0214

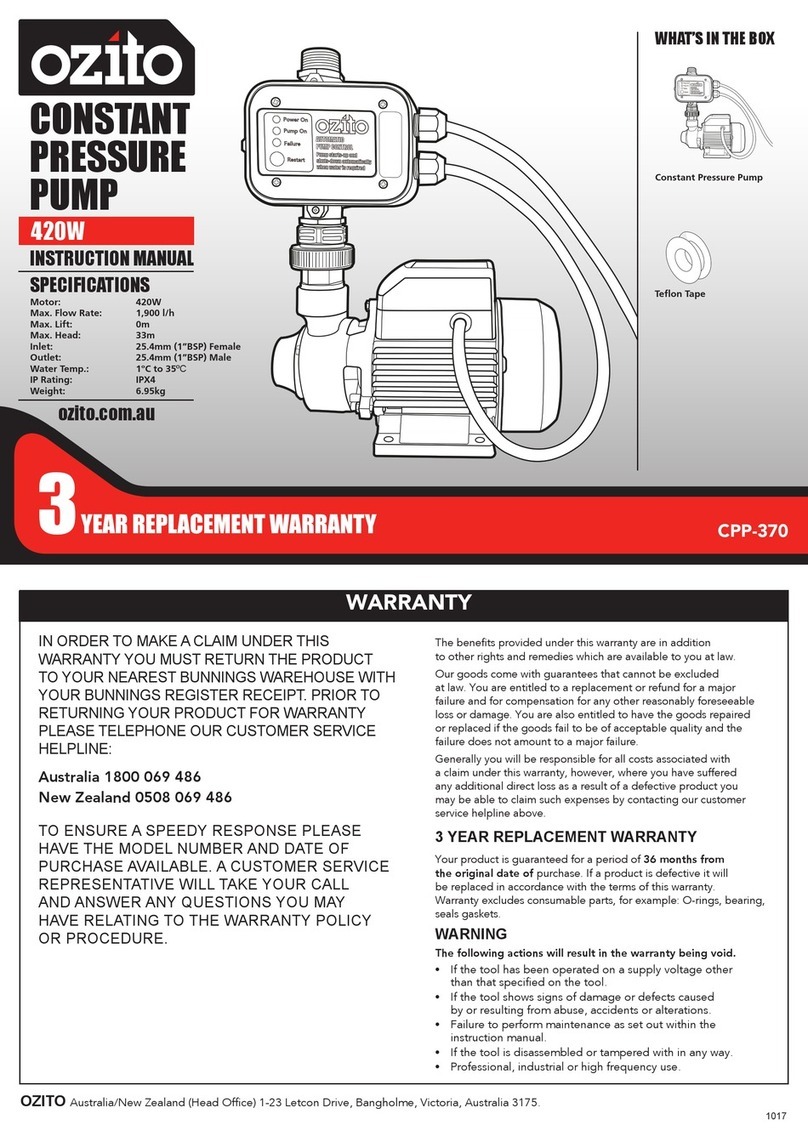

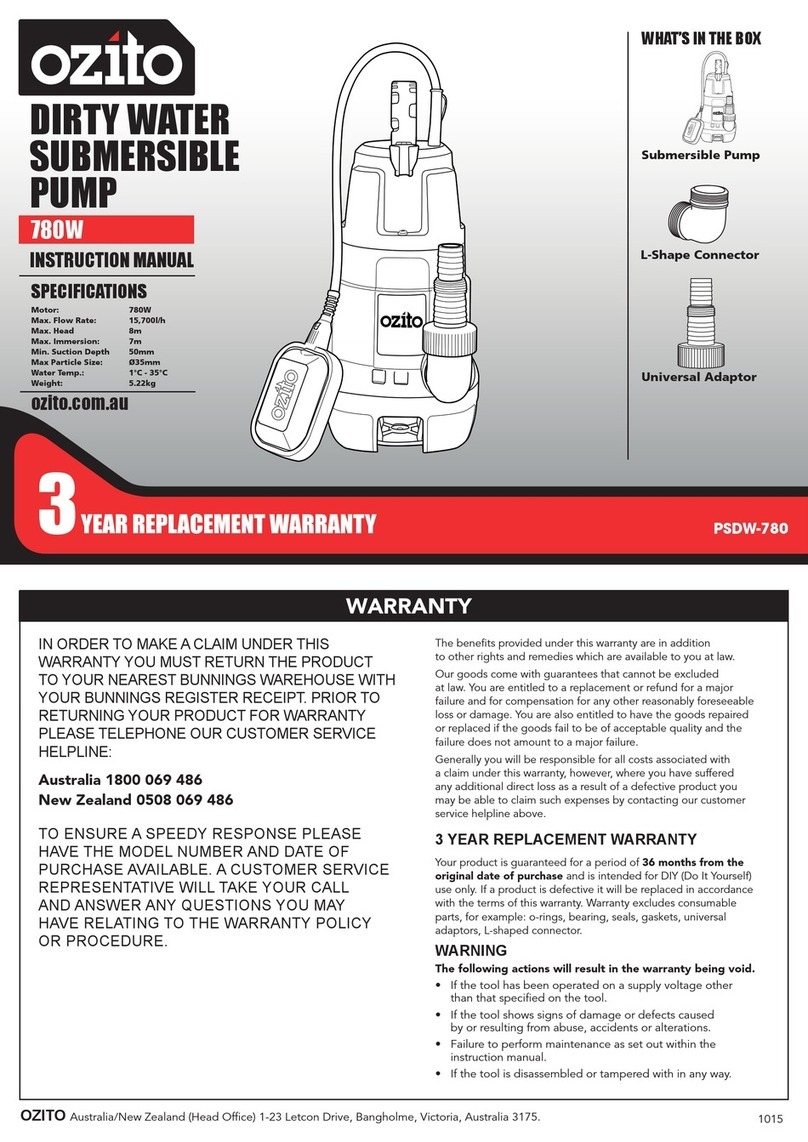

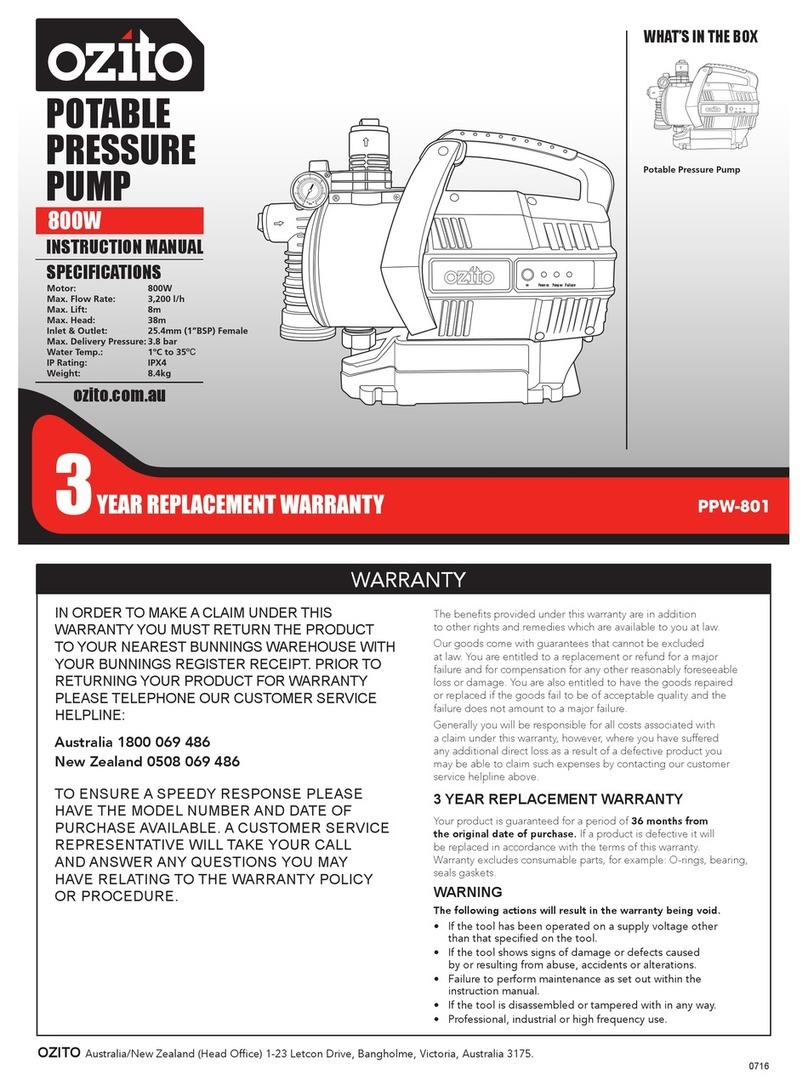

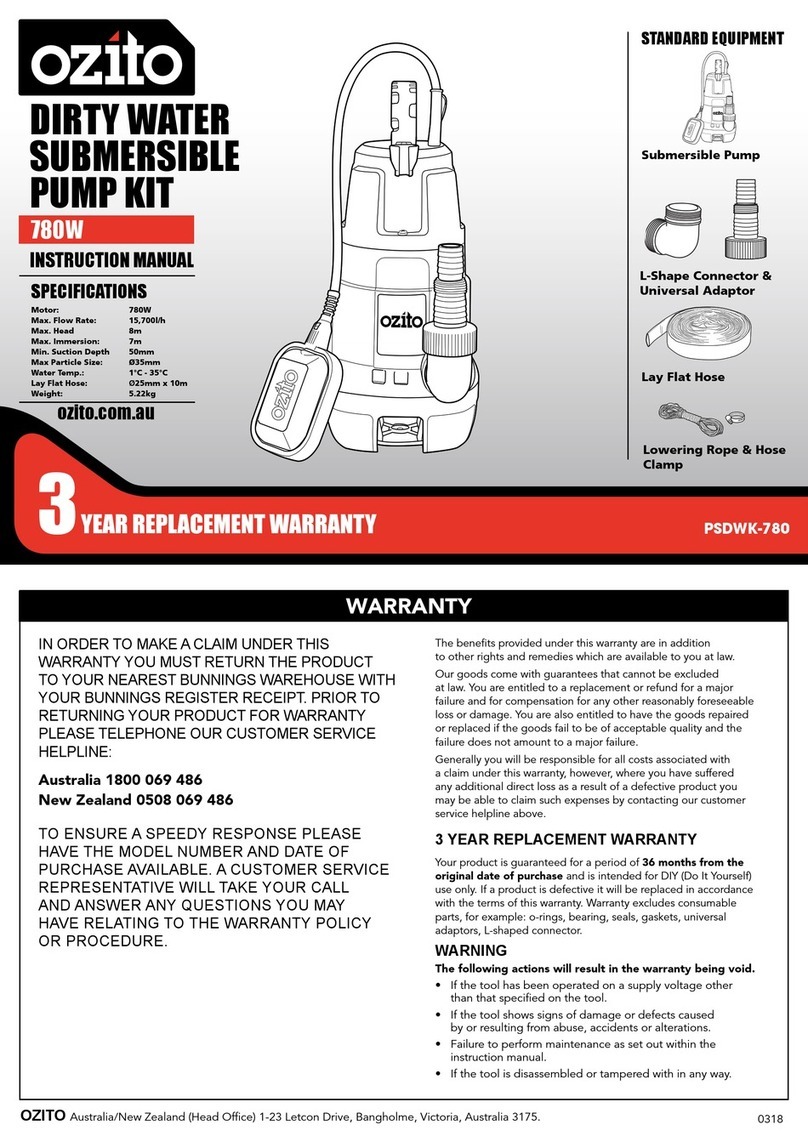

SUBMERSIBLE

WATER PUMP

750W

INSTRUCTION MANUAL

SPECIFICATIONS

Motor: 750W

Max. Flow Rate: 13,000l/h

Max. Head 8m

Max. Immersion: 7m

IP Rating: IPX8

Max Particle Size: Ø30mm

Water Temp. : 1°C - 35°C

Weight: 5.0kg

PSCD-750

WHAT’S IN THE BOX

Submersible Pump

Universal Adaptor

IN ORDER TO MAKE A CLAIM UNDER THIS

WARRANTY YOU MUST RETURN THE PRODUCT

TO YOUR NEAREST BUNNINGS WAREHOUSE WITH

YOUR BUNNINGS REGISTER RECEIPT. PRIOR TO

RETURNING YOUR PRODUCT FOR WARRANTY

PLEASE TELEPHONE OUR CUSTOMER SERVICE

HELPLINE:

Australia 1800 069 486

New Zealand 0508 069 486

3 YEAR REPLACEMENT WARRANTY

Your product is guaranteed for a period of 36 months from the

original date of purchase and is intended for DIY (Do It Yourself)

use only. If a product is defective it will be replaced in accordance

with the terms of this warranty. Warranty excludes consumable

parts, for example: o-rings, bearing, seals, gaskets, universal

adaptors, L-shaped connector.

WARNING

The following actions will result in the warranty being void.

• If the tool has been operated on a supply voltage other

than that specified on the tool.

• If the tool shows signs of damage or defects caused

by or resulting from abuse, accidents or alterations.

• Failure to perform maintenance as set out within the

instruction manual.

• If the tool is disassembled or tampered with in any way.

INSTALLATION

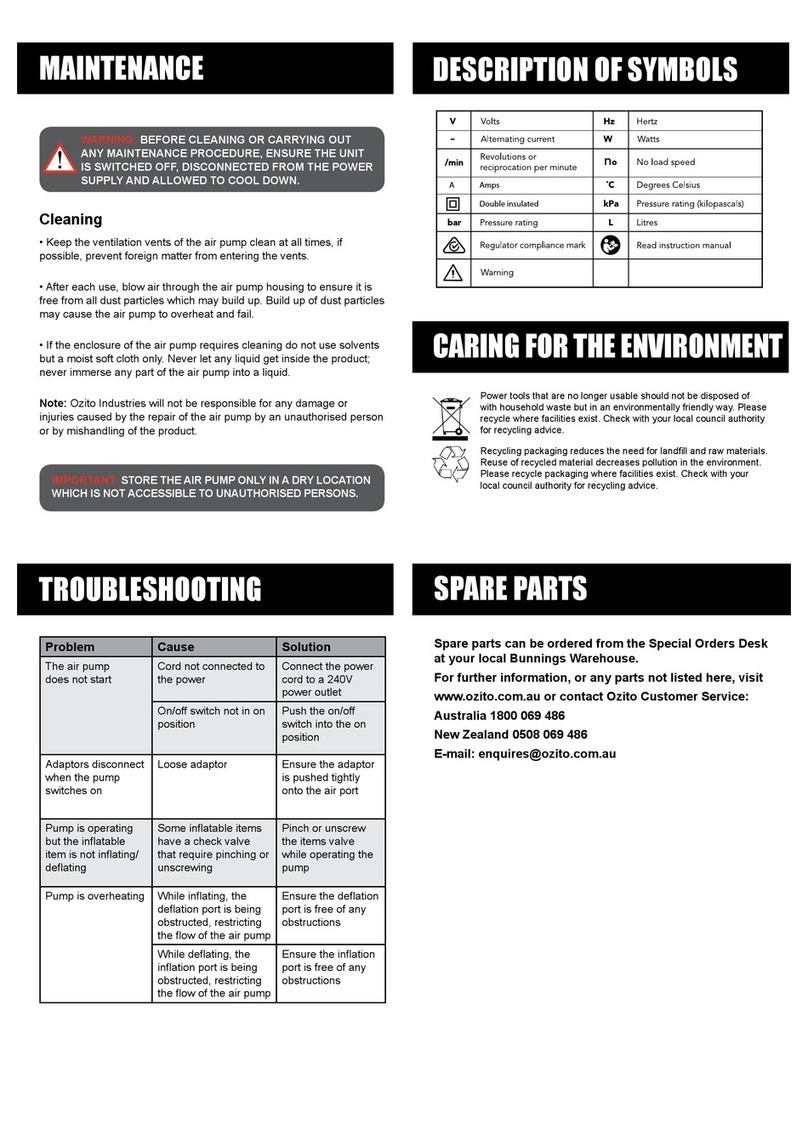

DESCRIPTION OF SYMBOLS

CARING FOR THE ENVIRONMENT

TROUBLESHOOTING

Power tools that are no longer usable should not be disposed of

with household waste but in an environmentally friendly way. Please

recycle where facilities exist. Check with your local council authority

for recycling advice.

Recycling packaging reduces the need for landll and raw materials.

Reuse of recycled material decreases pollution in the environment.

Please recycle packaging where facilities exist. Check with your

local council authority for recycling advice.

WARRANTY

TO ENSURE A SPEEDY RESPONSE PLEASE

HAVE THE MODEL NUMBER AND DATE OF

PURCHASE AVAILABLE. A CUSTOMER SERVICE

REPRESENTATIVE WILL TAKE YOUR CALL

AND ANSWER ANY QUESTIONS YOU MAY

HAVE RELATING TO THE WARRANTY POLICY

OR PROCEDURE.

OZITO Australia/New Zealand (Head Office) 1-23 Letcon Drive, Bangholme, Victoria, Australia 3175.

The benefits provided under this warranty are in addition

to other rights and remedies which are available to you at law.

Our goods come with guarantees that cannot be excluded

at law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure.

Generally you will be responsible for all costs associated with

a claim under this warranty, however, where you have suffered

any additional direct loss as a result of a defective product you

may be able to claim such expenses by contacting our customer

service helpline above.

Spare parts can be ordered from the Special Orders Desk

at your local Bunnings Warehouse.

For further information, or any parts not listed here, visit

www.ozito.com.au or contact Ozito Customer Service:

Australia 1800 069 486 New Zealand 0508 069 486

SPARE PARTS

ozito.com.au

ADDITIONAL SAFETY INSTRUCTIONS FOR PUMPS

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save these instructions

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Donotoperatepumpsinexplosiveatmospheres,suchasinthepresenceofammableliquids,

gases or dust. Pumps create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while operating a pump. Distractions can cause you to lose control.\

2. Electrical safety

a. Pump plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs

with earthed (grounded) pumps. Unmodied plugs and matching outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the pump. Keep cord

away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of

electric shock.

d. When operating a pump, use an extension cord suitable for wet conditions. Use of a cord suitable for

wet use reduces the risk of electric shock.

e. This pump must be used with a residual current device with rated residual current of 30mA or less.

Use of an RCD reduces the risk of electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use common sense when operating a pump. Do not use

apumpwhileyouaretiredorundertheinuenceofdrugs,alcoholormedication. A moment of

inattention while operating a pump may result in serious personal injury.

b. Avoid accidental starting. Ensure the switch is in the off position before plugging in. Carrying pump

with your nger on the switch or plugging in pumps that have the switch on invites accidents.

c. Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

d. When operating a pump outdoors, use an extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

4. Pump use and care

a. Disconnect the plug from the power source before making any adjustments, changing accessories,or

storing pumps. Such preventive safety measures reduce the risk of starting the pump accidentally.

b. Maintain pumps. Check for misalignment or binding of moving parts, breakage of parts and any other

condition that may affect the pumps operation. If damaged, have the pump repaired before use. Many

accidents are caused by poorly maintained pumps.

c. Use the pump, and accessories etc., in accordance with these instructions and in the manner

intended for the particular type of pump, taking into account the working conditions and the work to

be performed. Use of the pump for operations different from intended could result in a hazardous situation.

5. Service

a. Haveyourpumpservicedbyaqualiedrepairpersonusingonlyidenticalreplacementparts.This will

ensure that the safety of the pump is maintained.

a. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly

qualied persons in order to avoid a hazard.

GENERAL SAFETY WARNINGS

ELECTRICAL SAFETY

WARNING! This product is intended for pumping water in a Home Domestic application. Do

not use it for corrosive, abrasive, explosive or dangerous liquids. Fluids other than water will

damagethewaterpumpand/orcreatearehazard.Failuretofollowallinstructionslistedbelow

mayresultinelectricshock,reand/orseriousinjury.

WARNING! This product is not suitable for use with drinking (potable) water.

This appliance is not intended for use by person (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

• Ensurethewaterpumpisdisconnectedfrommainspowerwheninstalling.

• Donotinstalloroperatethewaterpumpinanexplosiveenvironmentornearammablematerial.

• Donotoperatethewaterpumpwithoutliquid.

• Donotrunthewaterpumpdry.

WARNING! The water pump together with associated pipework operate under pressure. Do not

disconnect water pump or pipework until internal pressure has been released. Failure to do this

could result in personal injury and damage to property.

• Avoid inserting hands into the inlets/outlets of the water pump while it is connected to power.

• Before using the water pump, always inspect it visually. Do not use the pump if it is cracked and/or damaged.

If the water pump is damaged, contact Ozito customer service.

• The water pump has a built-in thermal protection overload switch. The water pump stops if an overload

occurs. The motor restarts automatically after it has cooled down.

• The pump must not be used when people are in the water.

• Never work or perform maintenance on the pump without rst making sure it has been disconnected from the

mains power.

• Pollution of the liquid could occur due to leakage of lubricants Important:

Avoid inserting hands into the mouth of the pump if it is connected to the mains.

The electrical connection must always be made in a dry area. Make sure that electrical connections are protected

from inundations.

Protect the plug and the power cable from heat, oil or sharp edges.

If damaged, The power cable must be replaced by a qualied electrician.

L-Shape Connector

Float Switch

PVCPolyvinyl chloride IPX8 Ingress protection from water

Regulator compliance mark Warning

Read instruction manual

Problem Possible Cause Solution

The pump does not start,

or pump water

Pump is not connected to the power supply

Float switch has not been activated, water

level too low

The impellor is stuck

The thermal overload protection is activated

The motor is damaged

Check that the pump is connected to the mains power supply

Manually raise the position of the oat switch

Turn pump off and inspect and clean obstruction

Wait for the motor to cool and it will automatically start operation

Contact Ozito customer service

The pump does not supply water

when the motor is running

Air bleed valve blocked

The suction base is obstructed/blocked

Air lock in the hose/tube and/or pump (air

bubbles)

Discharge hose/tube (not included) is kinked

or damaged

Clean the air bleed valve (Refer section 6 “air bleed valve”)

Clean the suction base of any foreign matter and debris

Perform several start-ups in order to remove all the air or lift and tilt the pump slightly while the

pump is running

Un-kink the discharge hose/tube. Or replace hose/tube

Disconnect the mains power and check the discharge outlet and lter for any foreign matter

The pump ow rate is reduced

The suction base is partially obstructed/

blocked

The hose/tube is obstructed

Air leak in the suction line or joints

Incorrect assembly leads to air and water

leakage in the discharge lines

Clean the suction base of any foreign matter and debris

Remove the obstructions

Check the suction line connections for air leaks and tighten or x where found

Ensure the discharge lines are the correct length and all assembly instructions are adhered to

Pump will not turn off, even

though the water level is low

The oat switch is stuck in the “on” position

Ensure that the oat switch is free to operate normally. Contact Ozito customer service if the

problem still occurs

Hose/tube does not stay on the

universal adaptor when water is

travelling through

The hose/tube is slightly wider than the

dimension of the universal adaptor

An adhesive can be used inside the hose/tube to prevent this or teon tape can be xed

around the universal adaptor or a hose clamp can be used

The pump operates intermittently The suction base is obstructed/blocked

Incorrect voltage is being used

The uid contains particles thicker than 35mm

The motor is faulty or damaged

Water level is below 50mm

Clean the suction base of any foreign matter and debris

Ensure the pump is connected into 230-240V power supply

Ensure the pump is not being used with particles thicker than 30mm.

Contact Ozito customer service

Ensure the water level is above 50mm

Air Bleed Valve Tool