We reserve the right to change the designs and technical specifications of our products.

3

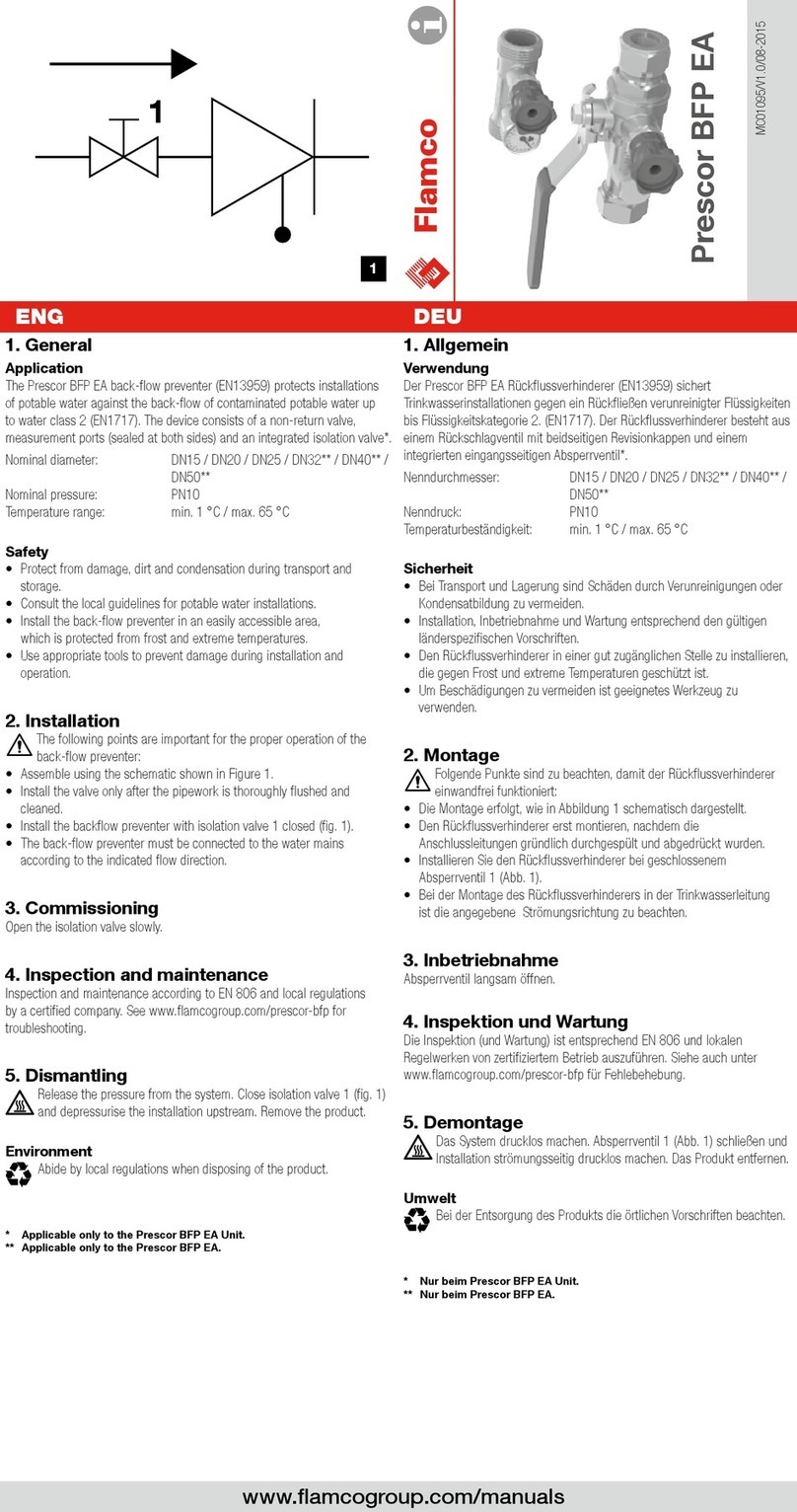

ENG

Table of contents

Acronyms .......................................................................................................................... 2

1. Safety instructions .................................................................................................... 5

1.1 Intended use ........................................................................................................................6

1.1.1 Use for intended purpose ................................................................................................................ 6

1.1.2 Improper use .................................................................................................................................... 7

1.2 Device designation...............................................................................................................7

1.3 Hazard notes........................................................................................................................7

1.4 What to do in the event of breakdown or leaks.....................................................................8

1.5 Spare and wear parts ...........................................................................................................8

1.6 Requirements on trained engineers......................................................................................8

1.7 Liability and copyrights........................................................................................................9

1.8 Earth bonding or protective earthing in accordance with VDE ..............................................9

2. Functional description ............................................................................................... 9

3. LogoThermic units ................................................................................................... 10

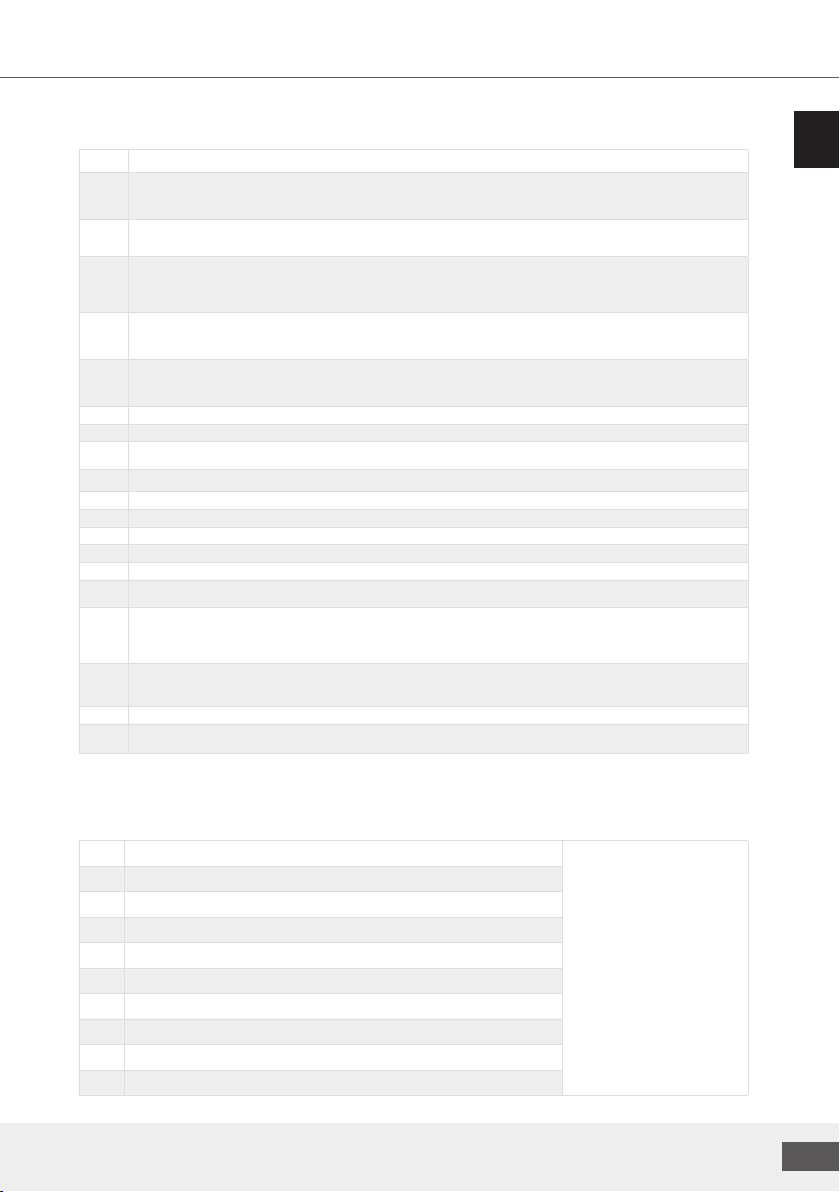

3.1 Technical data....................................................................................................................10

3.1.1 HIU characteristics and performance parameters........................................................................ 10

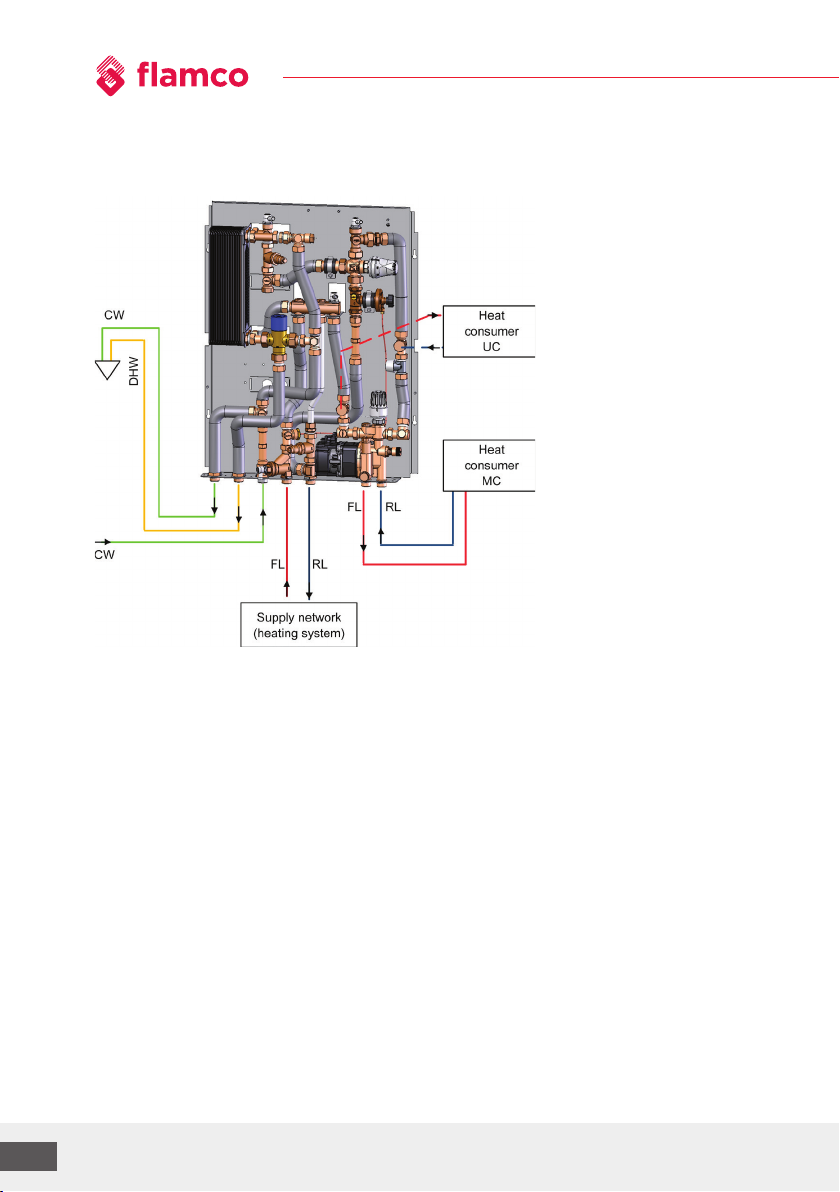

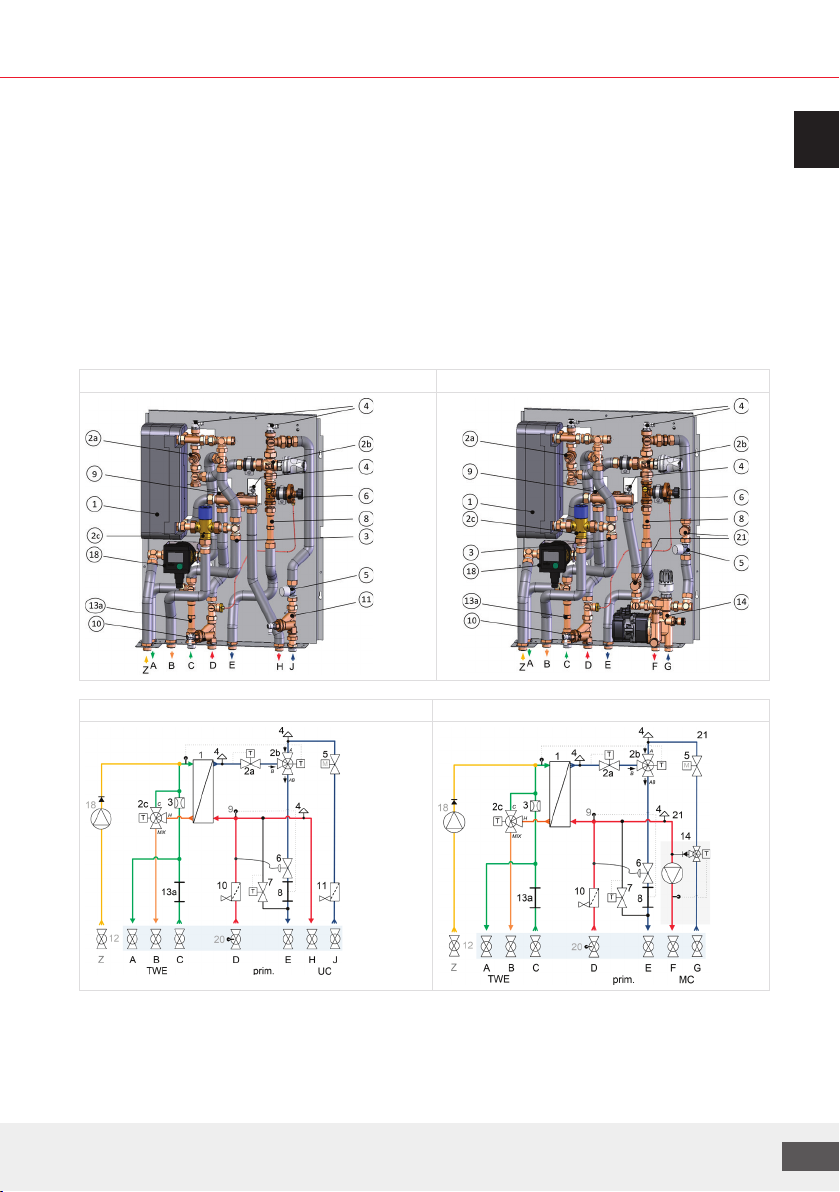

3.1.2 Components and hydraulic diagram...................................................................................11

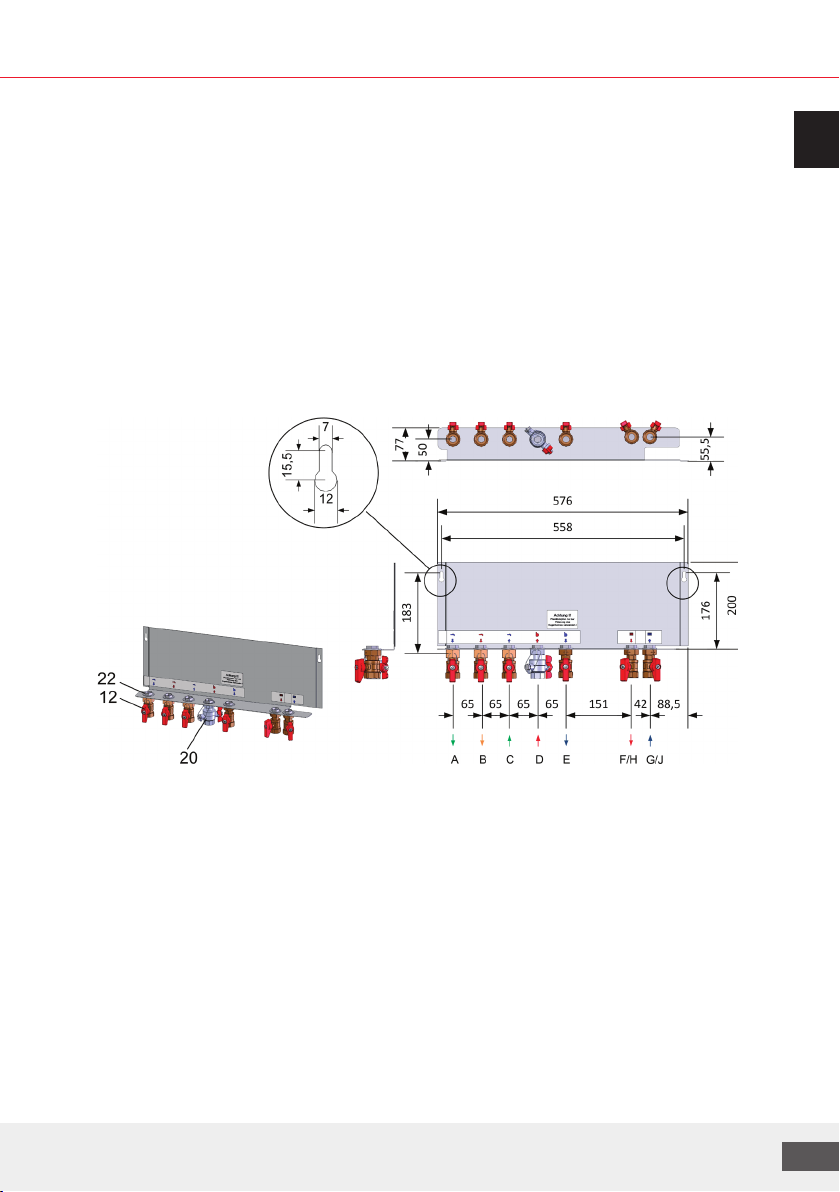

3.1.3 Dimensions ........................................................................................................................13

3.2 Variants..............................................................................................................................14

3.2.1 LogoThermic G2 with domestic hot water circulation (DWC) ...................................................... 14

3.2.2 Special variants .............................................................................................................................. 16

4. Installation ............................................................................................................. 16

4.1 SM/FM mounting rail with 7 ball valves (for MC/UC)............................................................17

4.2 DN20 ball valves, straight ...................................................................................................17

4.3 Completing stations ...........................................................................................................18

4.3.1 Optional heat meter installation ................................................................................................... 18

4.3.2 Optional water meter installation ................................................................................................. 18

5. Description of individual components and setting options .......................................... 19

5.1 Hot water limiter................................................................................................................19

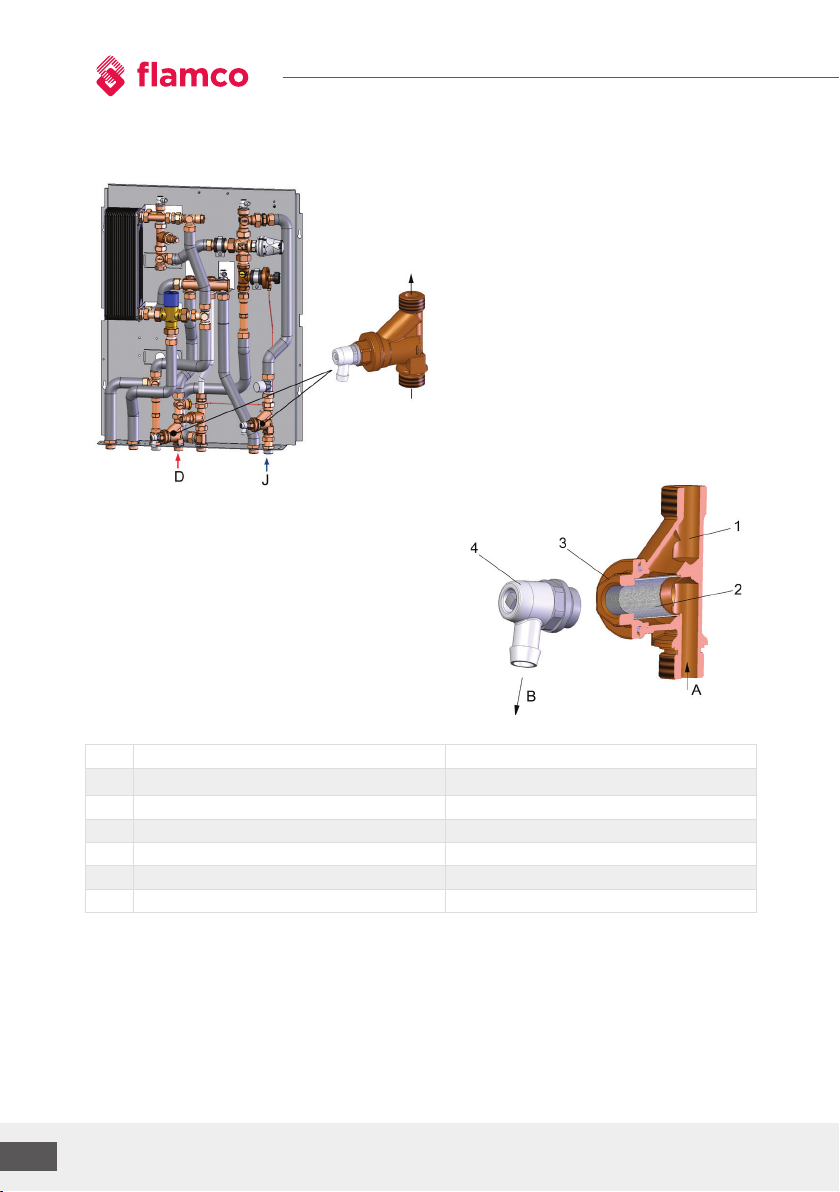

5.2 Dirt traps............................................................................................................................19

5.3 Zone valve for heating circuit .............................................................................................20

5.4 Dierential pressure regulator ...........................................................................................22

5.5 Thermostatic circulation bridge .........................................................................................23

5.6 Thermostatic control valves ...............................................................................................23

5.6.1 Thermostatic domestic water mixing valve, Flamcomix.............................................................. 24

5.6.2 Thermostatic head, type Rotherm II (only for stations with mixed heating circuit) ................... 25

5.7 Compact mixing circuit with high-eiciency pump (only for MC variant) ............................26

5.7.1 Secondary bypass on mixer (in compact mixing circuit).............................................................. 26

5.7.2 Heating circuit pump ..................................................................................................................... 26