Flexicon FF30 manual

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 1 of 29

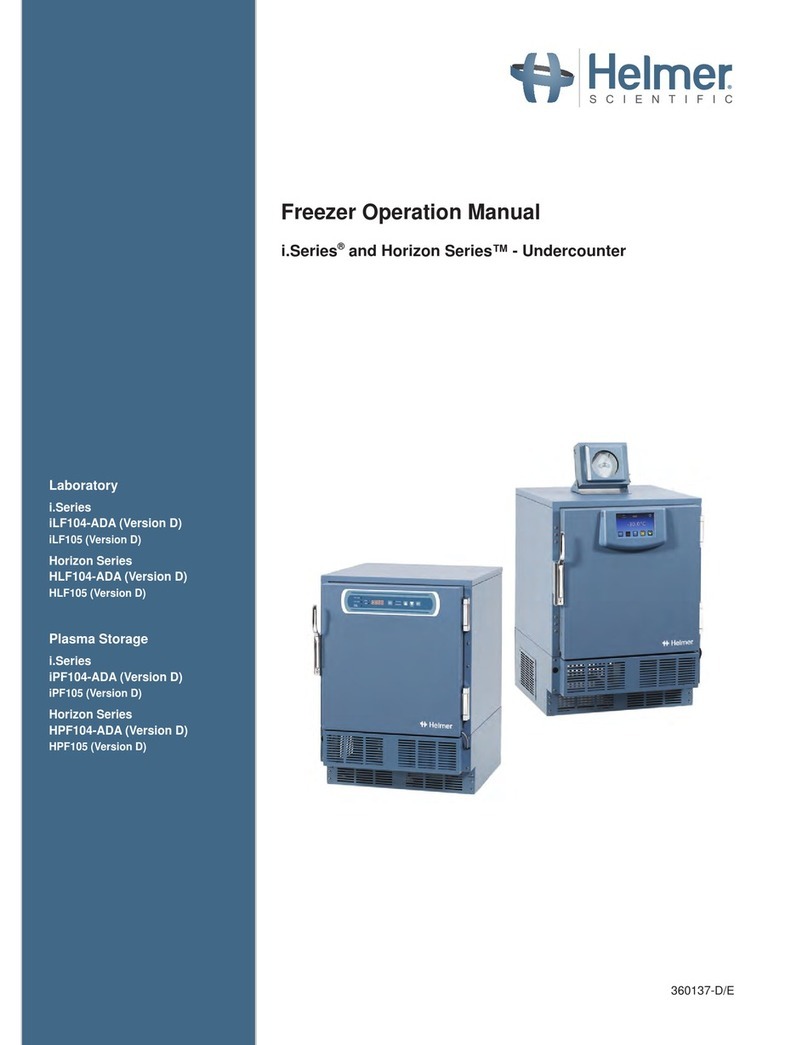

FF30

(Example; exact model may vary)

This instruction handbook is for the daily users of the equipment.

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 2 of 29

Table of Contents

1Introduction.........................................................................................................................4

1.1 FF30 ...................................................................................................................................4

1.2 Abbreviations in this manual ...............................................................................................4

1.3 Symbols on the machine.....................................................................................................4

1.4 Caution and employee safety..............................................................................................5

1.5 Essential training before daily use.......................................................................................5

1.6 References .........................................................................................................................5

1.7 Dismantling and disposal ....................................................................................................5

2General information.............................................................................................................6

2.1 Unpacking and inspection...................................................................................................6

2.2 Storing the FF30.................................................................................................................6

2.3 Mounting of support for inlet and outlet tray ........................................................................6

2.4 Technical specifications......................................................................................................8

2.4.1 Dimensions.........................................................................................................................8

2.4.2 Buttons / Control panel........................................................................................................9

2.4.3 Services............................................................................................................................10

2.4.4 Bottles, caps and trays......................................................................................................10

2.4.5 Ingress protection .............................................................................................................10

2.4.6 Weight...............................................................................................................................10

2.4.7 Materials of construction ...................................................................................................10

2.4.8 Fillers................................................................................................................................11

3Installation.........................................................................................................................11

3.1 Connections......................................................................................................................11

3.2 Mounting of format parts ...................................................................................................12

3.2.1 Bottle format parts.............................................................................................................12

3.2.2 Screw cap format parts .....................................................................................................14

4Daily Use ..........................................................................................................................16

4.1 Starting-up and running.....................................................................................................16

4.1.1 Adjusting the round table inner bottle guide ......................................................................16

4.1.2 Adjusting the inlet guide....................................................................................................16

4.1.3 Installing Inner bottle guide flexible tip...............................................................................17

4.1.4 Adjustment of the filling stand ...........................................................................................18

4.2 Adjusting the capping sensor............................................................................................18

4.3 Adjusting the height of capping head ................................................................................19

4.4 Adjusting the capping torque.............................................................................................19

4.5 Adjustments......................................................................................................................20

4.5.1 Index speed adjustment....................................................................................................20

4.5.2 Bottle ejector speed adjustment........................................................................................20

4.5.3 Capping time adjustment...................................................................................................20

4.5.4 Round table speed adjustment..........................................................................................20

4.6 Production START and STOP...........................................................................................21

4.6.1 Manual placing of caps .....................................................................................................21

4.6.2 Removing bottles from collection tray................................................................................21

4.7 Stepping bottles through the FF30....................................................................................21

5Malfunctioning...................................................................................................................22

5.1 Start-up alarms .................................................................................................................22

5.2 Runtime alarms.................................................................................................................22

5.3 Runtime warnings.............................................................................................................24

5.4 Trouble shooting...............................................................................................................24

6Cleaning............................................................................................................................25

6.1 Cleaning Frequency..........................................................................................................25

6.2 Preparations for cleaning ..................................................................................................25

6.3 Cleaning Guidance............................................................................................................25

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 3 of 29

6.4 Detergents or cleaning agents..........................................................................................25

7Maintenance & service .....................................................................................................26

7.1 Maintenance.....................................................................................................................26

7.1.1 Tension of toothed belt..................................................................................................... 26

7.1.2 Capping unit.....................................................................................................................27

7.1.3 Star wheel and bottle ejector ............................................................................................27

7.2 Service.............................................................................................................................28

7.2.1 Safety coupling.................................................................................................................28

7.3 Methods and frequency of inspections for safety functions...............................................28

8Change of voltage ............................................................................................................29

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 4 of 29

1 Introduction

All the photographs in this handbook are photo examples and may vary slightly from the exact model;

i.e. type of bottle used on the photograph, type of guiding on the inlet and outlet trays etc.

1.1 FF30

FF30 is a small-scale bottle handling, filling and capping machine.

A round table moves the bottles to the inlet, from which each bottle is moved further on by a star

wheel.

Filling is performed automatically, and capping is semi-automatic.

After capping the bottle is pushed to the outlet tray by a bottle ejector.

FF30 is delivered without the external filler; in order to perform the filling, a filler must be connected.

(See further information in section 2.4)

1.2 Abbreviations in this manual

App.

Approximately

A/R

Alarm / Reset

e.g.

As example

BPM

Bottles per minute

Fig.

Figure

Hz

Hertz

IH

Instruction Handbook

L/min

Litres per minute

Max.

Maximum

mA

milliampere

msec

milliseconds

PE

Protective Earth (electrical units safety measure)

RT

Round Table

VAC

Volt Alternating Current

VDC

Volts Direct Current

WMF

Watson-Marlow Flexicon a/s

1.3 Symbols on the machine

Warning against touching

Warning against high voltage

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 5 of 29

1.4 Caution and employee safety

This manual should be read before using the FF30.

It is strongly advised that

- Any kind of maintenance or cleaning of the machine not is carried out while power is

connected.

- Unauthorised / non-trained personnel should not open the cover of the electrical parts.

- The machine is placed in such a way that it is not exposed to high humidity, high temperatures

or other abnormal operating environment.

- The machine is not to be used in explosion hazardous environments.

1.5 Essential training before daily use

Read the section with Daily Use, thoroughly before using the machine.

Protective equipment and protective devices are installed:

➢If the star wheel is jammed it will stop immediately

➢The capping machine will stop if it is unable to reach lower position during capping; e.g. this

way fingers or instruments will not be squeezed if they are placed between the cap and the

capping head during production.

Always respect the symbols on the machine.

Cleaning must be performed as described in this IH.

1.6 References

N/A

1.7 Dismantling and disposal

Prior to dismantling, it must be observed that all services are disconnected, and fixing to other

equipment is removed.

WM-Flexicon machines may not be disposed using normal refuse

collection. The machines must be collected and disposed separately as

they contain electrical components such as batteries, electrolyte

capacitors, liquid crystal displays and printed circuit boards.

Further information is available on www.wmftg.com.

*

* (WEEE) DS/EN 50419

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 6 of 29

2 General information

2.1 Unpacking and inspection

Before unpacking the FF30 it should be checked if the crate is damaged.

When unpacking remove all four sides of the wooden crate.

Lift the FF30 away from the pallet by lifting it underneath the machine. Do not lift the machine by

lifting it in the top plate.

Please check that all ordered items have been received and that no items are damaged during

transport. In case of any defects or omissions, please contact WMF or your supplier immediately.

2.2 Storing the FF30

Before storing of the FF30 it should be checked if the crate is damaged.

In case of long-term storage of the FF30 before installation, the machine must be stored in the crate,

and placed in a dry room. The crate is not water resistant.

2.3 Mounting of support for inlet and outlet tray

If the inlet tray or outlet tray have been removed during shipping they must be mounted as shown

below. Use the supplied bolts and fasten them as shown below.

Inlet tray

Outlet tray

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 7 of 29

Accessory for

outlet tray

Smaller bottles can get

stuck side by side

when moved from the

star wheel to the outlet

tray.

To prevent that the

Bottle guide exit

accessory can be

mounted / hanged on

the outlet tray to

narrow down the

passage for the

bottles.

Bottle guide exit accessory

34-302-239 –15 mm

34-302-346 –20 mm

Bottle guide mounted / hanged on the outlet tray guide.

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 8 of 29

2.4 Technical specifications

2.4.1 Dimensions

Length: 1230 mm

Width: 795 mm

Height: max. 730 mm (incl. Feet)

Dimensions: mm / inches

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 9 of 29

2.4.2 Buttons / Control panel

ON/OFF –SWITCH

Main switch for the entire FF30

EMERGENCY STOP BUTTON

Emergency stop button for the entire FF30

and connected filler

Power ON

Power ON button which lights when power is on.

Cap sensor

Button for Cap sensor.

Lights when Cap sensor sees cap during adjustment.

Inlet sensor

Button for Inlet sensor.

Lights when Inlet sensor sees bottle during adjustment.

Ready

Ready button which lights when FF30 is ready

Alarm / Reset

Push button for cancelling errors.

The button flashes if an error occurs.

Fill

Enables filling; signal to an external pump.

Lights when the filling function is active.

Cap

Enables capping.

Lights when the capping function is active.

Step

Push button.

One push activates one step with the star wheel.

Adjust

Push button for adjustment mode.

Lights when Adjust is active.

Start

Push button for starting and stopping production.

Lights when Start is active

Delay

Potentiometer for adjusting the delay between each indexation.

1 = minimum time (~ fast process of bottles), 10 = maximum time (~ slow process)

Inlet speed

Potentiometer for setting the speed of the round table.

1 = slow 10 = fast

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 10 of 29

2.4.3 Services

All electrical systems are placed in the base cabinet.

Power supply:

100-127 / 200-240 VAC, 50/60Hz

Earthed by the main power switch

Consumption:

300 W

Compressed air:

0.6 MPa, clean and dry air

Consumption:

75 L/min at 20 BPM

Note:

Only authorised personnel can gain access to the installations.

The main power cable must be removed completely from power supply before the base cabinet is

opened.

2.4.4 Bottles, caps and trays

Bottle sizes

Diameter

Max Ø50 mm.

Height

Max 110 mm.

Cap sizes

Diameter

Max Ø50 mm.

Height

Max 40 mm.

Tray size inlet / outlet

Inlet

Outlet

Length / width*

290 mm / 260 mm

280-320 mm / 285 mm

Height of guide

30 mm

30 mm

*note –the trays are not rectangular. See picture on the front page.

2.4.5 Ingress protection

Ingress protection

IP52

2.4.6 Weight

Weight:

app. 60 kg

2.4.7 Materials of construction

➢AISI304 stainless steel

➢Anodised aluminium

➢Polyacetal

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 11 of 29

2.4.8 Fillers

A peristaltic filler or gear filler must be connected to FF30.

Optional fillers when filling are:

- PF7 Peristaltic filler

- 520 Di peristaltic filler

- DF32 Positive displacement filler

3 Installation

3.1 Connections

FF30 must be placed on a stable and horizontal bedplate.

FF30 and filler must only be connected to the specified power supply stated on the tag next to the

power connections, as seen on the pictures below (red circles).

The mains cable (1) is

connected to a single-phase

power supply with earth.

Compressed air is connected to

(2) by use of the supplied quick

release clutch.

All exhaust air is collected and

exhausted through the exhaust

filter (3)

3

2

1

The main cable of the filler is

connected to (4)

(Max. 4 Ampere)

The filler is connected to (5).

RS485 (6) is used for “remote

access” (e.g. during service, or

monitoring)

6

5

4

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 12 of 29

3.2 Mounting of format parts

3.2.1 Bottle format parts

A set of bottle format parts consists of 1 star wheel and 3 guides. All 4 are marked with one number

which together composes the customised parts for one specific bottle size. The number does not

have any reference to the bottle size; it is merely a number which is engraved on the parts to ensure

that the matching parts can be recognized.

Change of bottle format parts

Loosen the finger screw on the inlet sensor and turn

the sensor neck towards round table.

Dismount the bottle ejector by pressing down on it

while turning it away from the round table (see red

circle on first picture)

Move the star wheel

Finally move the guides one by one…

When the last guide has been removed another

size of format parts can be mounted. This is done

the opposite way of the dismounting procedure.

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 13 of 29

Adjustment of inlet sensor

The inlet sensor must be adjusted to see the bottle neck when the bottle enters the star wheel.

Place a bottle in the first slot of the star wheel. Loosen the sensor arm on the finger screw (yellow

circle) and adjust until the light hits close to the side edge of the bottle neck (red circles). Fasten the

screw again. The sensor head can be adjusted forwards and backwards by moving the sensor head

in the wanted direction (blue arrow and red circles).

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 14 of 29

3.2.2 Screw cap format parts

Screw cap format parts consist of 1 single capping head. If several sizes of capping heads have been

ordered, each size is marked with one number which together with the bottle format parts composes

the customised parts for one specific bottle size. The number does not have any reference to the

bottle size; it is merely a number which is engraved in the parts to ensure that the matching parts can

be recognized. E.g. bottle format parts marked with the number 1 –match the capping head marked

with the number 1.

Mounting of capping unit

Mount the capping unit on the two steel columns

Mount the two hoses for

compressed air.

Change of capping head

Hold the head with one hand

And with the other hand press

the quick coupling down

Pull the head down until it is

released from the coupling

When mounting another size of capping head, it is not necessary to touch the quick coupling. Just

press the head into the coupling until it clicks.

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 15 of 29

Adjustment of air pressure regulator on capping unit

In order to perform a correct capping it may be necessary to adjust the air pressure on the capping

unit.

This is done via the air pressure regulator, which is placed next to the ON/OFF switch.

Pull the rim of the button outwards to unlock it.

Firmer capping: Turn the rim clockwise

Looser capping: Turn the rim counter

clockwise

Press the rim inwards to lock it.

Perform some test runs and control if the capping is okay; if not –perform a new adjustment.

Factory settings; see the Format Table.

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 16 of 29

4 Daily Use

4.1 Starting-up and running

Installation section must be carried out before this chapter can be performed.

When the main switch is turned, an initial procedure starts and secure that the machine is ready for

production. The POWER ON will light if no errors are detected.

In case of error detection during initial procedure the ALARM button will flash.

See section 5 regarding alarms.

4.1.1 Adjusting the round table inner bottle guide

Adjust the inner bottle guide by loosening the finger

screws (black circles) and move the entire guide in

or out; depending on the bottle size.

Normally the bottles should be stopped by the guide

in such a way that only one bottle at a time can pass

the space between the inner and outer guides.

For large bottles it might be necessary to adjust the

sliding part (yellow circle) of the inner bottle guide

further in, allowing two bottles to pass side by side

between the inner and outer guides.

For mounting of the flexible tip of the inner guide see: 4.1.3 - Installing Inner bottle guide flexible tip.

4.1.2 Adjusting the inlet guide

Adjust the inlet guide by loosening the finger screws and move it to the right or left, depending on the

bottle size.

The bottles should be led to the first position of the star wheel; never to the outside of the star wheel.

Correct adjustment

Wrong adjustment

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 17 of 29

4.1.3 Installing Inner bottle guide flexible tip.

The moveable part (3) of the inner bottle guide can be extended with a flexible tip (6) to facilitate

running with small bottles.

The flexible tip (6) and its mounting screws (7) should be located in

the “Accessories bag 66-060-130” which came with the FF30.

Assemble as pictured below and fasten the screws (7).

For adjustment of the Inner Bottle Guide Movable Part see:

4.1.1 - Adjusting the round table inner bottle guide.

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 18 of 29

4.1.4 Adjustment of the filling stand

Loosen the finger screw at the bottom of the filling stand.

Adjust the filling stand and the filling nozzle over the centre of the bottle –over the second bottle

in the star wheel.

The nozzle tip should only be a few millimetres away from the bottle top to avoid squirt of

product.

4.2 Adjusting the capping sensor

Place a bottle with a cap in front of the sensor.

The cap must be placed detachable on the top of the bottle –not screwed.

Loosen the finger screw of the sensor and adjust until the light is just below the top of the cap

and close to the side edge of the cap.

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 19 of 29

4.3 Adjusting the height of capping head

Adjusting the height of the capping head must be repeated until the cap is tightened satisfactorily.

A correct capping function is depending on the placement of the capping unit, and the type of cap and

bottle.

Place a bottle with a cap underneath the

capping unit. The cap must be tightened into

end position.

Press ADJUST, to lower the capping unit.

Loosen the finger screw on the capping unit

and lower it until the capping head is resting

on the top of the screw cap. Fasten the finger

screw.

Now press ADJUST again, and the capping

head will return to top position.

Loosen the finger screw once more, and lower

the capping unit app. 5-10 mm before

tightening the finger screw again.

4.4 Adjusting the capping torque

Pull the black clutch casing

sleeve down.

Turn the capping head until the

adjustment lock plate is visible

through the slot.

Insert a screwdriver and

adjust torque by turning.

Increase = clockwise

Decrease = counter

clockwise

INSTRUCTION HANDBOOK

FF30

FF30 IH EN 74-216-201 v1.50

Page 20 of 29

4.5 Adjustments

4.5.1 Index speed adjustment

Speed is set via the DELAY function. The lower value, the faster the bottles will move from inlet to

filling and capping.

➢Press ADJUST (the capping machine will enter lower position)

➢Set speed on DELAY potentiometer, 1 = minimum time (~ fast process), 10 = maximum time

(~ slow process)

➢Press START to save the value (note the value)

➢Turn DELAY back to 0

➢Press ADJUST again to return to normal mode

The value is saved when the machine is turned off.

4.5.2 Bottle ejector speed adjustment

Speed is set via the DELAY function. The lower value, the faster the bottles will be pushed onto the

outlet tray.

➢Press ADJUST (the capping machine will enter lower position)

➢Set speed on DELAY potentiometer, 1 = minimum time (~ fast process), 10 = maximum time

(~ slow process)

➢Press STEP to save the value (note the value)

➢Turn DELAY back to 0

➢Press ADJUST again to return to normal mode

The value is saved when the machine is turned off.

4.5.3 Capping time adjustment

Capping time adjustment is set via the DELAY function. The lower value the adjustment is set at, the

shorter time the capping head will use on screwing the cap into place. Note: If the time is too short

the cap might not be fastened enough.

➢Press ADJUST (the capping machine will enter lower position)

➢Set speed on DELAY potentiometer, 1 = minimum time (~ fast), 10 = maximum time (~ slow)

➢Press CAP to save the value (note the value)

➢Turn DELAY back to 0

➢Press ADJUST again to return to normal mode

The value is saved when the machine is turned off.

4.5.4 Round table speed adjustment

See section 2.4.2

Table of contents

Other Flexicon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

KERN

KERN YDB-04 Operating and installation instructions

Thermo Scientific

Thermo Scientific RVT5105 Additional Instructions for Installation and Operation

Beckman Coulter

Beckman Coulter COULTER EPICS XL Getting started

Tinget

Tinget STE-A Technical manual

IKA

IKA KS 130 basic operating instructions

VERDER

VERDER Carbolite Gero HTMA 7/220 Installation, operation and maintenance instructions