FlexLink 5995512 User manual

Created by EBCCW 96:05Created by EBCCW 00:06Created by EBCCW 96:05Created by EBCCW 00:06

Spiral Elevator

C

r

eated by EBCCW 00:06

5478EN-3

Type 5995512

User Manual

Original Instructions 2011

Created by EBCCW 96:05Created by EBCCW 00:06

Created by EBCCW 00:06

Spiral Elevator

5478EN-3

© Flexlink Components AB 2010

All Rights Reserved

No part of this program and manual may be used, reproduced, stored or

transmitted in any form or by any means without the written permission of

FlexLink Components AB. The contents of this manual are for informational

use only. All information and specifications contained in this document

have been carefully checked to the best efforts of FlexLink Components

AB, and are believed to be true and accurate as of time of publishing.

However, due to continued efforts in product development FlexLink

Components AB reserves the right to modify products and its manuals

without notice.

FlexLink Components AB assumes no responsibility or liability on any

errors or inaccuracies in this program or documentation. Any kind of

material damages or other indirect consequences resulting from any

FlexLink Components AB product part, documentation discrepancies and

errors or non-anticipated program behavior are limited to the value of

appropriate products purchased from FlexLink Components AB. The

products are delivered to the customer at the ’as is’ state and revision level

they are on the moment of purchasing, and are declared in detail in the

license agreements between FlexLink Components AB and user. User

accepts and is obliged to follow the guidelines stated in the separate

license agreement needed in using any parts of this product package.

User Manual

5478EN-3

Created by EBCCW 00:06

Page I of II

5478EN-3

Content

1 Safety....................................................... 3

1.1 System information.................................. 3

1.2 The most important safety conditions...... 4

1.3 Description of safety provisions............... 5

1.4 Safety measures to be taken .................... 6

1.5 Explanation of symbols ............................ 7

2 Technical specifications............................ 8

2.1 Technical data........................................... 9

2.2 Ordering information.............................. 10

2.3 Operating conditions .............................. 11

3 Introduction ........................................... 12

3.1 Purpose of use ....................................... 12

3.2 Description of the Spiral Elevator ........... 13

3.3 Working principle................................... 19

3.4 Control units .......................................... 21

4 Unload the Spiral Elevator ...................... 22

4.1 Preparation............................................. 22

4.2 Unloading instructions ........................... 23

5 Mounting, installation, adjustment ......... 27

5.1 Provisions to be provided ...................... 27

5.2 Assembly ................................................29

5.3 Validation ................................................33

5.4 Integration in a (transport) system .........35

5.5 Setting of the Spiral Elevator...................37

5.6 Test run - partially loaded........................39

6 Technical maintenance............................43

6.1 Check and control procedures ................43

6.2 Maintenance procedures.........................47

6.3 Troubleshooting list ................................57

6.4 Maintenance schedule Spiral Elevator.....60

7 Put out of commission............................62

7.1 Disconnect the power sources................62

7.2 Disassemble............................................62

7.3 Transport ................................................63

7.4 Disposal..................................................64

7.5 Reuse......................................................64

8 Spare parts list........................................65

8.1 Spiral Elevator 5995512..........................65

9 Supplier’s information.............................66

10 Manufacturer’s declaration......................67

Page II of II 5478EN-3

Created by EBCCW 00:06

Page 1 of 68

5478EN-3

Preface

Purpose of this manual

The purpose of this manual is to describe various operations that are

intended for the user to perform.

This document contains remarks that point out a risky or specific situation

to the user. In many cases this situation is provided with one of the symbols

given below.

Compliance with the operations described in this document is important in

order to prevent dangerous situations and unnecessary damage to

the Spiral Elevator

It is recommended to keep one copy of this manual near the machine and

one copy with your technical documentation.

Structure of the manual

The user's manual has been composed in such a way, that a number

of operations can quickly and easily be found.

This manual does not describe operations that are not intended for the user

to perform.

The user's manual has been divided into sections which describe a variety

of functions including the safety and the safe operation of the

Spiral Elevator.

It is recommended that this manual is read by all users of this equipment

with particular reference to Section 1 on page 3: Safety.

.

General warning for danger!

.

Warning for electrical voltage!

.

Attention, this is an important notice!

Page 2 of 68 5478EN-3

Requirements of the user

The Spiral Elevator should only be operated by a person who has become

acquainted with section 1 'safety' and trained in the use of the unit.

The Spiral Elevator should only be installed by persons who have become

acquainted with section 4 'unload the Spiral Elevator.

. Note! Maintenance activities on the Spiral Elevator should only

be carried out by a technically qualified person.

. Note! Technically qualified employees means: persons that have

received adequate training for carrying out the activities involved.

Safety

Created by EBCCW 00:06

Page 3 of 68

5478EN-3

1 Safety

The Spiral Elevator has been designed such, that it can be used and

maintained in a safe way. This holds for the application, the circumstances

and the instructions described in the manual. Any person working with or

on this machine should study and follow the instructions contained within

this manual.

The company or the country in which the machine is used may require

extra safety measures. This particularly applies to the working conditions.

This manual does not describe how these are to be complied with. In case

of doubt, consult your government or safety officer!

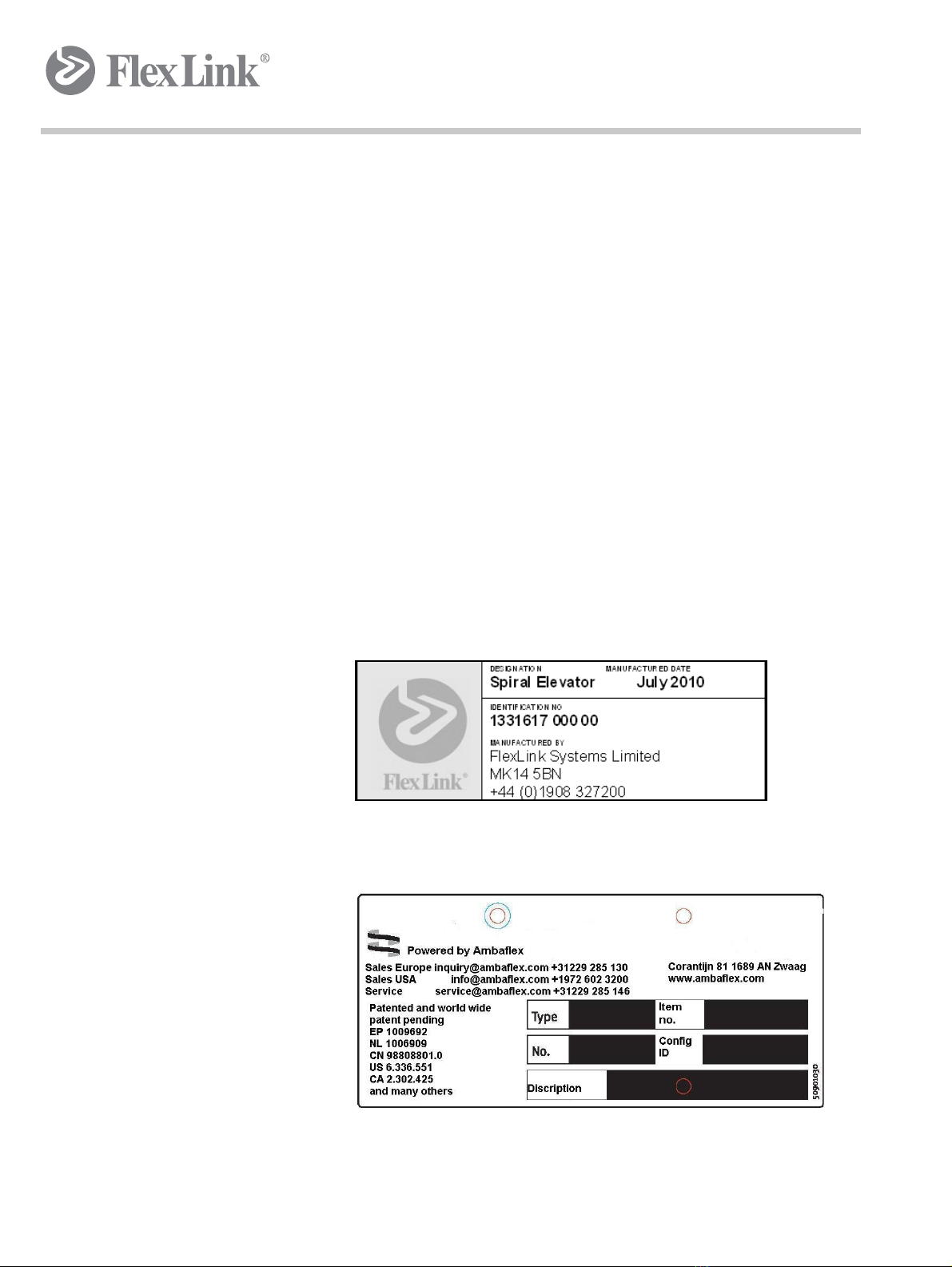

1.1 System information

The project number and/or general drawing number (identification number)

shall always be specified when communicating with FlexLink with respect

to the Spiral Elevator.

The following detail plates are generally attached to the Spiral Elevator.

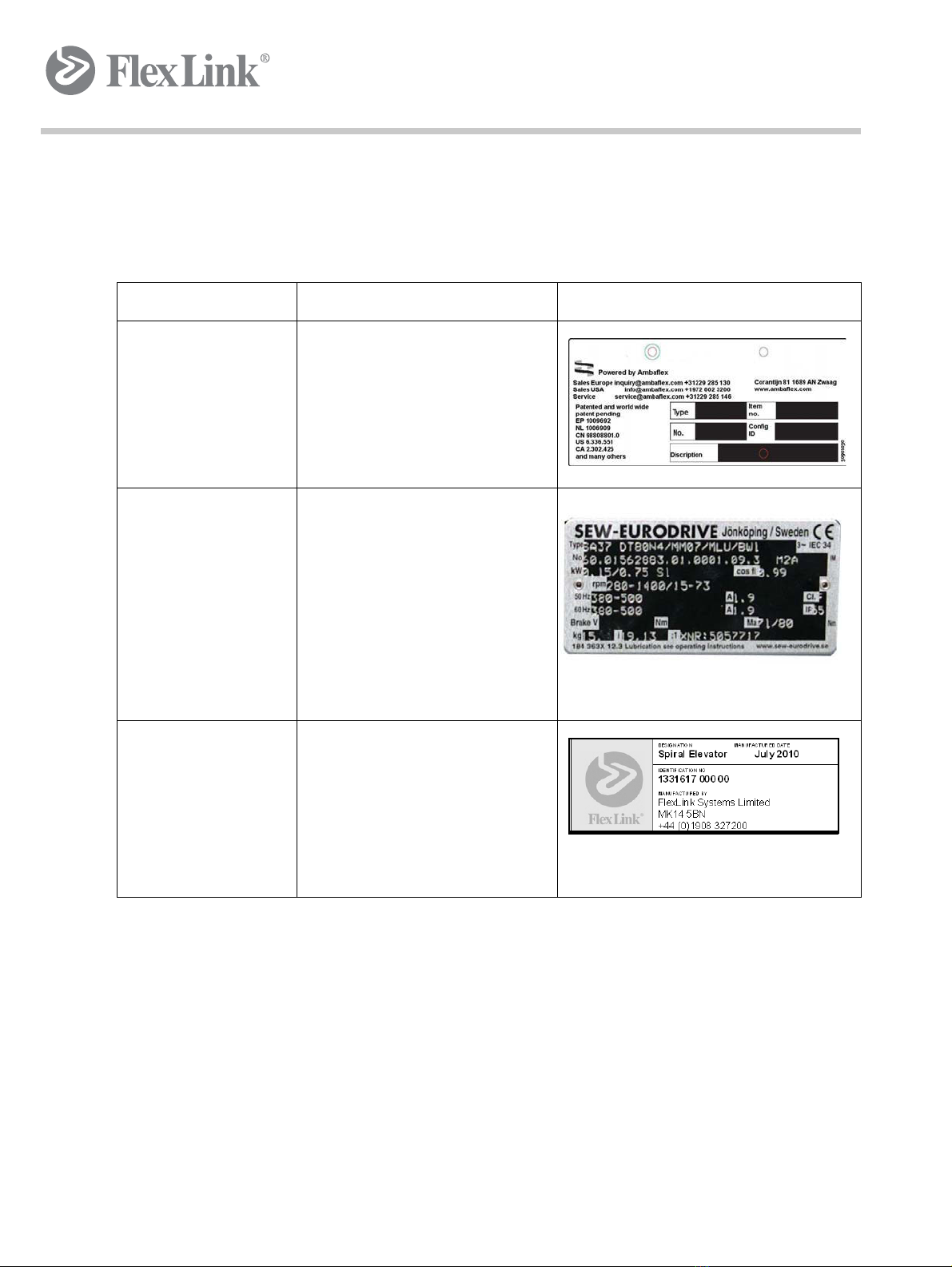

Figure 1 Example of Machine plate (system supplier)

Figure 2 Spiral Elevator plate ( Manufacturer)

Safety

Page 4 of 68 5478EN-3

1.2 The most important safety conditions

Before the Spiral Elevator is put in to service, the following safety

conditions must be met:

• Provide good ambient lighting.

• Equipment users should have read and understood the operating

instructions to operate, maintain or clean the machine.

• Equipment users should not reach into the machine while it is

running. Even if the machine is not running, it may be 'on', which

means it may start operating automatically.

• Safety provisions (where fitted), such as side plating, bottom

plating, emergency stops and detectors must not be removed or

deactivated while the Spiral Elevator is running.

• Before clearing of any jams, the unit should be stopped and safely

isolated.

Safety

Created by EBCCW 00:06

Page 5 of 68

5478EN-3

1.3 Description of safety provisions

As a standard the Spiral Elevator is not provided with control or any safety

provisions. Before putting the Spiral Elevator into service some safety

provisions are to be incorporated. The purpose of these safety provisions

is to protect the user, the product and the Spiral Elevator against undesired

situations (damage). If these safety provisions are not incorporated it will

invalidate the warranty.

The table below gives a general description of the safety provisions

required. Only technically qualified persons should work on the settings of

the safety provisions!

The safety provisions listed in the table are a general guide only. The actual

safety provisions to be used must be determined by relevant risk

assessment of the overall system.

Where the possibility exists for oversize product to enter the Spiral Elevator

it is recommended to install a detector prior to the Spiral Elevator and use

this to stop the elevator thus preventing damage from occurring.

Note! If an oversize product jams in the Spiral Elevator it may

damage the unit.

Control Remark

Emergency stop switch Each Spiral Elevator is to be provided with one or more emergency stop

switches that can be operated within reach of the user. The emergency

stop switch must make sure that the input and output conveyors or

machines are switched off simultaneously.

Motor protection The technical specification of the Spiral Elevator is, among other things,

geared to the load given in the technical specification, quotation or

drawing.

Should the Spiral Elevator (gear motor) become overloaded, this should be

detected by the motor protection in the control system. Without this

protection there is a chance that the gear motor or other components of the

Spiral Elevator will be damaged and this damage will not be covered by the

warranty.

Motor isolation Means of isolating the motor from the power supply must be provided and

within close proximity to the motor.

Safety

Page 6 of 68 5478EN-3

. Note! Only technically qualified persons are allowed to change

the settings of the safety provisions.

1.4 Safety measures to be taken

For a safe operation of the Spiral Elevator a number of safety measures are

to be taken. These include the following measures:

• Clean floor surface - With a clean floor surface the operator will

not be hindered while operating the Spiral Elevator. This can

prevent tripping or slipping, so that the operator does not

unexpectedly come into contact with the Spiral Elevator.

• Hearing protection -Different tests have shown that the

Spiral Elevator does not produce more than 85dB(A)

Mechanical Remark

Height / width

detector

Product entering the Spiral Elevator should not be of a size where the product

can become jammed in the Spiral Elevator.

In order to ensure that product cannot become jammed in the Spiral Elevator

due to oversize some automatic checks for width and height can be done.

This detection must take place before the Spiral Elevator in order to stop the

product or Spiral Elevator.

The maximum dimensions of the product are given in the technical

specification, quotation or drawing.

Transition guard The basic Spiral Elevator is not supplied with any guarding at the drive / idler

ends. A risk assessment should be conducted with consideration to the

adjacent conveyors/equipment product etc. to establish any requirements for

guarding.

Safety

Created by EBCCW 00:06

Page 7 of 68

5478EN-3

1.5 Explanation of symbols

Pictogram symbols have been placed on the Spiral Elevator in order to

identify to the user certain conditions or provide certain information on

components of the Spiral Elevator.

No. Description Picture

1.Spiral Elevator plate This contains the name and the

address of the initial

manufacturer, series or type

indication, serial number and the

year of construction of the Spiral

Elevator.

2.Gear motor plate This contains information of the

gear motor supplier along with the

CE-mark if appropriate. Also

indicated is the gear motor type,

applicable voltages, power, oil

type etc.

3. Machine plate This contains the system supplier,

installation date and the

Identification Number of the Spiral

Elevator and information of the

system supplier along with the

CE-mark if appropriate.

Example of Gear motor plate

Example of Machine plate

Technical specifications

Page 8 of 68 5478EN-3

2 Technical specifications

Below is the technical specification of the Spiral Elevator.

Further product details to which the Spiral Elevator has been designed are

contained within the overall Project Documentation (when purchased as

part of a Project System).

Use of the Spiral Elevator outside of the scope detailed within the technical

specification, quotation or documentation will invalidate the warranty.

General FlexLink Spiral Elevator specification

• 500 mm inclination per winding (9 degree)

• 3-8 windings

• 1000 mm nominal centreline diameter

• Speed 5 - 60 metres per minute

• Lower height:- 600, 700, 800, 900 or 1000 mm

- Adjustable -50/+70 mm

• Max load 10 Kg/m (specific Spiral Elevators may be with a lower

limit due to actual gear motor used)

• Product size:

- width= 50 - 200 mm

- length= 80 - 250 mm

- height= 1,5 x Length (max 300 mm)

- see Project Documentation if applicable

• Drive and idler ends are horizontal

• Chain width 100 mm

• Friction top chain

• Steel chain with bearings running on the inner guide rail

• Wet coated mild steel frame

• Column diameter 160 mm

• M8 thread for guide rail

Technical specifications

Created by EBCCW 00:06

Page 9 of 68

5478EN-3

2.1 Technical data

350

815

985

1000

n159

5°

8x45°

500 mm

(inclination)

Lower height

600/700/800/900/1000 mm -50/+70

Machine incl.

adjustable feet

5000 mm

(Max. heigth

8 windings)

AB

In/ Out Feed Configurations

Technical specifications

Page 10 of 68 5478EN-3

2.2 Ordering information

Example of a Spiral Elevator designation obtained from the FlexLink

product configurator:

5995512- Item number

A Chain width

B Spiral center of chain diameter

C Incline per winding

D Mild steel (S) material configuration

E Configuration A or B

F Transport direction up/down TU or TD

G Lower height 600/700/800/900/1000

H Number of windings 3,4,5,6,7,8

I Shaft diameter 20 mm (for gear motor type SA37) or 25 mm (for

gear motor type SA47)

For more information please contact your local FlexLink office.

Item no A B C D E F G H I

5995512 100 -1000 -500 - S - A -TU -800 - 3 - 25

Technical specifications

Created by EBCCW 00:06

Page 11 of 68

5478EN-3

2.3 Operating conditions

The circumstances under which the Spiral Elevator can be operated partly

depend on the materials selected. FlexLink has defined a number of

parameters within which the Spiral Elevator would be allowed to function.

Should the Spiral Elevator still be operated beyond these limiting values,

FlexLink cannot guarantee the good functioning of the Spiral Elevator.

As a standard no lighting is installed on the Spiral Elevator although this

can not be added as an option. Normal ambient lighting is sufficient to work

safely with the Spiral Elevator. The Spiral Elevator is not intended for use

in an open air environment or in an area with a risk of explosion, although

static safe materials are available.

If in doubt of the suitability FlexLink should be consulted.

Ambient temperature (in operation) 0 to +35°C

During transport / storage 5 to +40°C

Relative air humidity (RH) 30% to 95%, not condensing

Lighting Normal ambient lighting

Height Up to max. 2000 m above sea

level

Introduction

Page 12 of 68 5478EN-3

3 Introduction

This section deals with a number of general matters with respect to

the Spiral Elevator. This involves, among other things, the purpose of use,

the conditions of use and the working principle of the Spiral Elevator.

Should you have any further questions on the safe operation of the

Spiral Elevator please contact FlexLink.

The warranty conditions have been included in the FlexLink quotation or

are available separately from FlexLink.

FlexLink does not accept any liability for unsafe situations, accidents and

damages resulting from:

• Neglect of warnings or stipulations as displayed on the machine,

in this documentation or in the Project Documentation

(if applicable).

• Use in applications or circumstances other than those specified in

this manual, the quotation, the Project documentation

(if applicable), or FlexLink catalogue.

• Modifications to the machine. This also includes the use of

replacement parts other than those specified and supplied by

FlexLink.

• Insufficient or incorrect maintenance.

FlexLink does not accept any liability for the consequential damage in case

of failures of the machine, for example damage of products, interruption of

operation, etc.

3.1 Purpose of use

The purpose of use of the Spiral Elevator is to transport products / goods

in a vertical direction. This may be for bridging a difference in height or for

functioning as a cooling buffer.

It is not recommended to use the Spiral Elevator for transporting products

with parts that are protruding, hanging loose, for transporting products that

result in a higher load than mentioned in the documentation or for

transporting products with measurements deviating from those given in the

technical specification associated with the particular Spiral Elevator.

Additionally it is not permitted to walk, stand or sit on the Spiral Elevator or

to stick objects or body parts between the guards, conveyor plates or other

moving parts.

Introduction

Created by EBCCW 00:06

Page 13 of 68

5478EN-3

3.2 Description of the Spiral Elevator

The Spiral Elevator is applied in a (transport) system where products can

be transported vertically in a relatively small area. The Spiral Elevator can

be coupled to other transport systems and be built according to the

customer's needs.

Figure 3 Principle sketch (Transport direction up) / Configuration options

Before the Spiral Elevator is put in to service a suitable Risk Assessment

should be completed.

After integration / installation the Spiral Elevator should not be relocated

without further Risk Assessment

AB

Introduction

Page 14 of 68 5478EN-3

Configuration input / output

The configuration of the Spiral Elevator is available in different formats with

regard to input / output positions. These configuration types are expressed

in the letters A or B.

It is possible to have a configuration with which the output side is placed at

a different angle. For any special configurations please contact FlexLink.

Dimensions of the Spiral Elevator

The height of the Spiral Elevator is dependant upon the low level height

plus the number of turns of the spiral (see Technical Specification - Section

2 on page 8).

AB

Table of contents