FLEMING ST1100N User manual

EU CERTIFICATE OF CONFORMITY

CONFORMING TO EC Machinery Directive 98/37 EC

We:

Fleming Agri-Products Ltd

Newbuildings Industrial Estate

Newbuildings

Northern Ireland

BT47 2SX

declare in sole responsibility, that the products

Type: ST1300N,ST1600N,ST1600,ST2000 Slurry Tankers

to which this certificate applies, conforms to the basic safety

and health requirements of the EC Machinery Directive 98/37 EC,

and the Transposed Harmonised Standards:

BS EN 4254-1 (2009)

ST1100N,ST1300N,ST1600N,

ST1600,ST2000,ST2400

Slurry Tankers

Fleming Agri-Products Ltd

Newbuildings Industrial Estate

Newbuildings

Northern Ireland

BT47 2SX

Tel: (028) 7134 2637

Fax: (028) 7134 4735

Email:info@fleming-agri.co.uk

www.fleming-agri.co.uk

‘Quality, Strength & Personal Service’

This manual is provided to assist you in getting the best results from your

Slurry Tanker and ensure that you do so safely. If you have any queries

about the use of the Slurry Tanker contact your dealer before use. Please

keep this manual for future reference.

The Fleming range of Slurry Tankers are robustly designed and manufac-

tured to cater for all size of operations. The full length drawbar attached to

the axle reduces stress on the tank. The tank is coated internally with a pro-

tective coating for extended life. All Fleming Slurry Tankers are fitted with

the new series Battioni MEC/M vacuum pump which allows for longer con-

tinuous working periods than that recommended for traditional agricultural

pumps.

Currently there are four models within the Fleming Slurry Tanker range.

The table below specifies the standard equipment which is supplied with the

Slurry Tanker range. (See Table 2. for respective capacities).

1.1 FUNDAMENTAL PRECAUTIONS

On delivery, your dealer gave you an explanation of the operation and

maintenance of this Fleming Slurry Tanker. Please read and understand

these operating instructions before operating the machine for the first time.

It is essential that you observe all safety instructions.

Incorrect use or mishandling of the Slurry Tanker can endanger:

Life and Limb of the operator, other persons or animals within the vicinity

of the machine.

The machine and other material assets of the owner or third persons.

The performance of the Slurry Tanker

Anyone who is involved in the commissioning, operation or maintenance of

the Slurry Tanker must read and understand these instructions very careful-

ly and observe them at all times.

Table 1. Standard Equipment

Model

Capacity

Gallons

Wheels

Rec‟d

MEC

Pump

Hyd

Brakes Lights

Standard

Tyres

ST1300N 1300 No 8000M Yes Yes 550/65/22.5

ST1600N 1600 No 8000M Yes Yes 550/65/22.5

ST1600 1600 Yes 8000M Yes Yes 28.1 R26

ST2000 2000 Yes 11000M Yes Yes 28.1 R26

Never enter the area directly under the tanker and stand clear of the

danger zone when the wheel is removed

Prop axle with heavy duty axle stands as close as possible to the wheel

that is to be removed. Make sure the placing of the axle stand is the very

first part of the procedure and make sure the axle stand pins are of

correct specification.

Do not exceed the rated capacity of the axle stand. The weight that will

need to be jacked up will not exceed 2000kgs provided the slurry tanker

has been emptied properly.

Do not lift tanker off the ground by top crane hook when changing a

wheel.

Do not use a trolley jack or bottle jack when changing a wheel as they will

not have sufficient travel height.

AXLE STAND

1.2 AUTHORISED OPERATORS

Youths under the age of 16 must not operate the Slurry Tanker. The owner of

the machine must provide the operator with the operating instructions and

make sure they have read and understood them. Only then may the Slurry

Tanker be put into operation.

The owner must ensure that only authorised persons operate/work on this Slur-

ry Tanker. He is responsible for keeping any third persons or animals out of the

working area of the Slurry Tanker.

A SAFE DISTANCE OF AT LEAST 10M MUST BE OBSERVED BY ANYONE

WITHIN THE VICINITY OF THE SLURRY TANKER.

1.3 GENERAL SAFETY AND ACCIDENT PREVENTION REGULATIONS

Before operation make yourself familiar with all elements and controls of the

Slurry Tanker as well as their functions.

Ensure the Slurry Tanker is correctly and securely attached to the operating

vehicle. The recommended method of attachment is to use the tractor hook

hitch.

Always check that the hydraulic brake line is connected and functioning.

NEVER attach to a tractor which would be rendered unstable when the Slurry

Tanker is operated at its full capacity. Take note of the maximum load permissi-

ble on tractor draw bar.

The attaching and detaching of the Slurry Tanker to a tractor must be carried

out by only one operator. There should not be any other people in the vicinity

of the implement or in the tractor.

When detaching the Slurry Tanker from the tractor always ensure that it is safe-

ly positioned on a level surface and that blocks are positioned below each

wheel.

Table 2. Slurry Tanker Capacities

Model Unladen Weight (kg)

Approximate

Laden Weight (kg)

Capacity

(Litres)

ST1300N 2100 8012 5910

ST1600N 2280 9433 7274

ST1600 3340 10020 7274

ST2000 3500 12250 9092

NEVER allow children to play on or around tractors and machinery.

NEVER operate the Slurry Tanker unless all safety guards are fitted and are

firmly in position. ALWAYS ensure that all guards and covers are replaced

after carrying out maintenance or adjustments.

Do not make any sharp turns with PTO shaft in motion.

ALWAYS disengage the PTO before dismounting from the tractor.

Operators should not wear loose fitting clothing when working close to PTO

driven equipment. Keep long hair tied back. NEVER be in the vicinity of a

rotating PTO shaft.

ALWAYS disengage the PTO shaft, apply the hand brake, stop the tractor

and remove the key before carrying out any maintenance or adjustments to

the Slurry Tanker.

Before operation inspect the area around you. Keep children away. All visi-

tors and unauthorised persons should be kept well away from work area.

NEVER operate the Slurry Tanker with persons standing in the spreading

path. There is a danger of serious injury to both livestock and persons with-

in this area. A safe distance of at least 10m must be observed by anyone

within the vicinity of the Slurry Tanker.

Take extra care when operating the Slurry Tanker on sloping ground. .

Exercise extreme caution when turning on sloping ground. Especially with a

partially filled tanker as the inertia will cause the weight of the contents of

the tank to be thrown to one side of the tank. NEVER operate on ground

where there is a risk of the tractor becoming unstable

NEVER park the tractor and Slurry Tanker on a slope.

NEVER attempt to move the Slurry Tanker manually.

To avoid personal injury keep hands and limbs well away from the moving

parts.

Under NO circumstances should anyone, authorised or otherwise attempt

to use the Slurry Tanker as a means of personal transport. It is designed as

a special purpose farm implement and is unsuitable for the safe transporta-

tion of passengers. NEVER allow anyone especially children to travel any-

where between the tractor and an implement.

Where local laws permit ensure that a flashing amber beacon is mounted on

the cab of the tractor and is always used when transporting the Slurry Tank-

er on the road.

Always ensure that the rear view mirrors on the tractor are adjusted properly

and are kept in good order.

Fill pipe with identical ends connected to fill

points of separate tankers, used to empty tanker

that needs wheel changed.

Locations of jacking points are clearly labelled at the back of the tanker.

2.0 WHEEL CHANGING PROCEDURE

It is compulsory to employ a professional tyre fitter to carry out any

wheel changing maintenance. The tyre fitter must follow these

instructions carefully.

The slurry tanker must be connected securely to the tractor with

wheels chocked to minimise movement before wheel changing pro-

cesses can begin.

The slurry tanker must be emptied before any wheel changing

maintenance can begin. The tanker can be emptied into another va-

cant slurry tanker by means of one fill pipe with 2 identical connection

ends. Each end of the fill pipe can be connected to the fill points of the

2 separate tankers. When emptying the tanker, it is important to suck

into the empty tanker rather than blow from the full tanker.

When changing a wheel, always position the tanker on a hard, level

surface and if carrying out the procedure on a public highway,

consider the gradient of the camber before jacking or propping.

Jacking mechanism should have an extension of approximately

400mm to allow enough clearance for tyre to come off and to be put

on again when fully inflated. It is also highly recommended to use an

air actuated jack so that the tyre fitter can stand well clear of the slurry

tanker while Jacking.

Consult with your professional tyre fitter to determine if the tyre can be

fixed without removing it from the slurry tanker.

If the wheel must be removed, ensure that an axle stand prop is

appropriately positioned before the wheel is removed.

DO NOT PROP WITH DECAYED, UNEVEN TIMBER OR CEMENT

BLOCKS. Use appropriate timber as shown below.

Never enter the danger zone when the wheel is removed.

Jacking points must be

checked at regular intervals

and if damaged contact your

local dealer immediately.

SLURRY GASES CAN KILL. Vacate slatted houses of animals and people

when mixing is in progress. Do not stand near tank openings or stoop to floor

level when mixing. Secure suction hoses to prevent them from falling into the

tank. Do not enter a below ground level tank. If unavoidable attach a lifeline

held by two persons.

SLURRY GASES CAN BE FLAMMABLE. Never allow naked flames near the

tanker or tank openings.

NEVER open the rear door to enter the tanker without first decompressing the

tanker and venting all gases. If entering the tanker always have another person

standing by.

Before attempting to clear any blockages in the spread plate, ensure the pump

lever is in neutral, the tank is depressurised and the rear discharge valve is

closed.

NEVER DISTRACT PERSONS WHO ARE USING THIS MACHINE.

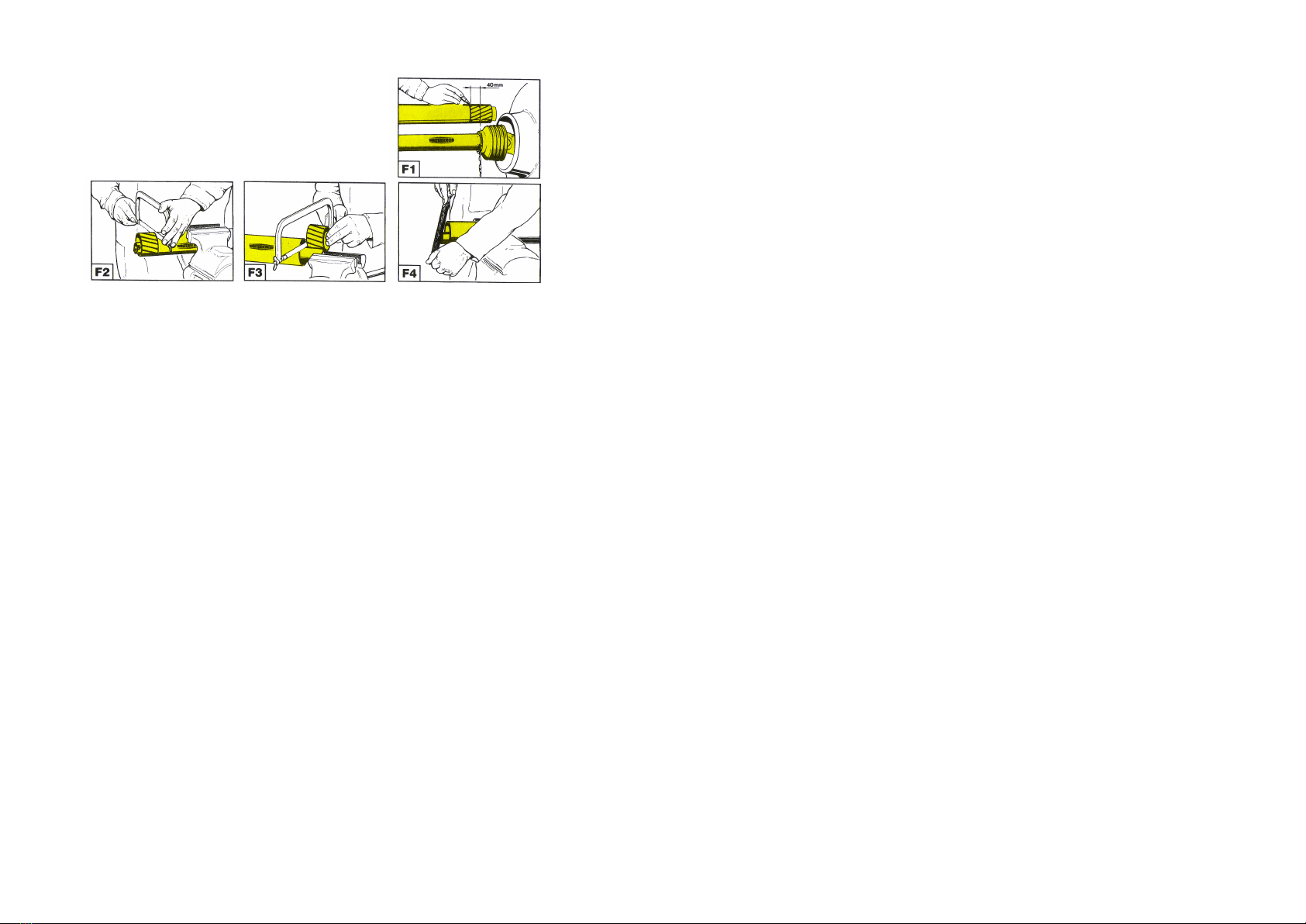

1.4 PTO SHAFT LENGTH

The PTO shaft length may be altered to suit individual tractors. During opera-

tion when the PTO is at its maximum extended length there must be a mini-

mum overlap of 1/3 PTO shaft length as shown in the minimum PTO overlap

diagram.

The Slurry Tanker should be hitched to the tractor and be checked in various

positions to ensure that the PTO drive line is the correct length. Remember

that undulating ground can also affect the length of the PTO shaft.

SHORTENING THE PTO SHAFT.

Set the tanker at its minimum distance from the tractor. Brake the tractor

and switch off the engine.

Separate the PTO. Attach the female part to the tractor PTO and the male

part to the tanker pump PTO. Ensure that the fixing pins have “clicked” into

position and are engaged.

Keeping the two halves of the PTO parallel line them up side by side. Fig 1.

Match mark where the two halves are to be shortened. Fig 1.

Taking one half of the PTO cut the shield at the mark. Fig 2.

Using the cut off piece as a guide (fig 3) cut the shaft.

Proceed in the same way with the other half of the PTO.

Trim and de-burr the two cut ends of the PTO and clean off all swarf. Fig 4.

Grease the two profiles and join the two halves of the PTO together.

Fit the PTO shaft to the tractor and tanker and check as before that its

length is correct ensuring that minimum overlap advice is observed and

that the PTO does not bottom when turning.

If the PTO is too short with a tendency

to separate, then it must be replaced

with a longer one.

If the PTO is too long, it should be

shortened using the following method.

1.9 HYDRAULIC SAFETY

The Slurry Tanker discharge valve and brakes are hydraulically operated. These

safety considerations should therefore be adhered to.

CAUTION The hydraulic system is under high pressure.

Ensure that only high-pressure hoses are used to connect supply to the Slurry

Tankers hydraulic cylinder(s). Check hoses regularly and renew any that are

damaged or worn.

Before working on the hydraulics release the pressure from the hydraulic sys-

tem and stop the tractor engine.

When connecting hydraulic rams make sure that the hydraulic hoses are cou-

pled correctly. Pressure should be released from the system both on the tractor

and on the implement side prior to coupling the hoses to the tractor hydraulics.

CAUTION Hydraulic oil forced out under pressure can break the skin and cause

severe injury. In the event of a hydraulic oil leak stop the tractor flow immedi-

ately. DO NOT PUT HANDS NEAR A LEAKING PIPE.

1.9 HYDRAULIC SAFETY

The Slurry Tanker discharge valve and brakes are hydraulically operated. These

safety considerations should therefore be adhered to.

CAUTION The hydraulic system is under high pressure.

Ensure that only high-pressure hoses are used to connect supply to the Slurry

Tankers hydraulic cylinder(s). Check hoses regularly and renew any that are

damaged or worn.

Before working on the hydraulics release the pressure from the hydraulic

system and stop the tractor engine.

When connecting hydraulic rams make sure that the hydraulic hoses are cou-

pled correctly. Pressure should be released from the system both on the tractor

and on the implement side prior to coupling the hoses to the tractor hydraulics.

CAUTION Hydraulic oil forced out under pressure can break the skin and cause

severe injury. In the event of a hydraulic oil leak stop the tractor flow

immediately.

DO NOT PUT HANDS NEAR A LEAKING PIPE.

1.8 OVERALL DIMENSIONS

Model Overall Length

(including

Sprinkler)

Width over

tyres

Height

ST1300N 6.275 metres 2.56 metres 2.65 metres

ST1600N 6.990 metres 2.56 metres 2.65 metres

ST1600 6.990 metres 2.49 metres 2.79 metres

ST2000 7 .00 metres 2.49 metres 2.99 metres

1.5 GENERAL OPERATING INSTRUCTIONS

Observe all maintenance requirements (See Section 1.7) and ensure operator

is competent with machine before commencing operations.

Before using the vacuum pump ensure that the PTO shaft is turning freely and

the direction of rotation is the same as indicated by the arrow on the pump.

Never turn the vacuum pump shaft in the opposite direction to that indicated

as this could damage internal components of the pump.

The Battioni MEC/M new series pump with long life blades may be continu-

ously operated for 15 minutes. However, prolonged uninterrupted working

times may cause excessive heating of the pump and damage to the vanes. If

it is expected that the pump will be used for a longer period because of the

density of the slurry to be processed then dilute or mix the slurry.

Operating pressure should be kept within the range of 0.5 – 0.9 bar to avoid

overheating the pump or breaking the vanes. Do not exceed 0.9 bar.

Ensure that oil drip feed is at the correct setting.

Regularly check the pump oil level.

Check the wheel nuts and wheel bearings daily for tightness.

Check daily that the discharge valve tongue fully opens. If it does not then re-

move the top of the valve complete with the ram by loosening the six socket

head screws securing the top valve housing to the main body. Clean out any

debris in the housing. The valve rod will break if this procedure is not carried

out.

The emergency breakaway handbrake should be connected to the tractor

every time the Slurry Tanker is used. The connection should be via a rope

attached to a solid part of the tractor such as the top link and not to a panel.

The rope should be tight enough for the handbrake to be operated if the tank-

er becomes detached from the tractor but loose enough so that the handbrake

is not applied during normal operation.

1.6 SLURRY TANKER OPERATION

Filling Procedure.

Read the sections in this manual regarding safety and maintenance.

Attach the suction filling hose to the quick attach fitting located at the rear of

the tanker.

Open the manual rear fill inlet valve with the operating handle.

Ensure that the end of the fill pipe is completely submerged before opera-

tion.

Ensure the vacuum pump oil drip feed is set to 1 drop every 3 seconds

Set the vacuum pump operating lever in the Suction position.

Engage the PTO at low rpm and increase to 350 rpm.

When slurry appears in the sight glass at the rear of the tanker, shut the in-

let valve with the operating handle.

Move the vacuum pump operating lever to the Neutral position.

Remove the suction fill pipe.

Spreading Procedure.

On arrival at the spreading site set the pump operating lever to the Pres-

sure position.

Engage the PTO at approximately 350 rpm while driving forward. Using the

hydraulic control, open the gate valve to the discharge unit at the rear of the

tanker.

TYRE PRESSURES

RECOMMENDED LUBRICANTS

GREASE

OIL

Brake Adjustment

It is highly recommended that brake adjustment is only carried out by

qualified service engineers.

For the safe operation of the tanker it is imperative that a routine mainte-

nance schedule is developed for cleaning, inspection, adjustment and

lubrication of brake components.

Adjustment of brakes should be carried out as frequently as required to

maintain safe operation. When resetting brakes. The hydraulic brake ram

should be 38mm – 50mm from the end of its stroke when the brake shoes

engage the hub.

At regular intervals remove the brake drums and check linings for wear and

the drums for cracks, scoring or any other form of deteriation.

Tyre BAR PSI

550/65-22.5 229

28.1 R26 229

Manufacturer Recommended Alternative

Shell Shell Retinax LX2 Shell Retinax LX

Mobil Mobil Grease H.P .222 Mobil Grease H.P.

Castrol Castrol LMX Spheerol A.P.T.Z.

Texaco Hytex EP2

Esso Unirex EP2

BP Energrease LC2

Manufacturer Application Recommended Alternative

BATTIONI

PAGANI POMPE Vacuum Pump oil

reservoir

Vacuum Pump Oil

VPO005BP

SAE20 (SAE30

in summer)

Any of the

above

Vacuum Pump

gearbox

EP90 Hypoid

MAINTENANCE SCHEDULE:

Grease the following Initially 8

hours

40 hours 160 hours

PTO shaft universal joints ··

PTO Shaft Male profile ··

Brake Cams ··

Wheel Hub Bearings ··

Check Initially 6 hours 40

hours

160

hours

Oil Drip Feed ··

Vacuum Pump Oil Reser-

voir level

··

Vacuum Pump Gearbox

Oil Level.

··

Gate Valves for blockages ··

Rear Door for leaks ··

Regular Tasks Initially 6 hours 40 hours 160 hours

Tighten nuts ··

Flush 1 litre of diesel

through Vacuum Pump

air intake with handle set

in the pressure position

··

Hydraulic hose

& 12v cable

Vacuum Pump Drawbar Springs

Road Lights

Site Glass

Rear Fill Port Quick

Attach Fitting.

Rear Fill Inlet Valve

Operating Handle

Rear Discharge Hy-

draulically Operated

Rear Discharge

Unit

Backdoor

Primary Float

Secondary

Float Valve

Front Side Fill Port

PTO INPUT

1.7 MAINTENANCE

As a rule, disengage the driving system and stop the engine prior to carrying

out maintenance, servicing, cleaning or repair work. ALWAYS remove the

ignition key.

Chock the machine with appropriate wheel chocks before carrying out any

maintenance work.

The manufacturer will not be responsible for any damages or injuries caused

by unauthorised repair, alterations or mishandling of the product.

Maintain the product with care. Check periodically for damage that would

affect the safe operation of the Slurry Tanker.

Regularly check all bolts and tighten if necessary.

Regularly lubricate the hydraulic cylinder, bearings and drawbar hinge bush-

es using clean grease.

Only use clean grease complying to Din 51502.

ALWAYS ensure all warning stickers are kept clean and in good condition.

CAUTION paintwork may be damaged if high-powered washers are used

when cleaning the Slurry Tanker.

Do not carry out any welding of the tank without opening the back door.

Check tyre pressures daily. An under inflated tyre on one side will cause se-

vere stability problems on undulating ground.

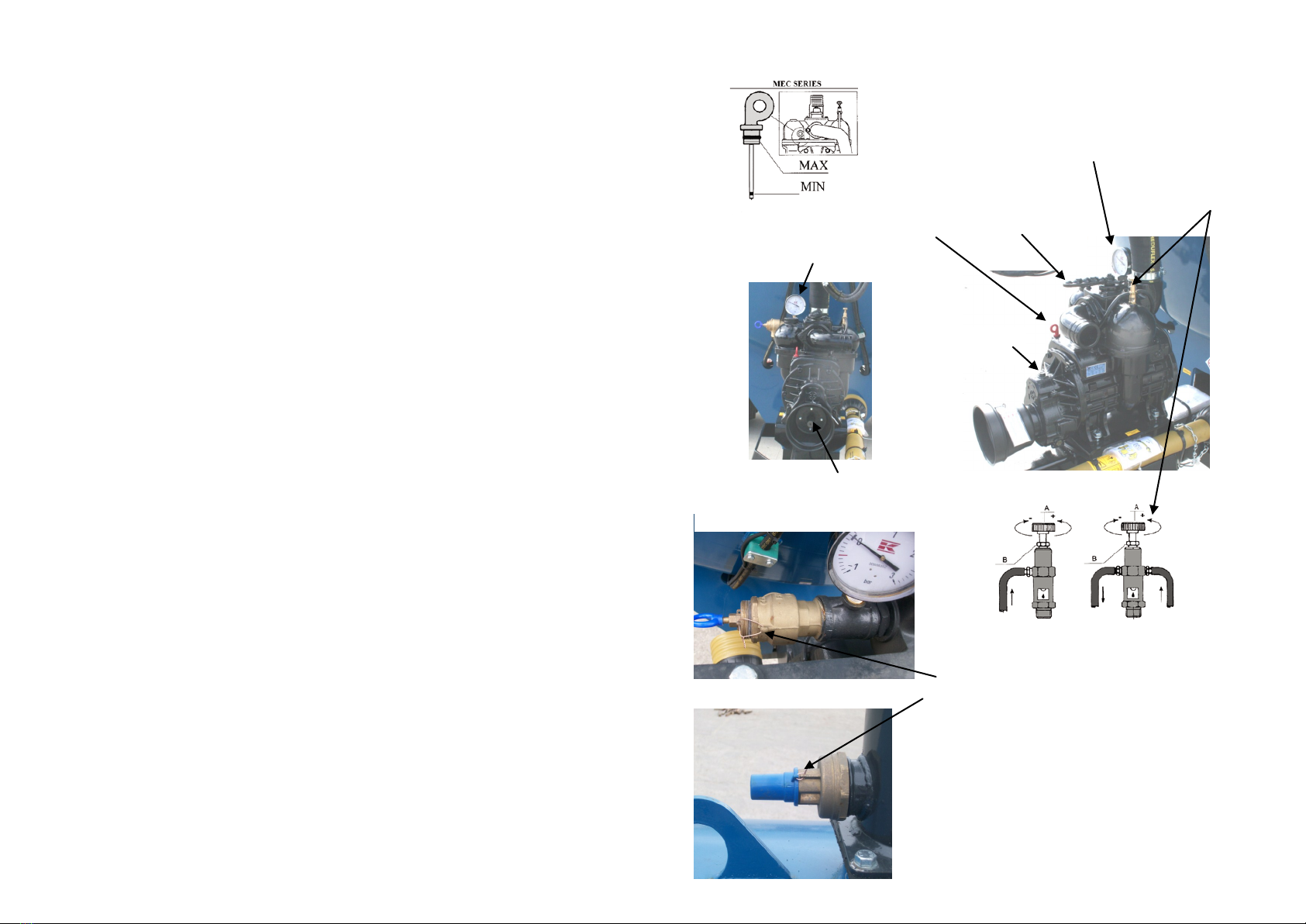

VACUUM PUMP MAINTENANCE.

Periodically check the oil level in the gearbox at the front of the pump. The

oil level should be at the top of the see through plug.

Change the gearbox oil after the first 50 working hours and then every 300

working hours. Use EP90 hypoid gear oil.

Check daily that the level of the cooling oil is always above the bottom mark

on the dip stick. Top up using Battioni Vacuum Pump oil or engine oil SAE20

(SAE30 summer).

Check that the cut out valves (Primary & Secondary Float Valves) are in full

working order and that the rubber balls are not soft and spongy. These

should be replaced every 12 months.

After every working day flush out the pump with diesel oil. This will prolong

the life of the vanes in the pump. To do this set the pump to Pressure and

suck 1 litre of diesel in through the air intake. As a further precaution suck a

small amount of oil into the pump to lubricate it and minimise corrosion.

If the tanker is to be stored unused for a period of time then disconnect the

hose that connects the pump to the tank. This will avoid the transfer of corro-

sive gases from the tank to the pump.

Vacuum Pump

Pressure Gauge

PTO Input

The minimum oil level is

indicated by the groove

at the bottom end of the

dipstick. Maximum is at

Oil Fill & Oil Level

Pressure Gauge

Oil Drip Feed

Pump handle.

P - Pressure

N - Neutral

V - Vacuum

Gearbox Oil Fill

Oil Drip Feed Adjustment

Loosen locknut „B‟ and turn the regu-

lator screw „A‟ until a flow rate of

one drop every three seconds is

obtained. Re-tighten locknut „B‟ after

adjustment.

WARNING

Pressure release valve comes preset at 0.9 bar and should

only be adjusted by a fully qualified service

engineer.

The decompression valve is preset at –0.7 bar and this also

should only be adjusted by qualified service engineers.

DO NOT USE THE TANKER IF THE SAFETY RELEASE

VALVES ARE NOT TIED WITH WIRE AS SHOWN IN THE

PICTURES.

SAFETY RELEASE VALVE

DECOMPRESSION VALVE

WIRE TIE

This manual suits for next models

5

Table of contents

Other FLEMING Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

Woodland Mills

Woodland Mills BUSHLANDER Operator's manual

Kendon

Kendon Stand-Up TRIKE/SPYDER/SIDECAR Ride-Up SRL owner's manual

Primo Water

Primo Water UT5x8-26HSS Assembly instructions

Joyner

Joyner JNSZ800MV owner's manual

Ammann

Ammann AP 240 operating manual

Carry-On Trailer Corporation

Carry-On Trailer Corporation 7x16CG User's manual - safety guide