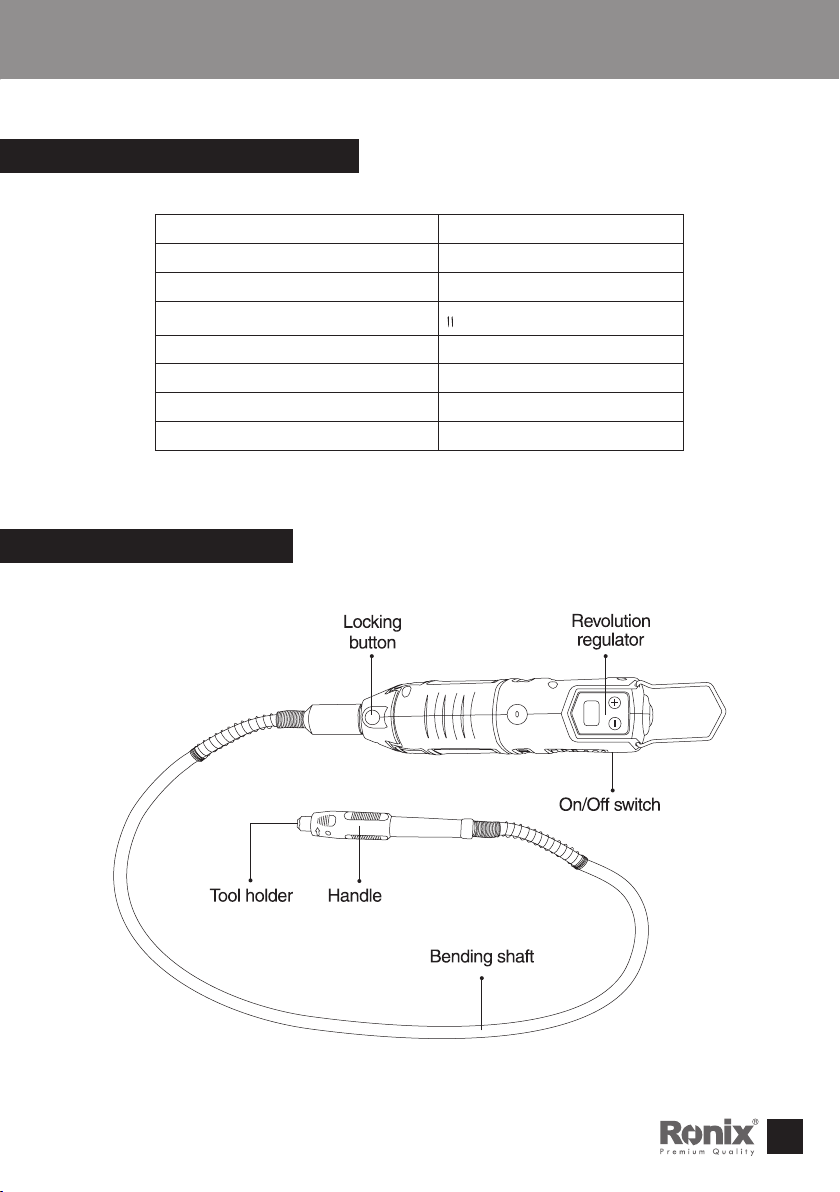

DIE GRINDER

must t precisely to the sanding spindle of your power tool.

Tools that do not t precisely to the sanding spindle of the power

tool will rotate unevenly, vibrate heavily and may cause loss of

control over the device.

- Do not use damaged tools. Before each use, check tools like

sanding discs for chips and tears, sanding plates for tears, wear

or heavy use, wire brushes for loose or broken bristles. If the

power tool or the tool itself is dropped, check to see whether it is

damaged or use an undamaged tool. When you have checked

and inserted the tool, ensure that you and any other people in

the vicinity are out of the sphere of inuence of the rotating tool

and operate the power tool for a minute at the highest revolutions.

Damaged tools will usually break within this test period.

- Wear personal safety gear. Depending on the work you are

doing, wear a full- face visor, visor or protective goggles.

If appropriate, wear a dust mask, ear defenders, protective

gloves or a special apron designed to keep sanding and material

particles away from you. Your eyes should be protected from the

ying objects that may be generated during various applications.

Dust or breathing masks must be capable of ltering the dust

generated during operation. If you are exposed to loud noise for

extended periods, you may suffer a loss of hearing.

- Ensure that other people are kept a safe distance from your

workplace. Anyone entering the workplace must wear personal

protective gear. Pieces of the work piece or broken tools may y

away and cause injuries even outside the direct working area.

- Hold the device by the insulated surfaces only when carrying out

work during which it is possible that the tool may come across

hidden power cables or its own cable. Contact with a cable that

carries power will subject the metal parts of the device to current

and will lead to electrical shock.

8