8

Safety Precautions

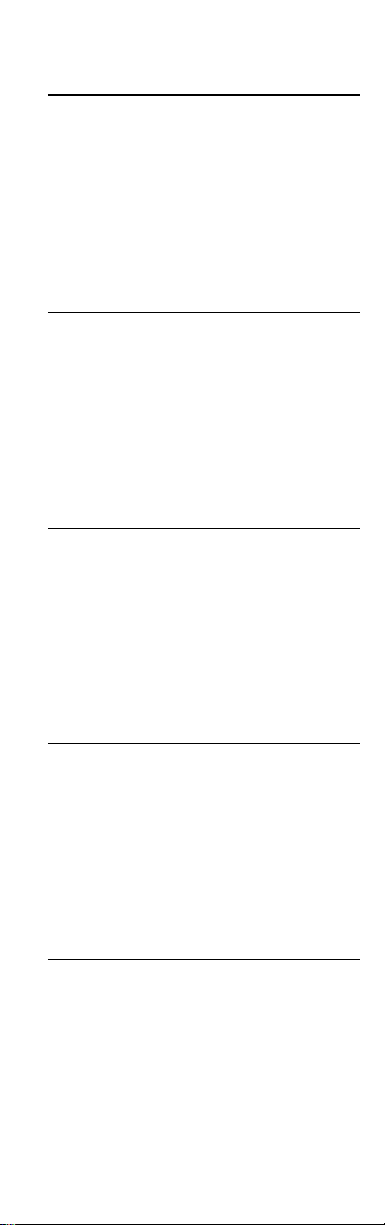

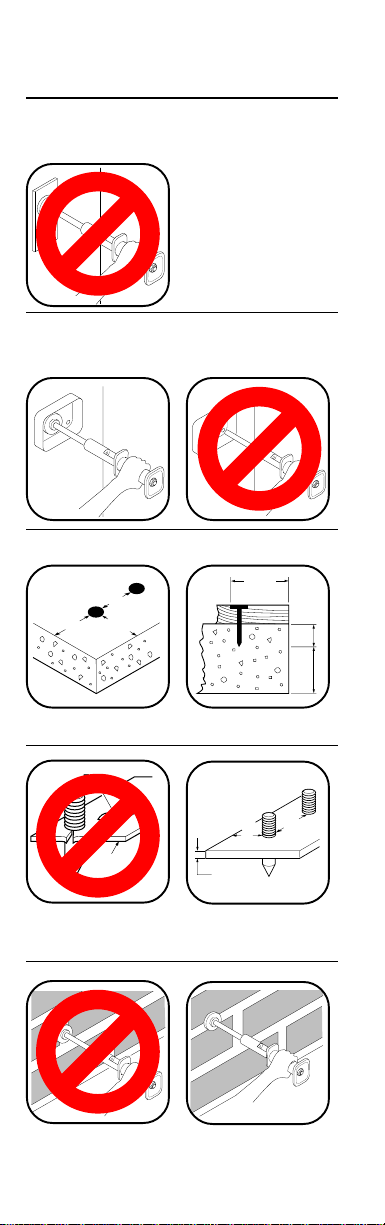

4. NEVER drive fasteners into thin or

easily penetrated materials unless

it is backed by concrete or steel.

When in doubt, such as when base

material is concealed, conduct a

CenterPunchTest.Checkcontinu-

ally to avoid fastening into unsuit-

able material, especially in older

buildings.

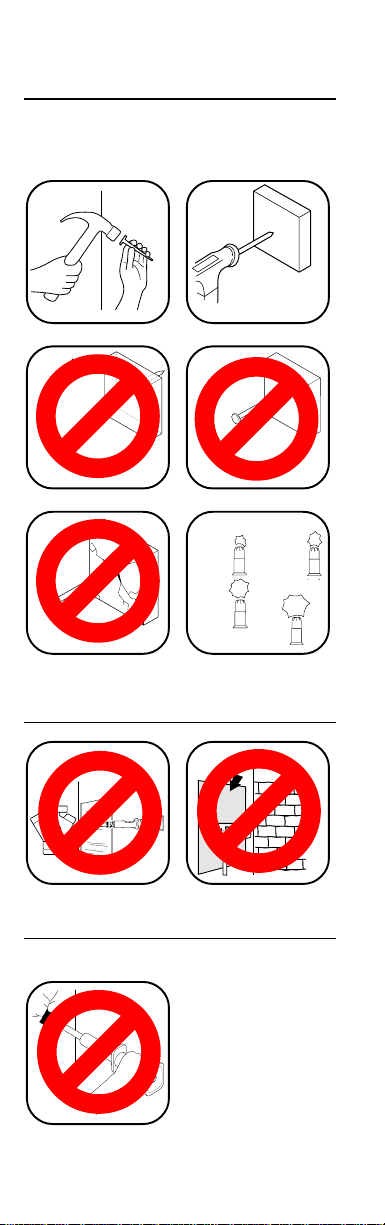

5. DO NOT fasten thru or within

12.7mm (1/2") of predrilled or pre-

punched holes.

6. DO NOT drive fasteners into con-

crete less than three times as thick

as the intended fastener penetra-

tion, within 76mm (3") of the edge,

within 76mm (3") of another fas-

tenerorwithin76mm(3") ofafailed

fastener.

7. DO NOT drive fasteners into steel

base material less then 4.8mm

(3/16") thick, within 51mm (2") of a

weld, within 12.7mm (1/2") of the

edgeorwithin25mm(1")ofanother

fastener.

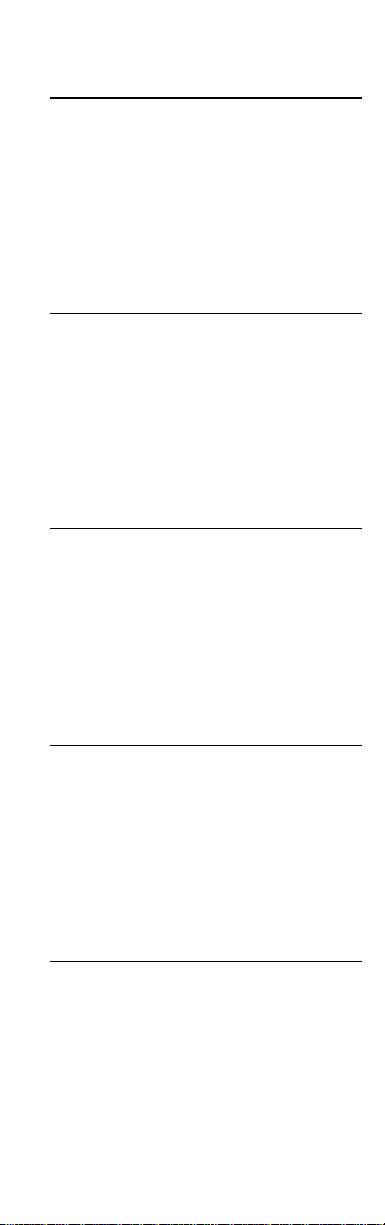

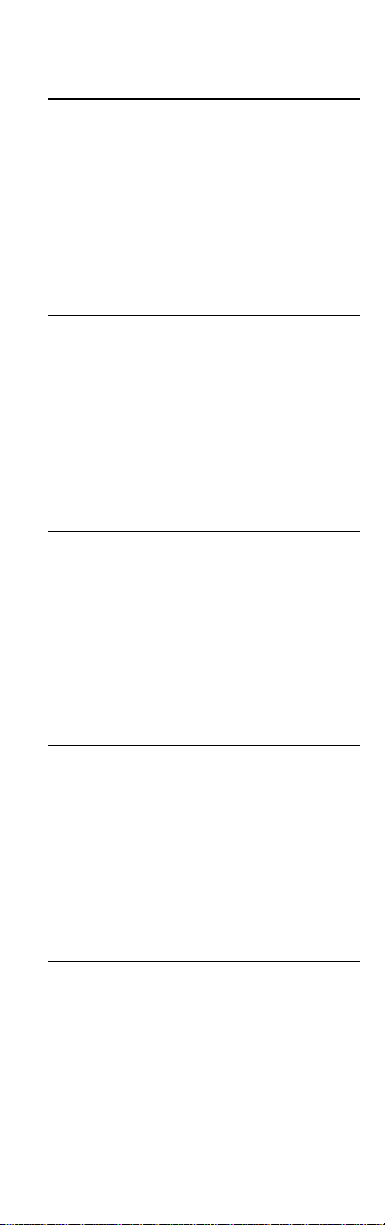

8. Whenfasteningintomasonrywalls,

always drive into horizontal mortar

joints, NEVER into vertical mortar

joints. BE CAREFUL, a poorly laid

joint may permit too much penetra-

tion, and/or unsatisfactory holding

power.