Flexicon PF7 User manual

PF7 Peristaltic Filler User Manual

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 1

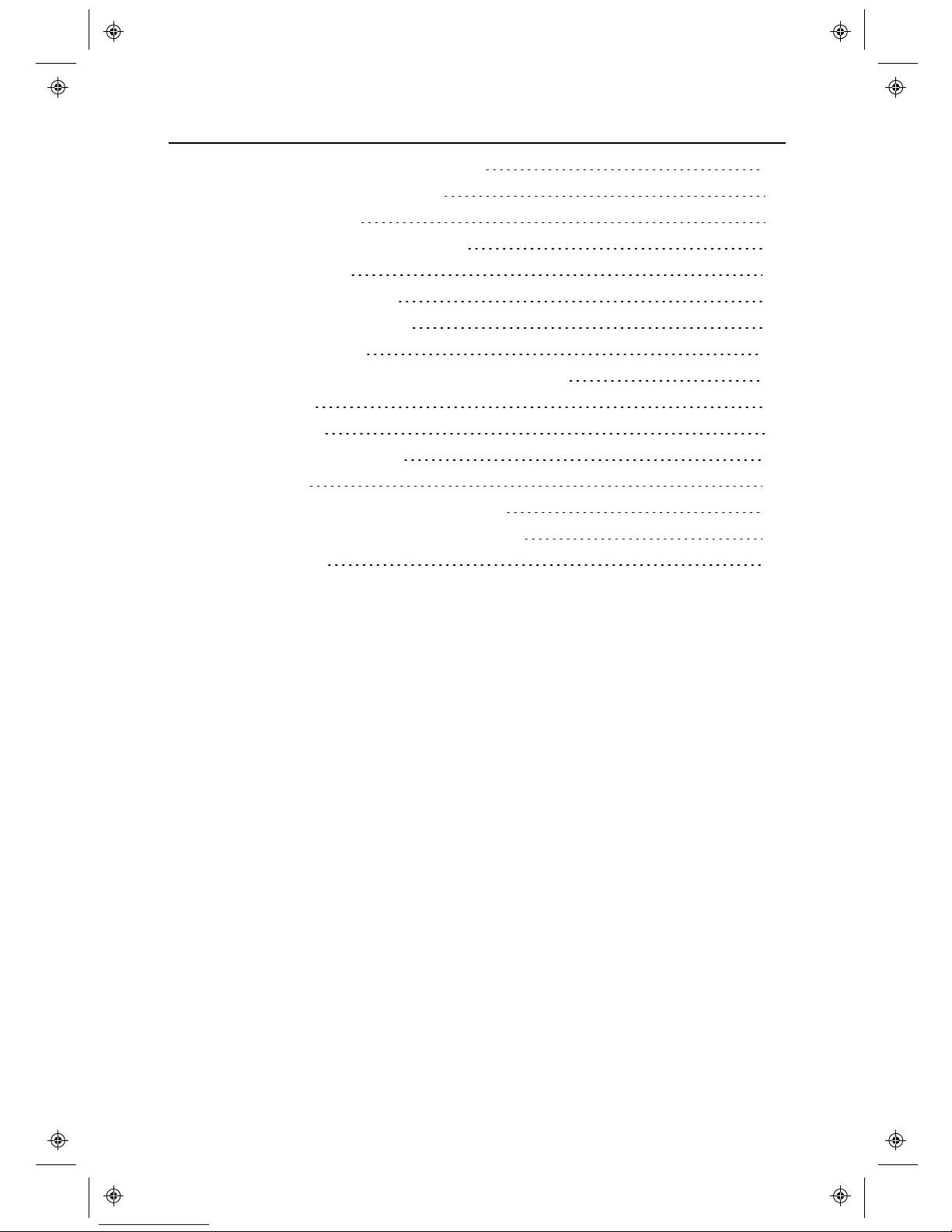

Contents

1 Declaration of conformity 3

2 Declaration of incorporation 4

3 Safety notes 5

4 Peristaltic pumps - an overview 8

5 When you unpack your pump 9

5.1 Unpacking your pump 9

5.2 Packaging disposal 9

5.3 Inspection 9

5.4 Components supplied 9

5.5 Storage 9

6 Pump operation 10

6.1 Keypad 10

6.2 Glossary of icons 10

6.3 Switching the pump on for the first time 11

6.4 Switching the pump on in subsequent power cycles 15

6.5 Menu navigation 16

6.6 Recipe Mode 16

6.7 Priming and continuous pumping mode 18

6.8 Calibrate mode 19

6.9 Dispense Mode 21

6.10 Reports mode 26

6.11 Settings mode 26

7 Setting up the fluid path 30

7.1 Tube selection 30

7.2 Placing the product container 31

7.3 Y-connector selection 32

7.4 Loading the tube 32

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

2m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

8 Good pump installation practice 34

8.1 General recommendations 34

8.2 Dos and don'ts 34

9 Connecting to a power supply 35

10 Control wiring 36

11 Pump specifications 38

11.1 Specification ratings 38

12 Troubleshooting 39

13 Pump maintenance (including cleaning) 40

13.1 Service 40

13.2 Cleaning 40

13.3 Pumphead Removal 40

14 Warranty 41

15 Information for returning pumps 42

16 Name and address of manufacturer 42

17 Disclaimers 42

1 Declaration of conformity

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 3

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

4m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

2 Declaration of incorporation

3 Safety notes

This safety information should be used in conjunction with the rest of this operating

manual.

In the interests of safety, this pump and pumphead should only be used by

competent, suitably trained personnel after they have read and understood the

manual and considered any hazard involved. If the pump is used in a manner not

specified by Watson- Marlow Ltd, the protection provided by the pump may be

impaired. Any person who is involved in the installation or maintenance of this

equipment should be fully competent to carry out the work. In the UK this person

should also be familiar with the Health and Safety at Work Act 1974.

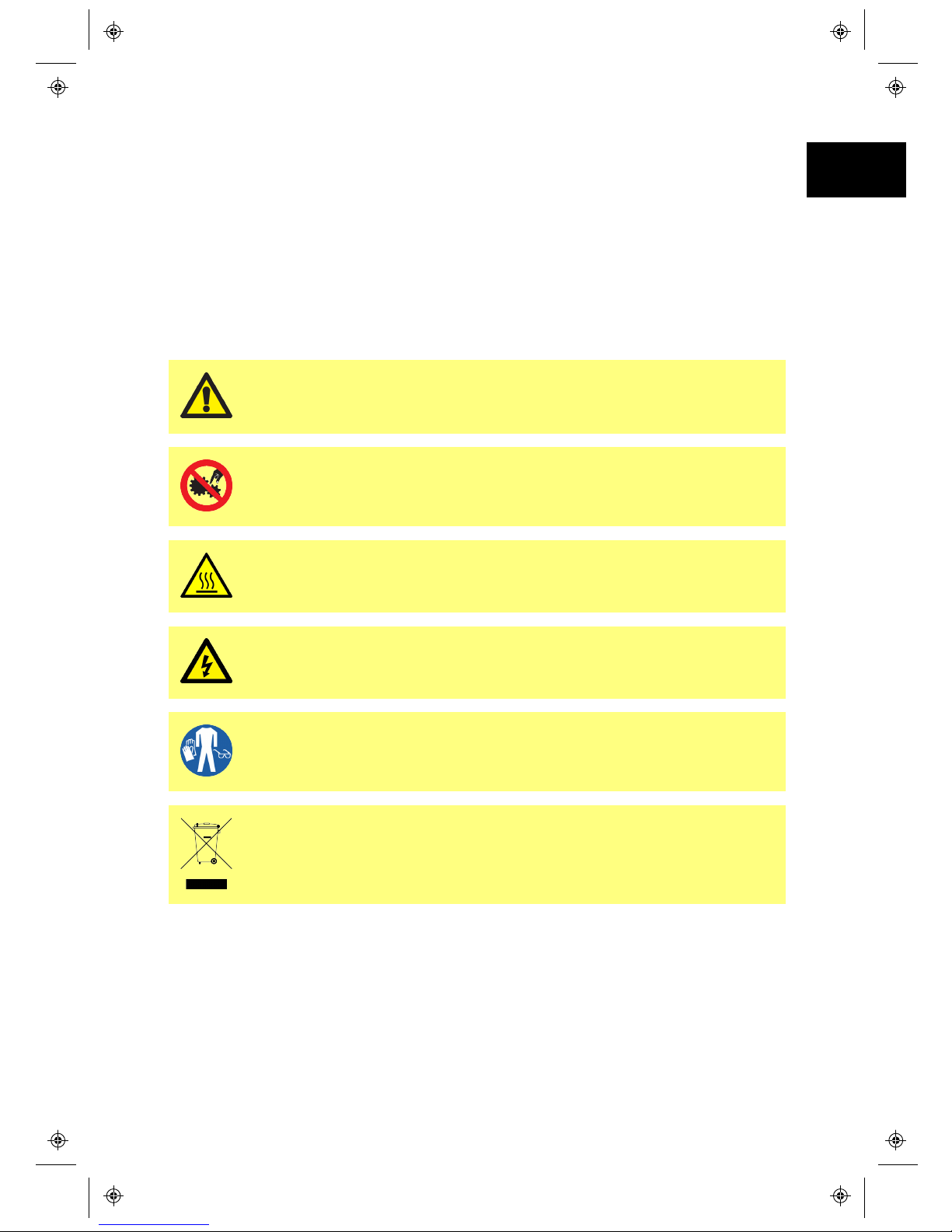

This symbol, used on the pump and in the manual, means: Caution,

refer to accompanying documents.

This symbol, used on the pump and in the manual, means: Do not

allow fingers to contact moving parts.

This symbol, used on the pump and in the manual, means: Caution,

hot surface.

This symbol, used on the pump and in the manual, means: Caution,

risk of electric shock.

This symbol, used on the pump and in the manual, means: Personal

Protective Equipment (PPE) must be worn.

This symbol, used on the pump and in the manual, means: Recycle

this product under the terms of the EU Waste Electrical and Electronic

Equipment (WEEE) Directive.

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 5

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

6m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

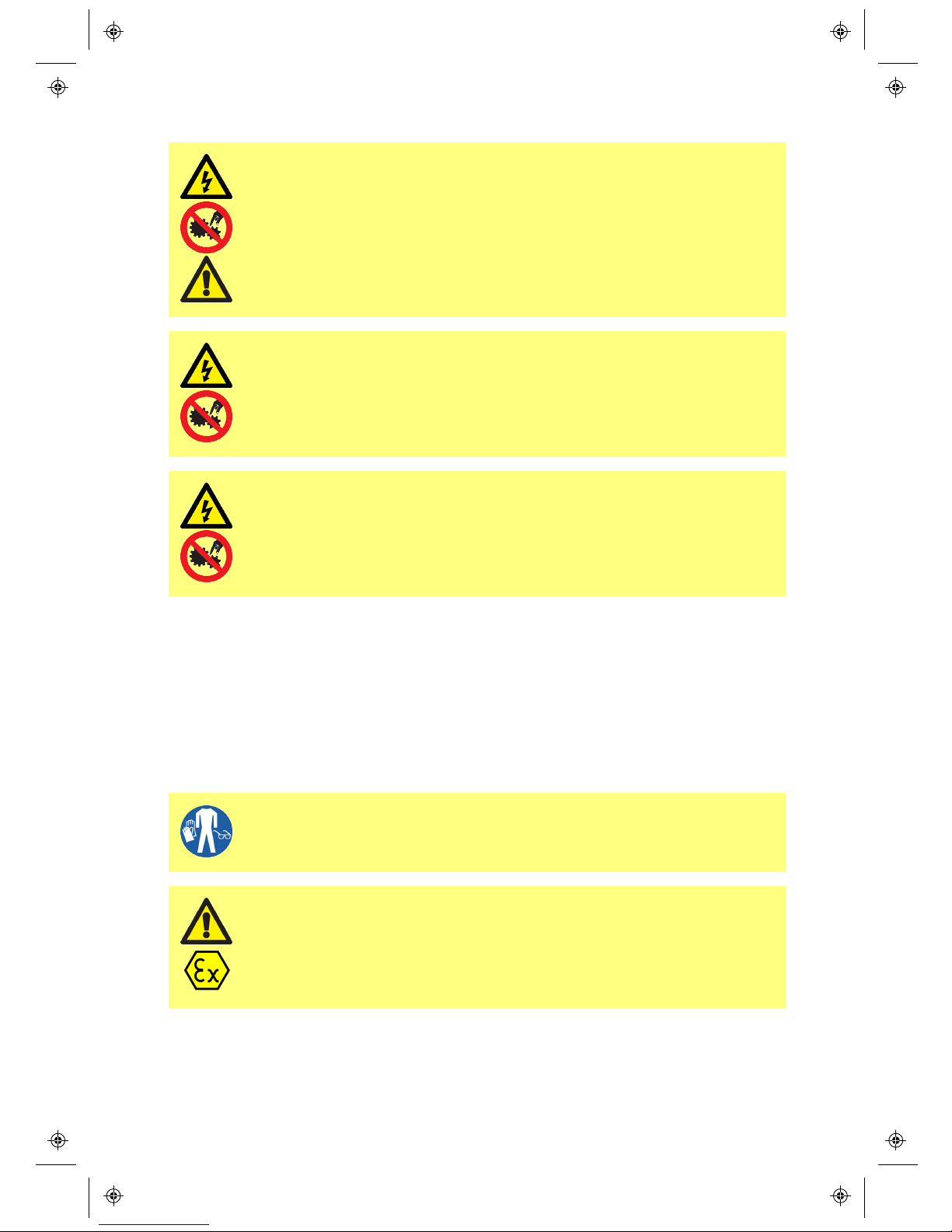

Fundamental work with regard to lifting, transportation, installation,

starting-up, maintenance and repair should be performed by qualified

personnel only. The unit must be isolated from mains power while

work is being carried out. The motor must be secured against

accidental start-up.

There is a user-replaceable type fuse in the fuse holder above the

power input connector at the back of the pump. In some countries, the

mains power plug contains an additional replaceable fuse.

There are no user-serviceable fuses or parts inside this pump.

This pump must be used only for its intended purpose.

The pump must be accessible at all times to facilitate operation and maintenance.

Access points must not be obstructed or blocked. Do not fit any devices to the drive

unit other than those tested and approved by Watson- Marlow Ltd. Doing so could

lead to injury to persons or damage to property for which no liability can be

accepted.

The pump's main plug is the disconnecting device (for isolating the motor drive

from the mains supply in an emergency). Do not position the pump so that it is

difficult to disconnect the mains plug.

If hazardous fluids are to be pumped, safety procedures specific to

the particular fluid and application must be put in place to protect

against injury to persons.

This product does not comply with the ATEX directive and must not be

used in explosive atmospheres.

The PF7 contains a non-replaceable Manganese Dioxide Lithium Battery (Li/MnO2),

IEC CR2032, with a typical capacity of 225mAh, containing 0.07g of Lithium.

Primary operator protection from rotating parts of this pump is

provided by isolating the pump from mains power before opening the

pump head tube bridge. The pump also provides a tube bridge open

indicator. If the tube bridge is opened, the tube bridge open screen is

displayed.

The tube bridge must be closed for the warning screen to clear and the pump to

start.

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 7

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

8m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

4 Peristaltic pumps - an overview

Peristaltic pumps are the simplest possible pump, with no valves, seals or glands to

clog or corrode. The fluid contacts only the bore of a tube, eliminating the risk of the

pump contaminating the fluid, or the fluid contaminating the pump.

How they work

A compressible tube is squeezed between a roller and a track on an arc of a circle,

creating a seal at the point of contact. As the roller advances along the tube, the

seal also advances. After the roller has passed, the tube returns to its original

shape, creating a partial vacuum which is filled by fluid drawn from the inlet port.

Before the roller reaches the end of the track, a second roller compresses the tube

at the start of the track, isolating a packet of fluid between the compression points.

As the first roller leaves the track, the second continues to advance, expelling the

packet of fluid through the pump’s discharge port. At the same time, a new partial

vacuum is created behind the second roller into which more fluid is drawn from the

inlet port.

Backflow and siphoning do not occur, and the pump effectively seals the tube when

it is inactive. No valves are needed.

The principle may be demonstrated by squeezing a soft tube between thumb and

finger and sliding it along: fluid is expelled from one end of the tube while more is

drawn in at the other.

Animal digestive tracts function in a similar way.

Suitable applications

Peristaltic pumping is ideal for most fluids, including viscous, shear- sensitive,

corrosive and abrasive fluids, and those containing suspended solids. They are

especially useful for pumping operations where hygiene is important.

Peristaltic pumps operate on the positive displacement principle. They are

particularly suitable for metering, dosing and dispensing applications. Pumps are

easy to install, simple to operate and inexpensive to maintain.

5 When you unpack your pump

5.1 Unpacking your pump

Unpack all parts carefully, retaining the packaging until you are sure all

components are present and in good order. Check against the components supplied

list, below.

5.2 Packaging disposal

Dispose of packaging materials safely, and in accordance with regulations in your

area. The outer carton is made of corrugated cardboard and can be recycled.

5.3 Inspection

Check that all components are present. Inspect components for damage in transit.

If anything is missing or damaged, contact your distributor immediately.

5.4 Components supplied

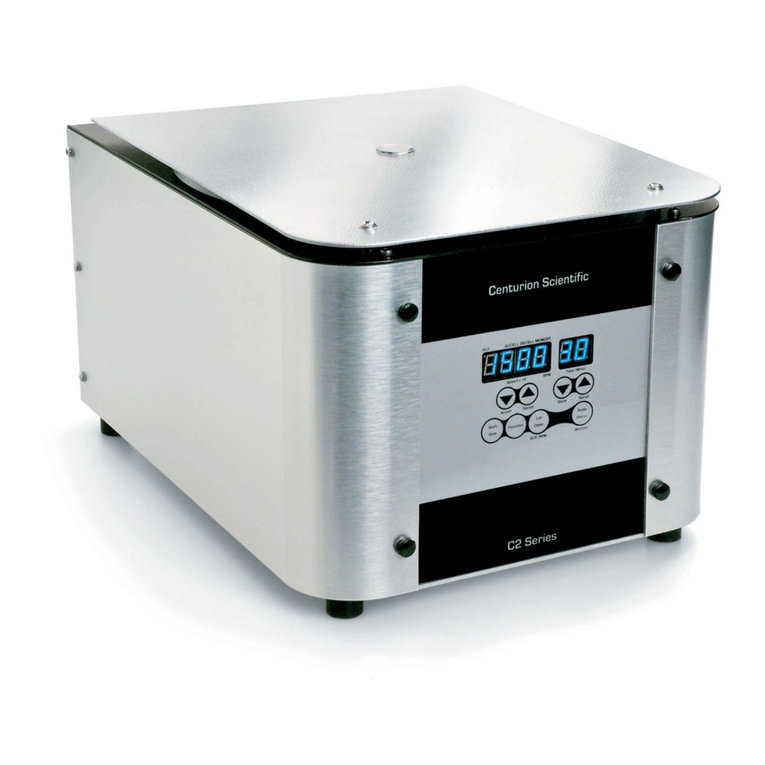

•PF7 pump drive unit, fitted with QC12 pumphead

•A QC12 pumphead tube clamp set

•The designated power cable

•Product manual

5.5 Storage

This product has an extended shelf life. However, care should be taken after

storage to ensure that all parts function correctly. Please observe the storage

recommendations and use-by dates which apply to tubing you may wish to bring

into service after storage.

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 9

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

10 m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

6 Pump operation

6.1 Keypad

The STOP key will immediately stop the pump, regardless of what screen is

currently displayed. If the pump is stopped part way through a fill, a message

stating this will be displayed.

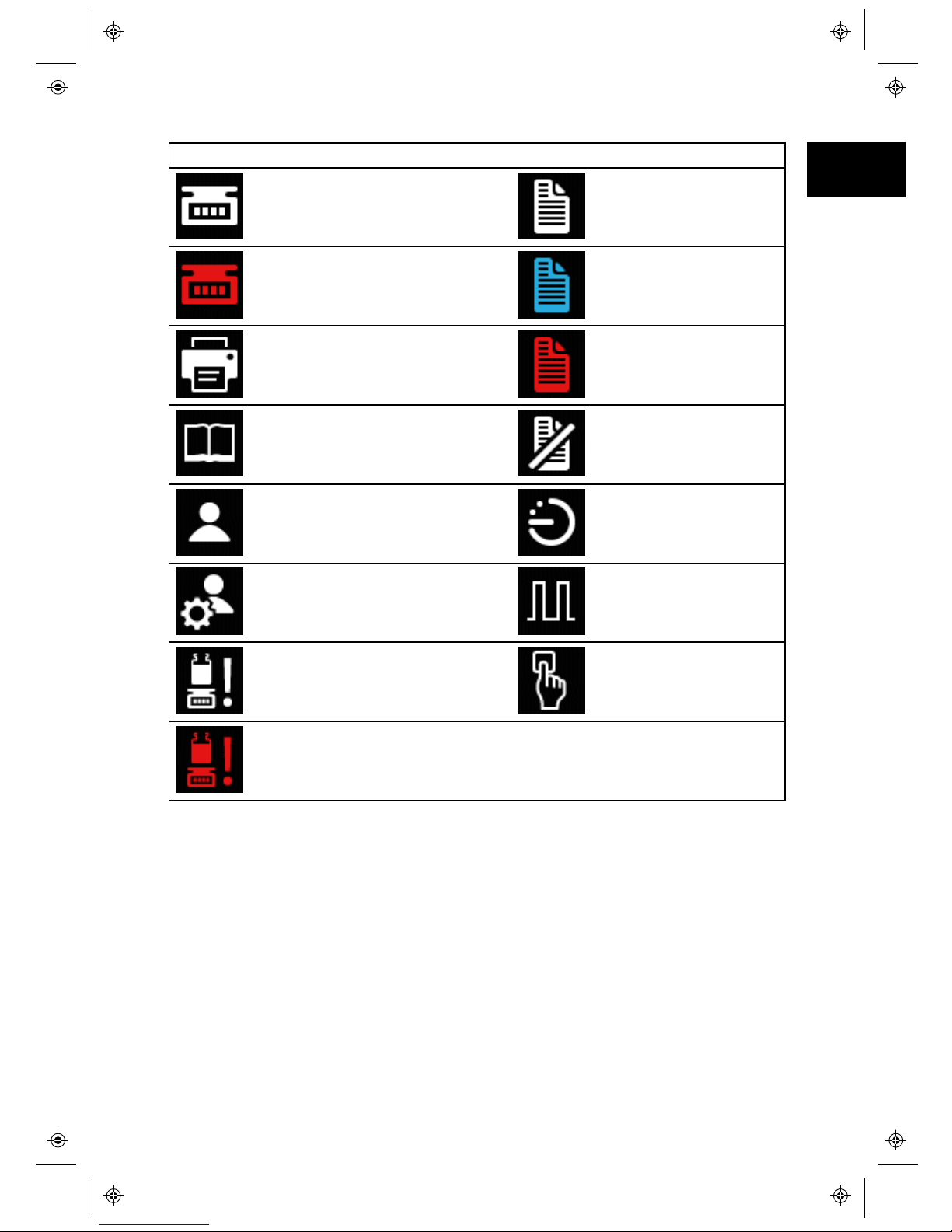

6.2 Glossary of icons

The PF7 uses a range of graphical icons to help navigation, in both the smart key

function indicator area and the screen info bar area.

Smart key icons

BACK TO PREVIOUS SCREEN

NO / CANCEL

EDIT

MODE

NEXT

PAUSE

RUN

STOP

YES/CONTINUE

Screen info icons

BALANCE CONNECTED (White Icon) REPORTING ON (White

Icon)

BALANCE CONNECTED

BUT NOT USABLE (Red Icon)

REPORTING IN PROGRESS

(Blue Icon)

PRINTER CONNECTED REPORTING ERROR

(Red Icon)

RECIPE REPORTING OFF

USER FILL ACTIVATION BY TIME

DELAY

ADMINISTRATOR FILL ACTIVATION BY

EXTERNAL INPUT

RECALIBRATION REMINDER FILL ACTIVATION BY

KEYPAD

RECALIBRATION REQUIRED

(Red Icon)

6.3 Switching the pump on for the first time

Powering up

Power up the pump. The pump displays the start-up screen with the Flexicon logo.

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 11

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

12 m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

Language selection

Select the display language using the up and down keys (∧/∨) and then the

.

Setting the time and date

Enter the time and date using the numeric keypad. The time format is hh/mm/ss

and the date format is yyyy/mm/dd. The time is 24hr format.

Pressing will move the selection forward. Once the time and date is

correct, press . Pressing at any point returns to the previous

screen.

Setting the filling method

The filling method defines how each fill will be started.

Time delay between fills, the next fill starts automatically at a set time delay

after the previous fill ends.

Keypad to start each fill, requires to be pressed to start every fill.

External input to start each fill , starts a fill whenever a signal is received

through the start input pin.

The Filling method icon will be displayed in the screen info bar area.

Select the display language using the up and down keys ( ∧/∨) and then press

. The filling method can be reset in settings mode

Setting the pump administrator

Enter a username for the pump administrator. The default username is USER1.

Press to delete characters.

Use the up and down keys (∧/∨) to scroll through the available characters. After 1

second of inactivity the next character can be entered. Use the numeric keypad to

enter numbers. Once the username is correct, press .

Additional users can be set up in settings mode.

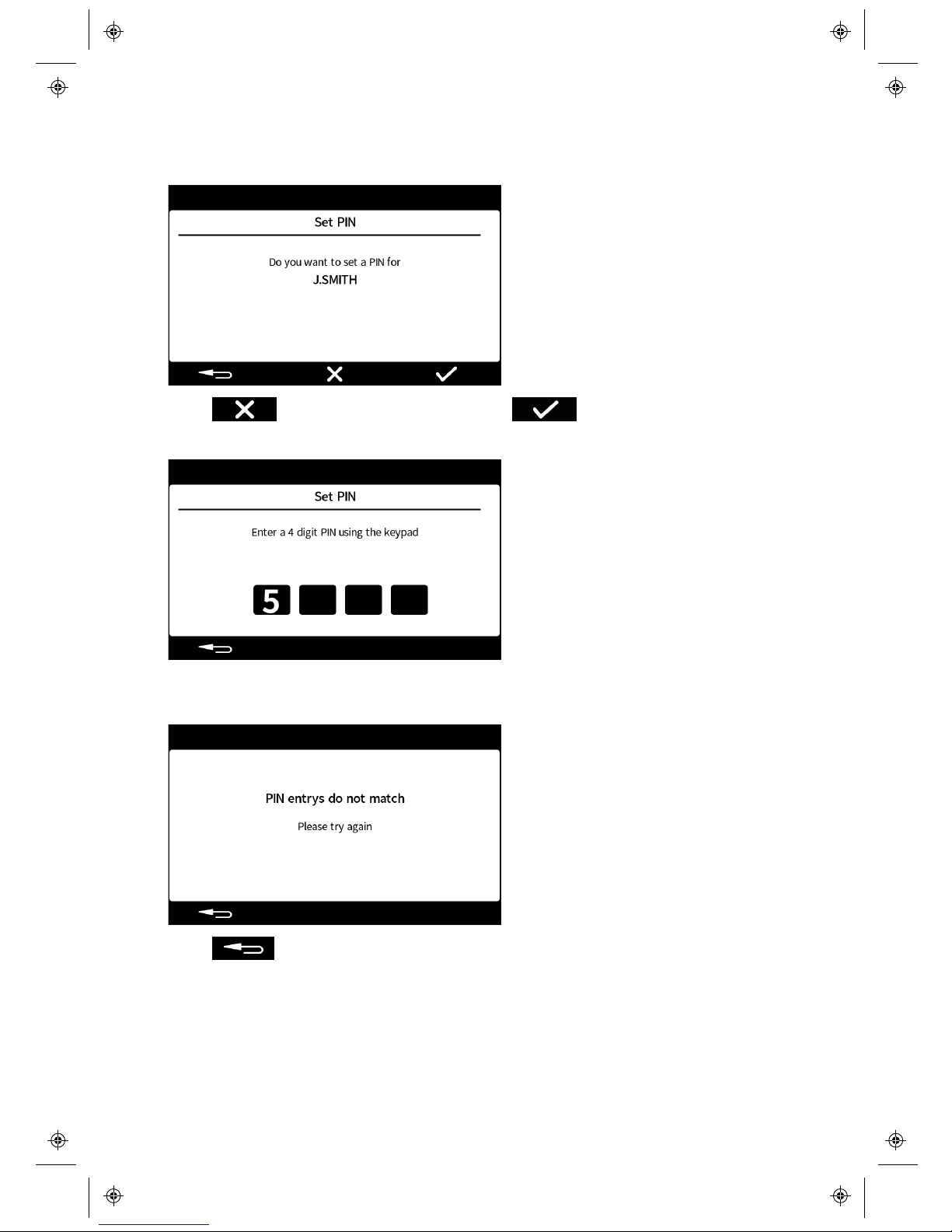

Setting a PIN

By setting a PIN number, a 4 digit number will be required to log in as the pump

administrator. A log in is required whenever the pump is powered on or a user has

logged out.

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 13

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

14 m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

Ensure you keep a record of PIN numbers. If you lose them contact your local

Watson-Marlow Ltd or Flexicon representative.

Press if a pin is not required or press if a PIN is required

If a pin is required, enter a 4 digit number using the numeric keypad

Re-enter the PIN when requested.

If the entry’s don’t match, the following screen will be displayed.

Press to return to the first PIN entry screen.

6.4 Switching the pump on in subsequent power cycles

Subsequent power-up sequences will show the initialisation screen and then the

Log-in screen.

Select the desired username using the up and down keys ( ∧/∨) and then press

.

The icon by the username indicates the type of user; either a pump administrator or

a user.

Entering your PIN number

If a PIN has been set for the selected user the following screen will be displayed.

Enter a 4 digit number using the numeric keypad and then press .

If an incorrect PIN is entered "Incorrect PIN, please try again" will be displayed.

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 15

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

16 m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

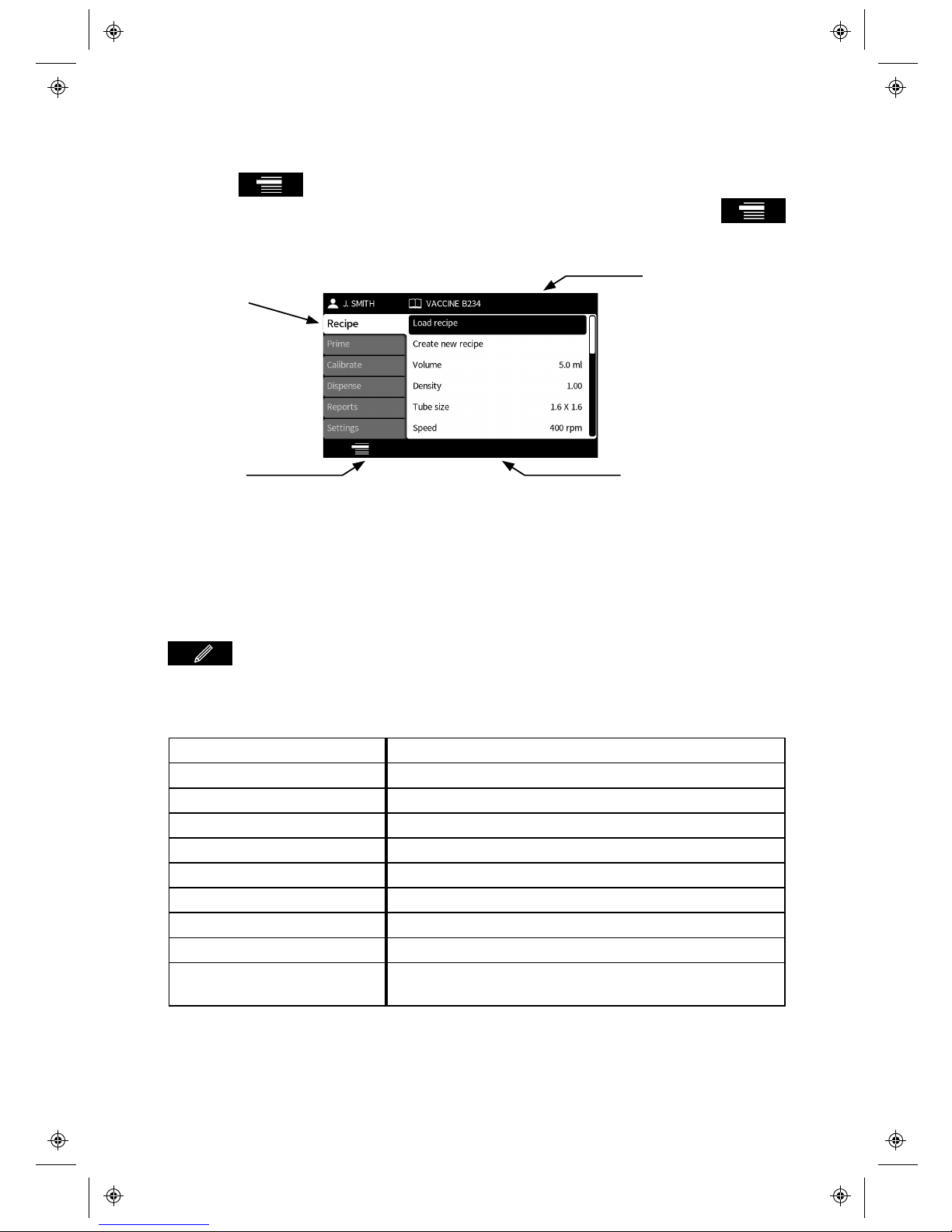

6.5 Menu navigation

Pressing scrolls through the PF7’s different modes. The active mode is

shown by the highlighted tab. The mode can be changed whenever the

icon is displayed. The PF7 has three smart keys, these change functionality

depending on the screen being displayed.

MODE tabs

MODE Icon Smart key icon bar

Screen info bar

6.6 Recipe Mode

Up to 200 recipes and 50 users can be stored in memory.

Editing a recipe

Select the Recipe tab to enter the recipe details.

Navigate through the recipe items using the up and down arrows (∧/∨) and press

to edit the value.

Each recipe item has clear entry instructions on the screen on how to edit or enter

details.

Recipe Item Description

Load recipe Load a recipe from a list of stored recipes

Create a new recipe Create a new recipe using the recipe items set

Volume Fill volume

Density Fluid density

Tube size Tube size selection

Speed Pumphead rotor speed

Acceleration Rate at which the motor accelerates

Deceleration Rate at which the motor decelerates

Anti-drip Relative amount at which the motor reverses at the end

of each dispense

Recipe Item Description

Start delay Length of time from the pump receiving a start signal

and the fill starting, (keypad or external input)

End delay Length of time from the motor stopping and the pump

being ready to start the next fill

First Fill delay The time between a start signal and the first fill starting

Between fill delay The time between one fill ending and the next fill

starting

Recalibration reminder Period between recalibrations after which a reminder

will be displayed

Recalibration pause Period between recalibrations after which the batch will

be paused until a recalibration is performed

Protected recipe If a recipe is set to be protected then it cannot be edited

in any way

Save recipe Saves the current filling parameters under a recipe

name

Print recipe Prints the current filling parameters

Delete recipe Deletes a saved recipe

Creating a new recipe

When the Create new recipe option is used, some of the recipe parameters are

automatically generated to give the recommended values for that fill. However, all

recipe parameters can be edited after the new recipe has been created.

Remember that filling accuracy can also be influenced by the length of the tubing

and the position of the product tank.

Whilst creating a new recipe, you will be asked if the viscosity of your liquid is most

closely represented by the range (less than) <50cP or by the range (greater than)

>50cP.

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 17

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

18 m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

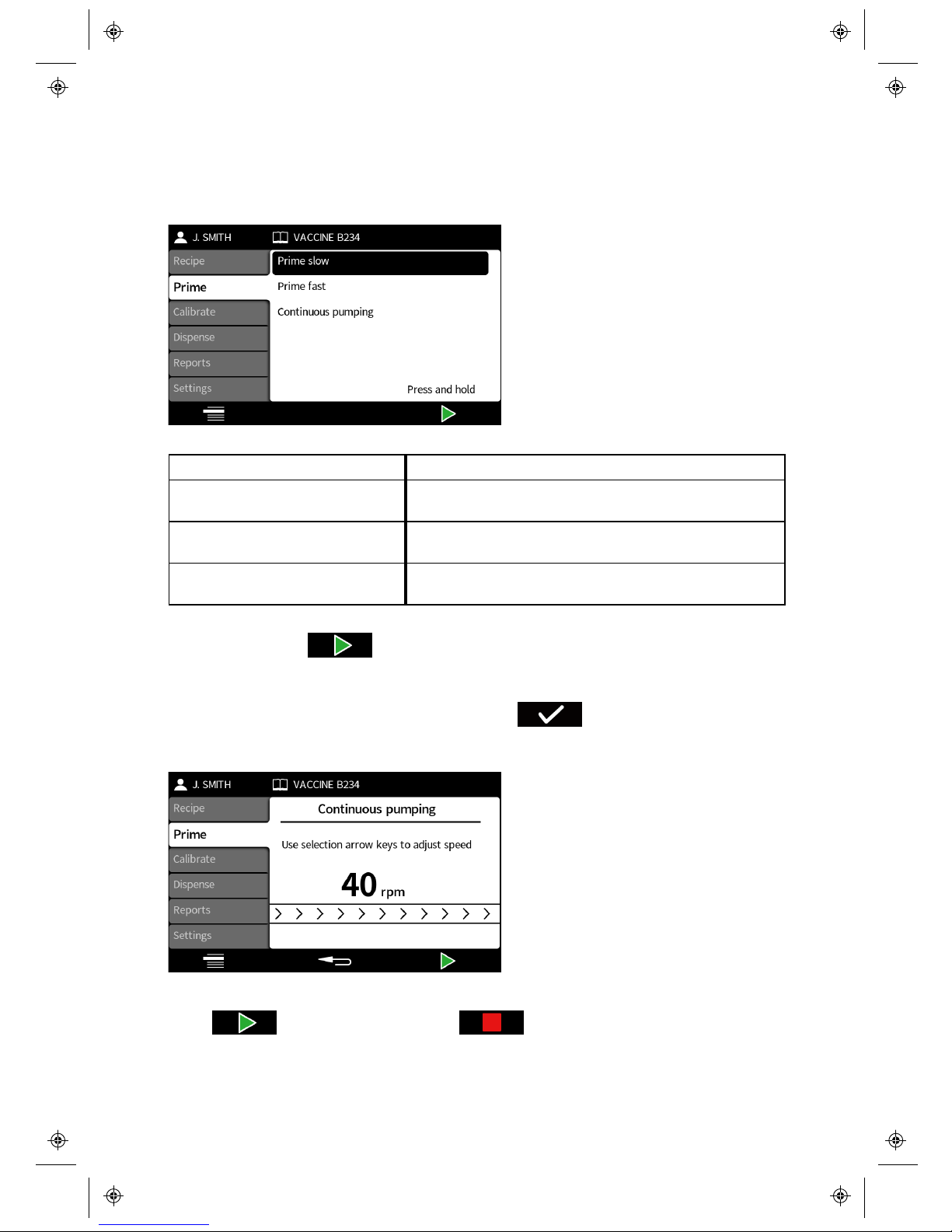

6.7 Priming and continuous pumping mode

The Prime mode allows you to prime the pump or run the pump continuously.

Navigate through the prime items using the up and down keys (∧/∨).

Prime item Description

Prime slow The pump will run forwards (slowly) as long as the

key is held down

Prime fast The pump will run forwards (fast) as long as the key

is held down

Continuous pumping The pump will run forwards at the set speed until the

stop key is pressed

Press and hold the key to prime the pump when using prime slow or prime

fast. The speed of the prime slow and prime fast can be adjusted in the settings

menu.

If continuous pumping is highlighted and the is selected the continuous

pumping screen is displayed. This allows you to select the speed the pump runs at

when continuously pumping.

Adjust the pump speed using the up and down keys (∧/∨).

Press to Start pumping. Press or the Stop key to stop pumping.

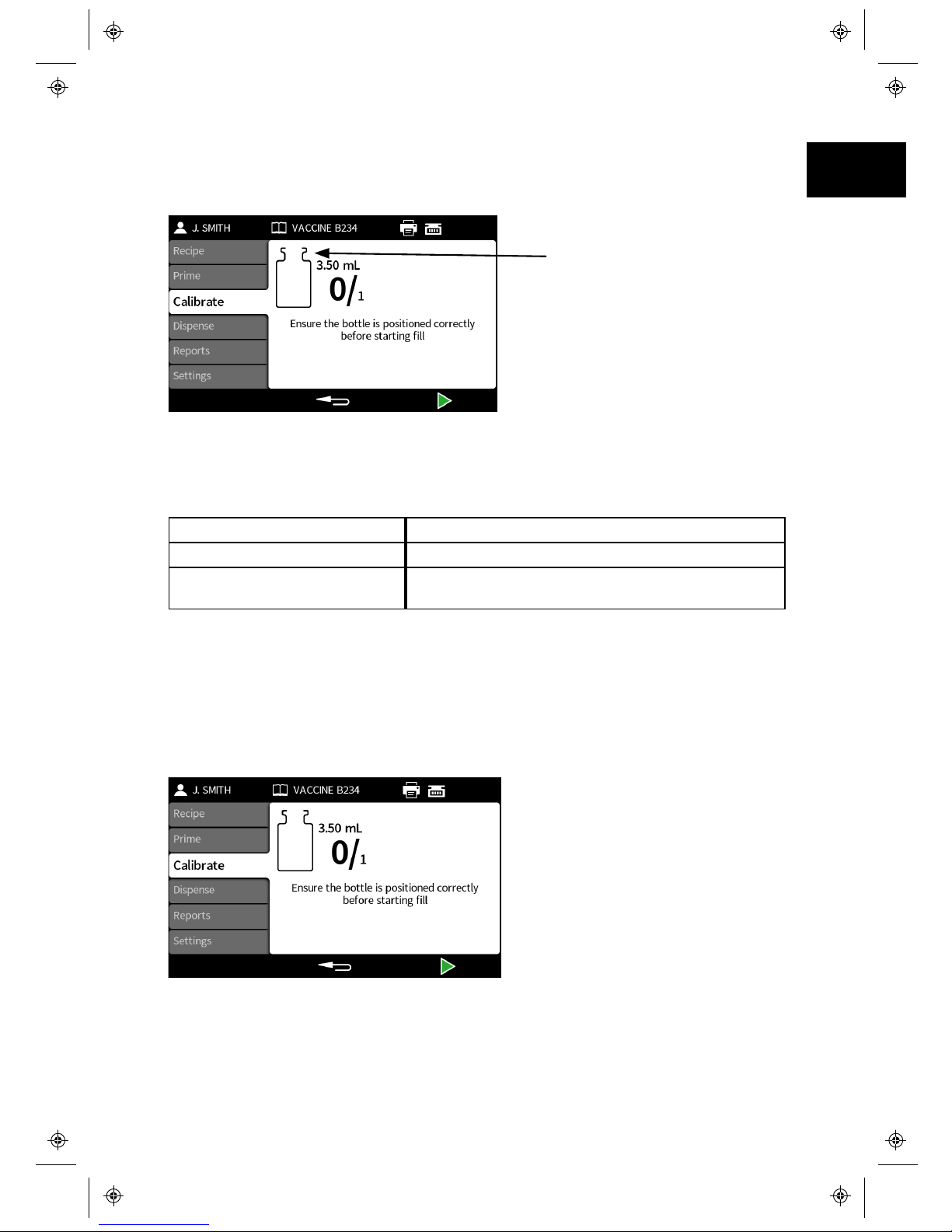

6.8 Calibrate mode

Calibrating the pump before starting a batch and following any change to the recipe

or fluid path is recommended to achieve the optimum filling accuracy.

Calibration icon: The number

within the vial shows how

many calibration fills have

been carried out since the last

batch or recipe parameters

change

The pump uses the current recipe parameters during the calibration process, i.e.

volume, density, tube size, speed, acceleration, deceleration, and anti-drip. The

units used in calibration can be volume or mass and are set through the settings

tab.

Calibrate item Description

Single fill calibration A calibration is done using a single fill

Multi-fill calibration A calibration is done using an average value

calculated from all the fills taken (2 and 99 fills)

If Multi-fill calibration is selected, a screen will be displayed to enter the number of

fills that will be used to create an average fill calibration value.

If a balance is being used, it should be tared (set to zero) using the bottle(s) that

will be used for the calibration fill(s)

Calibration fill(s)

How the fill(s) are started depends on the selected filling method.

m-PF7-Peristaltic Filler User

Manual-02:PB0439/2 19

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

20 m-PF7-Peristaltic Filler User

Manual-02:PB0439/2

Time delay between fills - Press or use the external input to start the

first calibration fill. If doing a Multi- fill calibration, any further fills will start

automatically after the Between fill delay has elapsed.

Keypad to start each fill - Press to start the first calibration fill. If doing

a Multi-fill calibration, press to start any further fills.

External input start each fill - Press or use the external input to start

the first calibration fill. If doing a Multi-fill calibration, press or use the

external input to start any further fills.

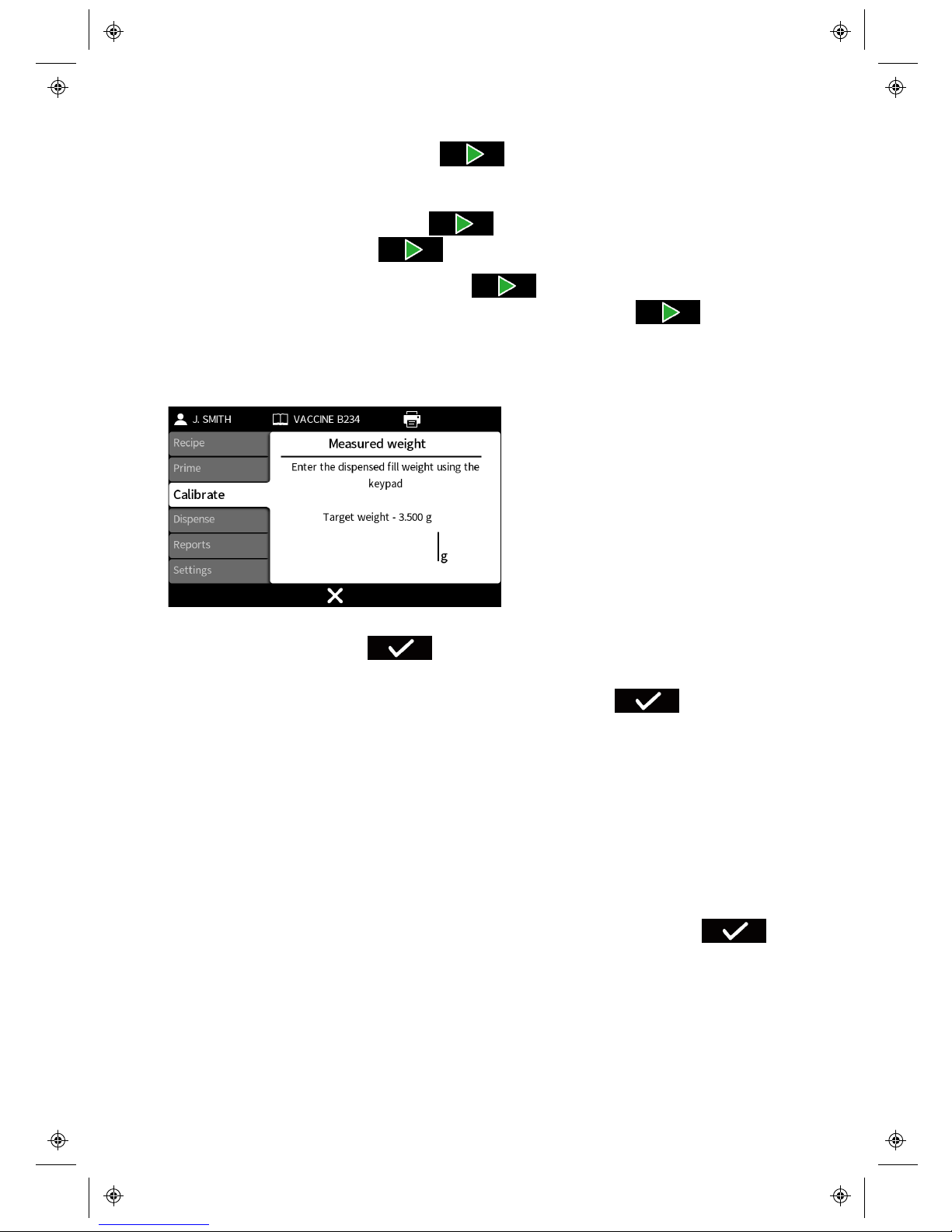

Calibration value entry

If not using a balance connected to the pump, enter the dispensed value using the

numeric keypad and press .

If a balance is connected to the pump, the balance value will be automatically

displayed. Place the filled bottle(s) on the balance and press .

If a multi-fill calibration has been performed, the entered value should be the total

value of all fills.

Calibration outside an acceptable level

If the calibration value entered is outside of the acceptable calibration range a

warning screen will be displayed.

Calibration summary

A calibration summary will be displayed. If the values are correct, press to

complete the calibration process.

Other manuals for PF7

1

Table of contents

Other Flexicon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Roland

Roland VersaUV LEF2-200 Product guide

Thermo Scientific

Thermo Scientific 88882015 operating manual

Metrohm

Metrohm Eco Dosimat product manual

Thermo Scientific

Thermo Scientific SmartView SV100A user guide

Agilent Technologies

Agilent Technologies 5100 ICP-OES Site preparation guide

Oxford Instruments

Oxford Instruments X-MET8000 Series user manual