FLARING FM 155E User manual

- 1 -

Operation Manual

FM155E MIG Welding Machine

- 2 -

Version

Due to product version upgrades or other reasons, the contents of this document are not regularly

updated. Unless otherwise agreed, this document is intended as a guide only and all statements,

information and recommendations in this document do not constitute any guarantee, expressed or

implied.

The pictures in this document are for reference only. If the picture is different from the real one, then

prevail in kind.

Contents

Contents......................................................................................................................................... - 2 -

1 Product brief introduction......................................................................................................... - 3 -

1.1 Summarize.............................................................................................................................................. - 3 -

1.2 Technical parameters.............................................................................................................................- 4 -

1.3 Accessories list.................................................................................................................................... - 5 -

2 Installation instruction............................................................................................................... - 6 -

2.1 Welding wire Installation steps:............................................................................................................- 6 -

2.2 MIG Torch explosive chart.................................................................................................................... - 7 -

2.3 Gas shielded welding Installation........................................................................................................ - 8 -

2.4 TIG Torch explosive chart ................................................................................................................... - 8 -

3 operating instructions............................................................................................................. - 10 -

3.1 Operation panel interface................................................................................................................... - 10 -

3.2 Welding operation instruction............................................................................................................. - 11 -

3.3 Polarity conversion joint...................................................................................................................... - 14 -

3.4 Welding environment and safety....................................................................................................... - 15 -

3.5 Welding problems and solution......................................................................................................... - 16 -

4 Trouble shooting and error checking.................................................................................- 17 -

5 Daily maintenance and checking....................................................................................... - 20 -

6 Attention................................................................................................................................. - 23 -

7 Appendix ⅠWelding parameter list.................................................................................. - 29 -

8 Service GUARANTEE......................................................................................................... - 31 -

- 3 -

1 Product brief introduction

1.1 Summarize

1IGBT Inverter

Technology

The principle is to use the single tube IGBT (the inverter frequency can reach

25-50KHz) to convert 50/60Hz to dc and then to high frequency and lower voltage

rectification,The pulse width modulation (PWM) output can be used for welding

high-power dc power supply ,due to switching power inverter technology is

adopted, the weight of the welder has dropped considerably, the conversion

efficiency of the whole machine is increased by more than 30%.

2SUPERIOR

PERFORMANCE

The machine can meet the requirement of gas protection welding. The gas

shielded welding machine is equipped with unique digital electronic reactor circuit.

The welding process of short circuit transition and mixed transition can be

controlled very precisely. It has excellent welding characteristics. Compared with

silicon controlled welder and tapped welder, it has the following advantages:

stable wire feeding speed, light energy, energy saving and no electromagnetic

noise。

It also has the characteristics of small splash,stable arc, deep pool and high

load.

3Wide Voltage

Our welding machine is equipped with power supply voltage compensation

device,The power supply voltage can continue to work when the rated voltage is

within 15% range.When using longer cables, in order to reduce voltage drop, use

a larger section of the cable is recommended or use the recommended

configuration length.

4Multifunction

The machine is a versatile product which include MIG gas, MIG gasless, Lift TIG ,

Stick welding and spool gun function. It has the advantages of high efficiency

and power saving, and it is suitable for welding of multi-metal and multi-process

requirements.

5Digital Control

The machine use full digital panel display ,Wire feeding speed and welding

voltage centralized regulation can be achieved. It is easier to adjust welding

parameters.Thanks to digital control, the machine comes with synergy software, it

match wire diameter, material and current. Excellent choice for freshman welder

and easier for welding professionals. Additional voltage and inductance setting for

professionals to find the precise welding performance for different project.

6Portability

The equipment applicable to family customers.Portable, light weight with only

12.8KG. 80% duty cycle on 116A, perfect for on-site job and DIY project.With

fluxed core wire, this welder can weld sufficiently without bringing heavy gas

cylinder. This is your ultimate welding stationary partner!

- 4 -

1.2 Technical parameters

Machine type FM 155E

Supply voltage (V) 1 phase AC 110V/ 220V±15%

Frequency (Hz) 50/60

Rated Max. input

current (A)

110

29 (MIG)

36.7 (STICK)

21.4 (TIG)

220

20 (MIG)

27.4 (STICK)

16.7 (TIG)

Output current

adjustment (A)

110V

30-100 (MIG)

30-100 (STICK)

30-100 (TIG)

220V

30-150 (MIG)

30-150 (STICK)

30-150 (TIG)

Output voltage (V)

110V

15.5-19 (MIG)

21.2-24(STICK)

11.2-14 (TIG)

220V

15.5-21.5 (MIG)

21.2-26(STICK)

11.2-16 (TIG)

No load voltage (V) 50±5

Duty cycle (%) 80

Power factor 0.7

Efficiency (%) 85

Wire feeder type All-in-one

Wire feed speed

(m / min) 2-15

Wire diameter (mm) 0.8/1.0

Insulation grade F

Enclosure protection

class IP21

Suitable plate

thickness (mm) 0.5-5

Net Weight (kg) 12.8

Overall dimension

(mm) 510×310×350

- 5 -

1.3 Accessories list

Order Number Pictures (Reference only) Name Qty

1FM 155E 1

2MIG Welding Gun Torch 1

3Welding Electrode Holder Set 1

4Earth Electrode Holder Set 1

5Gas hose 1

6Flux Cored Welding Wire 1

This equipment is mainly used in industry. In the indoor environment, the equipment may

produce radio interference. Please take precautions before use.

- 6 -

2 Installation instruction

2.1 Welding wire Installation steps:

The wire holder filled with wire installed on the wire feeder. The hole position of the wire plate

should be aligned with the fixed plug on the shaft.

The wire coil should be rotated and loosen the wire, to prevent the wire from loosening, the

new wire disk head is usually inserted into the fixed hole at the edge of the wire. In normal

use, to prevent the bending of the wire to be stuck, please cut this part of wire.

0.030”(0.8mm)/0.040”(1.0mm)diameter

4”(100mm 1kg)wire spool

According to the diameter of the wire, choose different wire feed roller.V roller for stainless

steel and carbon steel. Knurled roller for flux cored wire. Please match diameter notes on the

roller with the welding wire diameter.

Roller size: external diameter ∮25mm/ internal diameter ∮7mm/ height 7.5mm

- 7 -

Loosen the pressure wheel nut, to pass through the guide wire tube into the wire feed wheel

groove, adjust the pressure wheel pressure welding wire, guarantee the welding wire is not

sliding, and not blocking while feeding the wire.

The welding gun is inserted into the output socket of the front panel and screwed

tightly.

And put the wire into the gun.

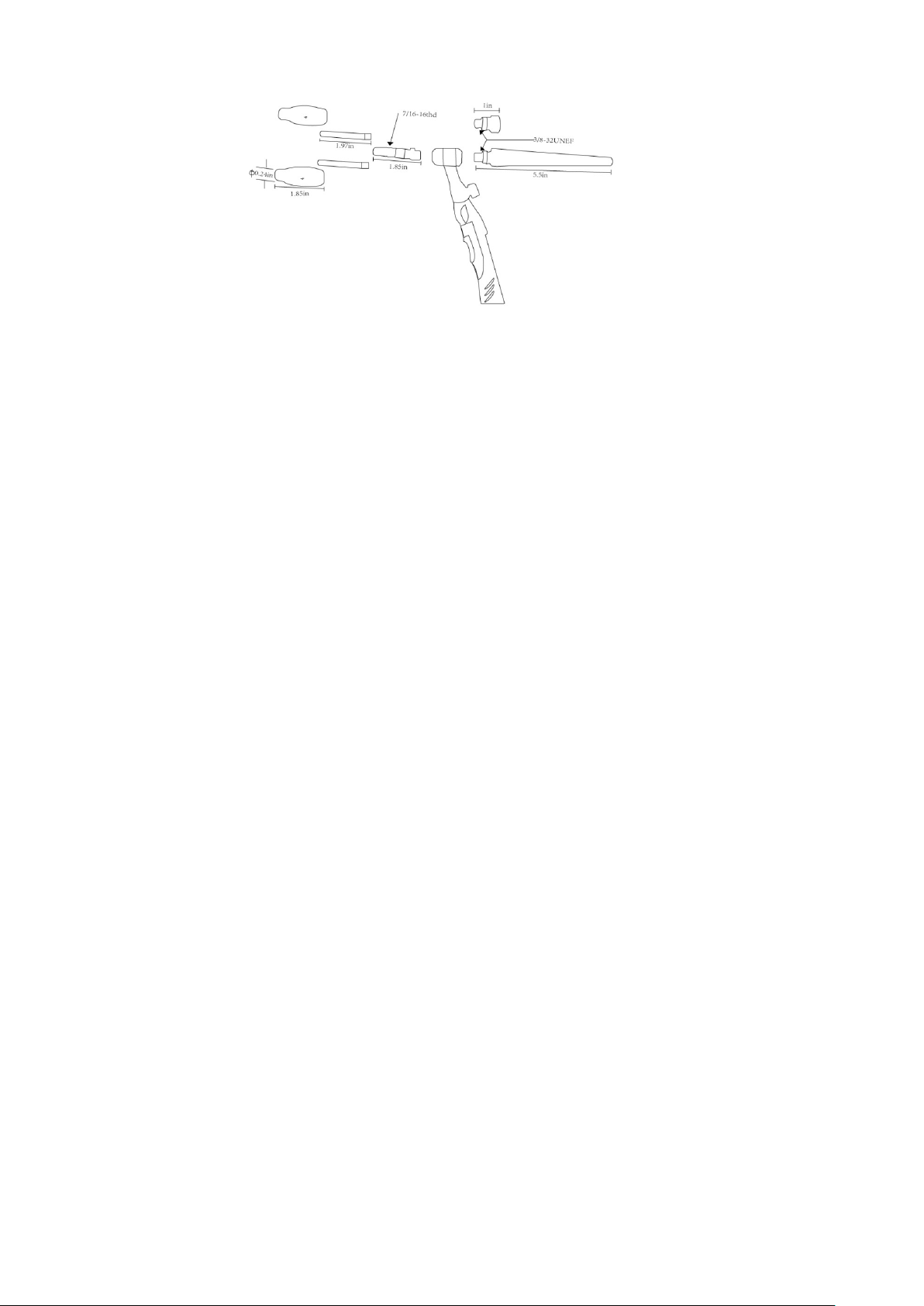

Unscrew the nozzle contact tip. And feed the wire through the torch. After the wire

successfully go through. Please install the contact tip. For fluxed core wire, please fasten

Ceramic nozzle, for solid wire please fasten copper nozzle.

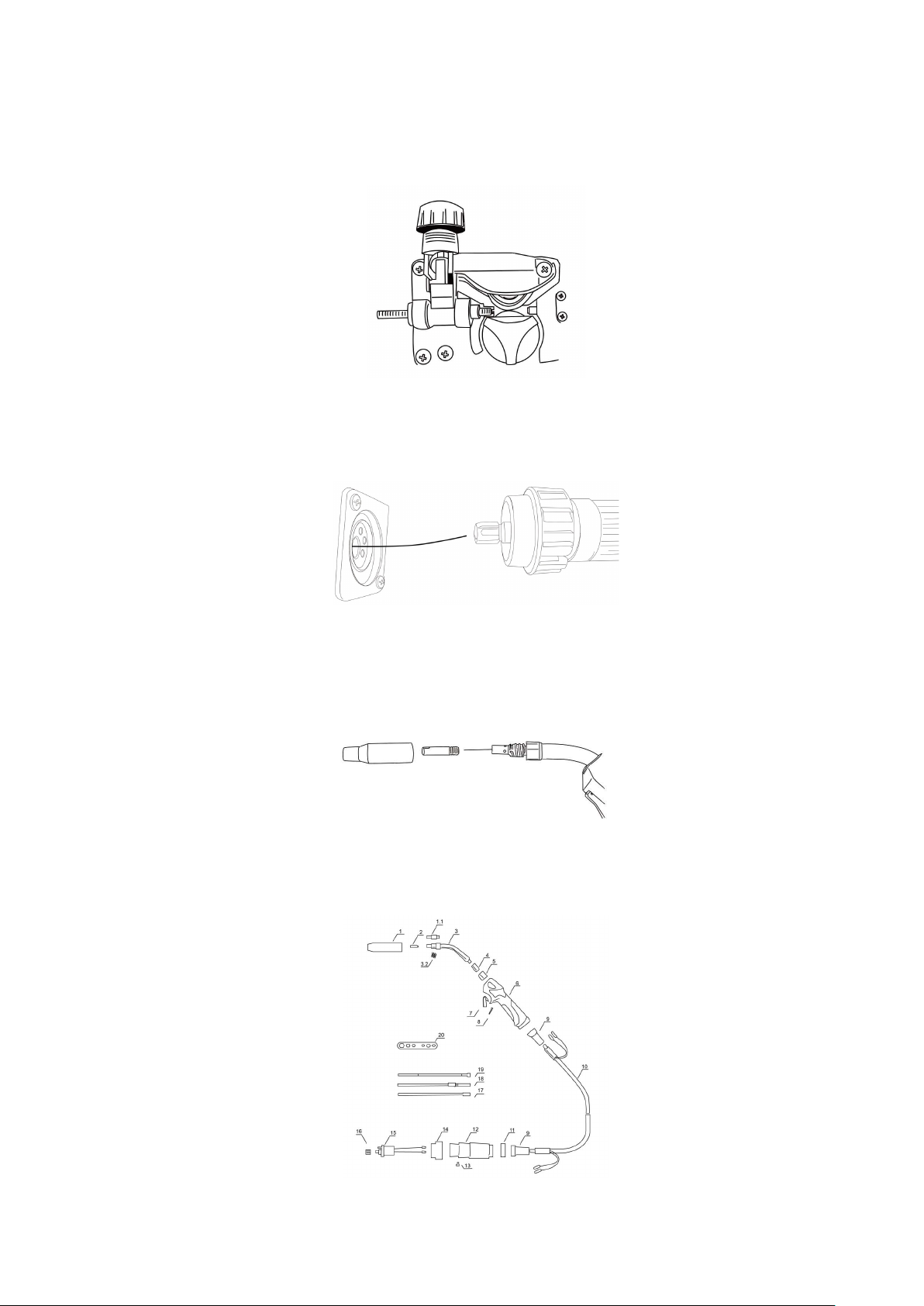

2.2 MIG Torch explosive chart

- 8 -

Torch nozzel 1 and contact tip 2 are consumables. Please change when needed.

2.3 Gas shielded welding Installation.

MIG welding

The gas cylinder containing the carbon dioxide gas, mixture gas or argon gas decompression

flow meter is closely connected with the intake inlet of the machine.

Connect the machine rear gas fast plug and gas regulator with the gas hose in accessories.

LIFT TIG welding

The gas cylinder containing the argon gas decompression flow meter is closely connected

with the gas tube on torch.

2.4 TIG Torch explosive chart (Not included in standard accessories)

- 9 -

- 10 -

3 operating instructions

3.1 Operation panel interface

1Current display:Displays preset current and actual welding current.

2

MIG welding torch switch (Effective only in MIG 0.8/MAG 0.8/FLUX 1.0):The welding machine

only be operated with the Spool gun torch in the Spool gun torch mode; The MIG torch only be

used for welding in the MIG torch mode.Please check the switch status when using.

3This light is on in Stick mode

4This light is on in LIFT TIG mode

1

2

3

4

8

6

9

57

11

10

- 11 -

3.2 Welding operation instruction

On display

After open the power supply. 【Multifunctional data display window 】Flash 3 seconds (Or any

buttons and knobs on the front panel). Enter the welding mode saved last time.

Stick Manual welding operation procedures

There are two ways to connect the dc welder normally:

Positive connection :Welding pliers connected to the negative pole, workpiece connected to

positive pole. Suitable for acid electrode.

negative connection: workpiece connected to the negative pole, Welding pliers connected to the

positive pole. Suitable for basic electrode.

The welding function is selected according to the welding process requirements of the workpiece,

5

Voltage minor adjust function. When the output current remains unchanged, the output

voltage can be adjusted in the range of - 3V to + 3V. Better welding effect can be obtained

according to personal habits and workpiece differences.

6Mode switch: , The function is cycled between STICK, LIFT TIG, MIG 0.8, MAG 0.8 and FLUX

1.0 with each click.

7

Current adjust function. Only the current is adjusted, but this machine is a digital machine.

The parameters of current, voltage and wire feeding speed have been matched. After

adjusting the current, other parameters follow the transformation and matching.

8

OC light :

When the welding load is overloaded and the output current of the machine is too large, the

internal temperature of the machine is too high, and the machine fault light will be on. This is

normal. The machine can recover after the heat dissipation becomes normal. Please restart

the power supply; When damaged, the fault light will be on, in this case, the machine is

abnormal and needs maintenance, please contact the supplier.

9AC 110V:This light is on when the input voltage is 110V

10 AC 220V:This light is on when the input voltage is 220V

11 MIG welding mode shift button:

MIG 0.8, MAG 0.8, FLUX 1.0.

- 12 -

incorrect data adjustment may cause arc instability, spatter and adhesion occur, we can change

the polarity joint for different workpiece as above.

Make sure the cable is connected to the soldering pliers and the quick plug,Connect the quick

plug to the corresponding fast socket ,And tighten it clockwise. The ground clamp clamps the

workpiece.

When the welding stop, operation [manual welding and gas protection welding switch key],

Manual welding indicator light, into manual welding mode.

In Manual welding mode, adjust【Multifunctional data adjusting knob】The welding current can be

changed, in【Multifunctional data display window】display. The welding current range is 30A to

maximum current 150A adjustment.

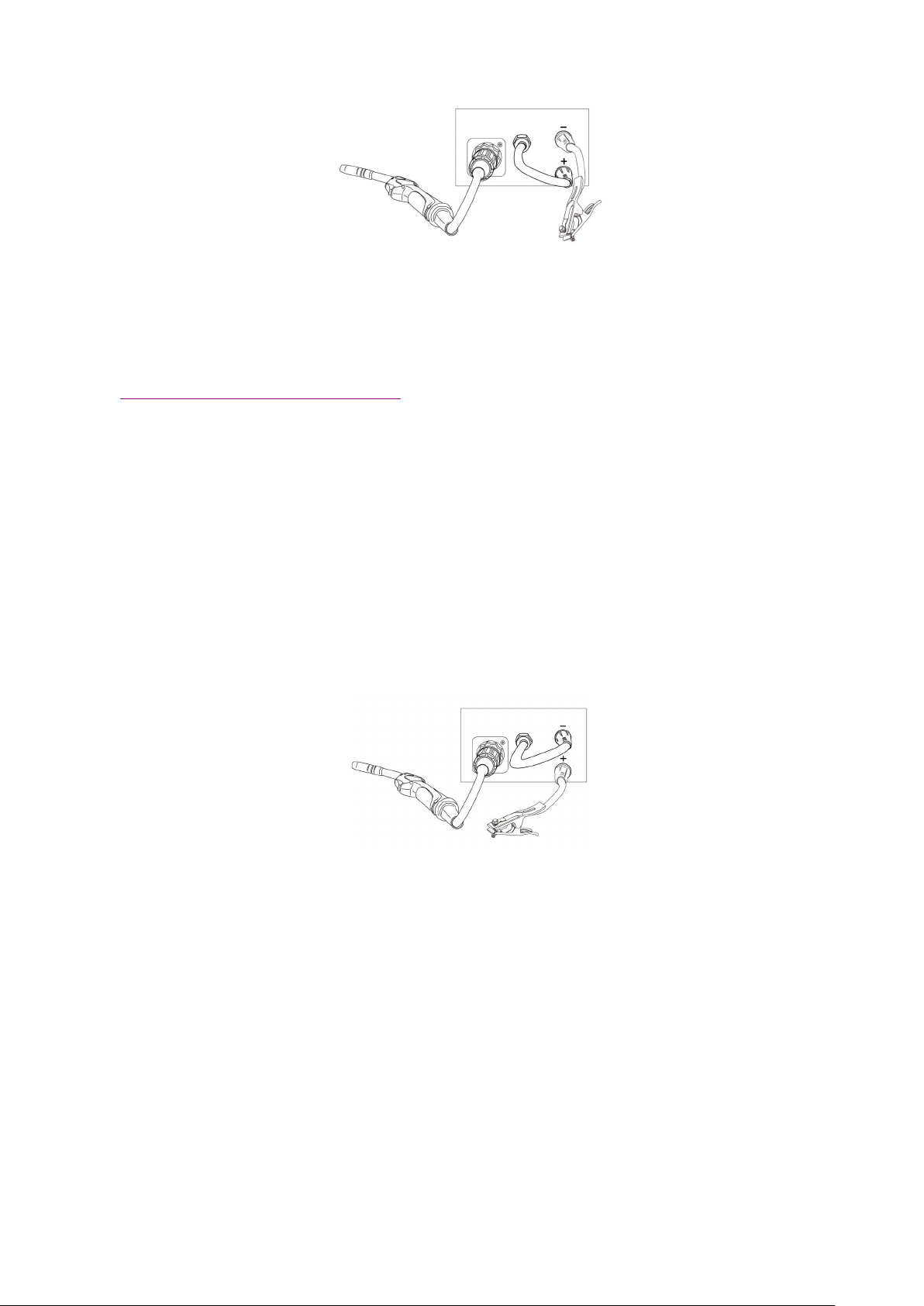

Operating procedures for MIG

gas protection welding

Welding wire Installation. (Refer to 3.1)

Please choose wire feed roller.V roller for stainless steel and carbon steel.

Connected with The gas cylinder. (Refer to 3.3)

insert the fast plug of the ground wire in the front panel on the fast socket.

Check wire operation:press torch switch, the wire feeder will feed the wire through the torch tip.

Select MIG mode on the front control panel(Make sure you are not in SPOOL GUN state). After

that, select the right material and diameter you are welding with. Adjust current according your

workpiece thickness.

To find the best welding performance and suitable for your welding habits. You may also adjust

voltage and inductance to build a perfect welding bead and penetration.

- 13 -

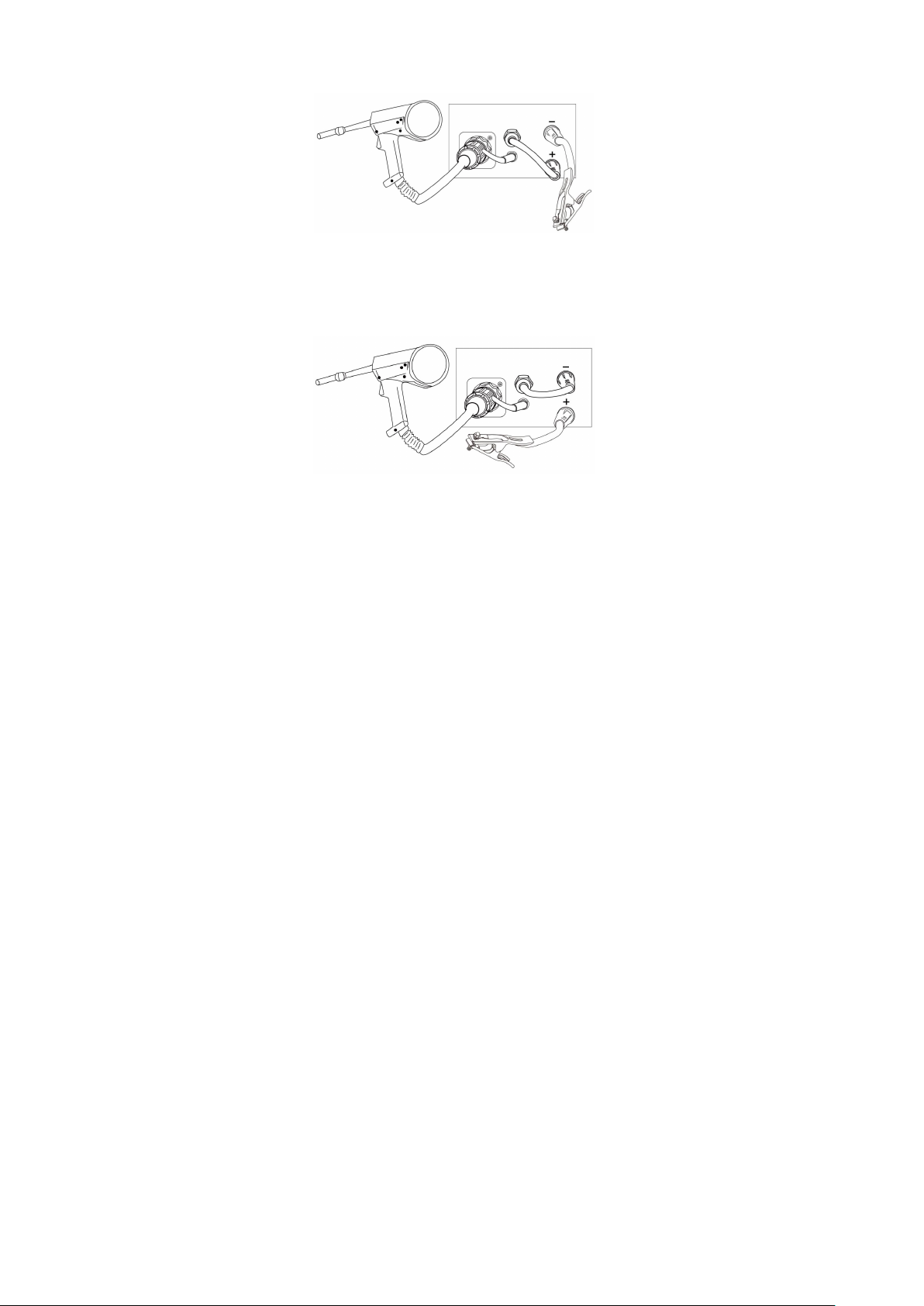

Solid wire

Gasless welding

Welding wire Installation. (Refer to 3.1)

Please choose wire feed roller. Knurled roller for flux cored wire.

insert the fast plug of the ground wire in the front panel on the fast socket.

Check wire operation:press torch switch, the wire feeder will feed the wire through the torch tip.

Select MIG mode on the front control panel(Make sure you are not in SPOOL GUN state). After

that, select the right material and diameter you are welding with. Adjust current according your

workpiece thickness.

To find the best welding performance and suitable for your welding habits. You may also adjust

voltage and inductance to build a perfect welding bead and penetration.

flux cored wire

Spool Gun torch welding

This machine can be connected to a Spool gun torch. (package does not include a spool gun).

The use of spool gun torch is similar to that of MIG gun, except that the wire is fed through the

wire feeding mechanism of the spool gun torch itself. In the spool gun mode, the feeding

mechanism of the original machine does not work.

Select spool gun mode on the front control panel or turn on the “Spool gun” switch at MIG mode.

(This toggle switch is in the wire feeding warehouse of the machine or near the “Mode” button).

Aluminum welding is supported in spool gun mode.

- 14 -

Solid Wire

flux cored wire

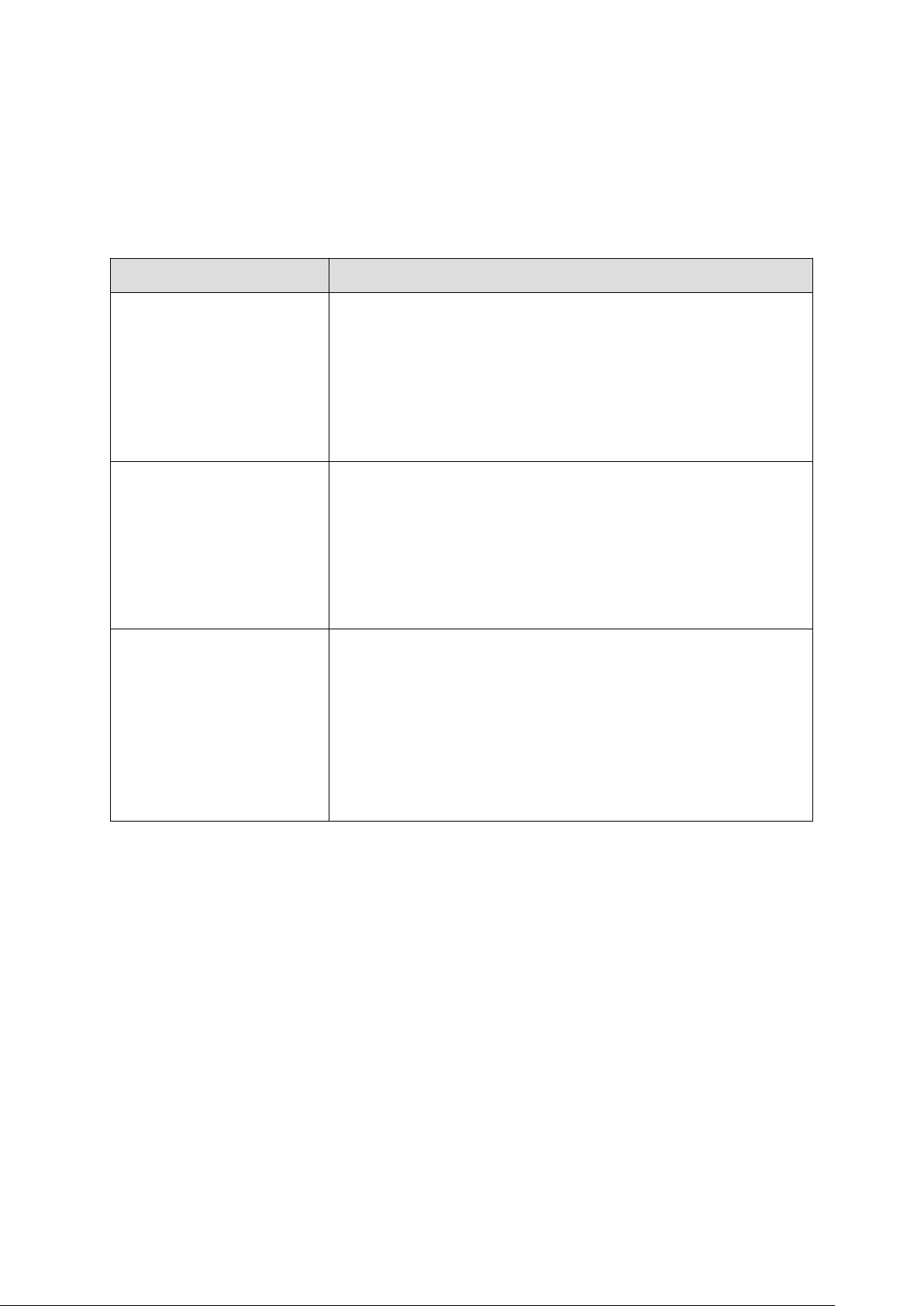

Operation of LIFT TIG function

Please follow installation draft to install the TIG torch and earth clamp. In Lift TIG welding mode,

adjust【Current adjusting knob】The welding current can be changed. The welding current range

is 30A to maximum current 150A adjustment.

TIG welding function are for thin workpiece welding or stainless steel welding. Usually choose Ar

gas as protecting gas.

Connect the gas hose with gas tube on torch.

Connect the TIG torch on negative plug.

Connect the Earth cable on positive plug.

Fault display:

OC light

When the welding load is overloaded and the output current of the machine is too large, the

internal temperature of the machine is too high, and the machine fault light will be on. This is

normal. The machine can recover after the heat dissipation becomes normal. Please restart the

power supply; When damaged, the fault light will be on, in this case, the machine is abnormal and

needs maintenance, please contact the supplier.

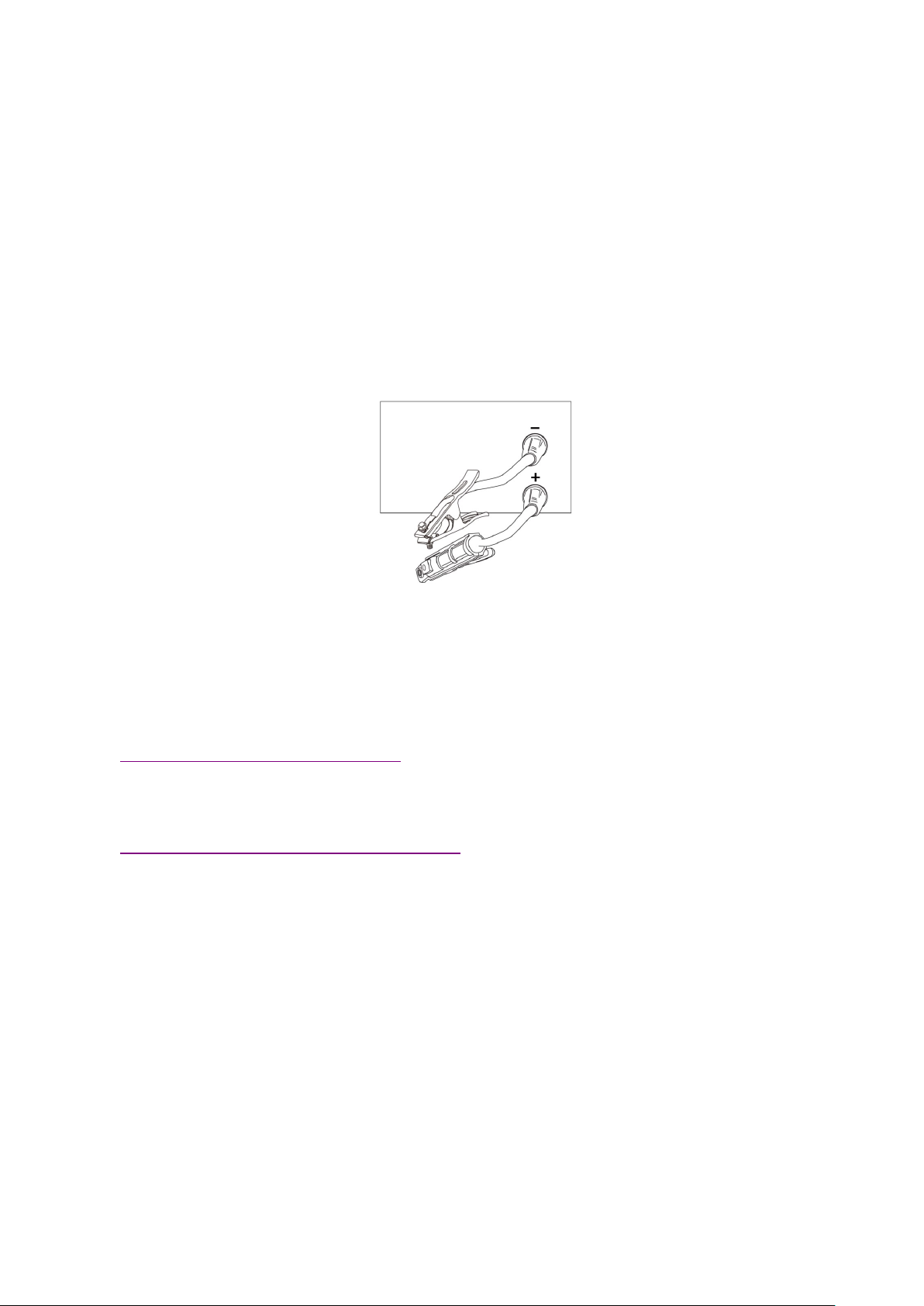

3.3 Polarity conversion joint

This machine has the polarity conversion; There are positive output terminal and negative output

- 15 -

terminal between wire feeder and wire spool; When use solid wire with gas protection, torch

socket should be connected to the positive output terminal, ground cable should be connected to

the negative output terminal; When use flux-cored wire, the ground cable should be connected to

positive terminal.

3.4 Welding environment and safety

Working surrounding

a) Welding should be carried out in dry surroundings. The air humidity level should not be higher

than 90%.

b) The temperature should be between -10C to 40C.

c) Don’t use the welding machines in sunshine or rain. Keep it off water.

d) Don't use the machines in the places of dust or corrosive air.

e) MIG welding should not be carried out in places with quick air flow.

Safety norms

Protection circuit of over-voltage, over-current and over-heat circuits are designed in the welding

machines. It will stop working automatically when the input voltage, output current or internal

temperature exceed the rated value. But if the machines are excessively used, such as with input

voltage higher than the rated, the machine might be damage. Please pay close attention to the

following matters.

a) Keep good ventilation!

The welding machines work with high welding current. Nature air flow can’t reach the requirement

of heat dissipation. So the fans are installed as cooling system to ensure stable performance.

Make sure the ventilation windows are not covered or blocked. The distance between the

machines and things around should not be less than 0.3m. Good ventilation is good for welding

performance and operational life.

b) Never over load!

Check the maximum rated current (according to the Duty Cycle chosen). Make sure the welding

current is never higher than the rated value. Over current running will obviously shorten the

operation life, even damage the machine.

c) Never over voltage!

The Input Voltage could be found in Technical data diagram. The auto-compensation function

will keep the welding current in the rated range. If the input voltage exceed the permissible value,

the machine would be damaged. Users should take protective measures in advance to avoid it.

d) Make sure earth connected before operation.

- 16 -

On the rear panel of welding machine, a screw for earth connecting would be found. It must be

ground connected with cable whose section is bigger than 6mm2before operation, to avoid accidents

caused by static or electricity leak.

3.5 Welding problems and solution

The phenomenon listed below may happen due to relevant accessories used, welding material,

surroundings and power supply. Pleas improve surroundings and avoid these problems..

Arc starting difficulty. Arc interruption happens easily:

a) Examine whether grounding wire clamp contacts with the work pieces well.

b) Examine whether each joint has improper contact.

The output current fails to reach rated value:

The deviation of power voltage from rated value may cause that the output current does no accord

with adjusted value. When the power voltage is lower than rated value, the maximum output

current may be lower than rated value.

The current can not keep stable during operation:

This situation may relate to the following factors:

a) The voltage of electric power network changes;

b) Serious interference from electric power network or other electric facilities.

Gas vent in welds:

a) Examine whether the gas supply circuit has leakage.

b) Examine whether there is sundries such as oil, dirt, rust, paint etc. on the surface.

- 17 -

4Trouble shooting and error checking

Notes: The following operations must be performed by qualified electricians with valid

certifications. Before maintenance, you are suggested to contact local distributor to verify

qualification.

Malfunctions Solution

The meter show nothing;

Fan does not rotate;

No welding output

Confirm the power switch is on.

Power supply available for input cable.

Check if the three phase commute bridge is damaged.

There is malfunction occurs in the supplementary power

source on control board (contact dealers).

The meter shows;

Fan works normally;

No welding output

Check if all the sockets in the machine are connected well.

There is open circuit or badness of connect at the joint of

output terminal.

The control cable on the torch is broken off or the switch is

damaged.

The control circuit is damaged.(contact to dealers)

the meter shows;

Fan works normally;

Abnormal indicator lights.

It might be over-current protection, please turn off the power

switch; restart the machine after the abnormal indicator light

winked.

It might be overheating protection, please wait for about 2-3

minutes until the machine renew without turn off the power

switch.

It might be multifunction of inverter circuit. (contact dealers)

Even the machine comes up with abnormal phenomenon such as welding unable, arc unstable or

bad welding effect, it is still early to judge that there is malfunction on the machine.

The above-mentioned abnormal phenomenon may be caused by some reasons. For example:

tight parts loosen, forgetting to switch on, wrong set up, cable broken and gas rubber pipe cracked,

etc. Therefore, please test and inspect these factors before deliver it back to the factory because

a large number of troubles may be easily solved probably.

For this reason, an initial diagnosis list for general welding troubles is shown below. A trouble

happened may be found in the column of “Abnormal items” on up-right of the list, please inspect

and maintain for the corresponding items which have “〇" mark in the column according to the

following list respectively.

- 18 -

Initial problems diagnose

Abnormal Items

Area and Item to be Inspected

and Maintained

No arc Starting

No Gas out

No Wire Feeding

Bad Arc Ignition

Unstable Arc

Dirt on Edge of Weld bead

Wire Stick to material

Wire

Stick

to

Conductive

Tip

Blowhole Formed

Distribution Boxes

(Input Protection

Devices)

Turn on power supply or not?

Fuse burnt out

Connection joint loose

〇 〇 〇 〇 〇 〇

Input Cable

Examine whether the cable

is cut off.

Connection joint loose

Over heat

〇 〇 〇 〇

Welding Power

Operation

Turn on power supply or not?

Phase Lacking 〇 〇 〇 〇 〇 〇 〇 〇

Gas Cylinder and

Gas Regulator

Turn on gas supply

Residual Amount of Gas in

the cylinder

Set value for flow

Connection joint loose

〇 〇

Gas supply hose

(the whole line

from the high

pressure cylinder

to the weld gun)

Connection joint loose

Gas hose damaged 〇

Wire Feeding

Device

Wire feeding wheel does not

match with the diameter of

wire in texturing tube

Crackle on wire feeding

wheel, groove blocked up or

defect

Too tight or loose of the

handle

Wire powder accumulated on

the inlet of SUS pipe

〇 〇 〇 〇 〇

- 19 -

Weld Gun and

Cable

1. Weld gun cable rolled up

or over curved

2. Adaptability of conductive

tip, wire feeding pipe and

cable diameter Worn,

blocked up or deformation,

etc.

〇 〇 〇 〇

Body of weld gun

Loose connection of

conductive tip, nozzle and

nozzle contactor

Contactor of weld gun body

is not plunged in or tightened

well

〇 〇

Power supply cable

of weld gun as well

as cable of switch

control

Break off (bending fatigue)

Damaged by weighted drop 〇 〇 〇 〇 〇

Surface Condition

of Parent material

and length that

wire stretches out

Oil, dirty, rust and paint

residues

Too long length of wire

stretched out

〇 〇 〇 〇 〇

Output Cable

Cross-section of cable that

connects to parent material

is not enough

Loose connection of (+),

(-)output cable

Bad electric conductivity of

parent material

〇 〇 〇

Lengthened Cable

Cross-section of cable is not

enough

It is rolled up or folded

〇 〇 〇 〇

Work Condition for

Welding

Welding current, voltage,

angle of weld gun, welding

rate and wire length

stretched out should be

confirmed once again

〇 〇 〇 〇 〇

- 20 -

5 Daily maintenance and checking

Daily maintenance

a) Remove dust regularly with dry compressed air. If the welding machine is used in

surroundings with heavy smoke and polluted air, it is necessary to remove dust at least one

time one month.

b) The pressure of compressed air shall fall to required level to prevent damage to small

components in the machine.

c) Examine inside electric joints and ensure perfect contact (Especially plugs and sockets).

Fasten the loosing joints. In case of oxidation, remove oxide film with sand paper and connect

again.

d) Prevent water from entering into the machine and prevent the machine from getting moist. If

any, blow and dry. Measure the insulation with megohmmeter to make sure it is qualified to

use.

e) If the welding machine is not used for a long time, pack the machine in original package and

store in dry surroundings.

f) Every time the wire feeder operates for 300hours, grind the electrical carbon brush and clear

up the armature commutator. Rinse speed reducer, apply 2# Molybdenum Disulfide lubricant

to the turbine, whirlpool rod and bearing.

All the maintenance and testing must be carried out when the power supply is totally cut

off. Please make sure the power is off before opening the closure.

Daily checking

WELDING POWER SUPPLY

Position Checking keys Remarks

Control panel

Operation, conversion and installation of the switch

Check the state of the power indicator light

Lead to unstable arc and

wire sending

Cooling fan Check if the fan state and the sound is normal or not

Clean the residue and

check the reason and

solve it

Power part

Check if there is abnormal liberation and sound

when the power is on

Check if there is smell when the power is on

Whether the outside color change or get warm

This manual suits for next models

1

Table of contents

Popular Welding System manuals by other brands

Weco

Weco POWER PULSE DIGITAL 405d instruction manual

Jefferson

Jefferson JEFTIG GT Series Operator's manual

Hypertherm

Hypertherm XPR300 instruction manual

Abicor Binzel

Abicor Binzel ABIMIG A155 operating instructions

Parweld

Parweld XTM 221Di Operator's manual

Miller Weldmaster

Miller Weldmaster 112 Extreme manual