7

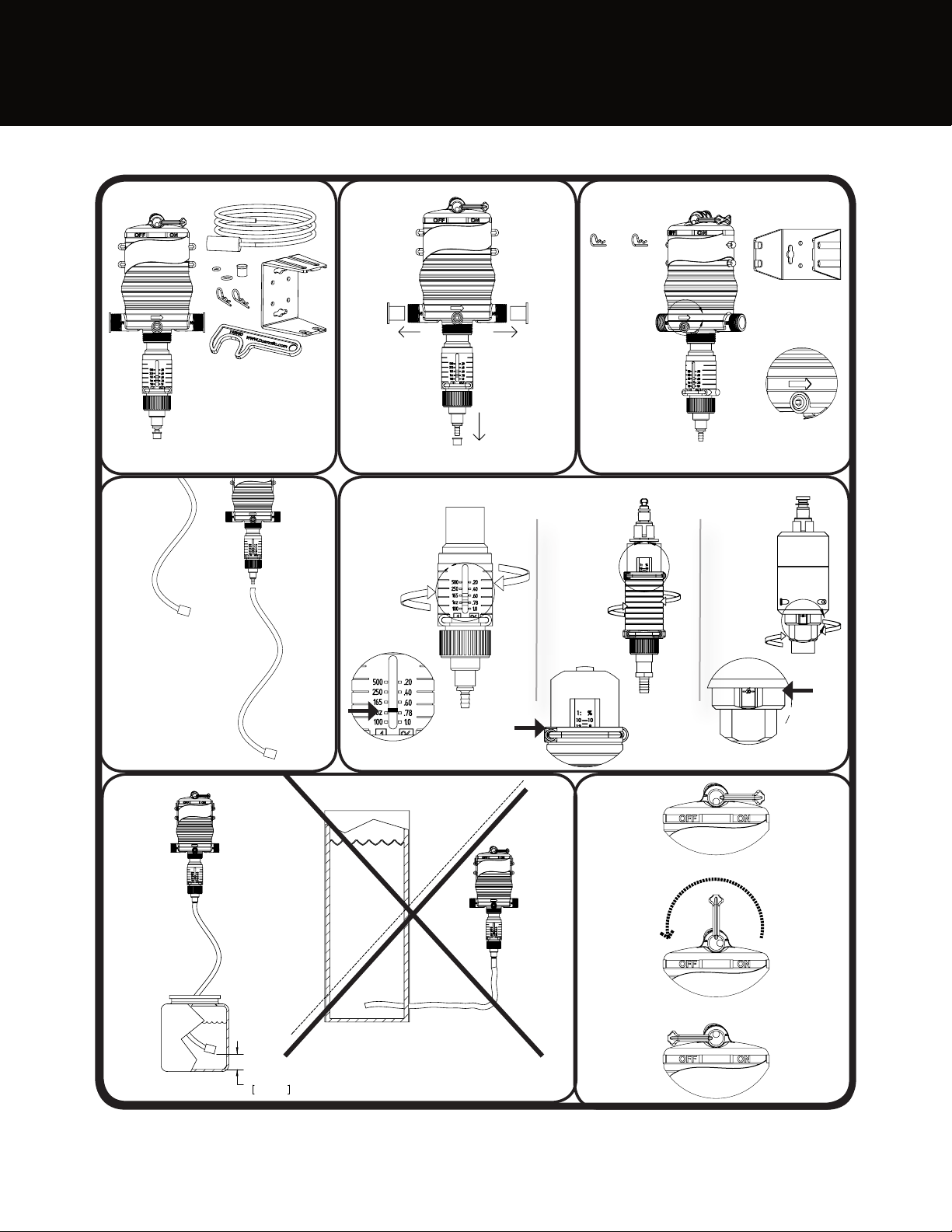

Remove Red Caps Prior to Installation

Your injector is 100% factory tested before delivery

and may contain a small amount of water. The three

red plastic caps are fitted after testing to ensure

cleanliness of the injector.

Before Applying Aggressive Chemicals

Please consult your distributor, chemical manufacturer

or contact Hydro’s customer service to confirm

compatibility with your injector. Always wear

proper safety protection as recommended by

chemical supplier.

Label all Fluid Lines, Valves and Connections

If the solution that is being injected is not suitable

for drinking, all fluid lines should be labeled:

Warning - not for human consumption!

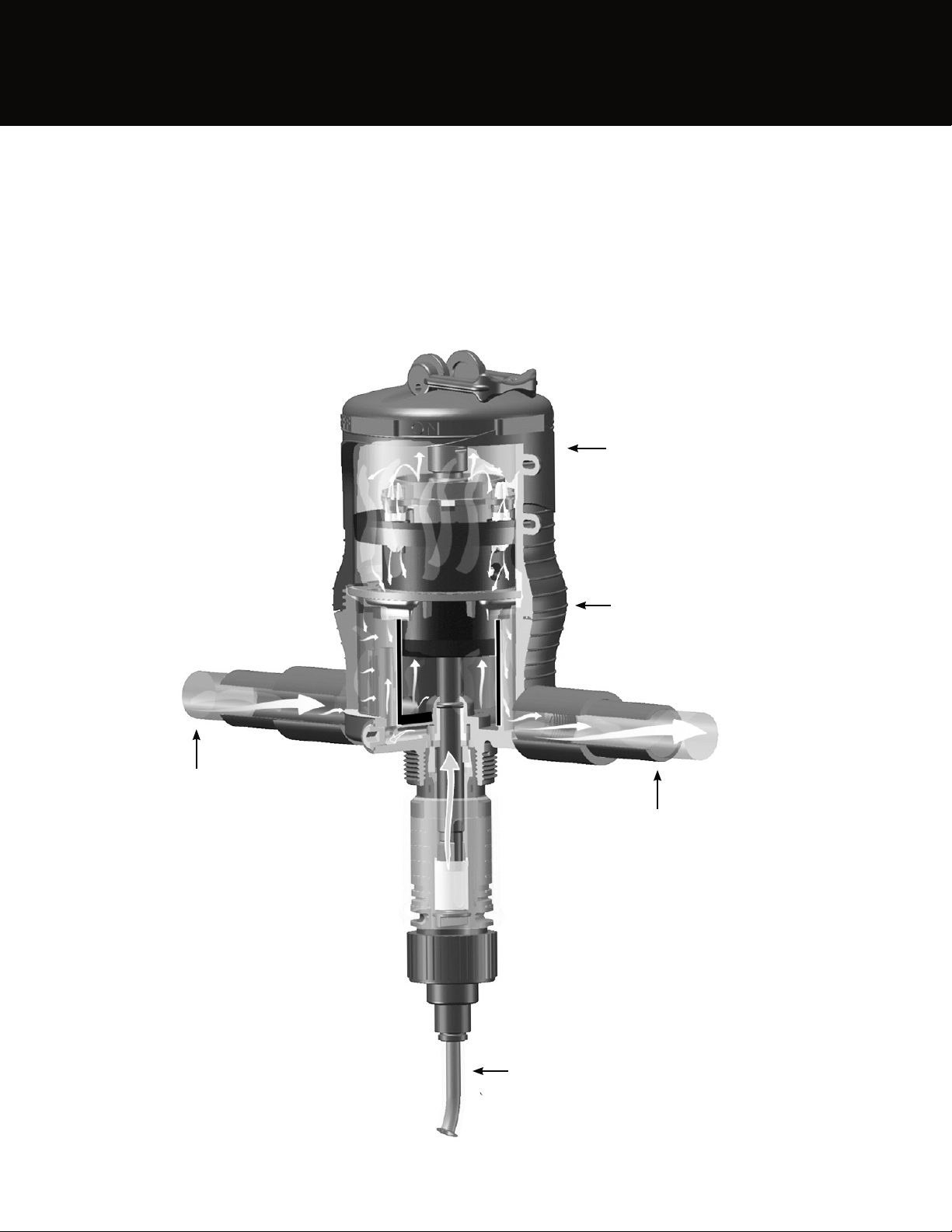

Monitor Outlet Flow

It is the user’s responsibility to monitor the output

of chemical injected.

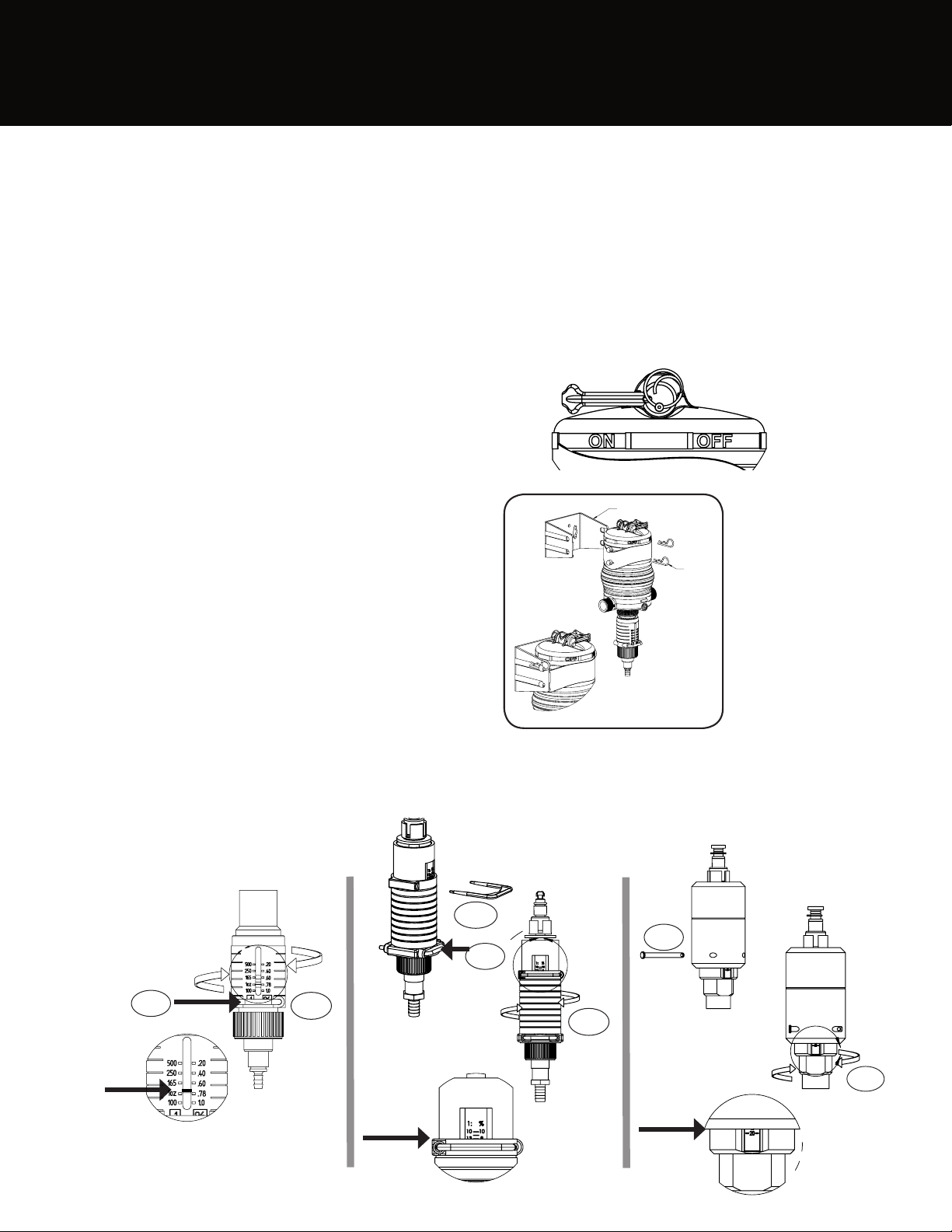

A Filter is Recommended and Required

Install a filter of 140 mesh (104 micron) or finer

depending on your fluid quality to prolong the working

life of the injector and for the warranty to be valid.

A filter is imperative since most fluid contains

impurities or particles, especially if the fluid source

comes from a well, pond or lake.

For A Long Service Life

Start with clean fluid by using an inline filter to reduce

impurities. Keep the solution container covered and

clean. Keep the suction tube filter 2" (5 cm) from

the bottom of the container. Perform maintenance

procedures as recommended (see Maintenance

page 10).

Soluble Powder Use

Ensure the chemical is completely dissolved before

starting the injector. If necessary, dissolve the chemical

in hot water and allow to cool before using. Failure to

thoroughly dissolve the chemical will cause premature

wear to the dosage piston and the inner cylinder.

!

Please read this instruction manual thoroughly. Following the procedures, will increase the life of your injector.

Warning: Please read precautions thoroughly before operation. Must meet all

applicable local codes and regulations.

Avoid a Potentially Hazardous Chemical Accident

Select a safe location. Chemical container should be

kept away from children and/or high usage areas

and the location must also not be susceptible to

freezing temperatures.

Avoid Solution Contamination

Use only clean FILTERED fluid. Do not allow

contaminants to enter the solution container. They

can be pumped into the fluid line and may cause the

spread of disease. Dirt, debris and other contaminants

in the solution container may cause excessive wear

to the unit.

Fluid Temperature

Min: 34°F (1°C), Max: 100°F (38°C)

Maximum Fluid Pressure

0.4%, 1%, 2.5%, 5% - 140 psi (9,6 bar)

10% & 20% models have maximum operating

pressure of 65 psi (4,5 bar). Operating pressure and

flow are reduced while using remote injection kit.

Install a pressure regulator and/or pressure relief valve

to ensure operating pressure does not exceed the

maximum specification.

Before Removing An Injector From The System

Release fluid pressure. While the system is in

operation, turn off the incoming fluid valve. Leave the

out going valve open. This will relieve the pressure

at the injector and all parts of the system after the

injector. Injector is now safe to remove.

Keep From Extreme Temperature

Protect the injector from freezing temperatures or

excessive heat.

Rinse Injector After Each Use

Additive allowed to remain in injector can dry out,

foul or damage the lower end at the next start-up

(see Maintenance page 10).

Injector Not in Use for an Extended Period

If the injector has not been stored properly deposits

may have dried onto the motor (see Maintenance

page 10). Before operation, soak entire unit into room

temperature water approx. 72°F (22°C) for an eight

hour period.

Safety Precautions/Warranty Compliance

General Tips