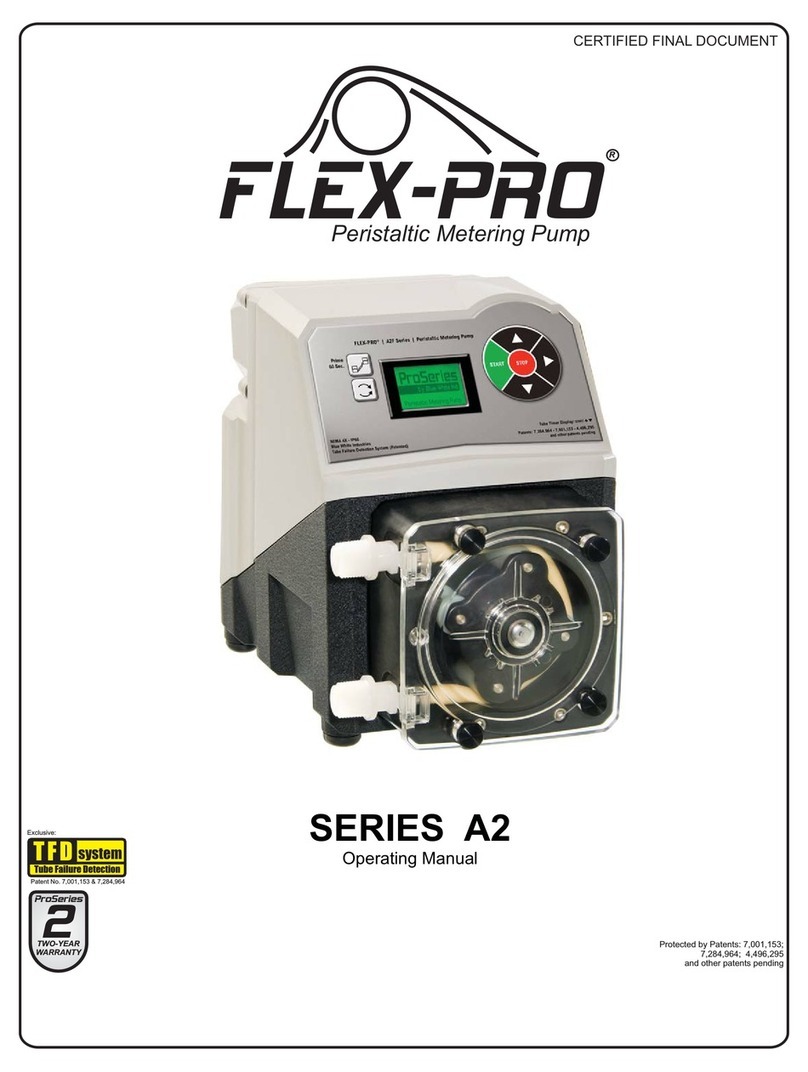

1.4 Features

Enclosure Rating:

NEMA 4X: Constructed for either indoor or outdoor use to provide a degree of protection to personnel against

incidental contact with enclosed equipment; to provide a degree of protection against falling dirt, rain, sleet, snow,

windblown dust, splashing water, and hose-directed water; and that will be undamaged by external formation of ice

on enclosure.

IP66: No ingress of dust; complete protection against contact. Water projected in powerful jets against enclosure from

any direction shall have no harmful effects.

Page 4 Page 5

1.2 Specifications

Maximum working pressure (excluding pump tubes):

125 psig (8.6 bar)

Note: see individual pump tube assembly maximum pressure ratings.

Maximum Fluid temperature (excluding pump tubes):

o o

185 F (85 C)

Note: see individual pump tube assembly maximum temperature ratings.

Ambient Operating Temperature

O O O O

14 F to 115 F (-10 C to 46 C)

Ambient Storage Temperature

O O O O

-40 F to 158 F (-40 C to 70 C)

Operating Voltage:

A3 MODELS: 96 to 264VAC-50/60Hz, 220W

A4 MODELS: 96 to 264VAC-50/60Hz, 350W

Power Cord Options:

115V60Hz = NEMA 5/15 (USA)

230V60Hz = NEMA 6/15 (USA)

220V50Hz = CEE 7/VII (EU)

240V50Hz = AS 3112 (Australia/New Zealand)

Enclosure:

NEMA 4X (IP66), Polyester powder coated aluminum.

Maximum Overall Dimensions:

A3 models: 8-1/8”W x 10-3/4”H x 15-1/4”D (20.6W x 27.3H x 38.9D cm)

A4 models: 12-1/8”W x 14-1/4”H x 18-5/8”D (30.8W x 36.1H x 47.3D cm)

Approximate shipping wt:

A3 models: 33 lb. (15.0 Kg)

A4 models: 58 lb. (26.3 Kg)

Motor speed adjustment range 2,500:1:

0.05% - 100% motor speed

Motor speed adjustment resolution:

0.1% increments > 10% motor speed

0.01% increments > 1% motor speed and < 10%

0.001% increments < 1% motor speed

Maximum viscosity:

12,000 Centipoise

Maximum suction lift:

30 ft. Water, 0 psig (4.5 m, 0 bar)

Display

3 color VGA backlit LCD, UV resistant.

Display Languages

English, Spanish, French or German selectable.

Keypad

Ten button positive action tactile switch keypad.

Security

Programmable 4-digit password.

Wetted components: Non-Wetted components:

Pump Tube Assembly (Model Specific - 2 provided):

Tubing: . . . . . Norprene or Norprene Chemical or Tygothane® ® ®

Adapter fittings: .PVDF

Enclosure:

413 Aluminum (Polyester powder coated)

Pump Head:

Valox (PBT) thermoplastic®

Pump Head Cover:

Polycarbonate for added strength and chemical resistance.

Permanently lubricated sealed motor shaft support ball bearing.

Cover Screws:

Stainless Steel

Roller Assembly:

Rotor:..................................Valox (PBT)®

Rollers: ...............................Nylon

Roller Bearings: .................SS Ball Bearings

Motor Shaft:

Chrome plated steel

TFD System Sensor pins:

Hastelloy C-276

Power Cord:

3 conductor, SJTW-A Water-resistant

Tube Installation Tool:

GF Nylon

Mounting Brackets and Hardware:

316 Stainless Steel

Injection / Back-flow Check valve:

Body & insert: . . . . . . PVDF

Check Ball: . . . . . . . . Ceramic

Spring: . . . . . . . . . . Hastelloy C-276

Ball Seat O-ring: . . . . . TFE/P (optional EP)

Static Seal O-ring: . . . . TFE/P (optional EP)

Ancillary Items provided

With “S” tubing type connections only:

Suction Tubing: . . . . . 3/8” OD x 1/4” ID x 10’ Clear PVC

Discharge Tubing: . . . . 3/8” OD x 1/4” ID x 10’ Polyethylene (LLDPE)

Suction Strainer: .....PVDF

With “B” tubing and “M” M/NPT connections only:

(Available on ND, NKL, NK, NGG, NEE and A4 only)

Suction Strainer:

Body: .................PVDF

Check Ball: ............Ceramic

Ball Seat O-ring: . . . . . . . . TFE/P (optional EP)

1.3 Materials of construction

!Peristaltic pump design does not have valves that can clog requiring maintenance.

!Self priming - even against maximum line pressure. By-pass valves are not required. Cannot vapor lock or

lose prime. Syphoning cannot occur.

!Output rates to: 158.5 GPH (600 LPH) and pressures to 125 PSI (8.6 Bar).

!No maintenance brushless variable speed motor.

!Specially engineered tubing for long life at high pressures.

!Patented Tube Failure Detection (TFD) system. Senses tube failure by detecting chemical in the pump head.

No false triggering.

!2500:1 turndown ratio.

!SCADA Inputs include: 4-20mA, 0-10Vdc, and Pulse inputs for remote external speed control and 0-30 VDC /

contact closure remote start/stop.

!Operator friendly digital touch pad with menu driven software.

!VGA Graphic multi-color backlit LCD displays remote/local control status, motor speed, output rate, input

signal values, service and alarm status.

!Outputs include: Scalable 4-20mA or pulse, one 250V/6A relay and three 115V/1A contact closures assignable

to monitor up to 17 different pump functions including TFD, FVS, remote/local control setting, motor on, fault,

current operating mode, and others.

!Two CNC precision machined squeeze rollers and two alignment rollers for optimum squeeze, unparalleled

accuracy, and tube life.

!Heavy duty rotor - single piece plastic rotor means no flexing and increased accuracy (no metal springs or

hinges to corrode).

!Inject at maximum PSI in either direction (clockwise and counter clockwise).

!Patent pending feature for extended tube life.

!Compatible with Blue-White’s output Flow Verification Sensor (FVS) system.

1.5 Agency Listings

Symbol Explanation

!

WARNING, risk of electric shock

CAUTION, refer to users’ guide

GROUND, PROTECTIVE CONDUCTOR TERMINAL

Flex-Pro Flex-Pro

This pump is ETL listed to conforms to the following:

UL Standard 778 as a motor operated water pump

CSA Standard C22.2 as process control equipment

This pump complies to the Machinery Directive 98/37/EC, BS EN 60204-1, Low Voltage Directive

73/23/EC BS EN 61010-1, EMC Directive 89/336/EC, BS EN 50081-1/BS EN 50082-1.

For “C” Tri-clamp and “Q” Quick Disconnect connections:

(Available on ND, NKL, NK, NGG, and NEE only)

No accessories provided

*Quick Disconnect Valves sold separately