4

To avoid eyes being hurt by spatters, please wear protective goggles.

Please wear welding specialized protective clothing, such as leather protective gloves, long-sleeved

clothes, welding spats, aprons, etc.

Please install protective barrier to protect standbys from hurting by arc light.

Please wear sound insulation devices when noise is too huge.

Please use ventilator for air exchanging; please take anti-wind measures so that to avoid poor

welding performances resulted from direct blowing to arc.

2) Cable connection check

Fix welder—place welders on dry, flat position which is of good ventilation.

Please make sure the correct and tight connection of grounding cable, power input cable, welding cable

and workpiece side cable.

3) Other items’ check

Please check the shielding gas, welding environment, welding torch and make sure they are all in good

condition.

1.3 Precautions for discard

Pay attention to the following when discarding welding machine:

Burning the electrolytic capacitors in the main circuit or on the PCBs may cause an explosion.

Burning the plastic parts such as the front panel may produce poisonous gas.

Dispose it as industrial waste.

2. PRODUCT DESCRIPTION

2.1 Function and Features

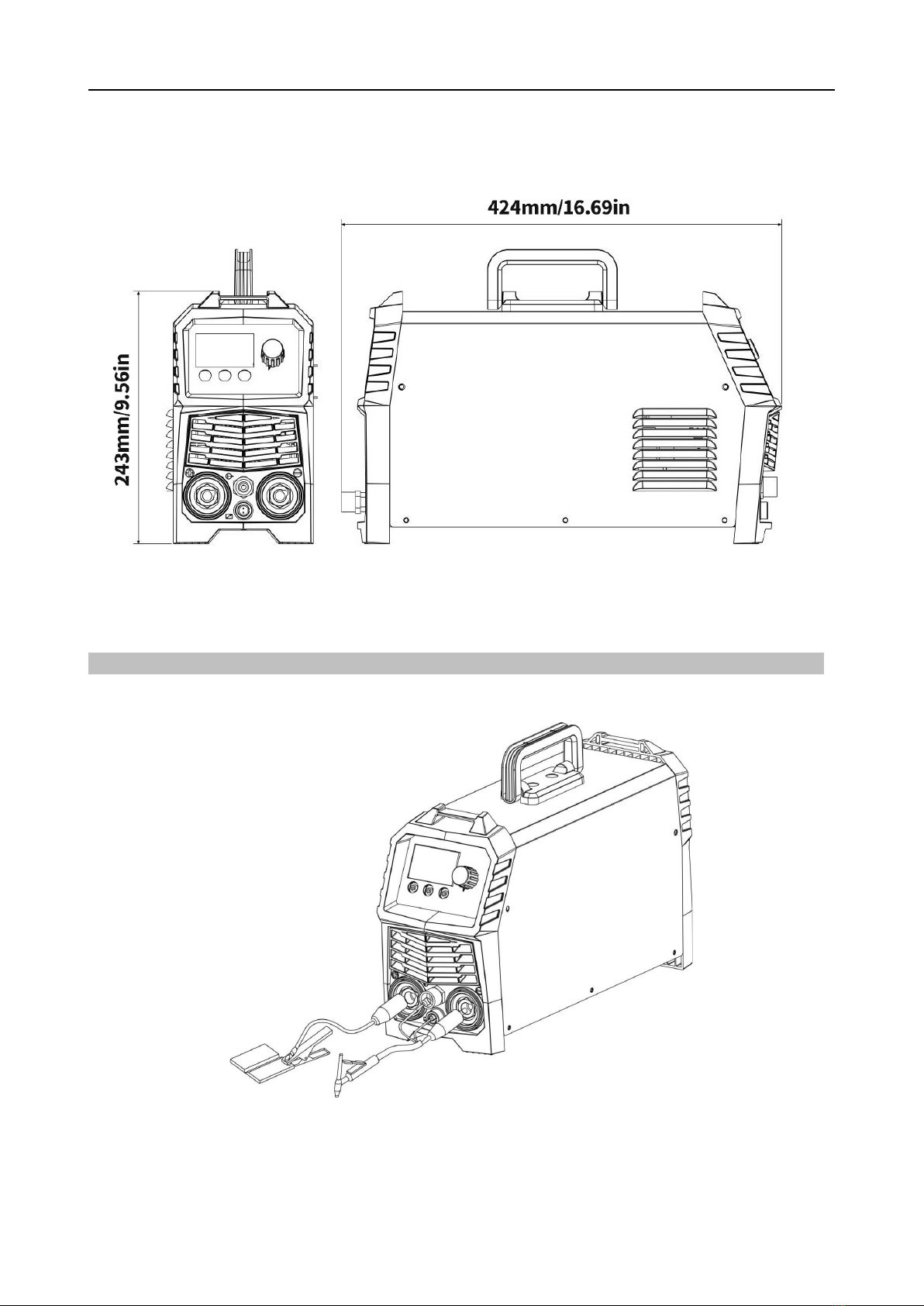

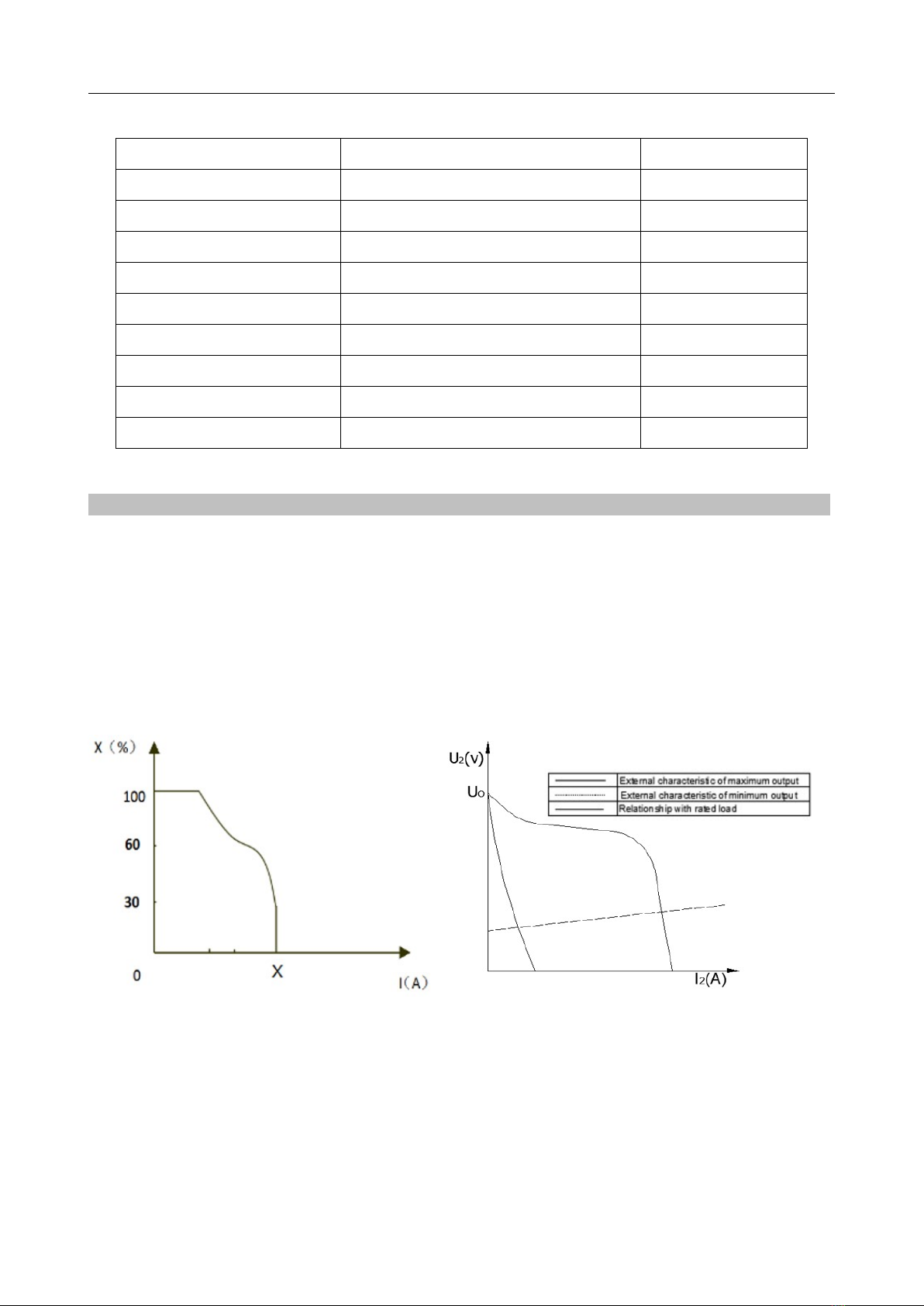

TIG welder is of constant current external characteristic. Welding current will not be changed per arc

length but being kept at a very stable level. It adopts PWM technology and high-power switching

element IGBT (discrete) to rectify AC110V/AC220V (50Hz/60Hz) voltage to DC310V, after inverting

it to 45KHz, there is a voltage step-down and rectification again, stable welder current is obtained by

output current feedback and adjustment.

Built-in MCU technology and IGBT inverter Welder, totally digital control, which ensures great and

stable welding performance.

TIG200 is TIG and MMA 2 in 1 Multi-Process welding machine.

MMA/Stick welding features: hot start, arc force and an-stick.

TIG welding features: 2T/4T Operation, current regulation, post-flow adjustable, down-slope.

Fan-On-Demand power source cooling system operates only when needed, reducing noise, energy

use and the amount of contaminants pulled through the machine.

Portable and Lightweight: 11.68lb, carry with handle or shoulder strap.

Digital Welder Expert, Know You More

https://www.arccaptain.com