flakt woods STRA-04 Instruction Manual

STRA-04 Room controller. Installation and maintenance manual.

Fläkt Woods 8790 GB 2016.03 1Specifications are subject of alteration without further notice.

Contents STRA-04 for Optivent

Installation instructions........................................................................2

Controller................................................................................................3

Display handling...................................................................................3

Technical data........................................................................................4

Configuration........................................................................................4

Operating modes..................................................................................6

Control...................................................................................................7

Condensation detector/Window contact/Frost protection.............8

Parameter settings................................................................................9

Function key........................................................................................11

STRA-04 Room controller. Installation and maintenance manual.

Fläkt Woods 2 Specifications are subject of alteration without further notice.

STRA-04 for Optivent

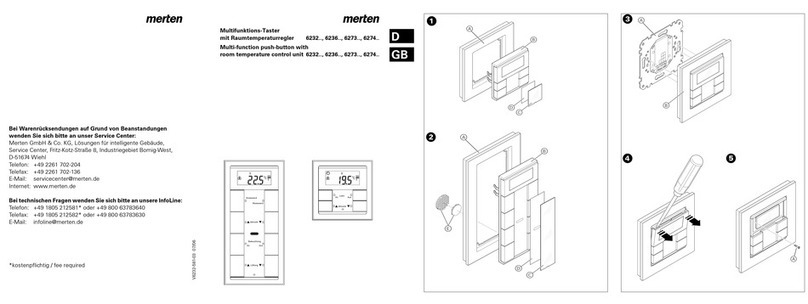

Installation instructions

Follow local safety regulations when installing the product. For information on putting the product into operation, see

the manual "STRA Manual", which can be downloaded from www.flaktwoods.com.

1. 2.

3. or 4.

5. Dimensions

Dimensions given in mm

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

STRA-04 for Optivent

Fläkt Woods 3 Specifications are subject of alteration without further notice.

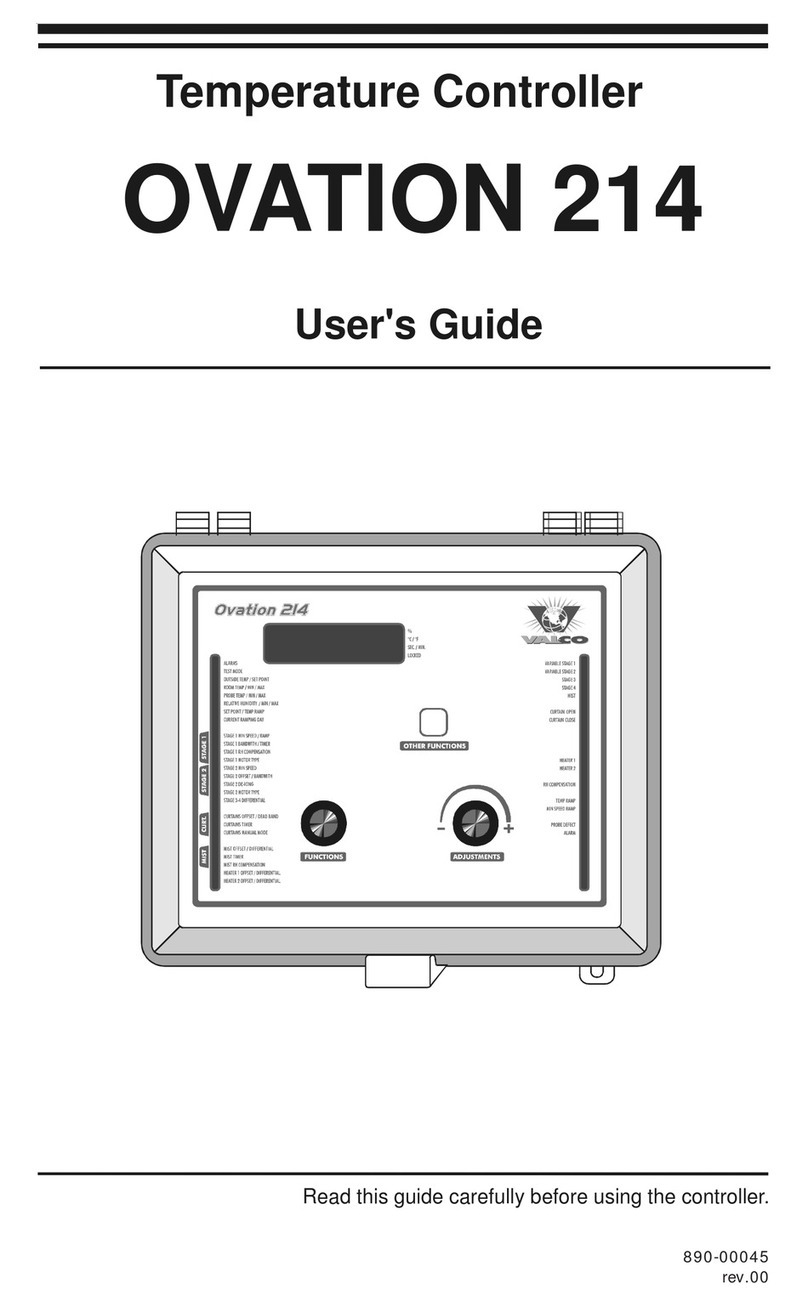

Connection diagram for STRZ-05, STRZ-18, STRZ-09,

STRZ-70, EMSS and window contact STRZ-38

Connection diagram for STRZ-05, STRZ-18, STRZ-09,

STRZ-70, EMSS and condensation sensor STRZ-16

Setpoint adjustment

In Occupied mode, the controller operates from a heating

setpoint (FS = 22°C), or a cooling setpoint FS = 24°C) that

can be changed using the INCREASE and DECREASE

buttons.

When the INCREASE button is pressed, the current

setpoint is raised by 0.5°C per press up to the maximum

limit (FS = +3°C). When the DECREASE button is pressed,

the current setpoint is reduced by 0.5°C per press down to

the minimum limit (FS = -3?).

Switching between heating and cooling setpoints is done

automatically in the controller depending on the heating

and cooling requirement.

Function button

If the Function button is pressed briefly (less than 5

seconds) when the controller STRA-04 is in the Preset

operating mode (Parameter 45, FS = 3 = Occupied), the

controller switches to the Bypass operating mode. If the

button is pressed briefly when the controller is in Bypass

mode, it will switch to Preset mode.

If the Function button is pressed and held for more than

5 seconds, the controller switches to Unoccupied mode,

regardless of the current operating mode. If the button is

pressed briefly in Unoccupied mode, the controller will

return to Bypass (for 60 minutes – this is a preset time that

can be changed via setting of parameter 12).

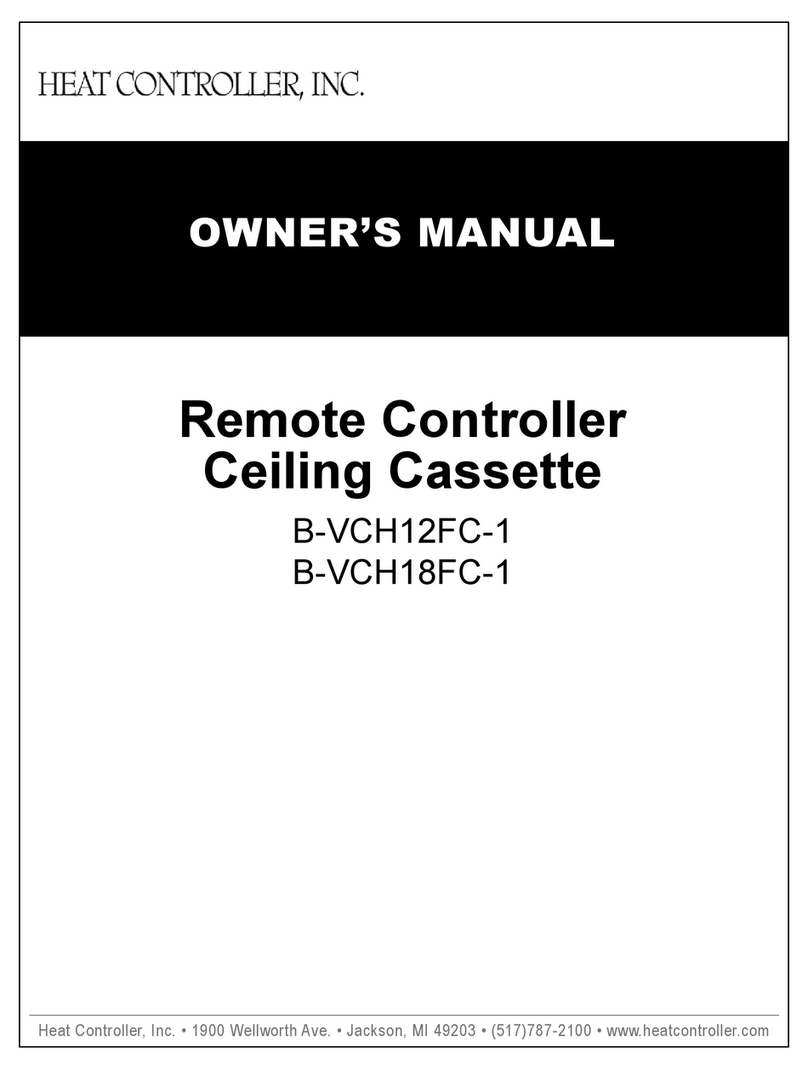

Display handling

The display on the controller STRA-04 has the following

indications:

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

STRA-04 for Optivent

Fläkt Woods 4 Specifications are subject of alteration without further notice.

Different parameter values can easily be set in a

parameter menu shown on the display, using the buttons

on the controller. The parameter value is changed using

the INCREASE and DECREASE buttons, and the change

is confirmed with the Function button.

Technical data

Supply voltage 18...30 V AC, 50...60 Hz

Internal consumption 2.5 VA

Ambient temperature 0...50°C

Storage temperature -20..+70?

Ambient humidity Max 90% RH

Protection class IP20

Communication RS485 (EXOline or Modbus) with

automatic detection/change-over

Modbus - Bacnet 8-bit, 1 or 2 stop bits. Odd, even (FS) or

no parity.

Communication speed 9600 bps (not changeable)

Built-in temperature sensor NTC type, measuring range, 0...50°C,

measurement accuracy +/-0.5°C at

15...30°C

Material casing Polycarbonate, PC

Weight 110 g

The product meets requirements for

prevailing European EMC standards

CENELEC EN 61000-6-1 and EN

61000-6-3 and prevailing European

LVD standard IEC 60 730-1. The

product is CE marked.

Inputs

External room sensor PT1000 sensor, 0…50°C. A suitable

sensor is Fläkt Woods STRZ-05.

Occupancy detector Closing potential-free contact. A

suitable occupancy detector is Fläkt

Woods STRZ-09.

CO 2 sensor STRZ-18-1-1 CO 2 sensor (0-10V).

Outputs

Forced ventilation 24 V AC actuator, max. 0.5 A

Valve actuator, thermal actuator

or Optivent 2 outputs

Valve actuator 0…10 V DC, max. 5 mA

Thermal actuator 24 V AC, max. 2.0 A

Control Heating or cooling

Exercise FS = 23 hour intervals

Terminal block Lift-type for max. cable cross-section

2.1 mm 2

Connection

To keep the unit as compact as possible, the

communication input on the STRA-04 is not galvanically

separated from the supply voltage. This means that it is

vital to be able to distinguish clearly between G and G0,

as well as the communication input's A and B.

All STRA regulators that share a transformer and

communication loop must use the same transformer pole

for G (terminal 10) and G0 (terminal 11), respectively. On

the communication loop, the A terminal (terminal 42)

may only be connected to another A terminal, and the B

terminal (terminal 43) to another B terminal. Otherwise

there is a high risk of short circuiting, which would ruin

the components.

Configuration

Use the parameter menu in the display to configure the

electronic unit. See the Parameter Settings section.

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

Fläkt Woods 5 Specifications are subject of alteration without further notice.

STRA-04 for Optivent

Terminal Designation Function

10 G Supply voltage 24 V AC

11 G0 Supply voltage 0 V

20 GDO 24 V AC out common for DO. Internally connected to terminal 10, G.

21 G0 0 V common for UO. Internally connected to terminal 11, G0.

23 UO1 Control of heating

For 0...10 V DC valve actuator, max. 5 mA (FS). The valve actuator´s 0…10 V control signal terminal is connected to

terminal 23 and its supply terminals are connected to terminals 10 and 11. Make sure that the reference pole G0 is

connected to the correct terminal on the actuator.

alternatively

For 24 V AC thermal actuator, max. 2.0 A. The thermal actuator is connected between terminals 23 and 20, GDO.

22*UO2 Control output cooling.

For 0..-10 V or 2-10 V DC valve actuator, max. 5 mA (FS). The valve actuator's 0…10 or 2-10 V control signal terminal

is connected to terminal 22, and its supply terminals are connected to terminals 10 and 11. Make sure that the

reference pole G0 is connected to the correct terminal on the actuator.

alternatively

For 24 V AC thermal actuator, max. 2.0 A. The thermal actuator is connected between terminals 24 and 20, GDO.

30 Al1 For external room sensor PT1000. Measuring range 0...50°C. Connect sensor between terminal 30 and 41, AGnd.

31 AI2 For 0-10V CO 2 sensor, input signal.

32 DI1 Occupancy detector. Potential free contact is connected between terminal 32 and 40, +C. Closed contact indicates

occupancy.

Also see Occupancy detector section.

33 DI2/CI Fläkt Woods STRZ-16 (FS) condensation detector. Connect the sensor between terminal 33 and 41, AGnd.

alternatively

Window contact DI). Connect potential free contact between terminal 33 and 40, +C. Closed contact indicates

closed window.

40 +C 24 V DC out common for DI and UI (with digital function)

41 AGnd Analogue earth, reference for AI and UI with analogue function)

42 A RS485 communication A

43 B RS485 communication B

*On version 1.4.x.x.x has UO2 and UO3 switched pin for STRA-04, UO2= Pin 22 and UO3=24.

You can with parameter 328 switch back UO2 to pin 24 like in 1.3.x.x.x by set 328 to 0.

Version 1.4 is introduced since June 2013.

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

STRA-04 for Optivent

Fläkt Woods 6 Specifications are subject of alteration without further notice.

Operating modes

STRA-04 has five operating modes. The Function button

can be used to switch between three of them. These

operating modes can be set via the parameter menu

(parameter 45) in the display. Occupied is the preset

operating mode.

Off

Operating mode Off means that the controller is inactive

(heat and cooling are disconnected). However, the

temperature must not drop below the set minimum

temperature (parameter 6, FS=8°C). If the room

temperature drops below the minimum temperature, the

controller will start heating.

On the display, the background lighting is not lit, and

only OFF is shown.

Unoccupied

The Unoccupied operating mode is an energy-saving

mode. This means that the room controlled by the

controller is currently not in use, or is not used for long

periods, e.g. during evenings, nights, weekends or by non

presence when using occupancy sensor. Both heating and

cooling are disconnected within a temperature interval

with adjustable min./max. temperatures (Parameters 4

and 5, FS min=19°C, max=27°C).

The background lighting is not lit on the display, but the

current room temperature (or setpoint, depending on the

configuration) is shown. OFF is shown on the display in

this case too.

Stand-by

The Stand-by operating mode means that the room is in

energy save mode and not currently in use, e.g. during

nights, weekends or evenings. This mode is currently not

used by default settings from Factory but it can be used

instead of unoccupied mode by non presence when using

occupancy sensor. The room temperature is controlled

around the applicable heating and cooling setpoints with

an extended temperature interval (FS = +/-3°C).

For example, if the heating setpoint is 22°C and the

cooling setpoint is 24°C, the controller will allow a

room temperature between 19°C and 27°C. In addition,

the setpoint values can be locally adjusted +/- 3°C via

a setpoint knob or via the display on the room unit.

Display: background lighting is lit (dimmed) and

STANDBY, and current room temperature (or setpoint,

depending on configuration) is shown on the display. For

further information, see Occupancy Control section.

Occupied

The Occupied operating mode means that the room is

in use and is adjusted according to Comfort mode. The

controller adjusts the room temperature around a heating

setpoint and a cooling setpoint (Parameters 1 and 2,

FS heating setpoint=22°C, cooling setpoint=24°C). The

setpoint values can also be locally adjusted +/- 3°C via the

display on the unit, or via a central command.

On the display, the background lighting is lit (dimmed)

and the occupancy indicator is lit (see Display Handling

section). The current room temperature (or setpoint

depending on the configuration) is shown.

Bypass

The Bypass operating mode means that the controller

adjusts the room temperature in the same way as in the

Occupied mode. The output for forced ventilation is also

activated (10V cooling output UO2). After a configurable

time (Parameter 12, FS=60 minutes), the controller

automatically returns to Preset mode. Bypass is normally

activated by pressing the Function button, the occupancy

detector (depending on the configuration), or via a central

command. This operating mode is useful in conference

rooms where many people are present simultaneously for

a limited period of time.

The background lighting on the display is lit (dimmed).

The occupancy detector and the symbol for forced

ventilation are lit (see Display Handling section). The

current room temperature (or setpoint, depending on the

configuration) is shown.

Activation operating modes

Preset operating mode

Occupied is the preset operating mode. The desired

operating mode is configured in the parameter menu on

the display (parameter 45). The operating mode in the

room controller is changed if the following commands/

events occur:

• When the Function button is pressed

• When the occupancy detector is activated/deactivated

• When the CO value on the 2 analogue input is exceeded

• If central control is used, e.g. central time control or

central booking system.

Function button

Bypass

(Forced ventilation)

Button/ Tim er

Occupied

(

Preset operating m ode

)

Shutdow n

(U noccupied)

> 5 s

Shutdown (Off or Unoccupied)

If the Function button is pressed and held for more than

5 seconds, the controller switches to Shutdown mode,

which may be Off or Unoccupied regardless of the current

operating mode The activated operating mode, Off or

Unoccupied, is configured via the display. The factory

configuration is Unoccupied.

8790 GB 2016.03

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

STRA-04 for Optivent

Fläkt Woods 7 Specifications are subject of alteration without further notice.

If the Function button is pressed briefly when the

controller is in Shutdown or Preset mode, the controller

will switch to Bypass mode. If the button is pressed

briefly when the controller is in Bypass, the operating

mode will switch to Preset.

After a configurable time in Bypass (FS=60 minutes), the

controller automatically returns to the preset operating

mode.

For further information on using the Function button in

combination with central control, see the Central Control

section below.

Occupancy detector

A STRZ-09-1 occupancy detector can be installed for

local control of the operating mode with regard to room

occupancy. If occupancy control is installed, parameter

45 should be changed to 1 = Unoccupied and parameter

17 changed to 3. This will achieve the function illustrated

in the picture above, where the activated occupancy

detector shifts to the Occupied operating mode. When the

occupancy sensor is deactivated, the controller returns to

the Unoccupied operating mode (to save energy).

Control

STRA-04 can be configured for different control states/

control sequences (Parameter 11, FS = 4 = Heating/Cooling

with VAV control and forced supply air function):

• Heating

• Heating/Heating

• Heating/Cooling

• Heating/Cooling with VAV control and forced supply

air

• Heating/Cooling with VAV control

• Heating

• Cooling/Cooling

For the control states, UO1 is used for the left control

function and UO2 is used for the right control function. If

only one control function is active (Heating or Cooling),

only UO1 is used.

Heating/Cooling with VAV control and forced air

supply

Same control function as for Heating/Cooling, except

cooling is controlled via a supply air damper (supply

air below min. temperature). In the event of forced

ventilation, the cooling controller (10V on cooling output

UO2) is set to full cooling (full supply air flow) regardless

of the controller output signal.

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

STRA-04 for Optivent

Fläkt Woods 8 Specifications are subject of alteration without further notice.

CO 2 control (P control)

Fläkt Woods STRZ-18-1 is an active CO 2 sensor

(0-10V)and is activated in room controller by setting

parameter 81 to 5. When the controller exceeds the CO 2

value (parameter 112 FS =500 ppm), it starts controlling

against a fully open damper (UO3). The damper opens

fully at Parameter 113 (FS=1000 ppm). Heating/Cooling

(PI) in controlled concurrently with the CO 2 control.

If heating is required, the heating signal increases on

heating output UO1.

Window contact

When the window contact has been configured, the

regulator is set to normal operation when the window is

closed. When the window is open, the controller goes into

Off mode, the heating and cooler outputs are set to 0 V

and the frost protection function is activated.

Frost protection

STRA-04 has built-in frost protection, which is activated

when the controller is not in use. The frost protection

prevents the temperature from dropping below 8°C. The

fan speed and controls automatically return to normal

when the frost protection is deactivated.

Control the light with an occupancy sensor

It’s possible to control the operation of the light with

an occupancy sensor through a relay and its socket

(STRZ-73-b). The light will switch off when the room

is unoccupied. The socket for wiring is screwless quick

connection.

Parameter 60 should be changed to 1 when using this

function.

Wiring diagram

Parameter settings

STRA-04 is delivered with a number of factory settings.

To achieve the desired function, the controller must

be adapted to its application. This is done via the

parameter menu in the display. The applications can vary

dramatically, and incorrectly set parameters can impair

the controller's and application's function. For this reason,

make sure you set the parameters that are critical to your

particular application. If in doubt, contact Fläkt Woods

TSS Controls.

Parameter menu

In STRA-04, various parameter values can be set in a

parameter menu. This parameter menu is accessed by

simultaneously pressing the INCREASE and DECREASE

buttons for about 5 seconds until the Service indication

lights up in the display. After this, press the INCREASE

button twice.

Initially, the parameter menu will only show a parameter

number (P01, P02, P03 etc.). You can scroll between the

parameters by pressing the INCREASE and DECREASE

buttons. When the right parameter has been selected,

press the Function button. The parameter value will be

shown and the parameter number will disappear.

The parameter value can now be changed with the

INCREASE and DECREASE buttons. When the

INCREASE and DECREASE buttons are held pressed

down, the value in the display will start scrolling, first

slowly and then with increasing speed, in about 3-4 steps

with roughly 2-3 seconds between the steps.

Confirm/Reject

To confirm the changed parameter, press the Function

button again. The display will return to showing the

parameter number. Before confirming the change, you can

retrieve the original value (the value that was displayed

before you made the change) by simultaneously pressing

the INCREASE and DECREASE buttons. The original

value will be shown on the display.

Return

After about 1 minute, or when the INCREASE and

DECREASE buttons are pressed simultaneously while

you are in the menu, the display will return to normal.

The word Exit will appear in the display after the last

parameter. By pressing the Function button when Exit

appears, you can exit the parameter menu. If you press

INCREASE, you reach the first parameter. If you press

DECREASE, you reach the last parameter.

8790 GB 2016.03

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

Fläkt Woods 9 Specifications are subject of alteration without further notice.

STRA-04 for Optivent

Parameters

The following parameters are modifiable in the parameter menu FS = factory-set value):

Parameter

number

Description Values Unit FS STRA-04

1 Occupied Heating Setpoint N/A °C 22

2 Occupied Cooling Setpoint N/A °C 24

3 Standby Neutral Zone N/A °C 3

4 Unoccupied Heating Setpoint N/A °C 19

5 Unoccupied Cooling Setpoint N/A °C 27

6 Frost protection Setpoint N/A °C 8

7 P-Band N/A °C 10

8 I-Time N/A Seconds 300

9 Cooling Changeover difference temperature (Room and

media)

N/A °C 3

10 Heating Changeover difference temperature (Room and

media)

N/A °C 4

11 Heating/Cooling Functions 0=Heat, 1=Heat/Heat, 2=Heat or Cool via changeover,

3=Heat/Cool, 4=Heat/Cool with VAV and forced

ventilation, 5=Heat/Cool with VAV, 6=Cool, 7=Cool/Cool,

8=Heat/Cool with UO3, 9=Heat/Cool with Change-Over

4

12 Boost Mode Timer N/A Minutes 60

13 P.I.R Delay Off N/A Minutes 10

14 P.I.R Delay On N/A Minutes 0

15 Connected sensor on AI1 0=internal, 1=external, 2=Change over sensor 0

16 UI1 Signal 0 = Disabled, 1 = Change over sensor digital, 2 =

Change over sensor analogue

2

17 Connected sensor DI1 Input 0=Disabled, 1=Window contact, 3=P.I.R, 4=Change over

sensor

0

18 Connected sensor DI2 input 0=Disabled, 1=Window Contact, 2=Condensation

Sensor, 4=Change over sensor

0

20 Function of UO1 Signal 0=None, 1=Thermal actuator heat, 2= None, 3=Heating

actuator 0...10V, 4= None, 5=On/off actuator heat, 6=

None

1

21 Function of UO2 Signal 0= None 1= None, 2=Thermal actuator Cool, 3=

None, 4=Cooling actuator 0…10V, 5= None, 6=On/off

actuator cool

4

22 Function of UO3 Signal 0=None, 1=Forced Vent Digital, 2=Forced Vent 3 Step

Analog, 3=None, 4=Ordinary Analog output, 5=None,

6=Control of EC-fan

1

24 UO3 output in manual mode N/A % 0

28 Actuator type for UO3 0=0-10v, 1=2-10v, 2=10-2v, 3=10-0v 1

29 Heating Modulating Actuator Control 0=0-10v, 1=2-10v, 2=10-2v, 3=10-0v 0

30 Cooling Modulating Actuator Control 0=0-10v, 1=2-10v, 2=10-2v, 3=10-0v 0

31 Heating Thermal Actuator Time N/A Seconds 60

32 Cooling Thermal Actuator Time N/A Seconds 60

33 Travelling Time for Increase/Decrease Heating Valve

(Not in use)

Seconds 120

34 Travelling Time for Increase/Decrease Cooling Valve

(Not in use)

Seconds 120

35 Increase/Decrease NZ (Not in use) % 2

36 Heating Valve Periodic Exercise Interval 0=Inactive Hours 23

37 Cooling Valve Periodic Exercise Interval 0=Inactive Hours 23

38 Hysteresis for the heating thermostat function N/A K 2

39 Hysteresis for the cooling thermostat function N/A K 2

40 The minimum heat output in heating mode N/A % 0

41 Fan runs on low speed (Not in use) 0

42 Display View 0=Actual Temp Value, 1=Heating Setpoint, 2=Cooling

Setpoint, 3=Average of Heating/Cooling, 4=Only

Setpoint Displacement, 5=CO2, 6=Heating Setpoint +

Setpoint Displacement, 7=Cooling Setpoint + Setpoint

Displacement, 8=Average of Heating/Cooling Setpoints

+ Setpoint Displacement, 9=Calculated Flow in L/S

0

43 Highest Setpoint Offset Increase N/A °C 3

44 Lowest Setpoint Offset Decrease N/A °C 3

45 Normal Mode Function 0=Off, 1=Unoccupied, 2=Stand-by, 3=Occupied 3

46 Energy Saving Mode Function 0=Off, 1=Unoccupied 1

47 BMS Operating Mode 0=Off, 1=Unoccupied, 2=Standby, 3=Occupied, 4=Not

Used, 5=No Remote control

5

48 Minimum airflow on cooling UO2 in % of 0-10V.

Parameter is in use when cooling/heating mode with

VAV is selected

N/A % 0

49 Maximum airflow on cooling UO2 in % of 0-10V.

Parameter is in use when heating/cooling mode with

VAV is selected

N/A % 0

50 Fan Control (Not in use) 0=No Control, 1=Heating, 2=Cooling, 3=Both

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

Fläkt Woods 10 Specifications are subject of alteration without further notice.

STRA-04 for Optivent

Parameters

The following parameters are modifiable in the parameter menu FS = factory-set value):

Parameter

number

Description Values Unit FS STRA-04

51 Fan Speed 1 Limit (Not in use) %

52 Fan Speed 2 Limit (Not in use) %

53 Fan Speed 3 Limit (Not in use) %

54 Fan Start/Stop Hyst (Not in use)

55 Fan Speeds

56 External Temperature Sensor Calibration Gain AI1 N/A °C 0

57 Sensor Calibration Gain UI1 N/A °C 0

58 Internal Temperature Sensor Calibration Gain N/A °C 0

59 Filter factor for AI temperature N/A °C 0.2

60 Normally open/Normally closed DI1 0=N/O, 1=N/C 0

61 Normally open/Normally closed DI2 0=N/O, 1=N/C 1

62 Normally open/Normally closed UI1 0=N/O, 1=N/C 0

63 Heating Manual Override 0=Off, 1=Manual, 2=Auto 2

64 Cooling Manual Override 0=Off, 1=Manual, 2=Auto 2

65 Forced ventilation Manual Override 0=Off, 1=Manual, 2=Auto 2

66 Changeover Manual Override 0=Heating, 1=Cooling, 2=Auto 2

67 Manual Mode Heating Output N/A % 0

68 Manual Mode Cooling Output N/A % 0

69 Modbus Address N/A Set by production

(same as EXOline

ELA)

70 Modbus Parity 0=None, 1=Odd, 2=Even 2

71 Modbus Timeout N/A Milliseconds 3

72 Modbus Response Delay N/A Milliseconds 5

73 Heating output 0 = For N/C-actuator, 1=For N/O-actuator 0

74 HMI Displacement View 0=The offset, 1=The active setpoint + offset, 2=The

heating setpoint + offset, 3=The cooling setpoint

+ offset, 4=Occupied Heating Setpoint + Offset,

5=Occupied Cooling setpoint + Offset, 6=Occupied

Average + Offset

0

75 Free Cooling 0=Not Available, 1=Available 0

76 Forced Ventilation control mode 0=No Action, 1=Forced on Heat/Cool output at 100%,

2=Forced on Cool output at 100%

2

77 P.I.R Activated Operation Mode 3=Occupied, 4=Bypass 3

78 The Controller PLA Address. Used in EXOline Set by Production

79 The Controller ELA Address. Used in EXOline Set by Production

80 Cool output 0 = For N/C-actuator, 1=For N/O-actuator 0

81 AI2 Input 0=Disable, 5=CO2, 7=0-100% , 8=Flow calculation,

9=0-10V

0

82 Flow at 0 volt on AI2 (Not in use) l/s

83 Flow at 10 volt at AI2 (Not in use) l/s

84 The minimum time the valve is open when the calculation

of change over is made

N/A Seconds 60

86 Alarm triggers when temperature falls below N/A °C 15

87 Alarm triggers when temperature raise above N/A °C 40

97 CO2 Level to Change to Boost Mode N/A PPM 1200

98 CO2 Level below "Boost Mode CO2 Start" value to start

Boost Mode Timer countdown

N/A PPM 160

100 AI CO2 Filter N/A 0.2

104 CO2 Sensor PPM for 0v N/A PPM 0

105 CO2 Sensor PPM for 10v N/A PPM 2000

112 VAV CO2 Minimum Limit N/A PPM 500

113 VAV CO2 Maximum Limit N/A PPM 1000

114 Port Mode 0=EXOline/Modbus, 1=BACnet 0

115 BACnet address Above 127 = Slave Set by Production

(Last 2 Digits of

ELA)

116 BACnet device ID low 4 figures N/A Set by Production

(" A " of PLA &

ELA)

117 BACnet device ID high 3 figures N/A Set in Production,

uses "PL" of PLA

118 BACnet Max Master N/A 127

119 Com Speed Com bus speed 0=9600, 1=19200, 2=38400,

3=76800 (BACnet)

120 Reset com to factory default (Modbus 9K6, 8, N, 1) N/A

121 The lowest output the fan will need to start (Not in use) V

122 The highest speed of the fan (Not in use) V

125 The Model in Regin Range 1939 = STRA-07, 1943 = STRA-04, 1945 = STRA-14 Read Only 1943

126 Major Version N/A

127 Minor Version N/A

128 Branch Version N/A

129 Revision N/A

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

Fläkt Woods 11 Specifications are subject of alteration without further notice.

STRA-04 for Optivent

Parameters

The following parameters are modifiable in the parameter menu FS = factory-set value):

Parameter

number

Description Values Unit FS STRA-04

300 Voltage x 10 for nozzle 2 % N/A

301 Voltage x 10 for nozzle 3 % N/A

302 Voltage x 10 for nozzle 4 % N/A

303 Voltage x 10 for nozzle 5 % N/A

304 Max air level at 100% cooling N/A

305 Max air level at 100% CO2 N/A

306 Air level at Off, Unoccupied & Standby N/A N/A

307 Air level at Occupied mode N/A N/A

308 Air level Boost mode (Button only) N/A N/A

309 Free Cooling 0=Not Available, 1=Available See 75

322 Type of STRA 0=STRA-04, 1=STRA-14 Set by production

323 The floor the STRA is placed at 9999=Not Used in IPSUM 0

324 The room the STRA is placed 9999=Not Used in IPSUM 0

325 High 4 digits of the serial number

326 Mid 4 digits of the serial number

327 Low 4 digits of the serial number

328 Legacy Mode, set to 0 to use the old wiring terminal

order

0=Air on Pin 24, Boost on Pin 22, 1=Air on Pin 22,

Boost on Pin 24

1

8790 GB 2016.03

STRA-04 Room controller. Installation and maintenance manual.

User instruction

Fläkt Woods 12 Specifications are subject of alteration without further notice.

1. A brief pressure on the function key toggles between

forced supply air and normal operation.

Forced supply air is indicated by this symbol:

2. A long pressure (over 5 seconds) on the function key

shuts the controller off, i.e. it goes into sleep mode. The

background lighting on the screen is shut down.

3. A new brief pressure re-starts the controller and it goes

initially to forced supply air.

8790 GB 2016.03

Table of contents

Other flakt woods Temperature Controllers manuals