flamco MeiTronic W10B User manual

DEDE

W10B, W10, W20

Weather compensated heating controller

Witterungsgeführte Heizungsregler

3

EN

WEATHER COMPENSATED

HEATING CONTROLLER

W10B, W10 AND W20

INTRODUCTION

Weather compensated controllers W.. are intended for control of direct and/or mixing

heating circuit or two mixing heating circuits and d. h. w. warming with a boiler, solar

collectors and other energy sources.

4

EN CONTENTS

Introduction .....................................................................................................................................................3

USER MANUAL

Controller description..................................................................................................................................6

Initial controller setup..................................................................................................................................7

Graphic LCD display...................................................................................................................................10

Description of symbols presented on the display........................................................................... 11

Help, messages and warnings screen..................................................................................................16

Entering and navigating throug the menu ........................................................................................ 17

Menu structure and description............................................................................................................. 18

Temperature settings................................................................................................................................ 23

User functions ..............................................................................................................................................24

Operating mode selection....................................................................................................................... 27

Setting time programs.............................................................................................................................. 29

Basic settings ................................................................................................................................................ 31

Data overview .............................................................................................................................................. 33

SERVICE SETTING MANUAL

Controller parameters...............................................................................................................................34

User parameters.......................................................................................................................................... 35

Service parameters ....................................................................................................................................42

Parameters for floor screed drying .....................................................................................................65

Factory settings ..........................................................................................................................................66

Basic descriptions of controller operation .......................................................................................67

Mixing heating circuit.....................................................................................................................67

Direct heating circuit......................................................................................................................69

Heating curve....................................................................................................................................70

Liquid fuel boiler .............................................................................................................................. 72

Heat pump.......................................................................................................................................... 73

Pump for additional mixing in the boiler (Bypass pump) ............................................... 73

Domestic hot water ........................................................................................................................74

Domestic hot water circulation..................................................................................................76

Remote heating activation...........................................................................................................76

Operation of heating systems with two heat sources...................................................... 77

Divert valve operation by systems with two heat sources............................................. 78

Dierential controller.....................................................................................................................80

Minimum R6 pump speed level setup .....................................................................................80

Solar collector pump - impulsive mode................................................................................... 81

Source control with the Y2 analogue output ....................................................................... 82

Operation modes by sensors malfunction............................................................................. 83

Marking and description of temperature sensors...............................................................84

Sensor simulation ............................................................................................................................84

5

ENCONTENTS

INSTALLATION MANUAL

Controller installation................................................................................................................................ 85

Electrical connection of the controller...............................................................................................86

Connection of cables and sensors....................................................................................................... 87

Connection of temperature sensors ..................................................................................................88

Domestic hot water tank .........................................................................................................................89

RCD room units ...........................................................................................................................................90

Expanding the system on multiple heating circuits.......................................................................91

Connction of controller with internet cloud service HeatNext ................................................ 93

Installation and connection of VT safety limiter ............................................................................94

Controller malfunction and servicing ................................................................................................. 95

Technical data..............................................................................................................................................96

Disposal of old electrical & electronic equipment.........................................................................97

Hydraulic schemes .................................................................................................................................. 203

6 User Manual

EN

7

9

10

8

4

5

3

6

2

1Graphic display. button (one step back,

decrease).

Y2 output for energy source control. button (enters a menu,

confirms selection).

Y1 output for solar circulation

pump control.

button (Help).

button (one step forward,

increase).

Cover of the connection area.

button (Esc - return to previous). Screw for fastening the cover.

CONTROLLER DESCRIPTION

8

10

96

5

7

2

1

3

4

7User Manual

EN

INITIAL CONTROLLER SETUP

W.. heating controllers are equipped with an innovative solution which enables the

setup of controller in just three or four easy steps.

When the controller is connected to the network for the first time, the display first

shows the program version and company logo and then the first step of the procedure

for controller settings is presented.

STEP 1 - SET LANGUAGE

The controller requires a confirmation of language

selection with the button. In case you chose the

wrong language, return to the language selection

with the button.

Use buttons and to select the desired language.

Confirm the selected language by pressing .

If you do not find the desired language in the first screen, move to the next

screen with .

All schemes with mixing heating circuit are

available for radiators and floor/wall heating.

STEP 2 - SET HYDRAULIC SHEME

Select a hydraulic scheme for controller operation.

Move between schemes with buttons and

.

Confirm the selected scheme by pressing .

8 User Manual

EN INITIAL CONTROLLER SETUP

Later you can change the selected hydraulic scheme with service

parameter S1.1.

Later you can change the heating curve steepness with parameter P2.1.

The meaning of heating curve slope is described in chapter “heating curve”.

3. STEP - SET THE HEATING CURVE STEEPNESS FOR THE

FIRST CIRCUIT

The controller requires a confirmation of hydraulic

scheme with the button.

In case you choose the wrong scheme, return to

scheme selection with the button.

Set the heating curve steepness for room heating for

the first heating circuit.

Change the value with buttons and .

Confirm the selected value by pressing .

The controller requires a confirmation of the set

heating curve steepness with the button.

In case you choose the wrong heating curve

steepness, return to heating curve steepness

selection with the button.

9User Manual

ENINITIAL CONTROLLER SETUP

Later you can alter the set heating curve steepness with parameter P3.1.

The first and the second heating circuits are marked with their according

numbers on hydraulic schemes.

4. STEP - SET THE HEATING CURVE STEEPNESS FOR THE

SECOND CIRCUIT1

Set the heating curve steepness for room heating for

the second heating circuit.

Change the value with buttons and .

Confirm the selected value by pressing .

The controller requires a confirmation of the

heating curve steepness setting with the

button. In case you choose the wrong curve

steepness, return to heating curve steepness

selection with the button.

RESET

Disconnect the controller from power supply.

Press and hold the button and connect power supply.

Attention! The controller will be reset and requires additional setting. When

the controller is reset, all of its previous settings are deleted.

1This setting is not available in schemes with only one heating circuit.

10 User Manual

EN GRAPHIC LCD DISPLAY

On the LCD display we can look up all the important data for the controller operation.

DESCRIPTION AND PRESENTATION OF THE BASIC SCREEN

Review of temperatures, protection

functions and other data.

Heating circuit

Operation

mode

User functions

Room unit

Review of measured temperatures

Status of the controller’s control

outputs

Time and

date

Messages and

warnings

REVIEW OF DATA ON THE SCREEN:

Operation mode and user functions appear separately for each circuit on the upper

third of the screen. To switch between heating circuits and the screen with the

hydraulic scheme review use the button.

Temperatures, active outputs, protection functions and other data appear in the

middle section of the screen. To review temperatures and other data, use buttons

and . The number of sensors and other data displayed on the screen

depends on the selected hydraulic scheme and controller settings.

If you wish to retrieve the desired data after using the keyboard, look for the

data with buttons and , then confirm it by pressing the

button for 2 seconds.

If you press the button for 2 seconds, the temperature review will change

from a single line review into a double line review or vice versa. In the two-line

temperature review, the measured temperature appears in the first line, and

the desired or the calculated temperature appears in the second line.

11User Manual

EN

DESCRIPTION OF SYMBOLS

PRESENTED ON THE DISPLAY

SYMBOLS FOR HEATING CIRCUITS

SYMBOLS FOR OPERATION MODE INDICATION

Symbol Description

The first - mixing heating circuit.

The second - direct or mixing heating circuit.

D. h. w. warming.

Symbol Description

Room heating.

Room cooling.

Operation according to program interval - day temperature. *

Operation according to program interval - night temperature. *

Desired day temperature operating mode.

Desired night temperature operating mode.

D. h. w. warming according to program interval - switch-on interval. *

D. h. w. warming according to program interval - switch-o interval. *

Switch o.

Permanent switch-on of d. h. w. warming.

Manual operation mode.

Chimney sweep - emission measurement.

* The number inicates the first or the second time program accordingly.

12 User Manual

EN DESCRIPTION OF SYMBOLS

PRESENTED ON THE DISPLAY

Symbol Description

»PARTY« mode activated.

»ECO« mode activated.

Holiday mode activated.

One-time d. h. w. warming activated.

Anti legionella protection activated.

Liquid fuel boiler switch-o.

Solid fuel boiler switch-on.

Automatic switch over to summer heating mode.

Floor screed drying activated.

Operation with constant temperature of stand-pipe activated.

Remote switch-on.

Boost heating activated.

Symbol Description

Measured temperature.

Calculated or desired temperature.

Room temperature.*

Outdoor temperature.

Liquid fuel boiler temperature.

Solid fuel boiler temperature.

Gas boiler temperature.

Temperature of heat source obtained through BUS connection.

Combined fuel (liquid and solid) boiler temperature.

Heat source temperature - sensor in the pipeline.

SYMBOLS FOR OPERATION MODE INDICATION

SYMBOLS FOR INDICATION OF TEMP. AND OTHER DATA

- drying day

- duration of drying

* The number by the symbol or inside the symbol marks the first or the second heating circuit.

13User Manual

EN

* The number by the symbol or inside the symbol marks the first or the second heating circuit.

DESCRIPTION OF SYMBOLS

PRESENTED ON THE DISPLAY

Symbol Description

Stand-pipe temperature.*

Return-pipe temperature.*

Domestic hot water temperature.

Heat accumulator temperature.

Solar collectors temperature.

Floor screed temperature. *

Boiler return-pipe temperature.

Exhaust gas temperature.

Temperature of the area where heat pump is installed.

D. h. w. circulation pipe temperature.

Solar collectors temperature - dierential thermostat function.

Solid fuel boiler temperature - dierential thermostat function.

Heat accumulator temperature - dierential thermostat function.

D. h. w. storage tank temperature - dierential thermostat function.

Bypass pump - dierential thermostat function.

Burner.

Burner - second stage.

Bypass pump of the heating circuit (flashing indicates the pump

must be turned o).

R12345678

R12345678

Status of the controller's control outputs - relays are switched on.

Status of the controller’s control outputs - relays are switched o.

Mixing valve - closing (flashing indicates it must be closed).

Mixing valve - opening (flashing indicates it must be opened).

Change-over valve - closing.

Change-over valve - opening.

14 User Manual

EN

Symbol Description

Bypass pump for d.h.w.

Circulation pump for d.h.w.

Solar collectors bypass pump.

Boiler bypass pump.

Boiler leading pump.

Heat pump.

Electric heater.

Electric heater for d.h.w.

Output operation according to time program.

T1, T2, T3, ... T8

TR1, TR2

TA

TQ

Temperature measured by sensors T1, T2, T3, T4, T5, T6, T7 or T8.

Temperature measured by a room sensor or room unit.

Outdoor temperature, obtained through the BUS connection.

Heat source temperature, obtained through the BUS connection.

Y1 Y1 analogue output.

Y2 Y2 analogue output.

Symbol Description

Liquid fuel boiler overheating protection.

Solid fuel boiler overheating protection.

Solar collectors overheating protection.

Accumulator overheating protection.

D. h. w. storage tank overheating protection.

D. h. w. storage tank overheating protection - cooling directed into

the boiler.

D. h. w. storage tank overheating protection - cooling directed into

the collectors.

SYMBOLS FOR PROTECTION FUNCTIONS

DESCRIPTION OF SYMBOLS

PRESENTED ON THE DISPLAY

15User Manual

EN

Symbol Description

Devices connected to communication port COM.

Room unit is connected. The number beside room unit indicates,

whether this is the first or the second room unit.

Controller and communication port COM/BUS status.

Single controller - not in BUS network.

The first (master) controller in BUS network.

Intermediate (slave) controller in BUS network.

The last (slave) controller in BUS network.

Symbol Description

Message

In the event of exceeding the maximum temperature or when

a protection function is switched on, the controller will cause

an appropriate symbol on the display to flash. When maximum

temperature is no longer exceeded or when a protection

function has switched o, a turned on symbol will note the

recent event. By pressing the button, the message review

screen is retreived.

Error

In the event of sensor malfunction, BUS network error or COM

connection error, the controller will cause an appropriate symbol

on the display to flash. When the error is remedied or is no

longer present, a turned on symbol will note the recent event. By

pressing the button, the message review screen is retreived.

DESCRIPTION OF SYMBOLS

PRESENTED ON THE DISPLAY

SYMBOLS FOR THE INDICATION OF COMMUNICATION

BETWEEN DEVICES CONNECTED

SYMBOLS FOR MESSAGES AND ERRORS

Symbol Description

Protection again room freezing.

Frost protection - boliler switch-on to minimum temperature.

16 User Manual

EN HELP, MESSAGES AND

ERRORS SCREEN

By pressing the button, the help, messages and errors screen is retreived.

A new window opens in which the following icons are available.

Short instructions

Short instructions on the use of controller.

Controller version

Review of the controller type and program version.

Messages deletion

By pressing the button deletion of messages and errors all unconnected

sensors is executed.

Attention: You will not be able to delete the sensors necessary for the

controller’s operation.

Errors

List of sensors and other compounds malfunctions.

By pressing the buttons and navigate through the list of

errors. Exit the list by pressing the button.

Messages

List of exceeded maximum temperatures and list of protection functions

activations. By pressing the buttons and navigate through

the list of messages. Exit the list by pressing the button.

17User Manual

EN

If no button is pressed for some time, the screen lightning will be

switched o or reduced according to the setting.

ENTERING AND NAVIGATING

THROUG THE MENU

To enter the menu press the button.

To navigate through the menu, use buttons and , and confirm your

selection by pressing the button.

You can return to the previous screen by pressing .

18 User Manual

EN MENU STRUCTURE

AND DESCRIPTION

TEMPERATURES SETTING

Day temperature for circuit 1

Night temperature for circuit 1

Day temperature for circuit 2 *

Night temperature for circuit 2 *

D. h. w. temperature

USER FUNCTIONS

USER FUNCTIONS FOR THE FIRST HEATING CIRCUIT

PARTY operation mode.

ECO operation mode.

Holiday operation mode.

Function switch-o.

USER FUNCTIONS FOR THE SECOND HEATING CIRCUIT *

PARTY operation mode.

ECO operation mode.

Holiday operation mode.

Function switch-o.

USER FUNCTIONS FOR D.H.W.

* The setting is only available in schemes with two heating circuits.

19User Manual

EN

MENU STRUCTURE

AND DESCRIPTION

One-time switch-on of d.h.w.warming.

Function switch-o.

USER FUNCTIONS FOR ENERGY SOURCES**

One-time switch-on of liquid fuel boiler.

Switch-o of liquid fuel boiler.

Start-up of solid fuel boiler.

Function switch-o.

OPERATION MODE SELECTION

OPERATION MODE FOR THE FIRST HEATING CIRCUIT

Operation mode according to selected

time program.

Operation mode according to day temperature.

Operation mode according to night temperature.

Switch-o.

OPERATION MODE FOR THE SECOND HEATING CIRCUIT*

Operation mode according to selected

time program.

Operation mode according to day temperature.

Operation mode according to night temperature.

Switch-o.

* The setting is only available in schemes with two heating circuits.

** The setting is only available in schemes with change-over of heat sources.

20 User Manual

EN MENU STRUCTURE

AND DESCRIPTION

OPERATION MODE FOR D. H. W. WARMING

D. h. w. warming according to selected time

program.

Permanent switch-on of d. h. w. warming.

Switch-o.

SELECTION OF OPERATION MODE HEATING OR COOLING

MANUAL OPERATION OF OUTPUTS

CHIMNEY SWEEP

TIME PROGRAMS

TIME PROGRAM FOR THE FIRST HEATING CIRCUIT

The first time program.

The second time program.

TIME PROGRAM FOR THE SECOND HEATING CIRCUIT*

The first time program.

The second time program.

TIME PROGRAM FOR D. H. W.

The first time program.

The second time program.

BASIC SETTINGS

* The setting is only available in schemes with two heating circuits.

This manual suits for next models

2

Table of contents

Languages:

Other flamco Controllers manuals

Popular Controllers manuals by other brands

National Instruments

National Instruments sbRIO-9687 user manual

Hayward

Hayward RSR3 Series Installation, operation and maintenance instructions

Carrier

Carrier A Series installation manual

American Meter Company

American Meter Company 1213B2 Series Operating instructions manual

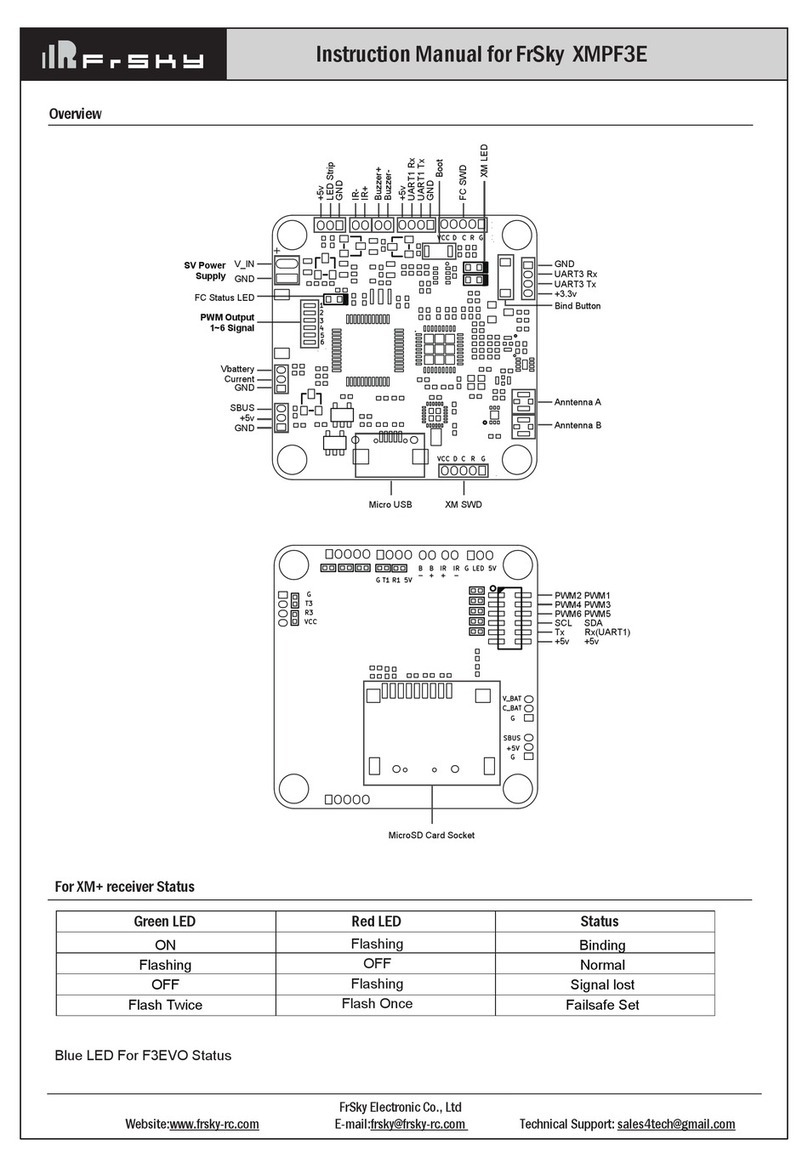

FrSky

FrSky XMPF3E instruction manual

Johnson Controls

Johnson Controls Hitachi C4IRK01 Operation manual