6

83-10003

MICRO SWITCH FKE

7

84-16500

PRINT FRIOMAT

8

84-16400

KEYBOARD FKE- SERIE 6-PRG.

9

83-09056

TRANSFORMER 240V/12V

10

15-00021

DRAIN BUCKET FKE 16DG 20/25 and 36

10

84-00112

DRAIN BUCKET FKE 16 EG

11

84-00290

FUSE HOLDER

12

83-07544

FEET ADJUSTABLE

13

83-07633

WHEEL 75 mm

14

84-00057

HEAT ELEMENT FKE-G 3kW/230V (Norge)

FKE 169/3619

14

84-00062

HEAT ELEMENT FKE-G 5kW/230V (Norge)

FKE 2010/1615/2515

14

84-00056

HEAT ELEMENT FKE-G 3kW/400V

FKE 169/3619

14

84-00061

HEAT ELEMENT FKE-G 5kW/400V

FKE 2010/1615/2515/3629

14

84-00072

HEAT ELEMENT FKE-G 7kW/400V

FKE 2014/1621/2521

15

83-10002

SENSOR FK16-G PT100 kl B 3-LEDER

16

82-00071

BASKET 1/2 FKE16-

17

84-00070

BASKET 1/1 FKE16-

15

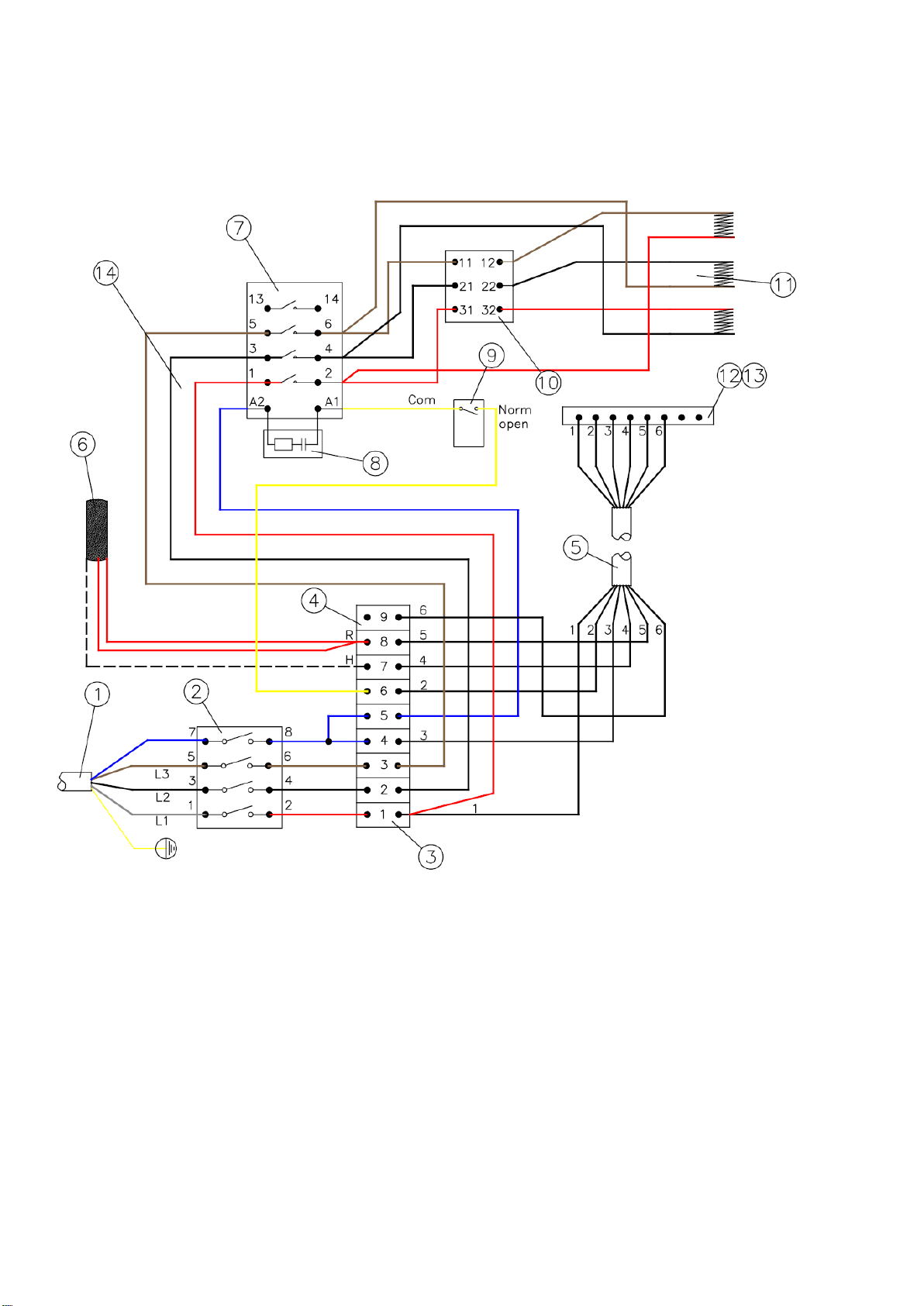

10 Wire diagram

FKE HEATING SECTION VSFK 16- OG 25-SERIES

16

Pos.

Item number

Description

1

72-03674

CABEL 5G2,5mm2

2

84-00068

POWER SWITCH 4-POL CA20 25A

2

84-00067

POWER SWITCH 4-POL CA25 32A

2

84-00105

POWER SWITCH CA40 40A

3

83-07608

TERMINAL BLOCK 6 MM²

4

83-07952

TERMINAL BLOCK 2,5 MM²

5

72-03675

CABEL 7G1,0mm2

6

83-10002

SENSOR FK16-G PT100 kl B

7

84-00080

CONTACTOR 3-POL 230V 20A

7

84-00066

CONTACTOR 3-POL 230V 32A

7

84-00553

CONTACTOR 3-POL 230V 40A

8

84-00288

CAPACITOR 0,22uF

9

83-10003

MICRO SWITCH FKE

10

72-03615

SAFETY THERMOSTAT

11

HEAT ELEMENT (SEE SPARE PARTS LIST)

12

84-00180

PLUG FOR MULTI PLUG, HUN

13

84-00183

CABLE BOX STRAIGHT FOR CHASSIS

14

81-05560

COMPLETE WIRING

17

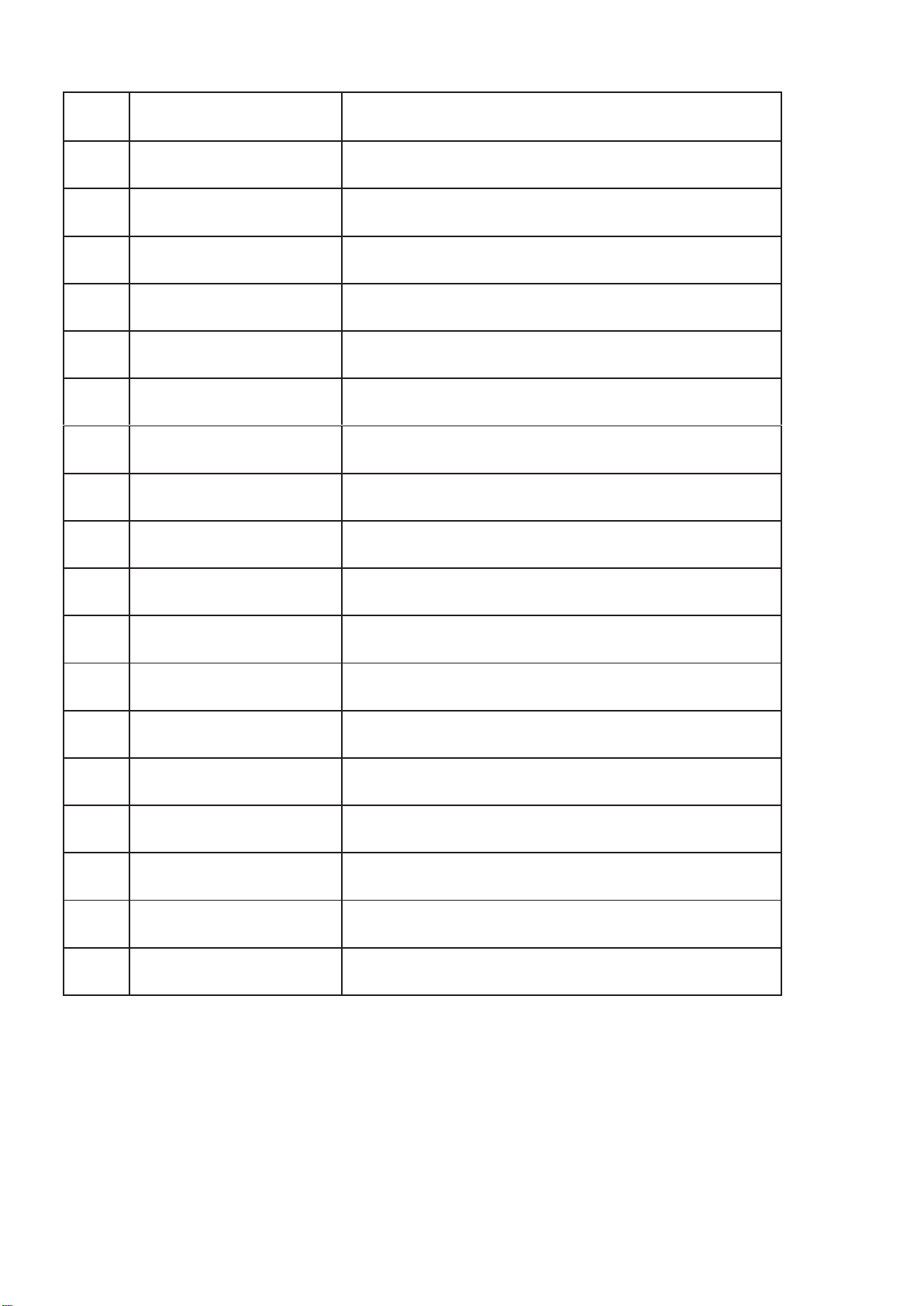

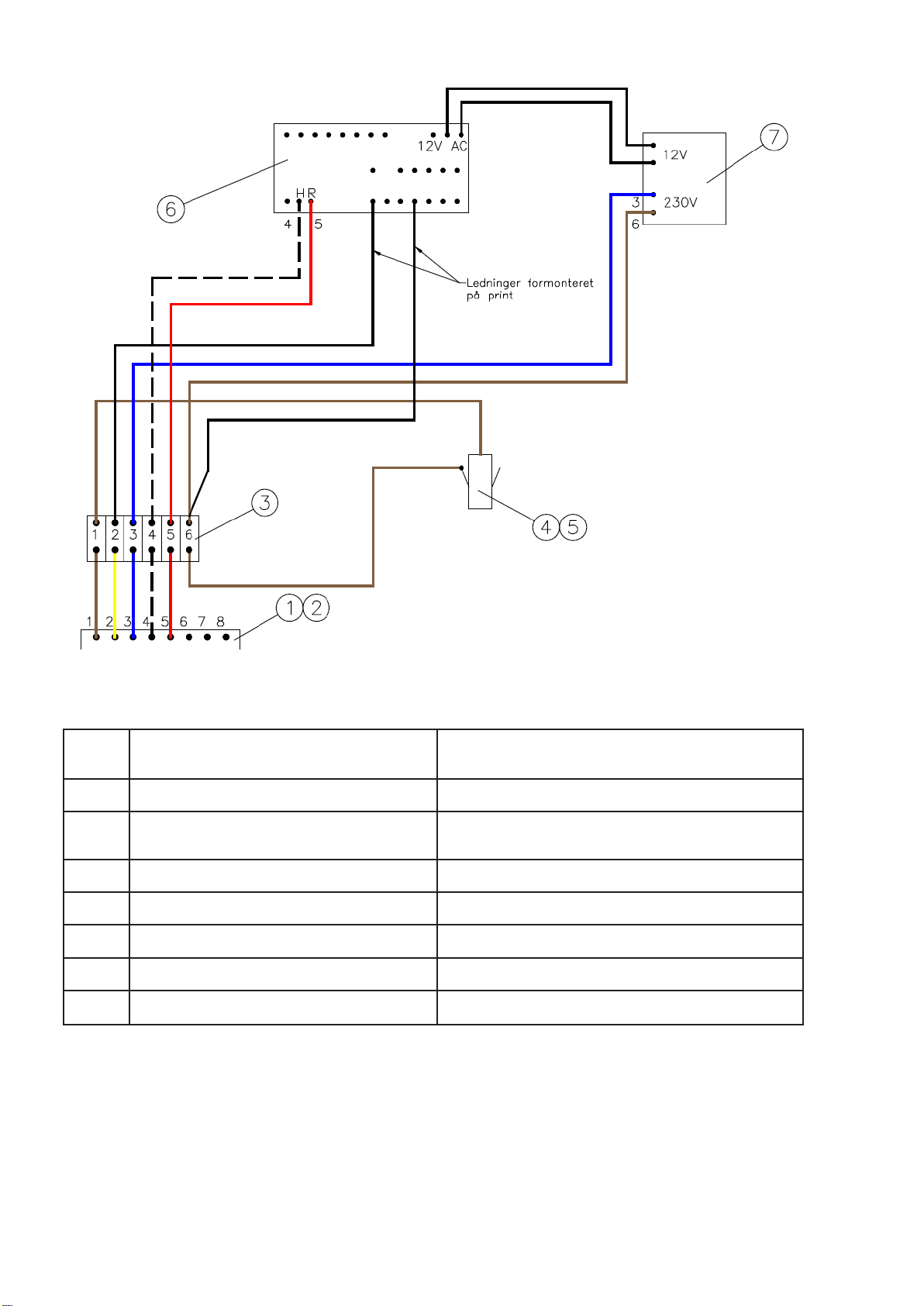

HEATING SECTION VSFK FKE 20-SERIES

18

Pos.

Item number

Description

1

72-03530

CABEL 5G2,5mm²

2

84-00068

POWER SWITCH 4-POL CA20 25A

3

83-08156

TERMINAL BLOCK 3-POL 2,5mm²

4

83-10002

SENSOR FK16-G PT100

5

88-00080

CONTACTOR 3-POL 230V 20A

6

84-00288

CAPACITOR 0,22uF

7

83-10003

MICRO SWITCH FKE

8

72-03615

SAFETY THERMOSTAT

9

84-00061

HEAT ELEMENT FK GULV 5kW/400V

9

84-00072

HEAT ELEMENT FK GULV 7kW/400V

10

84-00181

LINER FOR CHASSIS

11

84-00183

CABLE BOX STRAIGHT FOR CHASSIS

12

83-08156

TERMINAL BLOCK 6 mm²

13

81-05560

COMPLETE WIRING

14

72-03680

CABLE 12G1,0mm2

19

Front FKE 16- og 20 series

Pos.

Item number

Description

1

84-00181

LINER FOR CHASSIS

2

84-00182

TERMINALS FOR MULTI CONNECTOR,

ANGLE

3

83-08156

TERMINAL BLOCK 2,5mm²

4

84-00290

FUSE HOLDER

5

72-00130

MINIATURE FUSE 7A

6

84-16500

PRINT FKE HEATER CONTROL

7

83-09256

TRAFO 230/12V

20

Front FKE 20-series

Pos.

Item number

Description

1

83-08156

TERMINAL BLOCK 2,5mm²

2

84-16500

PRINT FKE HEATER CONTROL

3

83-09256

TRAFO 230/12V

4

84-00290

FUSE HOLDER

5

72-00130

MINIATURE FUSE 7A

This manual suits for next models

10

Table of contents

Other FKI Fryer manuals

Popular Fryer manuals by other brands

Fritel

Fritel Snacktastic 5801 user manual

Hamilton Beach

Hamilton Beach 35033C Use & care guide

Tower Hobbies

Tower Hobbies T17061BLK user manual

Tesla

Tesla AirCook & Grill QG800 WiFi manual

Gourmia

Gourmia GAF685 user manual

Mondial Designs Limited

Mondial Designs Limited FAST FRY PREMIUM Instruction and Technical Service Manual