2 3

Your satisfaction and safety require a complete understanding of this unit,

including its proper function and operational characteristics. Be sure operators are

given adequate training before attempting to put the unit in service.

1. Inspection: The carrier, when accepting shipment, also accept responsibility for safe

delivery and is liable for loss or damage claims. On delivery, inspect for visible exterior

damage, note and describe on the freight bill any damage found and enter your claim on

the form supplied by the carrier.

2. Inspect for concealed loss or damage on the unit itself,If any, the carrier will arrange

for official inspection to substantiate your claim. Save the shipping crate until you are sure

the unit has been delivered in good condition.

3. Return Shipment: If for any reason you must return the unit, contact your customer

service representative for authorization and supply nameplate data.

4. Accessories: Make sure that all of the accessories indicated on the packing list is

included with the unit. Carefully check all packaging before discarding. If there are any

damaged or missing items, please contact your dealer.

Receiving and Inspection Installation

Mini Roller Manual Mini Roller Manual

The symbol showns to the left indicates that this product shall not be

treated as household waste. In line with EU Directive 2012/19/EU

for waste electrical and electronic equipment (WEEE), this electrical

product must not be disposed of as unsorted municipal waste.

Please dispose of this product by returning it to the point of

sale or to your local municipal collection point for recycling.

Disposal and Recycling Information

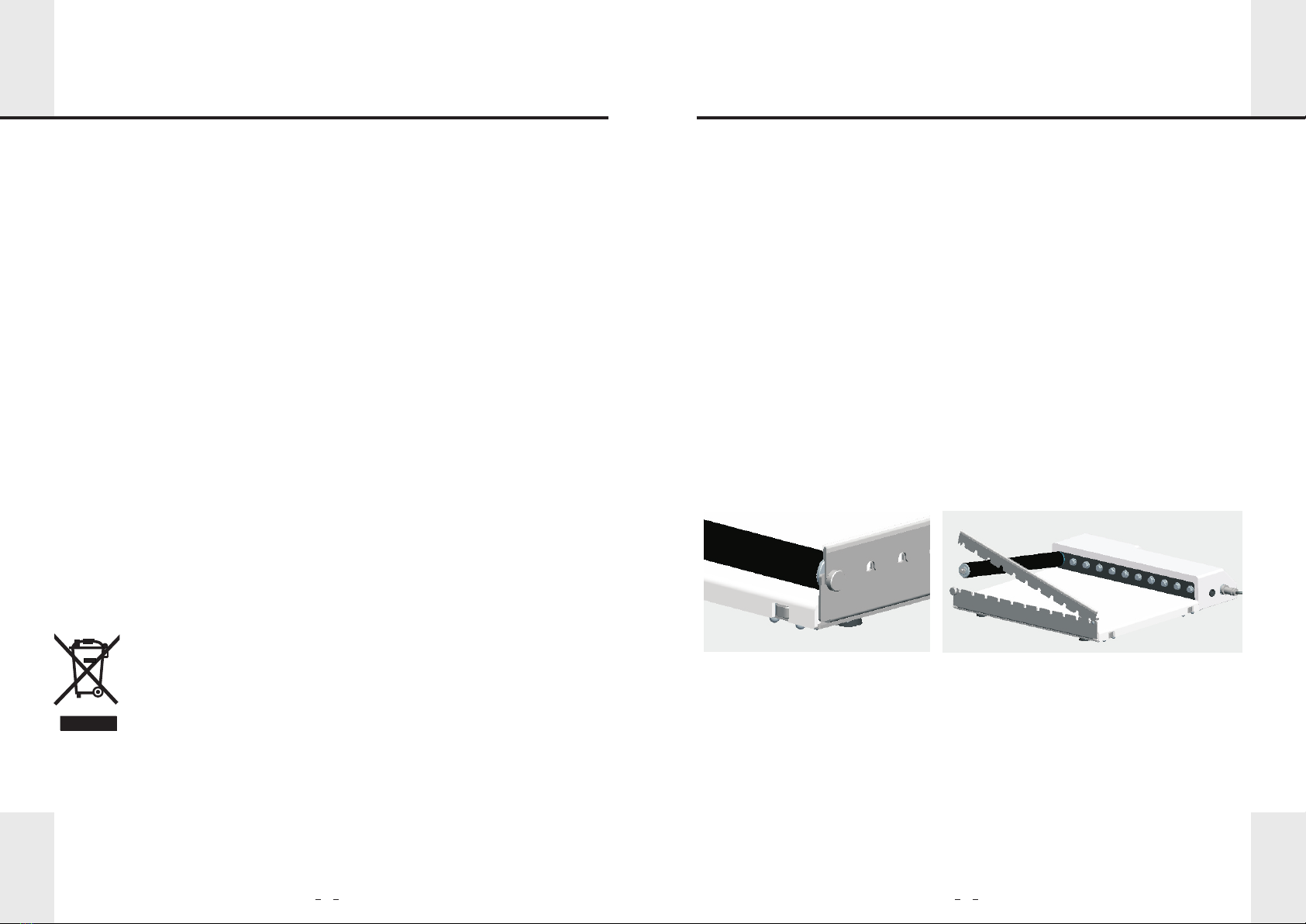

1. Control box installation (skip this step for ROL-02U series)

2. Roller bars removal and installation

Roller bars can be removed and installed for different sized tubes.

Fig-1

This unit is equipped with a separate control box (optional) Please fasten the nut

on the connection plug of control box to the unit.

NOTE: Keys on the panel of the unit will become invalid when control box is connected.

One control box controls one unit only.

.

2.1 Roller bars removal

Turn the knob counterclockwise to be loose on the unit end(see Fig-1) and then lift

the locking metal arm as shown in fig- 2.And remove it. Press the sheet metal to the

original position and clockwise twist the knob for fastening.

2.2 Roller bars installation

Turn the knob counterclockwise to be loose on the unit end (see Fig-1) and then

uplift the pressure sheet-metal. Aim Hexagon Hole of roller at Hexagon shaft of the

unit and press the other head into semicircle orifice. Press the sheet metal to the

knob position and clockwise twist the knob for fastening.

Fig-2

3. Rocking roller bars removing and installation

3.1 Rocking roller bars removing

The way of removing the rocking roller bars is the same as the way of removing the

roller bars.(see 2.1)

3.2 Rocking roller bars installation

Counterclockwise twist the knob to be loose on the unit end(see Fig-1)and then uplift

the pressure sheet-metal. Place the hexagon hole of the roller at the hexagon shaft of the

unit and press the other head into semicircle orifice.After installing the first rocking roller