3

4. SAFETY

"It is a violation of United States Department of Labor regulations to

per operation of this unit by any person under the age of 18 years."

The user should read and understand the PAD-350 and the attachment

instructions prior to operation. First time operators should be properly trained in safety

precautions and in the proper use and servicing of this equipment and attachments.

Switch the power "OFF" and disconnect the electrical suply before

mounting or disengaging an attachment, or for cleaning and servicing the equipment.

Before, connecting unit to power source it should also be in the "OFF"

position.

-Never insert hands into the hopper.

-Never insert any utensil into the hopper.

4.1. Note that the front housing of the attachment has a feed hopper. It

is also equipped witha a feed plate. Food to be processed must always be fed to cutting

surfaces by way of the hopper, and compressed against cutting sufaces with the feed

plate. Never try to feed product to cutting surfaces with your hands or any other way!

4.2. If during operation of a product jam occurs, immediately turn off

and disconnect the electrical supply to the power source equipment. Make sure rotation

has stopped. Unlatch the attachment's front housing, swing it toward you and then clear

the obstruction. Do not try to clear obstructions while the attachment is under power, and

again, never insert fingers or utensils into the hopper!

4.3. Wear protective gloves whenever handling the attachment's

knives, cutting plates, or cutting assemblies. They are very sharp and can cut you. For

safety, wash knives and cutting plates with a long handled scrub brush.

4.4. When assembling or disassembling the attachment, make sure it

rests on a stable working surface. Never rest knives, cutting plates or cutting assemblies

on surfaces that could be marred.

4.5. Before assembling the attachment and mounting it to power

source equipment, make sure that a comfortable working clearance has been

provided around the machinery. Always install the machinery where it will save the

operator steps.

4.6. Before assembling the attachment and mounting t to power

source equipment or dismounting the attachment after use, disconnect or lockout the

electrical supply to the power source equipment. This will prevent any chance of

accidental startup.

4.7. Before mounting the attachment to power source equipment,

make sure the front housing is securely latched to the rear housing.

10

Slicing Adjustable "S" knife assembly with stainless steel knife. Typical

usage:

LETTUCE - CUCUMBERS - CARROTS - CELERY - RADISHES - CABBAGE - PEPPERS - POTATOES -

CHINESE VEGETABLES - ONION - ZUCCHINI

Shredding assembly, with 5/16 Shredder Plate.

13. OPTIONAL: SHREDDER PLATES AND TYPICAL USAGE

Before trying to maintenance the attachment, review the safety

precautions paragraph carefully, and read all assembly-disassembly instructions on

Pages 2-6. Wear gloves when handling plate units.

Since the attachment contains no internal power source, most problems

can be immediately traced to improper assembly, improper adjustment or worn parts.

The Trouble Shooting Guide on Page 11 lists the most common problems and corrective

measures.

14. MECHANICS MAINTENANCE

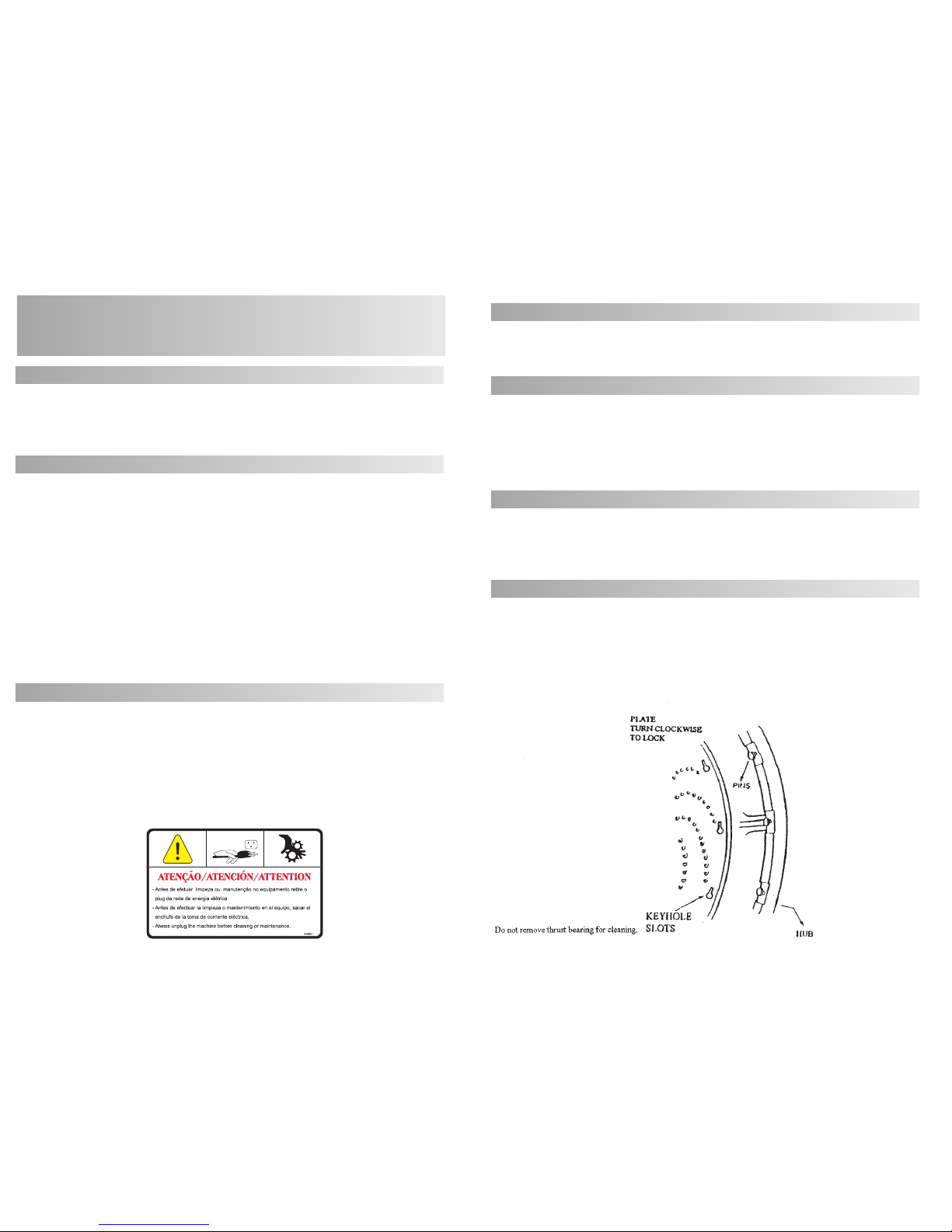

Figure 7

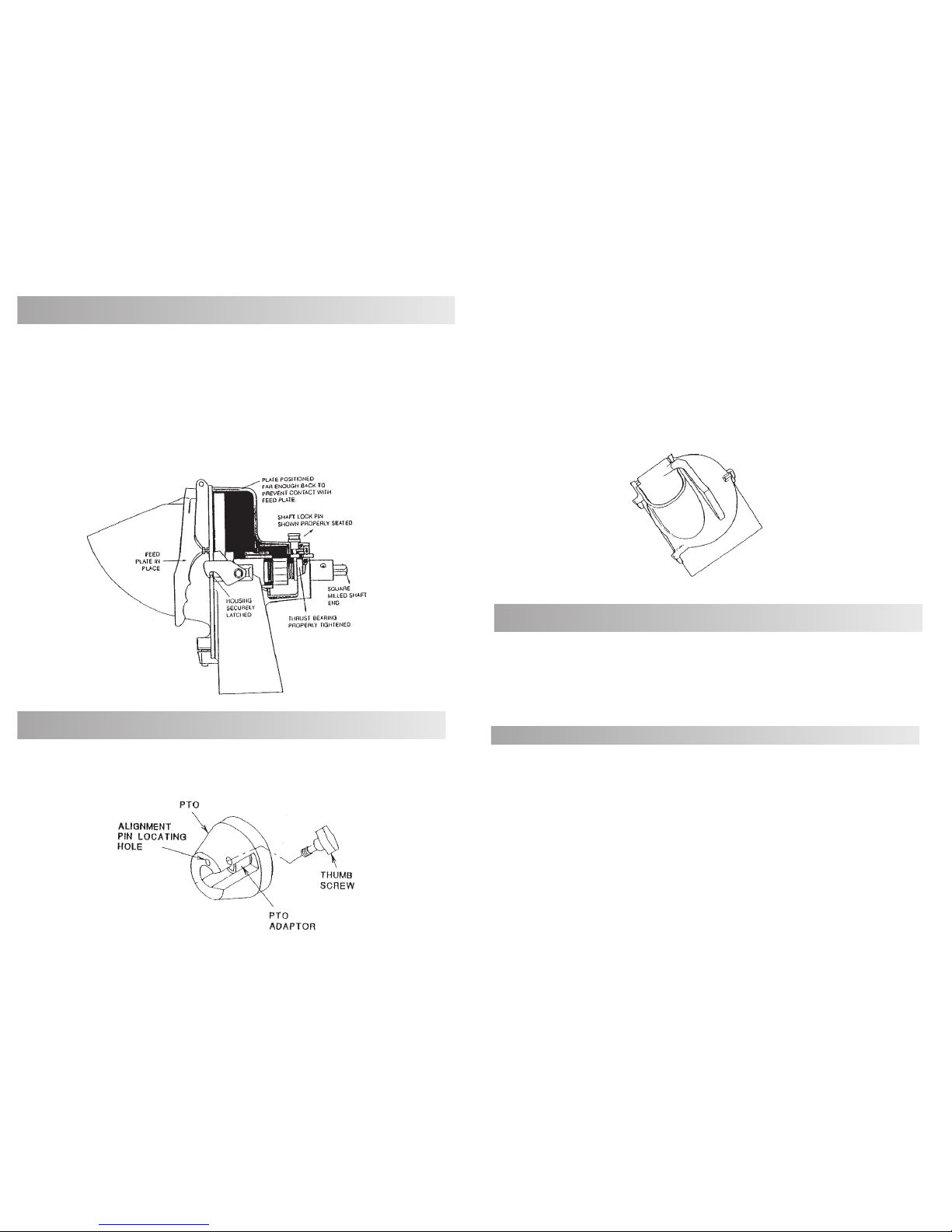

Figure 8

(Not included)

(Not included)