Fletcher-Terry Pneumatic FrameMaster User manual

1

USER’S MANUAL

IMPORTANT

Users of these drivers must read and un-

derstand the safety features and operating

instructions outlined in this manual.

The Fletcher-Terry Company

65SpringLane Farmington,CT 06032-3311

Tel.860.677.7331•800.843.3826 • Fax 860.676.8858 •www.fletcher-terry.com

FORM 080102

German Seite 11

French Page 21

Español Página 31

2

SAFETY INSTRUCTIONS

WARNING: Certain safety precautions are required when using pneu-

matic tools to prevent injury to the user and others in the area. Read and

follow all these instructions.

It is the employer’s responsibility to enforce compliance with these

safety warnings and procedures by all who use this driver. Keep the

manual available so all employees have access to it and the opportunity

to review procedures periodically.

The purpose of the Pneumatic FrameMaster® and Pneumatic

FlexiMaster® is to insert Fletcher Framer’s Points and Flexible Framer’s

Points in wooden frames to secure the glazing, matboard, artwork and

backing material. It must not be modified or used for any other applica-

tion.

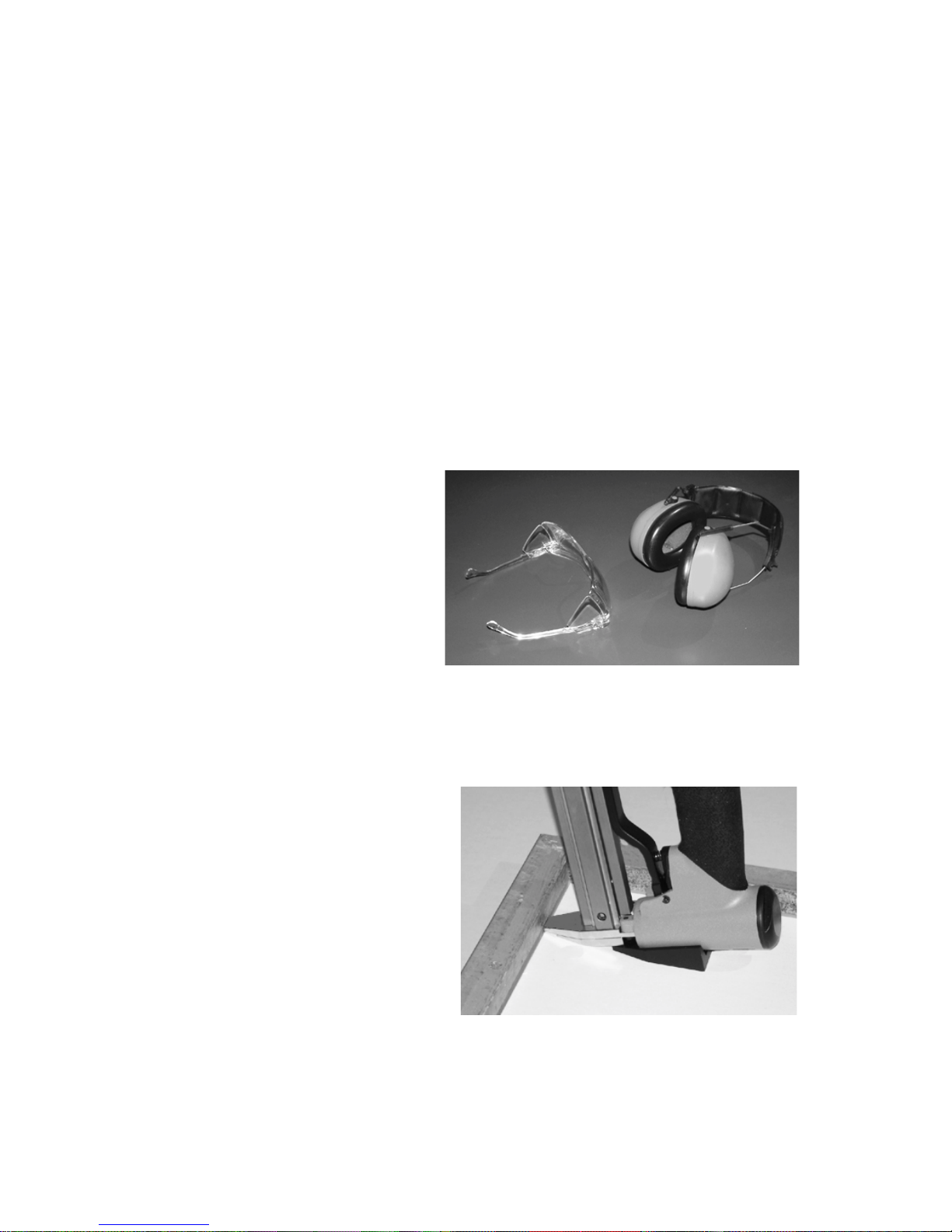

1. Use Safety Glasses.

Safety glasses with rigid

side shields must be worn

by the operator of this

driver as well as all others

in the work area. See

Figure 1.

2. Wear ear protection to

avoid possible hearing loss. See Figure 1.

3. Always assume driver contains points. Do not point the driver at

yourself or others. DO NOT

drive a point freely in the air.

4. Always hold the nose of

the driver tight against the

wooden frame before

operating the trigger. See

Figure 2.

5. Use clean, dry regulated

compressed air at 70 to

100PSI, (5 to 7 BAR). The system should include filter, pressure

regulator, and automatic oiler.

Figure 1

Figure 2

3

6. Do not connect this driver to an air supply with

maximum potential pressure greater than 200 PSI,

(14 BAR).

7. Never use oxygen, carbon dioxide, combustible

gases or any type of bottled gas as a source for this

driver. Explosion and serious injury may result.

8. Only connect driver to the air supply with a coupling

that removes all pressure when disconnected.

9. Disconnect the driver from the air supply before doing

maintenance, removing a jam, leaving the work area, moving to

another area or handing the driver to another person.

10. Connect the point driver to air supply before loading points to

prevent driving a point during connection. The driving mecha-

nism may operate when the driver is connected to air supply.

11. Never use the driver if it is leaking, has missing parts, or re-

quires repair. Make sure all screws and caps are securely

tightened.

12. Do not use the driver if the safety warning label is missing or

unreadable. Contact a Fletcher-Terry Customer Care Represen-

tative for a replacement.

13. Only use points, parts, and accessories recommended by

Fletcher-Terry.

14. Do not load points with the trigger depressed, to prevent uninten-

tional firing of a point.

16. Release trigger after firing a point. Never carry the driver with

your finger on the trigger.

17. Do not over-reach or use the driver from an awkward or insecure

position.

4

OPERATING INSTRUCTIONS

The Pneumatic FrameMaster® and Pneumatic FlexiMaster® are de-

signed to insert points into wooden frames to secure artwork, mat, glass,

and backing material. Fletcher Flexible Framer’s Points are used when it

is likely the secured material may be removed and reinstalled or re-

placed. Flexible Framer’s Points can be bent away from the material and

subsequently bent back in place.

Fletcher Framer’s Points are stiffer and provide greater holding power.

The two types of points are NOT interchangeable in the two pneumatic

point drivers.

Preparation of Point Driver

1. Attach an air supply nipple (1/4 NPT) in place of the plastic

plug in the handle. Choose the fitting that is compatible to your air

hose fitting. Be sure to use the type which purges air from the driver

when disconnected.

2. Connect the point driver to the air supply hose before loading

points, with the regulator set between 70 and 100 PSI, (5 to 7

BAR).

3. An in-line filter and oiler will extend the life of the driver. If an

oiler is not in the air supply, place one or two drops of Air Tool Oil

(12-648) in the connection nipple each day.

4. Check for air leakage and correct before proceeding.

5. All air line components such as hoses, connectors, filters,

regulators, etc. must have a minimum pressure rating of 150

PSI (10 BAR), or 150% of maximum system potential, whichever

is greater.

Loading Points

Remember, Framer’s Points and Flexible Framer’s Points are not

interchangeable. Use only Fletcher brand points to insure proper fit and

avoid the possibility of damaging the driver and voiding the warranty.

5

Pneumatic FrameMaster®:

1. Connect the point driver to the air supply before loading points.

2. Lay the driver on a table, release the magazine latch and slide the

magazine cover fully open.

3. Hold a full stack of Framer’s

Points at an angle with the glue

side down, and the sharp end of

the points under the lip of the

magazine groove as shown at A

in Figure 3.

4. Now lay the stack down so the

pointed ends of the stack

remain trapped under lip A in

the magazine groove.

5. Push on the End Cap to close and latch the cover.

Figure 3

Pneumatic FlexiMaster®

1. Release the magazine latch and slide its cover all the way open.

2. Lay the driver down as shown in Figure 4.

3. Position a stack of Flexible Framer’s Points with the pointed edge

away from the handle and the glue groove in the points facing

toward you and lay the

stack down.

4. Push on the End Cap to

close and latch the

cover.

Figure 4

A

A

6

Operation of Pneumatic Point Drivers

1. Wear safety glasses and ear protection recommended in Safety

Instructions, Figure 1.

2. Place the picture frame face down on a flat surface.

3. Rest the stabilizing shoe

flat on the backing and push

the nose piece firmly

against the frame as shown

in Figure 5.

4. Support the frame at

position Ato prevent it

from moving.

5. Pull the trigger and the

point will be fired into the wood. A puff of air will be exhausted from

the top of the driver which is normal.

6. The depth of penetration into wood is affected by the density of

the wood and can be adjusted by the amount of air pressure. Do not

exceed 100 PSI.

7. If the backing places the driver too close to the edge of the frame,

tilt the driver so the point will be driven at a downward angle into

the wood; otherwise it may ricochet off the frame and create a

hazard.

8. When you can no longer see points in sight hole B, add another

stack.

CAUTION: Remove your finger from the trigger before carrying the

driver. If some time will pass between frames, discon-

nect the air hose from the driver. Keep the driver pointed in

a safe direction at all times.

Figure 5

A

B

7

How to Clear a Jammed Point

1. IMPORTANT: Disconnect the driver from the air supply.

2. Remove the two Lower Guide Mounting Screws (A),

Figure 6. The Lower Guide and the Stabilizing Shoe

can now be removed as an assembly.

3. Unlatch the magazine and slide the cover open.

Maintenance (Daily)

1. Disconnect the driver from its air supply.

2. Clean the driver by wiping with a cloth. A non-flammable cleaning

solution may be used sparingly, but do not permit it to seep into the

driver where it may cause damage.

3. Check all accessible screws to insure they are tight.

4. Remove points and clean and inspect the magazine interior.

5. Call a Fletcher-Terry Customer Care Representative if more exten-

sive repair or assistance is required. 1.800.843.3826.

A

Figure 6

4. Push the jammed

point out of the opening

(B) in Figure 7. You can access it

from inside the magazine.

5. Reassemble the Lower Guide and

Stabilizing Shoe to the driver with

the two screws removed in step 2.

6. This procedure applies to both the Pneumatic FrameMaster® and

Pneumatic FlexiMaster®.

7. Connect the driver to air supply, reload a stack of points and close

the magazine cover.

Figure 7

B

A

8

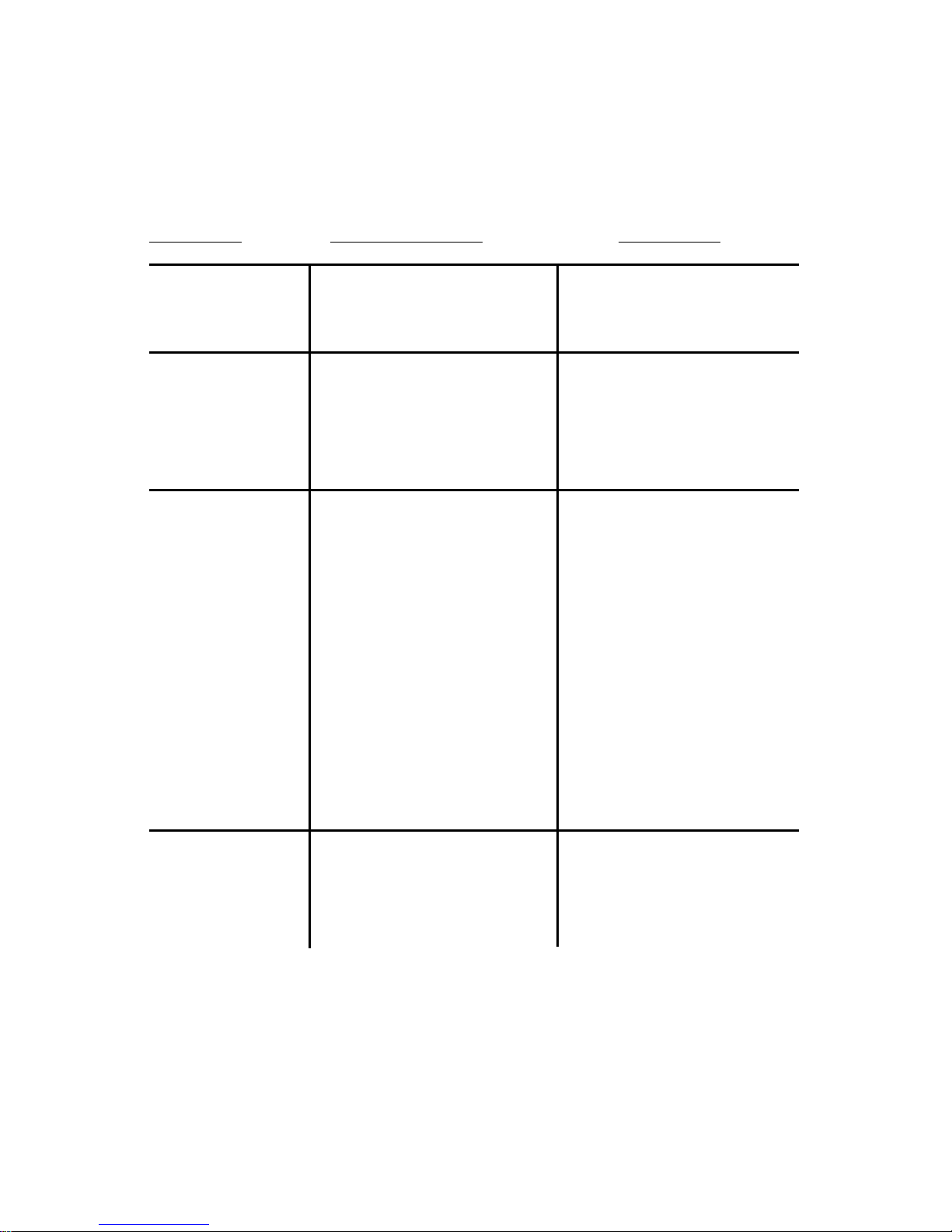

Trouble Shooting

CAUTION: ALWAYS disconnect air supply before performing any

service procedure.

Symptom Probable Cause Correction

Air leak Loosescrews Tighten screws

Connector nipple loose Tighten connector

Driver does not Inadequate air supply Verify and correct

fire, or is sluggish supply and pressure

Inadequate lubrication Put 1 or 2 drops of oil in

air supply connector

Frequent jams Incorrect points Use Fletcher brand

Points

Loose screws on Upper Tighten screws

or Lower Guides

Foreign matter in Open and clean

magazine magazine

Foreign matter between Remove Lower Guide

Upper and Lower Guides and clean the point

path

Other Contact a Fletcher-

Terry Customer Care

Representative at

800.843.3826

9

Pneumatic FrameMaster®

Ref.No. Part No. Description Quantity

1 12-635 Stabilizing Shoe 1

2 12-636 Upper Guide 1

4 12-637 Lower Guide 1

6 12-638 Trigger 1

8 12-639 Trigger Spring 1

9 12-640 Trigger Pin 1

10 12-641 Retaining Clip 1

11 12-642 End Cap 1

13 12-643 End Cap Screw 2

14 12-644 Stabilizing Shoe Screw 1

15 12-645 Lower Guide Mtg. Screw 2

16 12-645 Upper Guide Mtg. Screw 2

17 12-646 Guide Assembly Mtg. Screw 2

18* 12-647 3mm Hex Wrench 1

19* 12-648 Air Oil 1

*Not Shown

13

17

15

16

10

Pneumatic FlexiMaster®

Ref.No. Part No. Description Quantity

1 12-635 Stabilizing Shoe 1

3 12-670 Upper Guide 1

5 12-671 Lower Guide 1

7 12-672 Trigger 1

8 12-639 Trigger Spring 1

9 12-640 Trigger Pin 1

10 12-641 Retaining Clip 1

12 12-673 End Cap 1

13 12-643 End Cap Screw 2

14 12-644 Stabilizing Shoe Screw 1

15 12-645 Lower Guide Mtg. Screw 2

16 12-645 Upper Guide Mtg. Screw 2

17 12-646 Guide Assembly Mtg. Screw 2

18* 12-647 3mm Hex Wrench 1

19* 12-648 Air Oil 1

* Not Shown

This manual suits for next models

1

Table of contents