Table of Contents

A46JRT – 0260228 1

Table of Contents

EC Declaration of Conformity.....................................2

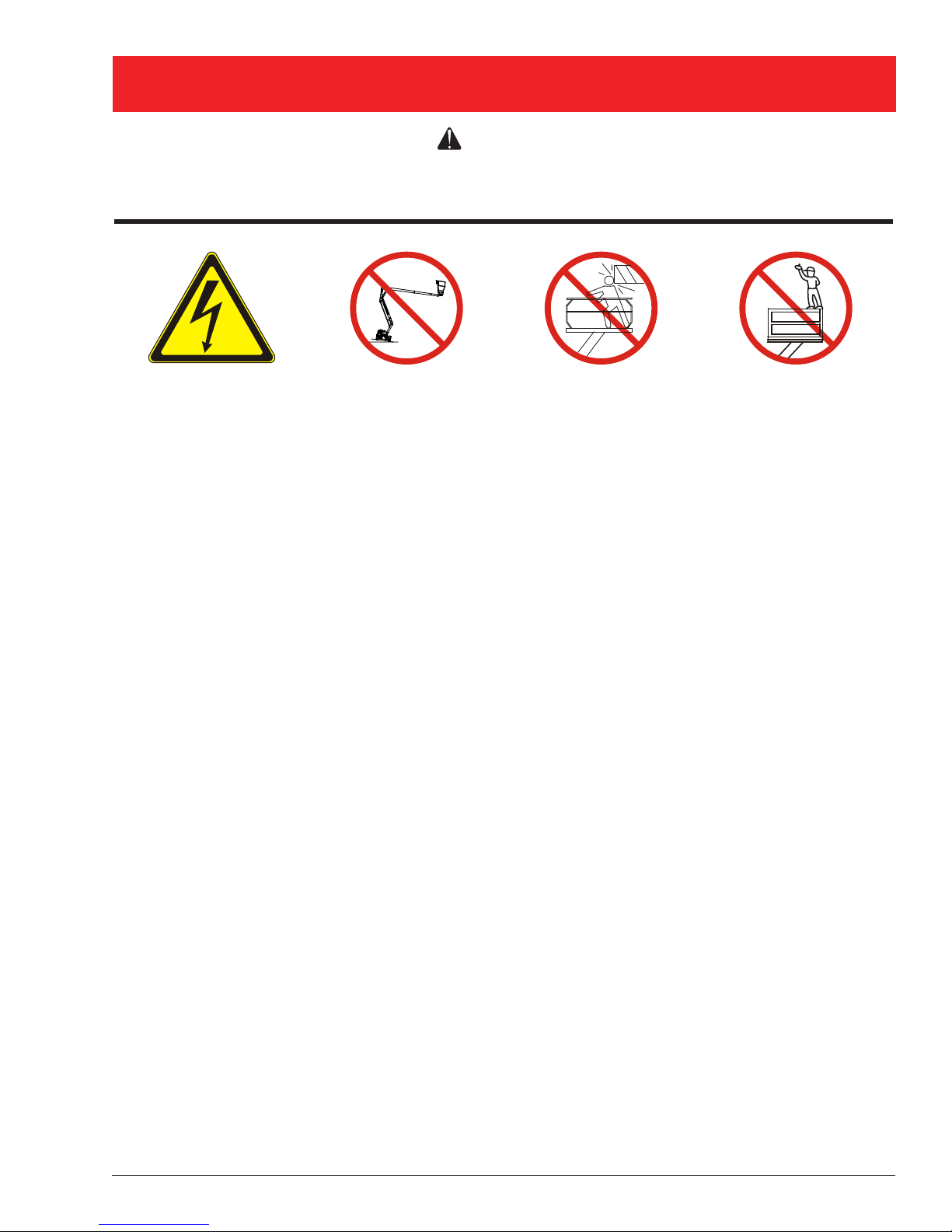

Safety Rules ...............................................................3

Fall Restraint Lanyard Anchor Points .........................4

Introduction.................................................................5

Component Identication............................................5

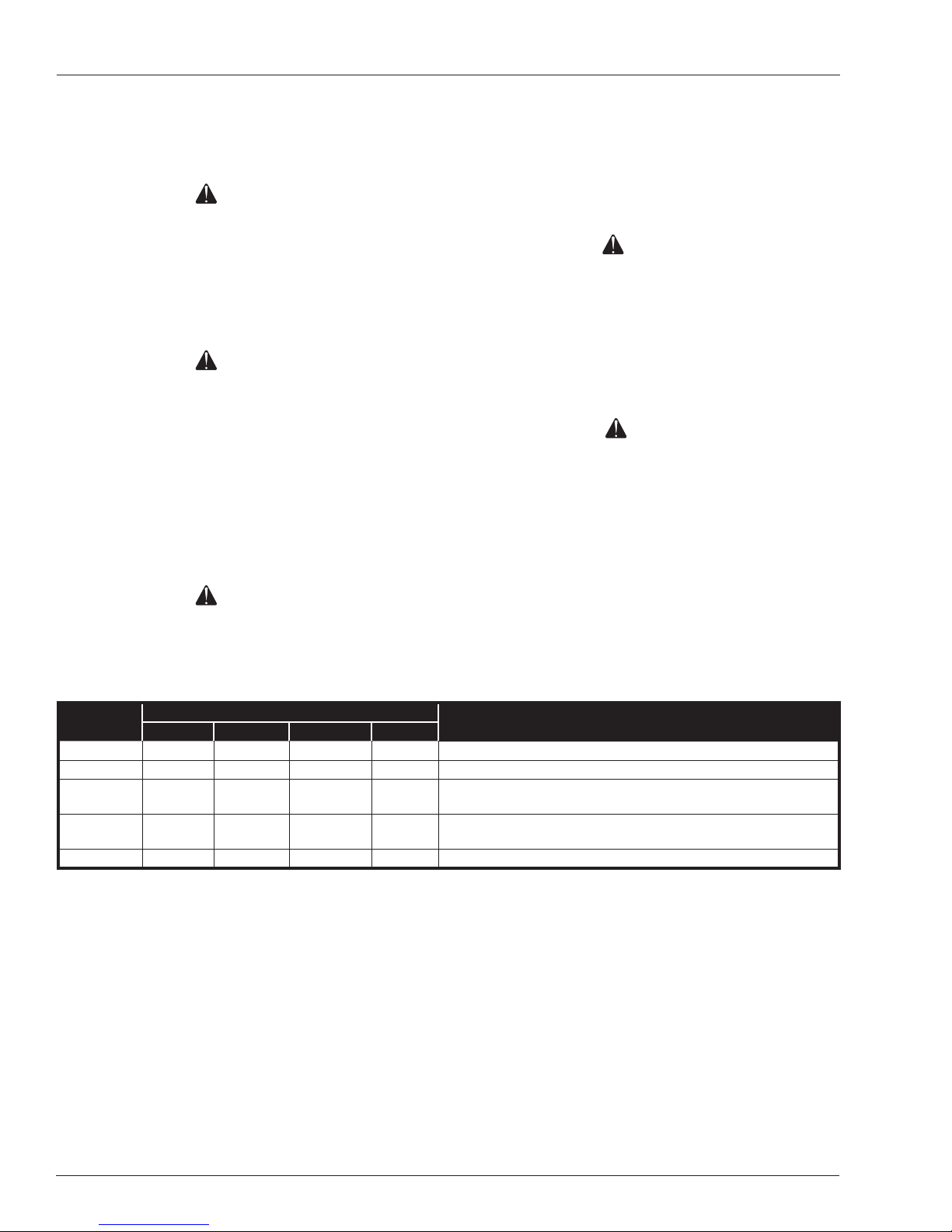

Special Limitations......................................................6

Platform Capacity....................................................6

Manual Force ..........................................................6

Platform Overload Sensing System ........................6

Beaufort Scale.........................................................6

Controls and Indicators...............................................7

Battery Disconnect Switch ......................................7

Lower Controls and Indicators ................................7

Upper Controls and Indicators ................................7

Battery Disconnect Switch..........................................8

Lower Controls ...........................................................8

Start Button .............................................................8

Emergency Stop Button ..........................................8

Controls Selector Switch .........................................8

Ground Operation Switch........................................8

Rotation Switch .......................................................8

Riser Switch ............................................................8

Boom Elevation Switch ...........................................8

Boom Extension Switch ..........................................8

Jib Articulation Switch .............................................8

Platform Level Switch..............................................8

Platform Rotation Switch.........................................8

Engine/Emergency Power Switch ...........................9

Diagnostic Center Display.......................................9

Platform Overload Warning Light ............................9

Tilt Warning Light.....................................................9

Hydraulic Oil Warm-Up Switch ................................9

Circuit Breaker Reset Buttons ....................................9

Upper Controls .........................................................10

Start Switch ...........................................................10

Emergency Stop Button ........................................10

Drive Joystick ........................................................10

Steer Switch ..........................................................10

Drive Range Switch...............................................10

Boom Speed Knob ................................................10

Rotation Switch .....................................................10

Riser Switch ..........................................................10

Boom Elevation Switch ......................................... 11

Boom Extension Switch ........................................ 11

Jib Articulation Switch ........................................... 11

Platform Level Switch............................................ 11

Platform Rotation Switch....................................... 11

Engine/Emergency Power Switch ......................... 11

Horn Switch........................................................... 11

Snorkel Guard Override Switch............................. 11

Platform Foot Switch ............................................. 11

AC Generator Switch ............................................ 11

Hydraulic Oil Warm-Up Switch .............................. 11

Pre-Operation Safety Inspection ..............................13

System Function Inspection .....................................14

Operation..................................................................15

Cold Weather Start-Up..........................................15

Hydraulic System Cold Weather Warm-Up ...........15

Hydraulic System Warm-Up Switch ......................15

Manually Warming The Hydraulic System ............15

Preparing for Operation.........................................16

Lower Controls ......................................................16

Upper Controls ......................................................16

Boom Operation ....................................................16

Driving and Steering..............................................16

Drive Speeds.........................................................17

Pivoting Front Axle ................................................18

Snorkel Guard Override Switch.............................18

Drive Motion Alarm................................................18

Electrical Power Outlet..........................................18

AC Generator ........................................................18

Air Line ..................................................................18

Emergency Lowering................................................19

Lower Controls ......................................................19

Upper Controls ......................................................19

After Use Each Day..................................................19

Transporting the Machine.........................................20

Preparing for Transportation .................................20

By Crane ...............................................................20

By Transport Vehicle .............................................20

Maintenance.............................................................21

Hydraulic Fluid ......................................................21

Check Hydraulic Fluid ...........................................21

Engine ...................................................................21

Oil Level ................................................................21

Battery Maintenance .............................................21

Inspection and Maintenance Schedule.....................22

Daily Preventative Maintenance Checklist ...............23

Preventative Maintenance Report.........................23

Specications ...........................................................24

Aerial Platform.......................................................24

Platform.................................................................24

Function Speed .....................................................24

Drive System.........................................................24

Tires ......................................................................24

Electrical System...................................................24

Hydraulic System ..................................................24

Engine ...................................................................24

Fuel Tank Capacity................................................24

Ambient Air Temperature Operating Range ..........24

Maximum Wind Speed ..........................................24

Sound Pressure Level...........................................24

Group Classification ..............................................24

Working Envelope .................................................25