flip IT FIL-18 User manual

flipIT Tech Line: 800 770-7042 1

© 2008 CBT Supply Inc.

Installation Manual for

flipIT-Kit Laptop Safe

FIL-18 FIL-23

How to install into any desktop using tem-

plates for cutting table top.

How to install into factory-cut table top.

Start at Step 5.

Installation is illustrated using the FIL-18.

The Widescreen version, FIL-23, installs

exactly the same way. The only difference

is that the width is greater.

Patent Pending

2© 2008 CBT Supply Inc.

WARNING

POWER TOOLS ARE DANGEROUS.

Review the safety procedures supplied by your power tools’ manufacturers. Heed all

warnings for your safety’s sake. Always use safety glasses and wear proper

apparel that won’t get caught in moving parts. CBT Supply, Inc. will not be held liable

for misuse of tools and disregard for power tool manufacturer’s safety precautions.

Getting Started These installation instructions guide you through the proper way of completing the

assembly of the flipIT®Laptop Safe Kit FIL-18 and FIL-23 with key lock. Improper

installation may void the warranty. It is especially important that the installer observe

proper care in protecting surfaces from abrasion.

For any questions or assistance, please contact Technical Service at

800-770-7042.

Tools Needed for

Full Installation

Tools needed for

pre-assembly:

• Power Drill

• Tape Measure

• Commercial-grade Jigsaw

• Phillips bit driver

• 3/8” Drill Bit

• 1/8” Drill Bit

• Pencil

• Permanent Marker

• Masking Tape

• Glue stick

Tools needed for installation

into factory cut desktop only:

• Screw gun or #2 Phillips

screw driver

• 1/8” Drill Bit

• Masking Tape

• Slot Screwdriver

• Crescent Wrench

STOP!

The installer must possess the skill to cut within the tolerance of the

template layout line if no factory-made cutout is made in the table top.

Do not attempt this installation without this level of craftsmanship skill.

If a factory made cut is provided, only skills of using a

screwdriver and drill are required.

flipIT Tech Line: 800 770-7042 3

© 2008 CBT Supply Inc.

You will be installing a lock on

one side, so allow 2.5” in addition

on each side of the cut-out—for

plates. Add an additional inch (3.5”)

for the lock side from a solid wall.

The placement of this leg bracket

is fine. If it were a wall, it would

be too close. Clearance is need-

ed for the”bone” in the unlocked

position.

IMPORTANT:

Planning Ahead

If you are installing flipIT into an assembled desk, see if it is possible to remove

the desktop to make the cut-out. If that is not possible, take care to make a work

environment that will protect the surface finish of your furniture and will be safe for

operating power tools.

The recommended placement of the cutout for the flipIT unit is 6 inches from the

user’s edge. This assumes a straight edge; not a round or contoured edge.

If you are experimenting with placement for an unusual application, we

recommend requesting additional templates and making dry-fit installa-

tions into scrap.

Based on this profile, a minimum of 24 inches of clearance, front to back, must

be allowed for the mechanism.

Counter Top Depth

6

Workstation Spacing

60

15.125

19

30

24

6

For FIL-18, use 30 inch

spacing from centerline to

centerline, or from common

reference point as shown on

the drawing (from right edge

of cut-out to right edge of

cut-out).

For FIL-23, use 33 inch

spacing, maintaining no less

than 8 inches between

cutouts.

For best long-term results,

consider placing a leg sup-

port or vertical panel

between cutouts to support

the top.

70

15.125

25

33

24

6

4© 2008 CBT Supply Inc.

Parts and Hardware Prepare a place to unpack box contents, using a packing blanket, carpeting or

cardboard sheet to protect finished surfaces from damage. Before assembly,

take inventory of the parts included.

Parts List:

1 (one) Laptop Safe, pre-assembled, shown in 2 views. The pneumatic cylinder ships installed on one end. To avoid

damage, keep the Laptop Safe in this position—top down—until installed in desktop cutout.

Phillips head wood screws, 3/4”, 4 are

used for installing the collar. Phillips head wood screws, 4 are

used for installing the lock bar assem-

bly BEFORE installing one way

screws.

One Way screws, 3/4”, 4 are used for

permanently installing the locking bar

assembly as a final step.

1 (one) locking bar assembly with cowl

and set of 2 keys. Fixed length.

Requires cutout placement 8” from

front edge.

Adjustable length lock available for

shorter distance between front ege

and cutout.

1 (one) paper template for top cut-out,

shown positioned for use.

flipIT Tech Line: 800 770-7042 5

© 2008 CBT Supply Inc.

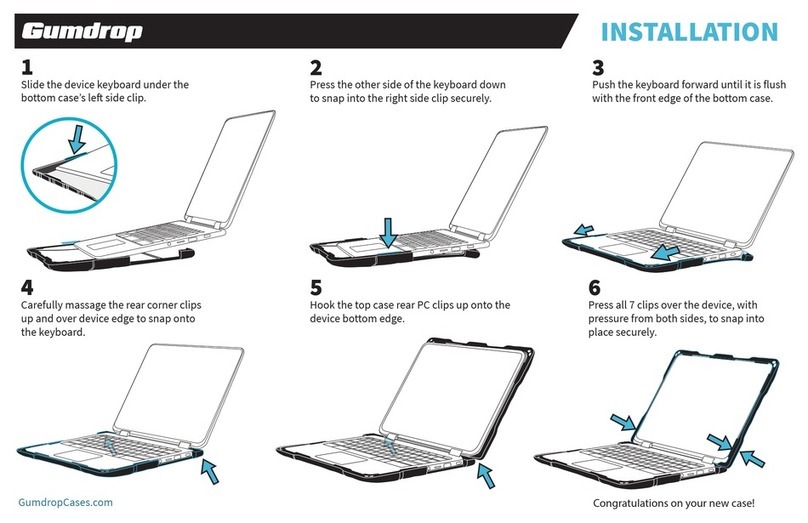

Step 1-

Establish Centerline

Step 2-

Adhere Cutout

Template to Desktop

To establish cutout placement, sit at the desk and look straight ahead, visualizing

where the screen would be. Use a tape measure and determine the centerline for the

cutout. Transfer the center line to the desktop with masking tape or some other

means that will not permanently mar or stain the finish.

The minimum clearance

area requirement

underneath for FIL-18 is

24” x 24” See page 3

Counter Top Depth.

12” is the center for a 24” width.

15” is the center for a 30” width.

Use a glue stick

on back of

template cut lines.

Align front edge of

template with

desktop centerline and

press in place.

6© 2008 CBT Supply Inc.

STEP 3 -

Drill Corner

Starting Holes

To make holes for starting your jig saw cut, use a 3/8” drill bit, place the point of the bit at the

corner mark and drill completely through the surface top. Repeat this step for each corner.

STEP 4 -

Saw the Hole for

flipIT

Place the jigsaw at the corner marking. Remove the layout line with the kerf of the saw cut for

a factory fit. You must have the skill to saw a straight line within the tolerance of the width of

the saw blade. Saw from corner hole to corner hole. Remove the remains of the paper tem-

plate when this step is finished.

flipIT Tech Line: 800 770-7042 7

© 2008 CBT Supply Inc.

Place the FIL in the cutout with shield facing the

user’s side. This is a tight fit. Watch your fingers! The gas spring is not connected, so you need to provide the open-

ing power. Relese the touch latch and pres on the back of the lid.

PULL the tray out, and gently assist by pulling the top lid. When

the gas spring is later installed, the assist is not required. The gas spring is not installed so you may freely move

the lid for clearance for installing collar screws.

Install the collar with 4 Phillips head wood screws in the holes provided at

these locations.

STEP 5 -

Install the Laptop Safe into Cut-Out in Table Top

Phillips head wood screws,

3/4”, 4 are used for

installing the collar.

12

34

8© 2008 CBT Supply Inc.

STEP 6 -

Connect the pneumatic cylinder. First, open the laptop safe…

Using a slot screwdriver blade, pry the locking cap off

completely and set it aside.

Place the end of the pneumatic on the mounting post

located on the collar frame. Press it until it snaps on. Put the locking cap back in place and press it in all the way.

The pneumatic is shipped attached to the lid. It should be

hanging freely. Bring it up to the top so you can work on it.

Open the lid completely using the same method as in step 5.

Here’s the end you will be installing.

flipIT Tech Line: 800 770-7042 9

© 2008 CBT Supply Inc.

STEP 7 -

Install the locking bar, preliminary. Install for left-handed (shown) or

right-handed operation

The default position for the

locking system is on the user’s

left; however, the shape of the

locking bar permits installation

on either side.

Plan ahead to avoid

interference with other

mounting hardware.

Your template allows

2.5” of clear area on

each side of the

cut-out.

Locate the slot in

the hinge for the lid

of the laptop safe.

The locking “bone”

should fall into place

easily. You will be

test fitting this

arrangement for

easy operation.

Mark the locations for drilling pilot holes.

Then use an 1/8” drill with depth gauge

and make precise pilot holes.

Approximately

1/2” of the

“bone” should

extend through

the locking slot.

10 © 2008 CBT Supply Inc.

Install using 2 Phillips head 5/8” wood screws.

DO NOT install with One Way screws at this time. If you find that

you need to relocate this bracket, One Way screws will do their

job too well. Install only this bracket at the “bone” end of the bar.

You will fine tune the location of the lock end of the system next.

Find the ideal location for the

lock end of the system by using

the key and rotating the lock

open and closed.

Nudge the location of the

bracket around until you find the

spot where the lock operates

smoothly.

Hold the bracket in position and mark the location for drilling

pilot holes. Drill precise pilot holes using 1/8” drill and depth

gauge. Install using 2 Phillips 5/8” wood screws.

flipIT Tech Line: 800 770-7042 11

© 2008 CBT Supply Inc.

Four One Way screws replace

the 5/8” wood screws you used

for the preliminary installation.

This exercise is to ensure correct

function before taking this final,

permanent step. One Way

screws act as a theft deterrent

because they are almost impossible to remove. Please do not skip the

preliminary step of installing with “regular” screws first.

STEP 9 -

Install the locking bar permanently.

STEP 8 -

Install the cowl over the lock assembly

One at a time, remove the Phillips head screw and replace with a One Way

screw using a manual, slot blade screwdriver. Performing this operation one

at a time keeps the integrity of the installation intact. Repeat this process

for each screw individually.

DO NOT remove all the screws and install all of the One Ways as a

group. You run the risk of losing a tolerance and that would risk destroying

the desktop in an attempt to remove the hardened metal One Ways.

After testing the position of the

lock assembly without the cowl, to

ensure proper alignment and func-

tion of the lock, install the cowl

into the same screw locations.

Test the function again before

installing one-way screws.

The Lock Cowl

12 © 2008 CBT Supply Inc.

Patent Pending

CBT Supply, Inc.’s patent pending flipIT®Laptop Safe has been

designed and tested to perform as an ergonomically correct,

space saving unit.

For more information on this and other flipIT®products,

call 1-800-770-7042

This manual suits for next models

1

Table of contents