flexicoil 6000 User manual

Printed in Canada Copyright © 1998 - 2003 by CNH Canada, Ltd. All rights reserved.

6000

NO-TILL AIR DRILL

OPERATOR’S MANUAL

RD-331V4

Ltd.

Starting at Serial No. DOC-114001

Canada:

CNH Canada, Ltd.

1000 - 71st Street East

P.O. Box 1928

Saskatoon, Saskatchewan

S7K 3S5

The content of this book was based on the most current information available as of the

date of copyright. It is the policy of CNH Canada, Ltd. to improve and develop our

products continuously. We reserve the right to make changes or add improvements, at any

time, without incurring any obligation to make such changes on machines previously sold.

EMPLOYER / OPERATOR CHECK LIST

In compliance with OSHA Standard 1928.57; all employers are required to instruct all operators, upon initial assignment

and at least annually thereafter, on practices for safe operation and servicing of this implement, stressing the following items:

- Keep all guards in place when the machine is in operation.

- Permit no riders on farm field equipment other than persons required for inspection or assistance in machine

operation.

- Stop engine, disconnect the power source, and wait for all machine movement to stop before servicing, adjusting,

cleaning, or unclogging the equipment, except where the machine must be running to be properly serviced or

maintained, in which case the employer shall instruct employees as to all steps and procedures which are necessary

to safely service or maintain the equipment.

- Make sure everyone is clear of machinery before starting the engine, engaging the power, or operating the machine.

- Instruct persons on safe operating, moving and transport practices.

- Instruct persons on the importance of proper jack placement before unhooking from the machine in field or transport

positions.

- Review lubrication requirements and practices. Check tire pressures.

- Instruct on the importance of safety chain and warning light safety devices, available for this implement.

- Review and be familiar with information detailed in the Safety, Operation, Maintenance and Adjustment sections

in this manual.

This sign-off chart has been included for your record keeping convenience.

Date: Signature of Operator Signature of Employer

REPAIR PARTS

i

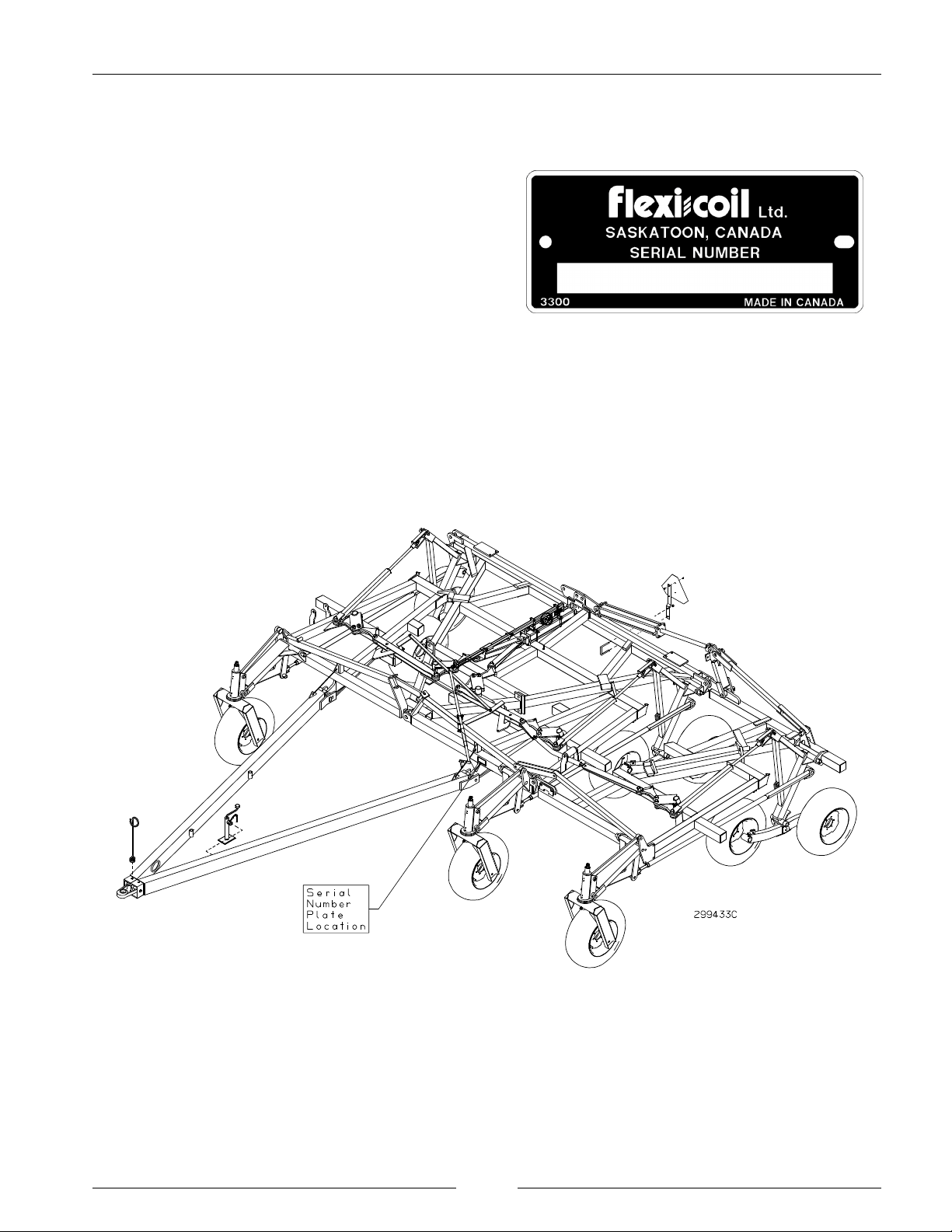

299433C

REPAIR PARTS IDENTIFICATION

The 6000 No Till Drill has a Serial Number Plate attached

at the location shown to identify the components installed

on this machine. The plate looks like the sample with a

serial number stamped on.

For easy reference, locate the Serial Number Plate at the

location shown on the figure. Record the numbers on this

sheet. When requiring repair parts, take this number into

your dealer.

REPAIR PARTS

ii

This Page is Left Blank

6000 NO-TILL AIR DRILL

iii

TABLE OF CONTENTS

Pages listed are a table of contents for that section

Section - Title ............................. Page

1- SAFETY ............................... 1-1

Safety

General Safety Practices

Safety During Operation

Safety During Transport

Safety During Servicing

Safety Decals

Safety Decal Locations

Hand Signals

2 - OPERATION ........................... 3-1

Connecting

Folding and Unfolding

Field Operation

Transporting

Disconnecting from the Tractor

3- MAINTENANCE ......................... 4-1

Servicing Safety Precautions

Daily Maintenance (Every 10 Hours)

Weekly Maintenance (Every 50 Hours)

Semi-Annual Maintenance (Every 200 Hours)

Before Seasonal Operation or Before Storage

Tire Pressures

Maintenance Table

Changing Tires

4- ADJUSTMENTS ........................ 4-1

Air Drill Leveling

Center Section Initial Leveling

Wing Initial Leveling

Setting the Frame Height

Final Leveling

Hitch Adjustment

5 - TROUBLESHOOTING ................... 5-1

Troubleshooting Table

SPECIFICATIONS

Machine Dimensions

Machine Specifications - Imperial Units

Machine Specifications - Metric Units

Tire Pressure and Wheel Bolt Torque

iv

This Page is Left Blank

page 1-1

SECTION 1

SAFETY

CONTENTS OF THIS SECTION

Page

SAFETY ............................................................ 1-3

GENERAL SAFETY PRACTICES ...................................... 1-4

SAFETY DURING OPERATION ........................................ 1-4

SAFETY DURING TRANSPORT ....................................... 1-4

SAFETY DURING SERVICING ........................................ 1-5

SAFETY DECALS .................................................... 1-5

SAFETY DECAL LOCATIONS ......................................... 1-6

HAND SIGNALS ..................................................... 1-8

SECTION 1 - SAFETY

page 1-2

This Page is Left Blank

SECTION 1 - SAFETY

page 1-3

DANGER!

WARNING!

CAUTION!

SAFETY

SAFETY-ALERT SYMBOL

This symbol is used to denote possible danger and care should be taken to prevent bodily injury.

This symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

THIS SYMBOL APPEARS WITH TEXT READING “DANGER!”, “CAUTION!”, OR “WARNING!” THESE

WORDS INDICATE THREE LEVELS OF POSSIBLE HAZARDS, THAT ARE DESCRIBED BELOW.

Indicates an immediate hazardous situation which

if not avoided, will result in death or serious injury.

The color associated with Danger is RED.

Indicates a potentially hazardous situation that if

not avoided, could result in death or serious injury.

The color associated with Warning is ORANGE.

Indicates a potentially hazardous situation which

if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices. The color associated with Caution is

YELLOW.

SECTION 1 - SAFETY

page 1-4

196152C

097002S

GENERAL SAFETY PRACTICES

REVIEW this manual before each season of use.

NEVER allow anyone unfamiliar, untrained or complacent

to operate the drill.

ALWAYS USE the jack supplied when unhooking the

drill.

NEVER transport the drill at speeds higher than 32 km/hr

(20 mph).

It is PREFERRED to transport the drill separately without

an air cart attached. This is however, not always practical.

If you are transporting the drill with a tow between air cart,

the air cart should not be empty. If you are transporting

the drill with a tow behind air cart, the air cart should be

empty.

BE SURE the drill is securely fastened to a large farm

tractor or an air cart that is attached to a large farm tractor

before operating hydraulics.

USE EXTREME CARE when making adjustments.

KEEP CHILDREN AWAY from all farm equipment.

SAFETY DURING OPERATION

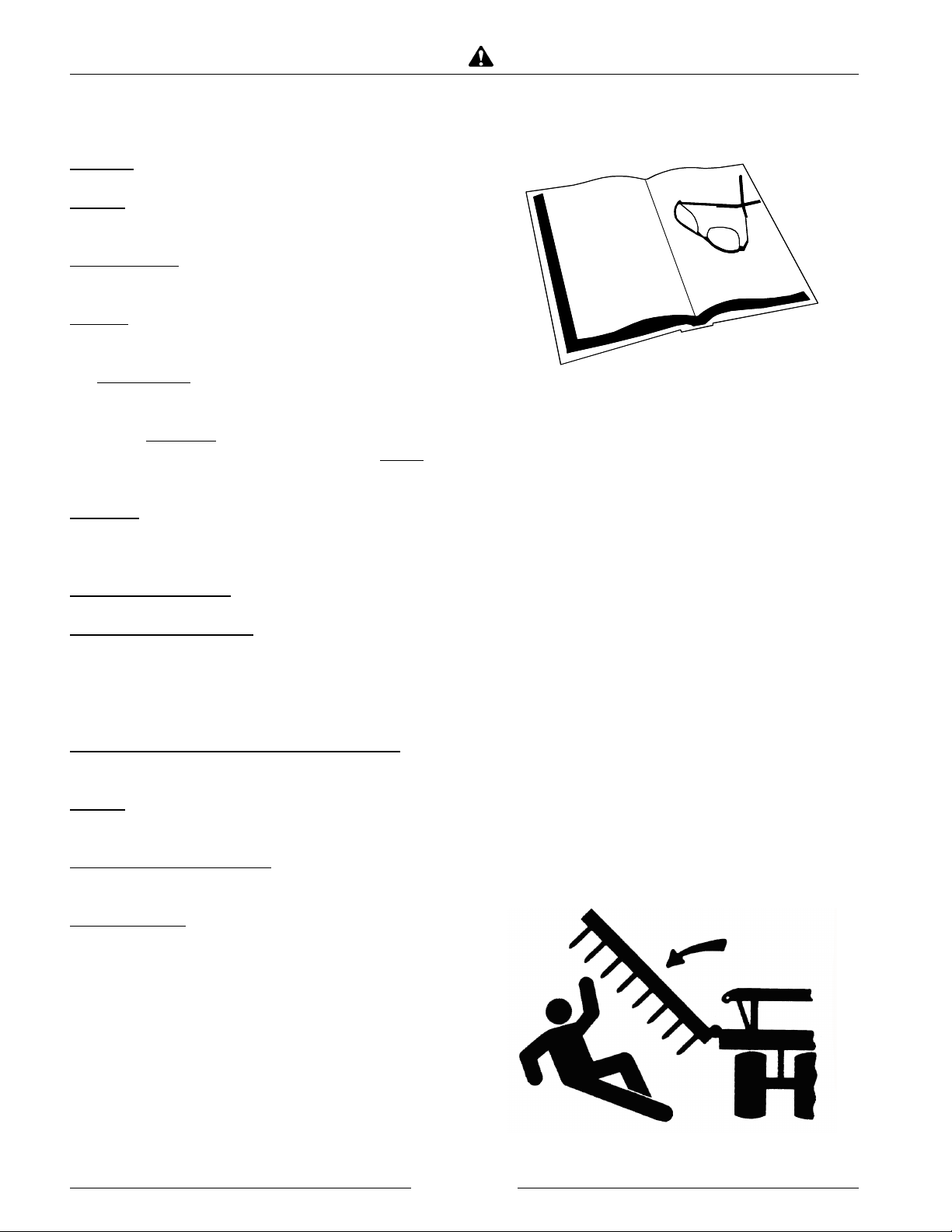

DO NOT ALLOW ANYONE ON THE DRILL while

operating the drill hydraulics.

NEVER disconnect the tractor from the drill while the

drill’s wings are raised in the air.

KEEP CHILDREN AWAY from the drill during

operation.

NEVER STAND within the radius of the raised wings.

Hydraulic or mechanical failure may result in rapid or

uncontrolled falling of the wings.

SECTION 1 - SAFETY

page 1-5

SAFETY DURING TRANSPORT

CHECK with local authorities regarding transport on

public roads. Obey all applicable laws and regulations.

ONLY TOW at a safe speed 32 km/hr (20 mph). Use

caution when making corners or meeting traffic.

BE SURE safety lighting is plugged in and that the red tail

light(s), amber flashers, and amber signal lights are all

working properly.

ALWAYS be certain that no one is behind or around the

drill before moving.

BE SURE all safety transport locks are in place before

transporting the drill.

BE SURE the reflector decals are clearly visible from all

sides of the drill and the Slow Moving Vehicle sign is at

the rear of the drill in clear view of overtaking traffic.

BE SURE all the wheel bolts are tight before transporting

the drill.

WATCH for power poles and overhead power lines.

ALWAYS lock the tractor drawbar when transporting the

drill.

ALWAYS park the drill on level ground and block the

wheels before unhooking from the towing vehicle.

NEVER subject the drill to steep side grades while in

transport position.

ALWAYS use the hitch jack supplied with the drill when

unhooking from the tractor.

BE SURE no upward pressure is exerted on the tractor

hitch by the drill hitch before disconnecting.

NEVER brake or decelerate during cornering.

ALWAYS enter corners slowly.

SAFETY DURING SERVICING

SHUT DOWN TRACTOR ENGINE, remove key from

tractor ignition and be certain all moving parts have

stopped before servicing implement.

ESCAPING HYDRAULIC FLUID HAZARD; escaping

hydraulic fluid under pressure can penetrate the skin

causing serious injury. Relieve pressure before

disconnecting hydraulic lines. Check/tighten all

connections BEFORE applying pressure. Use a piece of

cardboard or paper to search for leaks. NEVER use your

hand.

IF ANY fluid is injected into the skin, seek immediate

medical attention, if not treated within a few hours

GANGRENE MAY RESULT.

ONLY service implement when in full field position.

DO NOT OVERINFLATE tires. NEVER lean over a tire

while inflating it.

ALWAYS USE proper mounting procedures when

mounting a tire to wheel or rim. A tire not seated properly

may explode when being inflated causing serious injury or

death.

BLOCK wheels to prevent movement when servicing.

BE SURE all safety transport locks are in place before

servicing or adjusting opener assemblies or working on the

implement.

SECTION 1 - SAFETY

page 1-6

SAFETY DECALS

KEEP SAFETY DECALS CLEAN. Wipe clean when

necessary.

CHECK that the safety decals are not obstructed by the

openers. If the decals are covered up, replace in a location

that is clear to view.

REPLACE missing or unreadable decals. New decals are

available from your dealer.

To replace decals:

1. Remove the old decal. Clean the area where the new

decal will be affixed.

2. Remove the decal backing. Carefully affix the decal to

the drill.

3. Work the air bubbles out from under the decal. Use a

clean piece of paper or the decal backing itself.

SECTION 1 - SAFETY

page 1-7

DECAL LOCATIONS

PH-450.04

PH-450.04

GD-500.77

RD-300.05

PH-450.04

RD-300.05

SECTION 1 - SAFETY

page 1-8

HAND SIGNALS

It is often necessary in agricultural operations to communicate using hand signals when noise or distance inhibit

communication by voice. These hand signals, adopted by the Society of Agricultural Engineers, provide an easy means of

communication, particularly in the interest of safety.

THIS FAR TO GO - Place palms

at ear level facing head and

move laterally inward to indicate

remaining distance to go.

COME TO ME - Raise the arm

vertically overhead, palm to the

front, and rotate in large

horizontal circles.

MOVE TOWARD ME, FOLLOW

ME - Point toward person(s),

vehicle(s), or unit(s). Beckon by

holding the arm horizontally to

the front, palm up, and

motioning toward the body.

MOVE OUT, TAKE OFF - Face

the desired direction of

movement. Swing the arm

overhead and forward in the

direction of desired movement

until it is horizontal, palm down.

STOP - Raise the hand upward to

the full extent of the arm, palm to

the front. Hold that position

until the signal is understood.

SPEED IT UP, INCREASE

SPEED - Raise the hand to the

shoulder, fist closed. Thrust the

fist upward to the full extent of

the arm and back to the shoulder

rapidly several times.

SLOW IT DOWN, DECREASE

SPEED - Extend the arm

horizontally sidewards, palm

down, and wave the arm

downward (45° minimum)

several times, keeping the arm

straight. Do not move the arm

above horizontal.

START THE ENGINE - Simulate

cranking of vehicles by moving

arm in circular motion at waist

level.

STOP THE ENGINE - Draw right

hand, palm down, across the

neck in a ‘throat cutting’ motion

from left to right.

LOWER EQUIPMENT - Make

circular motion with either hand

pointing to the ground.

RAISE EQUIPMENT - Make

circular motion with either hand

at head level.

page 2-1

SECTION 2

OPERATION

CONTENTS OF THIS SECTION

Page

CONNECTING ....................................................... 2-3

FOLDING AND UNFOLDING .......................................... 2-4

DepthControlSafetyLock ............................................ 2-5

FloatingHitchSafetyLock ............................................ 2-6

Wingingup ........................................................ 2-7

Wingingdown...................................................... 2-7

FIELD OPERATION .................................................. 2-8

DepthControlValveandOperatingDepthAdjustments ..................... 2-8

GeneralFieldOperation .............................................. 2-9

TRANSPORTING ................................................... 2-10

Important Information about Transporting ............................... 2-10

TransportingtheDrill ............................................... 2-10

CalculatingtheMinimumTowingVehicleWeightforSafeTransport ......... 2-11

DISCONNECTING .................................................. 2-12

DisconnectinginFieldPosition-ImplementRaised ....................... 2-12

DisconnectinginFieldPosition-ImplementLowered...................... 2-12

Disconnecting in Transport Position .................................... 2-13

SECTION 2 - OPERATION

page 2-2

This Page is Left Blank

SECTION 2 - OPERATION

page 2-3

CAUTION!

Tractor to Air Drill Safety Chain Connection

CONNECTING

Lock tractor draw bar in its center position when

transporting machine.

Be sure depth control lock is securely engaged

before transporting; Be sure floating hitch safety

lock is locked before transporting.

Always connect a safety chain between the 6000

and the tractor or air seeder.

1. Always use a clevis hitch on the tractor when towing

the drill.

2. Secure the drill to the tractor drawbar or air cart using

an adequate draw pin, locked in place with a hairpin or

other proper locking device.

3. Retract and rotate jack, pinning jack in horizontal

position for storage. Using the pin connector chain,

secure the jack handle in the horizontal position to

prevent the handle from accidentally swinging down.

4. Connect the safety chain as shown. Be sure the safety

chain has enough slack to allow the implement to turn.

For a tow behind air cart, connect the heaviest safety

chain between the tractor and the air drill.

For a tow between air cart, connect the heaviest safety

chain between the tractor and the air cart. In either set-

up, it may be required to relocate the heaviest safety

chain.

5. Connect hydraulics to tractor. To avoid getting dirt in

the hydraulic system, wipe off tips before connecting.

Raise the depth control hydraulics to maximum height.

Manually engage the depth control safety locks.

6. If the air drill is equipped with a tow behind air seeder,

connect the cable harness to the connector on the

tractor. Connect the air seeder hydraulic hoses to the

tractor.

SECTION 2 - OPERATION

page 2-4

CAUTION!

FOLDING AND UNFOLDING

NOTE: Read this section before folding or unfolding the air drill.

The air drill is equipped with a manual depth control safety

lock system. The safety lock system is a mechanical

backup that will stop the drill from suddenly dropping

should the depth control hydraulic system fail (i.e.,

hydraulic hose failure).

Keep everyone clear of the machine when folding

or unfolding wings.

Be sure cylinder and attaching hoses are fully

charged with oil before operating system. Failure

to do so will allow wings to fall rapidly.

To avoid injury or death, do not contact electric

lines.

To avoid injury or death stand clear of machine

when wings are being folded or unfolded.

Mechanical or hydraulic failure can allow wings to

fall rapidly.

To avoid injury or death, do not adjust while

machine is in motion.

To avoid injury or death, ensure mechanical lock-

up hardware is installed before transporting or

servicing machine. Hydraulic failure can allow

openers to fall rapidly.

IMPORTANT: Never try to wing up the drill without having the frame raised all the way. If the drill is winged

up with the frame down, damage to the machine could result. Never lower the frame with the

drill in transport position.

SECTION 2 - OPERATION

page 2-5

Depth Control Safety Lock

DEPTH CONTROL SAFETY LOCK

The depth cylinder safety lock is latched and unlatched by

rotating a lever located on the front of the center section.

1. Raise the implement to the maximum height using the

depth control hydraulics.

2. Rotate lever until contact is made with the pin to

engage the depth control safety lock. There should be

enough friction that the safety lock will not rotate

without a considerable hand applied force. Adjust the

lock nut when necessary.

NOTE: Be sure the safety lock is engaged when

working under the machine.

SECTION 2 - OPERATION

page 2-6

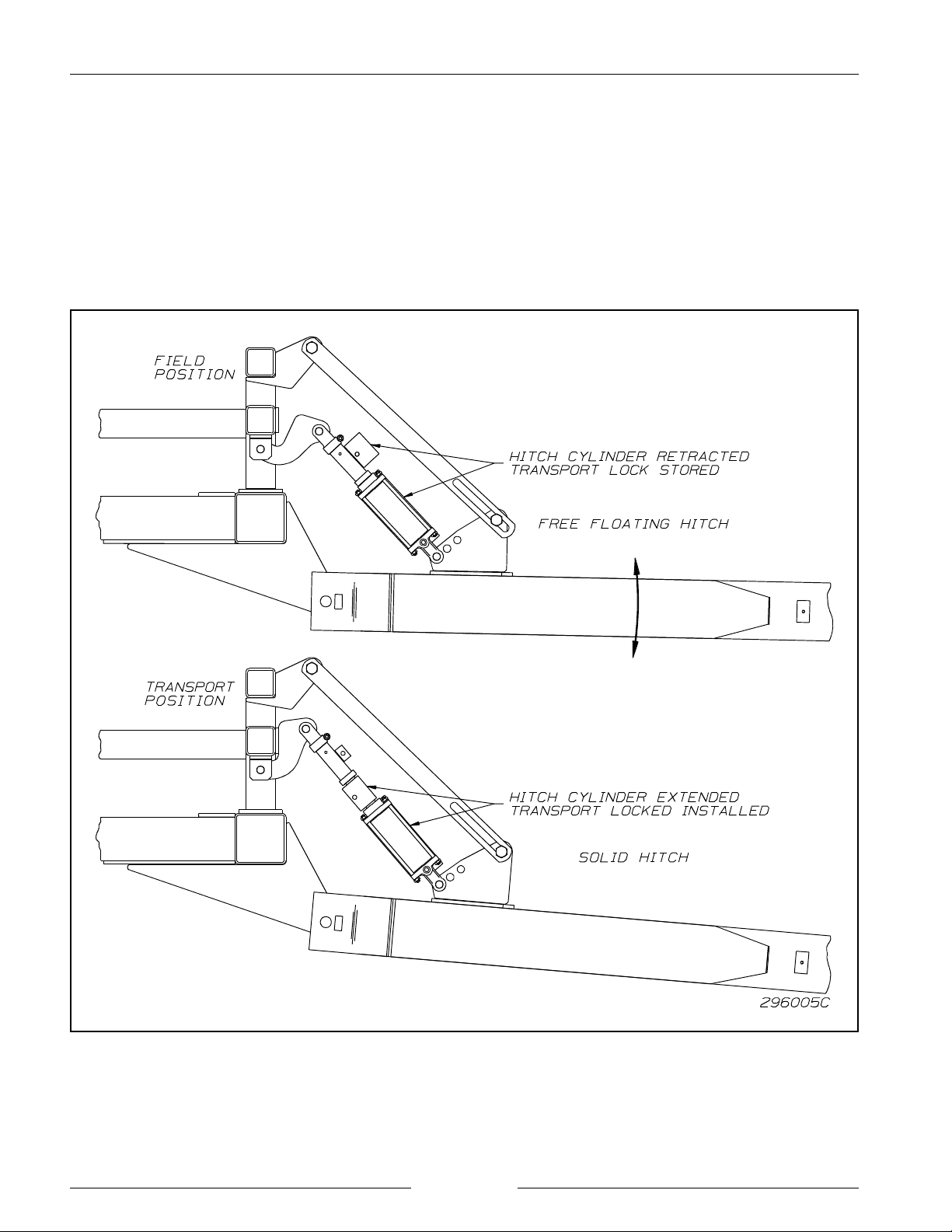

Floating Hitch Safety Lock

FLOATING HITCH SAFETY LOCK

The floating hitch safety lock is put in place when the hitch

cylinders are in the fully extended position.

1. With the drill in field position, fully raised, move the

transport lock from storage position to transport

position as shown.

Table of contents