Flight Systems 56-5047-00 User manual

56-5047-00

_________________

User’s Manual

Table of Contents

2 | Overview and Features

| Unpacking and Inspection

3 | Removal and Installation

4 | Voltage Adjust

| Factory Default

5 | Troubleshooting

6 | Fault Codes

9 | Warranty Information

Back | Repair and Technical Support

1

Overview and Features

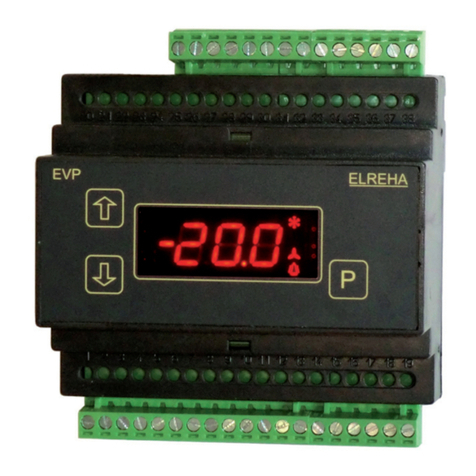

• Exact replacement for Onan© 300-5047 control modules

• Improved circuit design over OEM

• Over-sized heatsink for cooler operation

• Encapsulated in automotive grade urethane and fully

repairable

• Contains fault code system for easy troubleshooting

• Advanced detection system checks condition of brushes, slip

rings, and rotor while cranking. Generator will be prevented

from running if damage is likely.

• Communication port for connection to Flight Systems 327v2

modem. Allows for remote monitoring and remote start, (may

not be available upon initial release).

This controller, as with all Flight System built devices, comes

with a 2-year warranty and a 30-day return policy upon initial

purchase of the product.

Unpacking and Inspection

Be careful when unpacking your new controller so that nothing is

damaged. Do not expose your controller to static shock prior to or

following installation.

2

Removal and Installation

The controller is accessible through the front cover panel. The

controller connector can be accessed by removing the start/stop

switch cover. It is highly recommended to disconnect battery

power at the battery/disconnect switch before removing the

battery cable nut!

• Remove one nut to disconnect

battery cable.

• Remove one 10mm bolt holding

the start/stop switch cover. Place

cover aside without disconnecting

wires.

• Unclip controller wiring harness

using a small at screwdriver, if

needed.

• Remove two 10mm bolts holding

bottom front of controller housing.

The housing will not be removable

until the next step.

• Using an 8-inch socket extension, remove one 10mm bolt

behind controller housing. You will not be able to see this bolt

from the front.

• Remove controller housing through front of generator.

• Remove two 10mm screws holding the controller to the

housing.

• Installation is reverse of removal. Make sure wire connector

latches properly into control board mating connector. Do not

over-tighten the battery cable connection!

AFTER THREADING INTO A PLASTIC MOUNT ON THE

CONTROLLER, IT IS CONSIDERED INSTALLED, VOIDING THE

30-DAY RETURN POLICY!

3

Voltage Adjust (within 20 seconds after startup)

Due to variations in part tolerances and voltage sensing

transformer ratios, a voltage adjustment mode is provided. Under

most circumstances, the output voltage should be adjusted to

120v, no load, measured from a circuit breaker (hot) to chassis

ground.

• Press start 6 times; the status light will begin blinking to signal

that the controller is now in voltage adjust mode.

• Short press the start button to increase voltage by half a volt.

• Long press (more than 2 seconds) the start button to decrease

voltage by half a volt.

Wait for the status light to stop ashing. If the generator shuts

down before status light stops ashing, the voltage setting will not

be saved.

If the generator needs to be shut down during this operation, hold

stop for two seconds.

Factory Default

To restore all calibrations to factory default:

• Press the stop button ten times while generator is not running

and not in a fault condition. The status indicator will come on

solid.

• Hold stop button until status indicator turns off.

4

Troubleshooting

Blinking while Cranking

Causes: normal operation, no issue.

Solid Light while Cranking

Causes: open eld or high resistance, check slip rings and brushes

for continuity.

NOTE: Cranking will continue, attempting to clean the slip rings by

friction. Fuel is disabled until eld resistance returns to safe range.

No Response at Control Switch

Causes: faulty switch, poor connections, missing connections, or

dead battery

Starter Engages and Disengages

Causes: low cranking voltage

Starting Batteries Don’t Maintain a Charge

Causes: marginal battery, poor battery connections, or faulty

charging system

No AC Power While Generator is Running

Causes: a circuit breaker is off, tripped or malfunctioning, or poor

AC connections at controller harness or circuit breaker

Engine Surging Without Fault Shutdown

Causes: fuel leaks, restrictions or air bubbles, worn slip rings/

brushes, misadjusted or faulty governor, worn generator bearing

Testing the Generator’s Windings

This procedure requires an ohmmeter, set on the lowest resistance

scale (usually 200-ohm.) On the control board mating connector,

with the generator NOT RUNNING, measure these points:

• Pin 3 to Pin 13 – Quadrature winding = 2.0-4.0 ohms.

• Pin 1 to Pin 14 – Field winding (rotor) = 20-30 ohms.

• Pin 33 to Pin 34 - Main Stator winding = .30-.50 ohms.

5

NEW FEATURE

Fault Codes

At fault shutdown, the status indicator light will blink to indicate a

fault code. Blinking will continue for 5 minutes and then stop. To

restore blinking after timeout, press the control switch to STOP

briey, then press STOP 3 times.

No. 1 – Engine Over Temperature (Diesel Only)

While running, engine coolant temperature was above 239°F/115°C

for 10 seconds.

No. 2 – Low Oil Fault

(All Except HGJBB) While running, oil pressure dropped below 14

psi for 3 seconds.

(HGJBB) Oil level switch grounded for 30 seconds; low oil level.

No. 3 – Service Fault

A two-digit second-level fault occurred.

• Press STOP briey to activate the two-digit code indication.

The two-digit code consists of 1-5 blinks, a brief pause, and

then 1-9 blinks. The rst set of blinks represents the tens digit

and the second set of blinks represents the units digit. For

example, shutdown code No. 32 would be: blink-blink-blink-

pause-blink-blink-long pause-repeat

No. 4 – Over Crank

Cranking time exceeded 35 seconds.

Two-digit Service Faults

No. 12 – Over Voltage

After voltage regulation was enabled, output voltage was higher

than 150VAC for 75 milliseconds or higher than 138VAC for 3

seconds.

No. 13 – Under Voltage

After voltage regulation was enabled, output voltage was lower

than 108VAC for 5 seconds.

No. 14 – Over Frequency

Frequency was higher than 70Hz for 40 milliseconds or higher

than 66Hz for 6 seconds.

No. 15 – Under Frequency

Frequency was less than 54Hz for more than 8 seconds.

No. 17 – Fuel Pump Fault

Fuel pump circuit open. 6

No. 19 – Actuator Shorted or Open (EFI/Diesel Only)

Before cranking, the controller sensed an open or shorted

governor actuator or wiring.

No. 22 – Actuator Overload (EFI/Diesel Only)

Due to overloaded AC output or poor engine performance, the

controller kept the governor actuator at full-duty cycle for 60

consecutive seconds.

No. 24 – Faulty Engine Temperature Sender (Diesel Only)

After 10 minutes of running, the controller sensed an open

temperature sender or wiring.

No. 27 – VAC Sense Lost

While running, the controller lost stator AC sensing voltage even

though the eld was functioning normally.

No. 29 – High Battery Voltage

Before cranking, the controller sensed that incoming battery

voltage was greater than 19.2 volts for 5 milliseconds, or greater

than 19.2 volts for 1 second, while running.

No. 31 – Overspeed Fault (Carb/EFI Only)

Engine RPM greater than safe operating speed.

No. 32 – Starting Fault

The controller could not suitable detect cranking speed for 12

seconds. Possible open quadrature winding or broken brushes/

dirty slip rings.

No. 33 – Not a valid code

The controller is blinking 3 to indicate a service fault. Follow

instructions for No. 3 - Service Fault.

No. 35 – EEPROM Memory Checksum Fault

During power on, the controller detected corrupted EEPROM

memory.

No. 36 – Mechanical Fault

While running, engine speed fell to less than 500 RPM for .5

seconds, uncommanded by controller. This code can come up

when genset runs out of fuel.

No. 37 – Invalid Set Conguration (Carb/EFI Only)

Ratio of AC Frequency to ignition speed is not correct. Slipping

belt or broken engine coupling are the most frequent causes.

7

No. 38 – Field Overload

While running, eld voltage higher than 150VAC for 10 seconds.

No. 41 – Generator Rotor Short

During cranking, the controller sensed that the eld circuit/rotor

was shorted to ground.

No. 42 – ROM Fault

During power on, the controller detected a ROM error.

No. 43 – RAM Fault

During power on, the controller detected a RAM error.

No. 45 – Speed Sense Lost

The controller lost speed sense for .25 seconds.

No. 47 – Ignition Fault (Carb/EFI Only)

Ignition pulses from a magneto not detected for 1 second.

No. 48 – Loss of Field Sense

While running, the eld sense circuit on the controller failed, or

eld voltage dropped to zero.

No. 51 – Processor Fault

CRC verication failed on power up.

No. 52 – Fuel Injector Fault (EFI Only)

Open or shorted fuel injector.

No. 53 – MAT Sensor Fault (EFI Only)

MAT resistance greater than 300K ohms.

No. 56 – MAP Sensor Fault (EFI Only)

MAP sensor less than 50kPa while cranking.

No. 57 – Over Prime

The local or remote switch was held in the prime/stop position for

more than 3 minutes.

No. 58 – Exhaust Gas Temperature Fault (EFI Only)

EGT greater than 1200F for 2 seconds.

No. 81 – Exhaust Gas Temperature Sensor Open (EFI Only)

EGT below 140F for 2 minutes (or after 2 minutes from starting).

No. 82 – Exhaust Gas Temperature Sensor Shorted (EFI Only)

EGT is detected at 1832F for 1 second. Unit will not crank.

8

Warranty Information

This Flight Systems manufactured replacement controller is

warranted to be free from defects in materials and workmanship

for a period of two years from the date it was sold.

Flight Systems Limited Warranty covers the repair or replacement

of defective products within the warranty period. It does not cover

the cost of installation, removal costs incurred, or possible damage

to other equipment (including the generator or parts thereof) as a

result of this product.

Flight Systems (or its authorized agent) shall reserve the right to

determine the cause of malfunction. If we determine that it was

due to abuse, misuse, improper installation, acts of nature (such

as storm), failure to perform recommended genset maintenance

procedures, or problems elsewhere in the genset, the warranty

claim shall be dissolved and established standard repair rates

apply.

Flight Systems 30-Day Return Policy is only valid for 30 days after

initial purchase of any Flight Systems product. Installation of any

products will result in termination of the 30-Day Return Policy

on that product. Refund/Credit issued shall be less a 25% per

item restocking and testing fee as long as the product is in new

undamaged condition. Shipping charges are non-refundable.

9

Repair and Technical Support

If this product suffers a failure when out of warranty it can be

rebuilt. Applicable Flight Systems repairs are issued a one-year

warranty.

Please ll out and print our Repair Shipping Form located at

www.ightsystems.com and include it with any repairs. Repairs

can be shipped to:

Flight Systems

207 Hempt Road

Mechanicsburg, PA 17050

Any repairs not sent with proper contact information will be held

for no more than 6 months from the date received before being

recycled by Flight Systems.

Technical support is also available by phone or email for all Flight

Systems products:

Phone: 717-590-7330

Email: techs@ightsystems.com

Open Monday-Friday, 8am-5pm Eastern

Table of contents

Other Flight Systems Controllers manuals