9

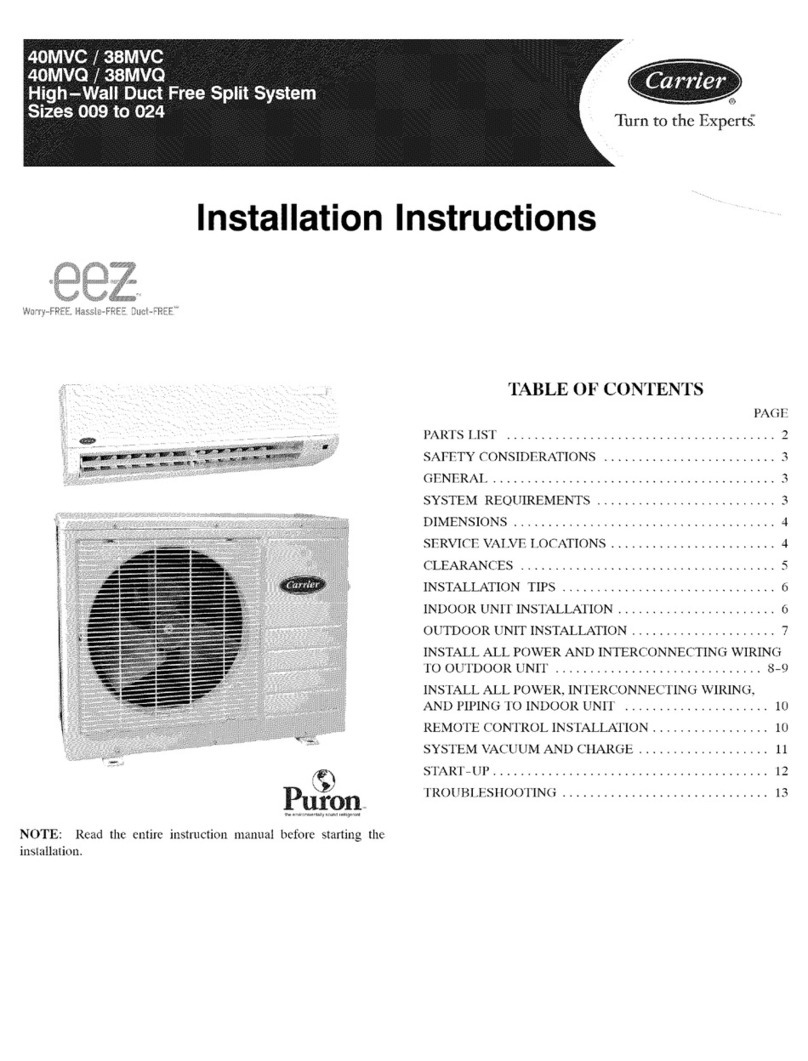

INSTALLATION TIPS

Ideal installation locations include:

Outdoor Unit

SA location which is convenient to installation and not exposed to

strong winds.

SA location which can bear the weight of the outdoor unit and

where the outdoor unit can be mounted in a level position.

SA location which provides appropriate clearances (see Fig. 5).

SDo not install the indoor or outdoor units in a location with

special environmental conditions. For those applications, contact

your Ductless representative.

OUTDOOR UNIT INSTALLATION

1. Use a rigid base to support the unit in a level position.

2. Locate the outdoor unit and connect piping and wiring.

CAUTION

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

or improper operation.

In regions with snowfall and cold temperatures, avoid

installing the outdoor unit in areas where it can be covered by

snow. If the outdoor unit is installed in areas where heavy

snow is expected, a field supplied ice or snow stand and/or

field supplied−installed wind baffle should be installed to

protect the unit from snow accumulation and/or blocked air

intake. Blocking the air intake may result in reduced airflow,

significantly reduced performance and damage to the

equipment.

NOTE: Install the outdoor unit on a rigid base to reduce noise

levels and vibration. Determine the optimal air outlet direction to

prevent discharged air from being blocked. If the installation site

is exposed to strong winds such as a coastal areas, ensure the fan’s

proper operation by installing the unit lengthwise along the wall

or use dust or shield plates. If the unit needs to be suspended, the

installation bracket should comply with the suspension

requirements in the installation bracket diagram. The installation

wall should be solid brick, concrete or the same intensity

construction, or take steps to reinforce and dampen the support.

The connection between the bracket and the wall as well as the

bracket and the air conditioner should be firm, stable and reliable.

Ensure there is no obstacle which may block the radiating air.

Strong

wind

Fig. 7 - High Wind Installation

MAKE REFRIGERANT PIPING CONNECTIONS

(OUTDOOR UNIT)

IMPORTANT: Use refrigeration grade tubing ONLY. No other

type of tubing may be used. Use of other types of tubing will

void the manufacturer’s warranty.

Do not open the service valves or remove the protective caps from

the tubing ends until all connections are made.

Bend the tubing with bending tools to avoid kinks and flat spots.

Keep the tubing free of dirt, sand, moisture, and other

contaminants to avoid damaging the refrigerant system.

Avoid sags in the suction line to prevent the formation of oil traps.

Insulate each tube with a minimum 3/8−in. (10 mm) wall thermal pipe

insulation. Inserting the tubing into the insulation before making the

connections will save time and improve installation quality.

1. Remove the service valve cover, if provided with the unit.

2. Cut the pipe, with a pipe cutter, at 90 degrees (see Fig. 8).

3. Remove the service connection, if provided with the unit.

Oblique

DŽ

90 Roughness

Burr

Fig. 8 - Cut the Pipe

4. Remove all the burrs from the cut cross section of the pipe

avoiding any burrs inside the tubes.

5. Remove the flare nuts attached to the indoor and outdoor

units.

6. Install the correct size flare nut onto the tubing and make a

flareconnection. Refer to Table 6 for the flare nut spaces.

Table 6—Flare Nut Spacing

OUTER DIAM. (mm) A (mm)

Max. Min.

Ø1/4”(6.35) 0.05 (1.3) 0.03(0.7)

Ø3/8”(9.52) 0.06 (1.6) 0.04(1.0)

Ø1/2”(12.7) 0.07 (1.8) 0.04(1.0)

Ø5/8”(15.88) 0.09 (2.2) 0.08(2.0)

Bar

Copper pipe

Clamp handle Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Fig. 9 - Flare Nut Spacing

7. Apply a small amount of refrigerant oil to the flare

connection on the tubing.

8. Align the center of the pipes and/or service valve.

Indoor unit tubing Flare nut Piping

Fig. 10 - Align Pipe Center

9. Connect both the liquid and gas piping to the indoor unit.

10. Tighten the flare nut using a torque wrench as specified in

Table 7.

11. Complete the installation.

Table 7—Tightening Torque

PIPE DIAMETER In.(mm) TIGHTENING TORQUE

Ft-lb N-m

Ø1/4” (6.35) 10 to 13 13.6 to 17.6

Ø3/8” (9.52) 24 to 31 32.5 to 42.0

Ø1/2” (12.7) 37 to 46 50.1 to 62.3

Ø5/8” (15.88) 50 to 60 67.7 to 81.3

Flare nut

Copper tube

Fig. 11 - Tighten the Flare Nut