Flare KP-017 Service manual

SWIMMING POOL HEAT PUMP UNIT

Installation & Instruction Manual

1. 1

2. Specifications 2

2.1 Performance Data of Swimming Pool Heat Pump Unit 2

2.2 Dimensions for Swimming Pool Heat Pump Unit 2

3. Installation and Connection 4

3.1 Installation of System 4

3.2 Swimming Pool Heat Pumps Location 5

3.3 How Close to Your Pool? 5

3.4 Swimming Pool Heat Pumps Plumbing 6

3.5 Swimming Pool Heat Pumps Electrical Wiring 7

3.6 Initial Start-up of the Unit 7

4. Usage and Operation 8

4.1 The Functions of the LCD Controller 8

4.2 How to Set Operation Parameter 8

4.3 To Choose Mode 9

4.4 How to know the Current Status 9

4.5 Operation Data Setting 10

5. Maintenance and Inspection 11

5.1 Maintenance 11

5.2 Trouble Shooting Guide 11

6. Appendix 12

6.1 Connection of PCB Illustration 12

Preface

CONTENTS

2.3 Discription of parts 3

1. PREFACE

●In order to provide our customers with quality, reliability and versatility,

this product has been made to strict production standards. This manual

includes all the necessary information about installation, debugging,

discharging and maintenance. Please read this manual carefully before

you open or maintain the unit. The manufacture of this product will not be hel

d responsible if someone is injured or the unit is damaged, as a result of

improper installation, debugging, or unnecessar y maintenance. It is vital

that the instructions within this manual are adhered to at all times.

The unit must be installed by qualifi ed personnel.

●The unit can only be repaired by qualified installer centre

personnel or an authorised dealer.

●Maintenance and operation must be carried out according to the

recommended time and frequency, as stated in this manual.

●Use genuine standard spare parts only.

Failure to comply with these recommendations will invalidate the warranty.

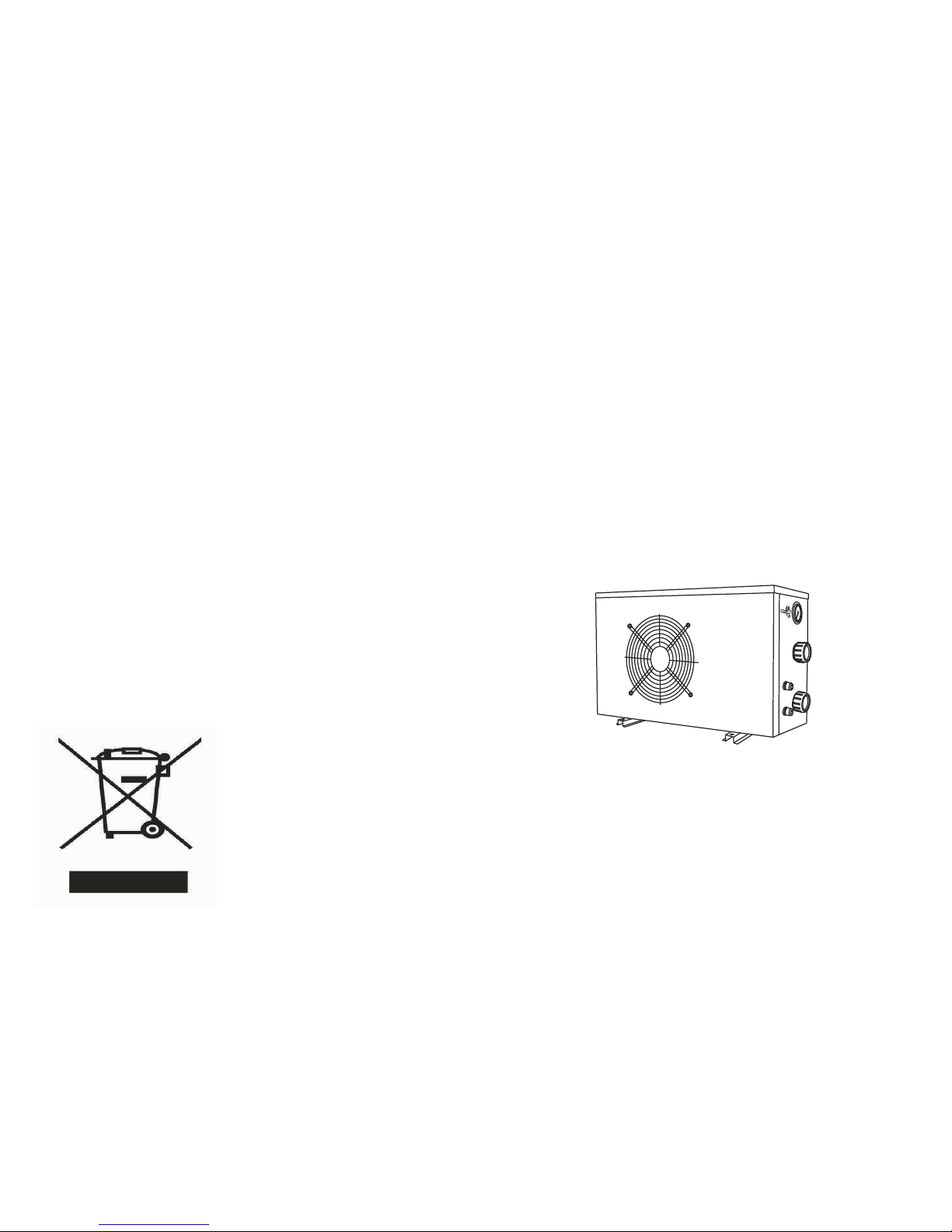

●Swimming Pool Heat Pump Unit heats the swimming pool water and

keeps the temperature constant.

This type of pump has the following characteristics:

1 Durable

The heat exchanger is made of PVC & titanium tube which can

withstand prolonged exposure to corrosives such as chlorine.

2 Installation flexibility

The unit can be installed outdoors or indoors.

3 Quiet operation

The unit comprises an effi cient rotary/ scroll compressor and a low-

noise fan motor, which guarantees its quiet operation.

4 Advanced controlling

The unit includes micro-computer controlling, allowing all operation

parameters to be set. Operation status can be displayed on the wire

controller.

1

6. APPENDIX

12

6.1 Connection of protectio n PCB illu stratio n

Y/G

C1

FAN MOTOR

C2

PCB

FM

XT1

RED

WHITE

R

S

C

COMPRESSOR

CM

CM

C1

BLACK

4

3

NL

LDB-1

C2

FM

OUT5

PCB

CONTROL BOARD

CREEPAGE

EXAMINE

LDB-1

WATER

TEMP.

COPPER

SENSOR

POWER

Y/G

COMPRESSOR

CAPACITOR 1

FAN MOTOR

CAPACITOR 2

COMPRESSOR

TEMPERATURE

/

3

CN3

LED

TRANSFORMER

AMBIENT

TEMPERATURE

BLACK

WHITE

CN1

CN2 CN4

WHITE

OUT4OUT3 OUT6 OUT7

M

HEATER

4

3

BLUE

BLUE

BLUE

BLUE

BLACK

YV1

YV2

BXT2

YV1 FOUR WAY

VALVE

YV2 SOLENOID

VALVE

XT1 TERMINAL

XT2 PUBLIC

TERMINAL

N

L

Y/G

2

2.SPECIFICATION

Check the water su pply devi ce and the release often. You sh ould avo id the condition of no water or air entering

into system , as this will influence unit's per formance and reliability. You sh ould clear the pool/sp a filter regularly

to avoid damage to the unit as a resu lt of the dirty of clogged filter.

The area ar oun d the un it shou ld be dr y, cl ean and wel l ve nt ilat ed. Cl ean the side heat ing ex chan ger

regul ar ly to mai nt ain good heat ex chan ge as con ser ve ene rgy .

The operation pressure of the refrigerant syst em sho uld only be se rvi ced by a cer tified technician .

Dischar ge all wat er in the wat er pump and wat er sys tem ,so that freez ing of the wat er in the pump or wat er

system does not occu r. You shou ld di schar ge the wat er at the bot tom of wat er pump if the un it wi ll not be

used for an ex tende d per iod of time. You shou ld che ck the un it thor ough ly and fill the sys tem wi th wat er

fully bef ore using it for the first time af ter a pr ol onge d per iod of no us age.

Check the power suppl y and cabl e con nec tion of ten, .Shou ld the un it begi n to oper ate abno rmal ly,

switch it of f and con tact yo ur cer tified Pol lrite tech nici an.

5.2 Trou bl e Sho ot ing Gui de

5.1 Mai nt enanc e

Malfuncti on LCD

Controlle r

Water te mp.

Sensor fail ure

Compressor Exhaust

temp. sensor failur e

Creepage

E 1

E 2

E 3

E 4

E 5

E 6

E 7

E 8

E 9

Reason

The sensor is open

or short circuit

Check or chan ge the sensor

Refrigerant is leakage.

The refrigerant system is block.

Ambient temperature is too high.

Resolut ion

Com pre sso r, motor, solen oid

valve , four way va lve,

capa cit or, co nd ense r he ater,

or electri cal ca ble are de fecti ve .

Ambient te mp.

Sensor fail ure

The sensor is open

or short circuit

Check or chan ge the sensor

The sensor is open

or short circuit Check or chan ge the sensor

The sensor is open

or short circuit Check or chan ge the sensor

Compressor over-current Compressor is over-load

Check the electrical parts and cable.

Wire controller

communication error

Condenser temp.

sensor failure

5. MAINTENANCE AND INSPECTION

11

refrigerant low pressure,

high pressure protection

signal cable of wire controller is loose.

wire controller is defective.

refrigerant pressure is

too low or to o high

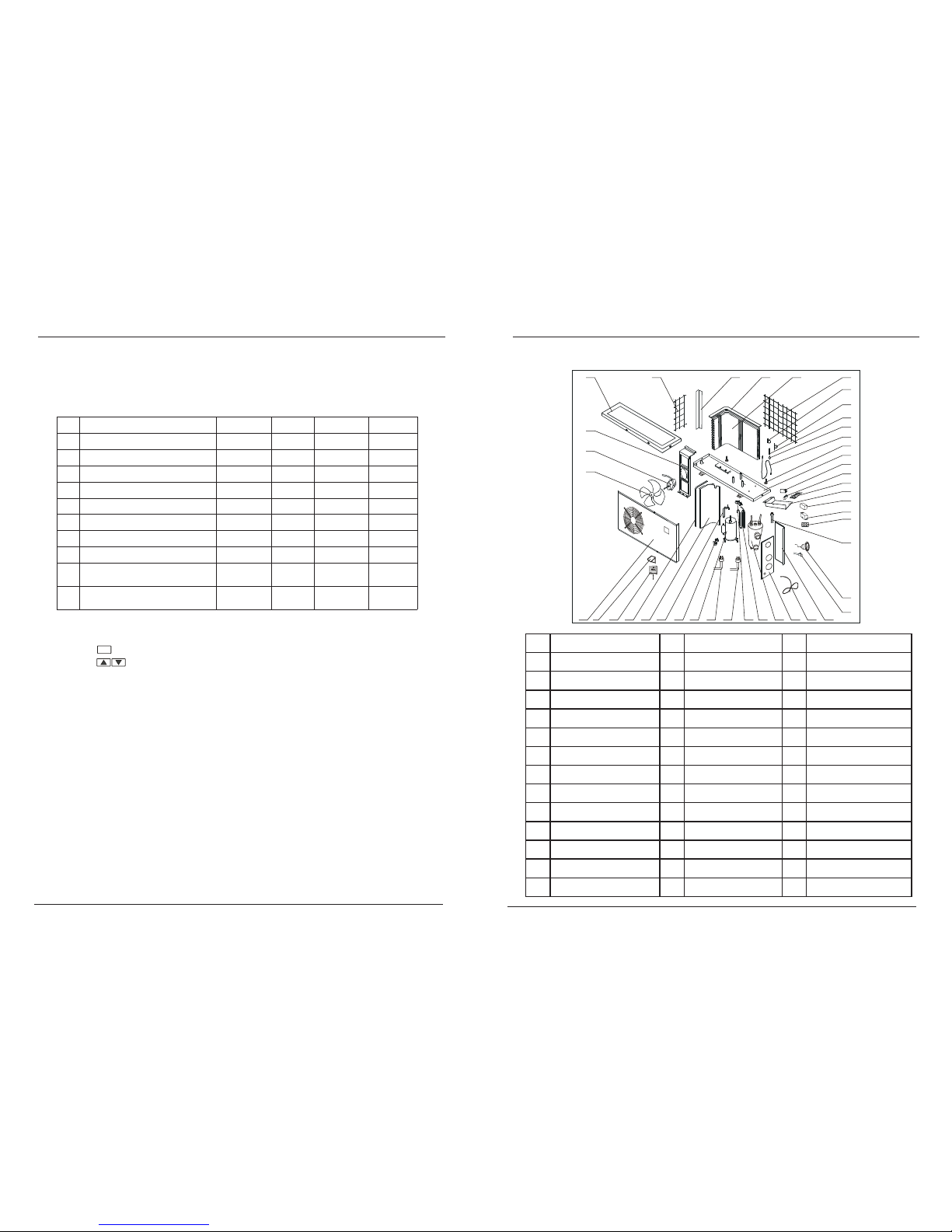

2.1 Per forma nce data of Swi mmi ng Pool Heat Pump Unit

UNIT Model

Heating Capacity kW

BTU/h

Heating Power Input kW

Running Current A

Power Supply V/Ph/Hz

Compressor Quantity

Compressor

Fan Quantity

Fan Power Input W

Fan Rotate Speed RPM

Fan Direction

Noise dB(A)

Water Connection mm

Water Flow Volume 3

m /h

Water Pressure Drop(max) kPa

Unit Net Dimensions(L/W/H) mm

Unit Shipping Dimensions(L/W/H)

mm

Net Weight/ Shipping Weight kg

KP-017

6.5

2200 0

1.7

8.5

220-240 /1/50

1

rotar y

1

50

850

hori zontal

47

50

1.5

6

955/305/550

1015 /330/610

53/58

2.2 The dimensions for Swimming Pool Heat Pump Unit

TYPE

B

A

C

D

SIZ E

E

F

unit:mm

KP-0 17

350

680

955

550

1015

380

A

B

D

C

E

F

Vertic al vis io n

Horiz onta l vis ion

Water Inlet

Water Outlet

Fan cover

Manometer

Water inlet pipe connector

Water outlet pipe connector

Air Inlet

Air Outlet

Power cable

Refrigerant charge valve

2.3 Discription of parts:

Compressor over-heat Compressor exhaust temp

is too high

Check signal cable of wire controller,

or change the w ire controller

Check refrigerant system.

1

2

3

4

5

6

7*

8

Turnround of defrosting

under heating mode

Defrost exit temp.

Temp. Of solenoid o valve switch on

Automatic restar ting

Mode(heating only/cooling & heating/

cooling only)

30~150min

5~45℃

3~15min

0/1/2

45min

25℃

3min

1

yes

time of exit defrost

under heating mode

yes

yes

yes

yes

yes

The unit's operation data can be set on the wire controller when the unit is on OFF

mode.

Please set according the below table:

Digit

0*

meaning

Max. setting water temp.

Range

0/1

(20~45/60℃)

default Adjust(yes/no)

yes

4. USAGE AND OPERATION

10

-7℃

1

0-1

0(no) 1(yes)

9

0/1 yes

Defrostin g start temp. -20~10℃

1

Water pump mode

*Remark:

All parameter can be set when the unit is OFF mode.

Press 3 seconds to enter in to settin g.

Press to change parameter.

All parameter can be revie w when the unit is ON mode,

but can not change.

Parameter 0:

0: temperature settin g range: 20~45 .

1: temperature settin g range: 20~60℃.

℃

0

3

Compressor protection exhaust temp. 70~110℃95℃

yes

0~25℃7℃

yes

M

Parameter 7:

0: alw ays open.

1: 30 seconds start before compressors start ing.

30 seconds stop aft er compressors stoppin g.

water pump stops when water temperature = settin g temperature.

fac tor y se tting

0

(20~45℃)

-7℃

15℃

F0 (150min)

3min

95℃

7℃

1

1

1

4.4 Operation data setting

2.SPECIFICATION

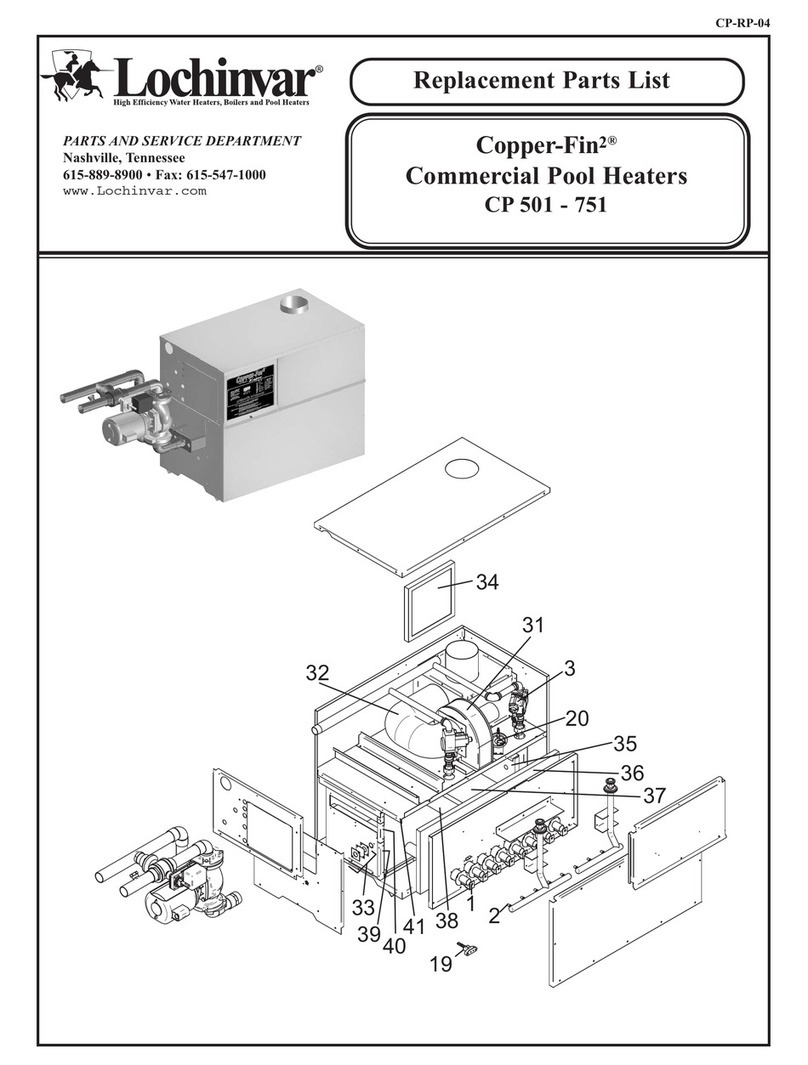

1 2 3 4 5 6 7 8 9 11 12 13 14 15 16

17

18

19

21

22

23

24

25

26

27

28

29

32

33

34353 6373839

40

41

42

30

10

20

31

1 Front panel 15 Power cord 29 Defrost sensor

2 Contr Right r d ol panel cover 16 ear boar 30 Filter

3 Wire controller 17 Refrigerant charge valve 31 One way valve

4 Verg Auxilliary capillary e board polyfoam 18 Pressure manometer 32

5 Verge board 19 Mouth of injecting gas 33 Capillary

6 Exhaust pipe 20 Terminal 34 Rear net

7 Solenoid valve 21 AC contactor 35 Condenser

8 Compressor 22 Cr Condenser top polyfoam eepage switch 36

9

High pressure interruptor (optional)

23 Electrical Box 37 Left carriage

10

Low pressure interruptor (optional)

24 Circuit Board 38 Left net

11 Four way valve 25 Motor Capacitor 39 Top cover

12 Gas returning pipe 26 Compre Motor bracket ssor capacitor 40

13 Titanium heat exchanger Frame Fan motor

27 41

14 Right size board 28 Feet 42 Fan

2.3 Explored view

Installation items:

The factory only provides the main unit and the water unit; the other items in the illustration

are necessary spare parts for the water system ,that provided by users or the installer.

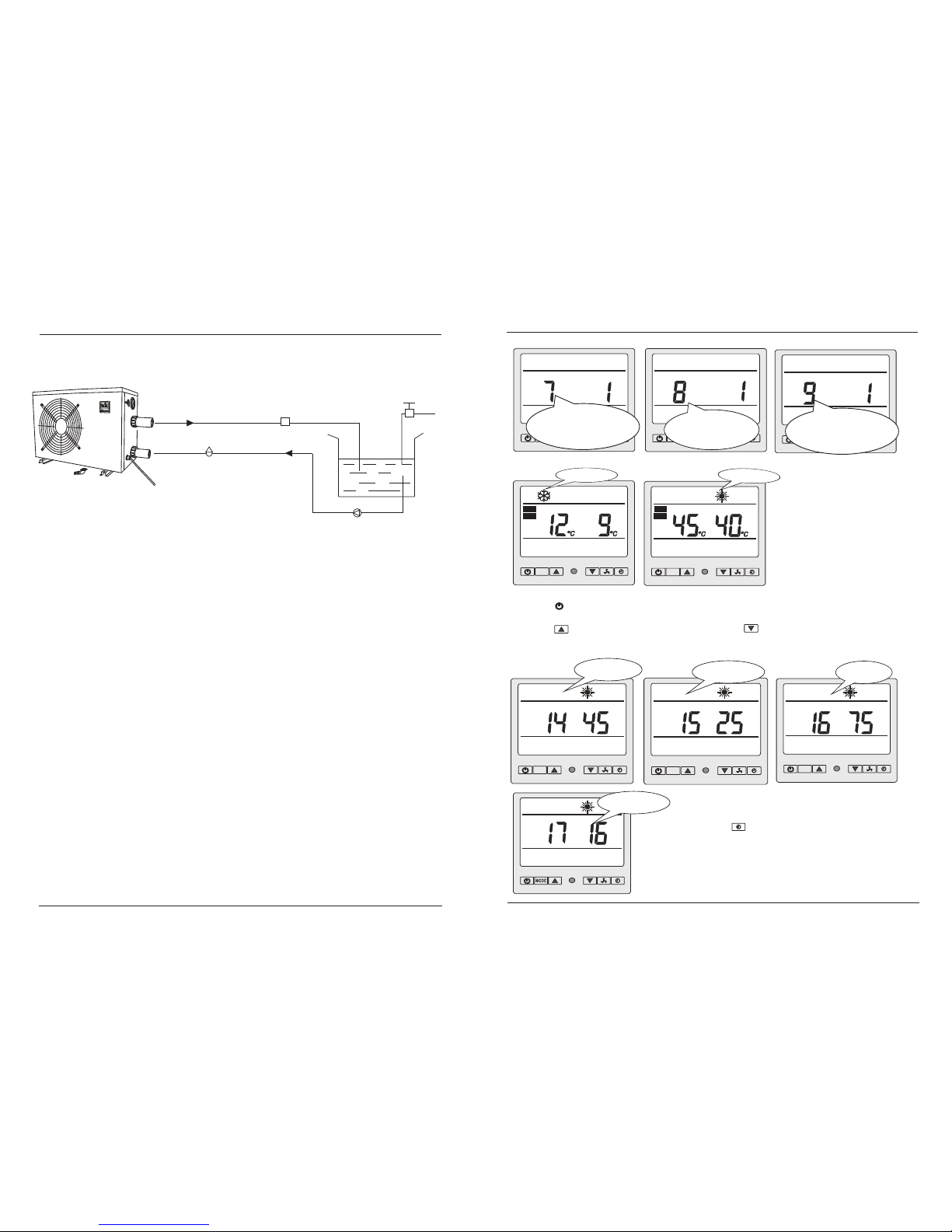

3.1 Installation illustration

Attention:

Please follow these steps when using for the first time

1.Open valve and charge water.

2.Make sure that the pump and the water-in pipe have been filled with water.

3.Close the valve and start the unit.

3.INSTALLATION AND CONNECTION

4

Chlori nato r cell

Wate r outle t

Pool

Valv e

Wate r

supply

Wate r inle t

Wate r pump

Sand fil te r

(or oth er ty pe fil te r)

4.3 How to choose Mode

Cooling mode Heating mode

M M

◎ Press “ M ” to choose mode(mode can be changed under running)

◎ Press “ ” to power on unit. Under running, the LCD displays the water setting temp,

water-out temp and current mode.

◎ Press ” to set temp. 1 degree higher, press ” to set temp. 1 degree lower.

4.4 How to know the current status?

Water outlet

temp. Ambient temp. compressor

exhaust temp.

M M M

Condenser temp.

◎Under running, press 3s to check the current status of the

unit. You can check water-out/ambient/compressor/condenser

temperature. If no buttons are depressed within 10 seconds,

the LCD will display water-setting/water-out temp.

When the unit is switched off, current water-out temperature

is displayed.

M

4. USAGE AND OPERATION

9

AUX

parame ter 9

Mode : 0(h eat ing onl y)

1(co oli ng an d heating)

2(he ati ng on ly)

fact ory s ett ing: 1

param eter 08

autom atic rest arting (0 /1)

facto ry settin g: 1

water p ump mode:

0: alre ady open

1: 30s st art befor e compres sor start

30s sto p after com pressor s top.

param eter 7

TEMP

SET

TEMP

SET

Con ne ct to po wer sup ply

4.1 The Functions of the LCD Controller

Heati ng mo de

(‘SUN’sym bol )

M

TEMP

C

C

SET

Pres s to turn on an d

turn of f the u nits.

Press to set and ch eck

the operat ion d ata .

Press to start ti mer on / tim er off.

Press 3 seconds t o che ck te mpe rat ure.

LCD srceen

Press b utton to ch oose cool ing or heat ing mode

Press t his butto n 3 seconds t o set or revi ew data.

M

water o utl et temp.

Param ete r valve

Cooli ng mo de

(‘SNOW’sy mbo l)

4.2 How to set operation parameter

M

compressor protectio n

exhaust temperature

(70~110℃)

factory setting: 95℃

parameter 1

to set the defrosting sta rt

temp. under heating mod e

(-20~10℃) factory setti ng:-7℃

parameter 2

defrosting exit tempe rature

(5~45℃)

factory setting: 15℃

parameter 4

tim e of defrostin g

(3-15 min)

factory setting: 3 min .

parameter 5

◎ Standby status-press" "button 3s to enter operation parameter setting interface.

◎ Press" "again to start setting(parameter from 0-9, see Operation Parameter Table).

◎ Under parameter setting, press " " or " " to set data for parameter from 0-9.

◎ N

,

◎ running, you can press " " 3s to check current parameter, but data can t

be changed.

o press in 10s, the LCD will display water-setting/water temperature (under running)or

water temperature (unit stops).

Whilst

4. USAGE AND OPERATION

8

The unit will perform well in any outdoor location provided that the following three factors are present -

1. Fresh Air - 2. Electricity - 3. Pool filter piping

The unit may be installed virtually anywhere outdoors. For indoor pools consult

the supplier. Unlike a gas heater, it has no draft or pilot light problem in a windy area.

DO NOT place the unit in an enclosed area with a limited air volume, where the units

discharge air will be re-circulated. DO NOT place the unit to shrubs which can block air inlet. These

locations deny the unit of a continuous source of fresh air which reduces it efficiency and

may prevent adequate heat delivery.

3.2 Swimming Pool Heat Pumps Location

Normally, the pool heat pump is installed within 7.5 metres of the pool. The longer

the distance from the pool, the greater the heat loss from the piping. For the most part ,

the piping is buried. Therefore,the heat loss is minimal for runs of up to15 metres

(15 metres to and from the pump = 30 metres total), unless the ground is wet or the

water table is high. A very rough estimate of heat loss per 30 metres is 0.6 Kw-hour,

(2000BTU) for

ever y 5 difference in temperature between the pool water and the ground

surrounding the pipe, which translates to about 3% to 5% increase in run time.

3.3 How Close To Your Pool?

5

3.INSTALLATION AND CONNECTION

Air inlet

Air outlet

2 5 00mm

700mm

3 0 0mm

500mm

700 m m

coerc ive

defro sti ng

M

M

M

temperat ure o f so l enoid valve

switch on (0 ~25℃)

factory se tti ng: 7℃

M

paramet er 6

M

parameter 3

Turnro und of defrosting

(30 ~ 150m in.)

factor y setting: 150 min.

pa ram eter 0

to set the max setting wate r

temp. (20~45/60℃)

factory setting: 20~4 5℃.

water setting t emp .

Digit no. Timer o n

Timer o ff

3.5 Swimming Pool Heat Pumps Electrical Wiring

NOTE: Although the unit heat exchanger is electrically isolated from the rest of the unit, it simply

prevents the flow of electricity to or from the pool water. Grounding the unit is still required to protect

you against short circuits inside the unit. Bonding is also required.

3.INSTALLATION AND CONNECTION

3.6 Initial startup of the Unit

circulate water through the heat exchanger.

Start up Procedure - After installation is completed, you should follow these steps:

1. Turn on your filter pump. Check for water leaks and verify flow to and from the pool.

2. Turn on the electrical power supply to the unit, then press the key ON/OFF of wire

controller, It should start in several seconds.

3. After running a few minutes make sure the air leaving the top(side) of the unit is cooler

(Between 5-10 ℃)

4. With the unit operating turn the filter pump off. The unit should also turn off

automatically,

5. Allow the unit and pool pump to run 24 hours per day until desired pool water

temperature is reached. When the water-in temperature reach setting, The unit just

shuts off. The unit will now automatically restart (as long as your pool pump is running)

when the pool temperature drops more than 2℃below set temperature.

Water Flow Switch - the unit is equipped with a flow switch that turns it on when the pool

pump is running and shuts it off when the pump shuts off. This switch is the same type used

in all gas pool heaters and is factory adjusted for normal pool installations. If the pool

water level is more than a few feet above or below the thermostat knob of the unit, your

dealer may need to adjust it at initial startup.

Time Delay- The unit is equipped with a 3 minute built-in solid state restart delay included

to protect control circuit components and to eliminate restart cycling and contactor

chatter. This time delay will automatically restart the unit approximately 3 minutes after

each control circuit interruption. Even a brief power interruption will activate the solid

state 3 minute restart delay and prevent the unit from starting until the 5 minute countdown

is completed. Power interruptions during the delay period will have no effect on the 3

minute countdown.

NOTE- In order for the unit to heat the pool or spa, the filter pump must be running to

7

The unit has a separate molded-in junction box with a standard electrical conduit nipple already

in place. Just remove the screws and the front panel, feed your supply lines in through the conduit

nipple and wire-nut the electric supply wires to the three connections already in the junction box

(four connections if three phase). To complete electrical hookup, connect Heat Pump by electrical

conduit, UF cable or other suitable means as specified (as permitted by local electrical authorities)

to a dedicated AC power supply branch circuit equipped with the proper circuit breaker,

disconnect or time delay fuse protection.

Disconnect - A disconnect means (circuit breaker , fused or un-fused switch) should be located

within sight of and readily accessible from the uni, This is common practice on commercial and

residential air conditioners and heat pumps. It prevents remotely-energizing unattended equipment

and permits turning off power at the unit while the unit is being serviced.

3.4 Swimming Pool Heat Pumps Plumbing

The Swimming Pool Heat Pumps exclusive full flow titanium heat exchanger

requires no special plumbing arrangements or bypass. The water pressure drop is

less than 10kPa at max. Flow rate. Since there is no residual heat or flame

temperatures, The unit does not need copper heat sink piping. PVC pipe can be run

straight into the unit.

Location: Connect the unit in the pool pump discharge (return) line

downstream of all filter and pool pumps, and upstream of any chlorinators,

ozonators or chemical pumps.

Standard model have slip glue fittings which accept 40mm NB

PVC pipe for connection to the pool or spa filtration piping. By using a

50 NB to 40NB you can plumb 50NB PVC piping straight into the unit.

Give serious consideration to adding a quick coupler fitting at the unit inlet and outlet

to allow easy draining of unit for winterizing and to provide easier access should

servicing be required.

Condensation: Since the Heat pump cools down the air about 4 -5℃, water

may condense on the fins of the horseshoe shaped evaporator. If the relative

humidity is ver y high, this could be as much as several litres an hour. The water

will run down the fins into the basepan and drain out through the barbed plastic

condensation drain fitting on the side of the basepan. This fitting is designed to

accept 3/4" clear vinyl tubing which can be pushed on by hand and run to a suitable

drain. It is easy to mistake the condensation for a water leak inside the unit.

NB: A quick way to verify that the water is condensation is to shut off the

unit and keep the pool pump running. If the water stops running out of the

basepan, it is condensation. AN EVEN QUICKER WAY IS to TEST THE DRAIN

WATER FOR CHLORINE - if the is no chlorine present, then it's condensation.

3.INSTALLATION AND CONNECTION

6

To pool

From pump

PVC COUPLER

RECOMMENDED(Provided)

CONDENSATION

DRAIN

BARB FTG

Table of contents

Popular Swimming Pool Heater manuals by other brands

Raypak

Raypak VERSA 185B Replacement parts

Raypak

Raypak VERSA 155C Operating and installation instructions

aquatherm

aquatherm AT800 installation manual

Rheem

Rheem Raypak Professional Series Installation and operating instructions

Brilix

Brilix XHP 200 Installation and user guide

DLP

DLP 30HPRA-E-410 owner's manual

Raypak

Raypak 406A Installation and operation manual

Pahlen

Pahlen 141600 Installation instruction

emaux

emaux HP3.8B Installation instructions manual

infrasave

infrasave 4002-CB Installation & owner's manual

iGenix

iGenix IG9512 Instructions for use

Lochinvar

Lochinvar COPPER-FIN II CP 992 -2072 Replacement parts list