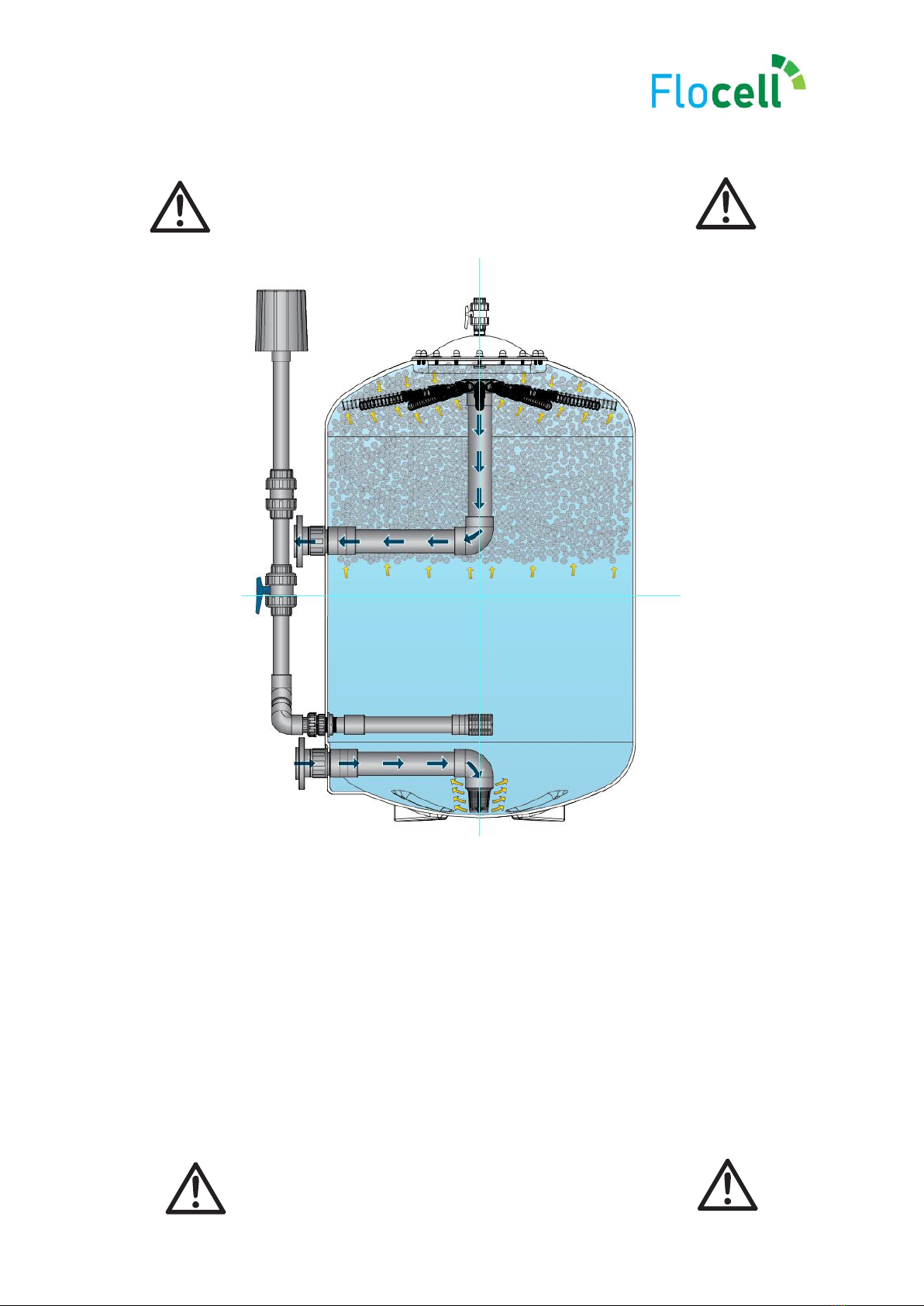

The installed air blower must be sited above the filter body or a

non-return valve installed before the air-supply to limit the

potential for accidental water ingress to the blower

Operation

•Before working on the filter or valves, make sure the pump is switched off

and the filter is de-pressurised. For greater safety, disconnect the pump and

possible electric installations connected to the mains.

•Never connect the filter directly to the water supply, since it’s pressure can

be higher than the maximum pressure of the filter (2bar / 30psi).

•As the parts connect using O-rings, it is not necessary to overtighten any

nuts / bolts.

•Do not clean plastic parts with solvents.

•Do not let children handle the filter or play near them.

•Protect the filter from freezing.

•Before connecting the pump, make sure that the filter lid is closed.

•Install the filter in an area with ventilation and adequate drainage as close

as possible to the water body, below the water level to help prevent an air

lock or vacuum from occurring.

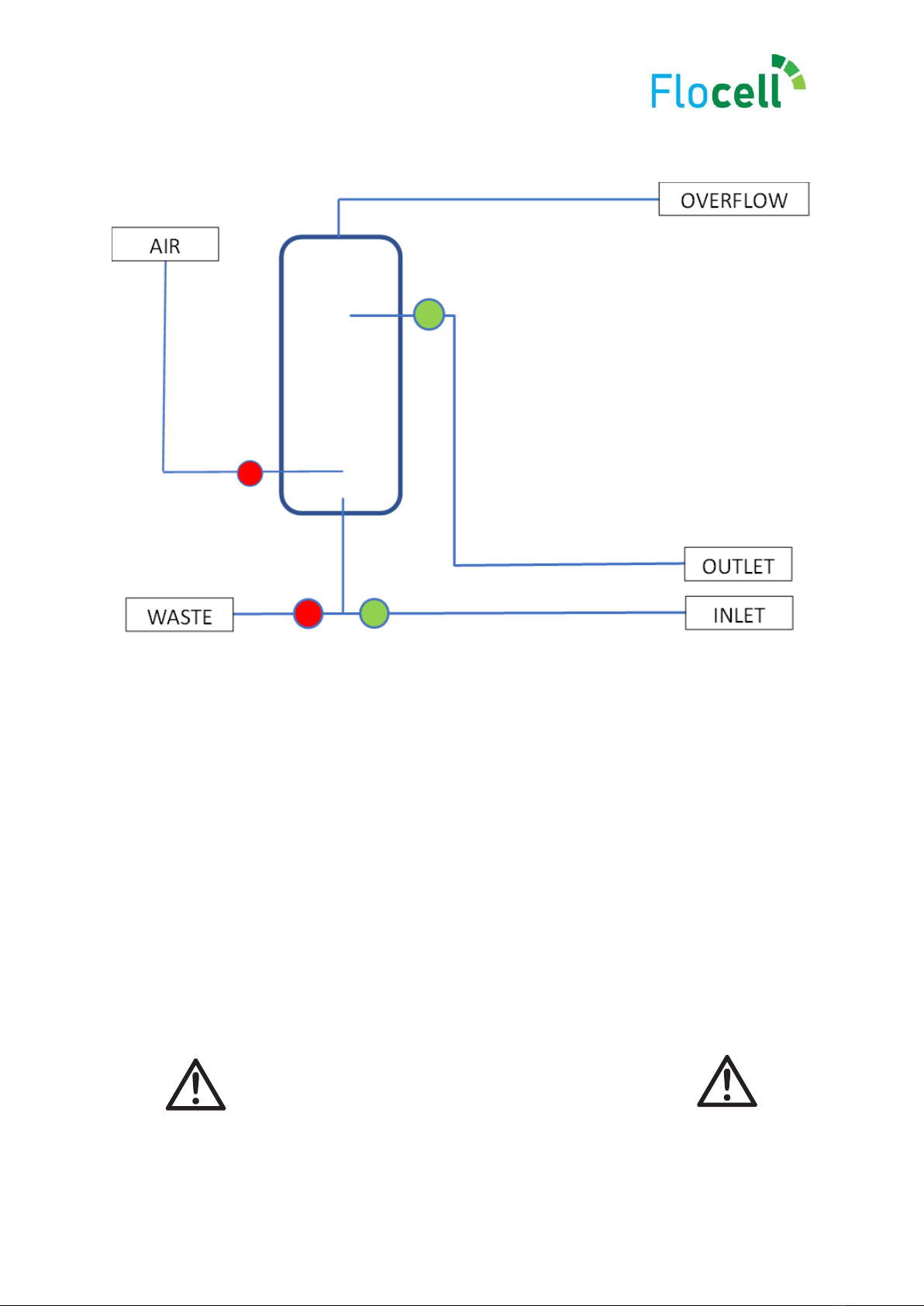

IMPORTANT –USE OF VALVES ON OVERFLOW LINE

In certain situations it may be beneficial to install a valve on the overflow line.

These situations may include (but are not limited to):

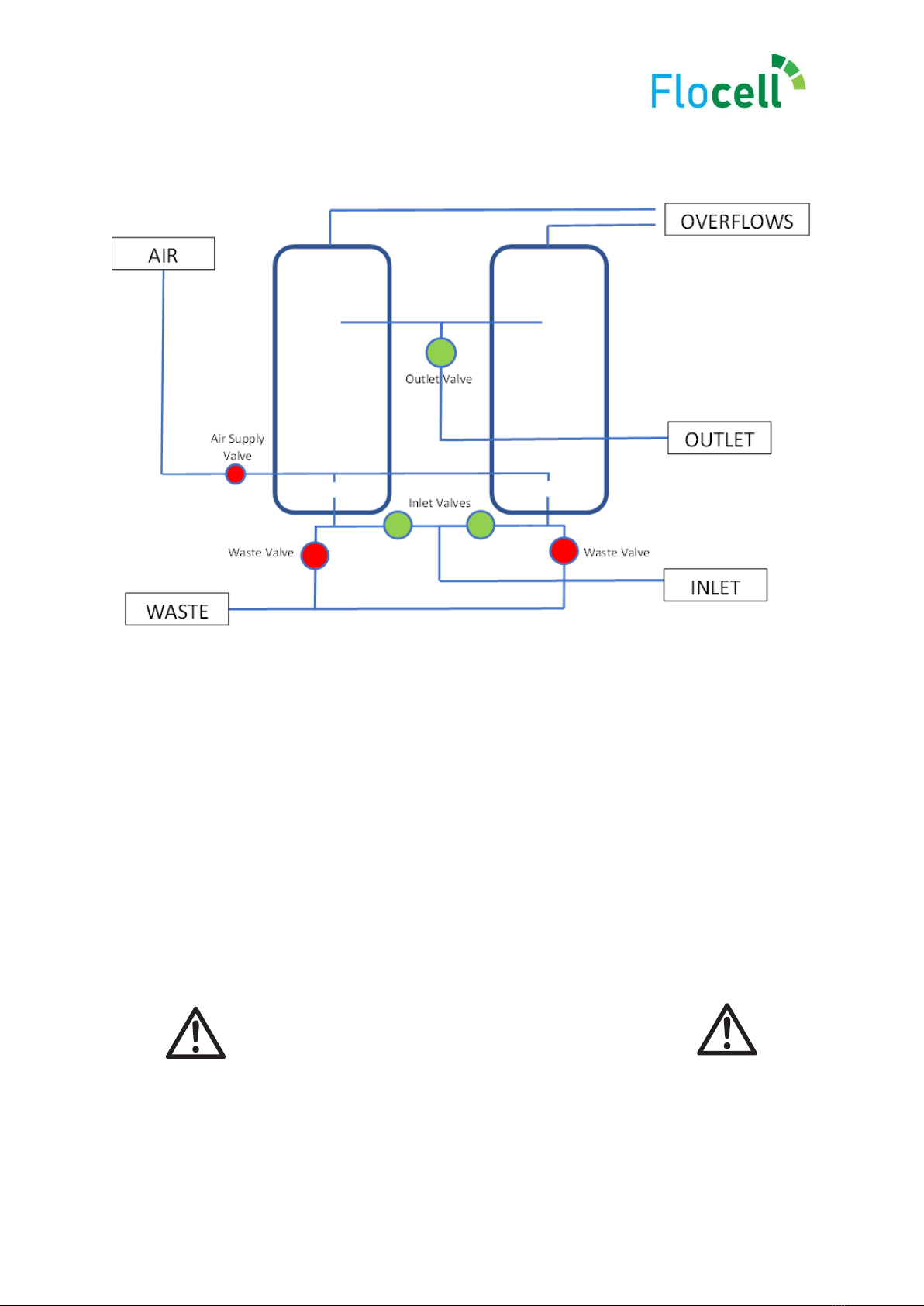

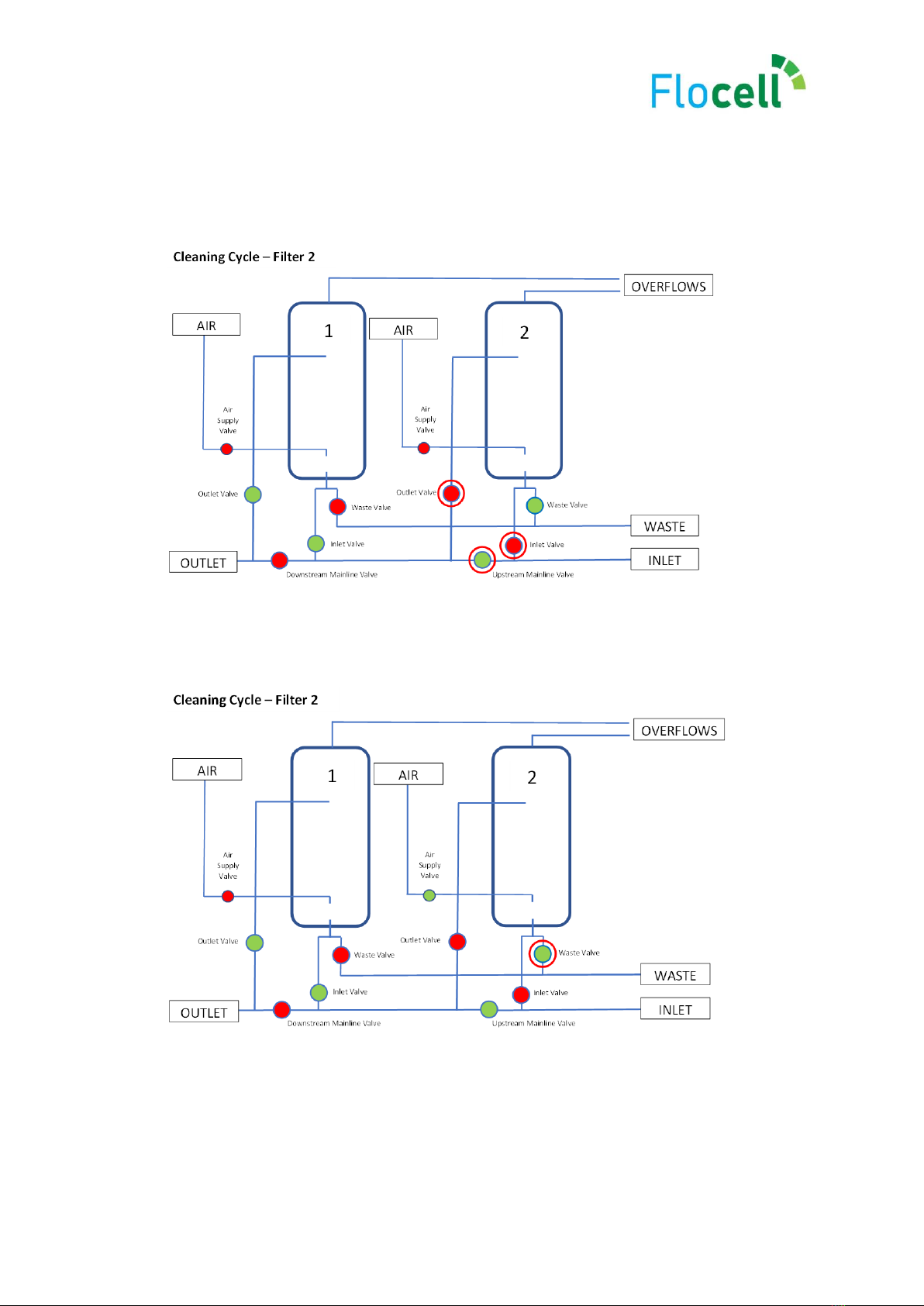

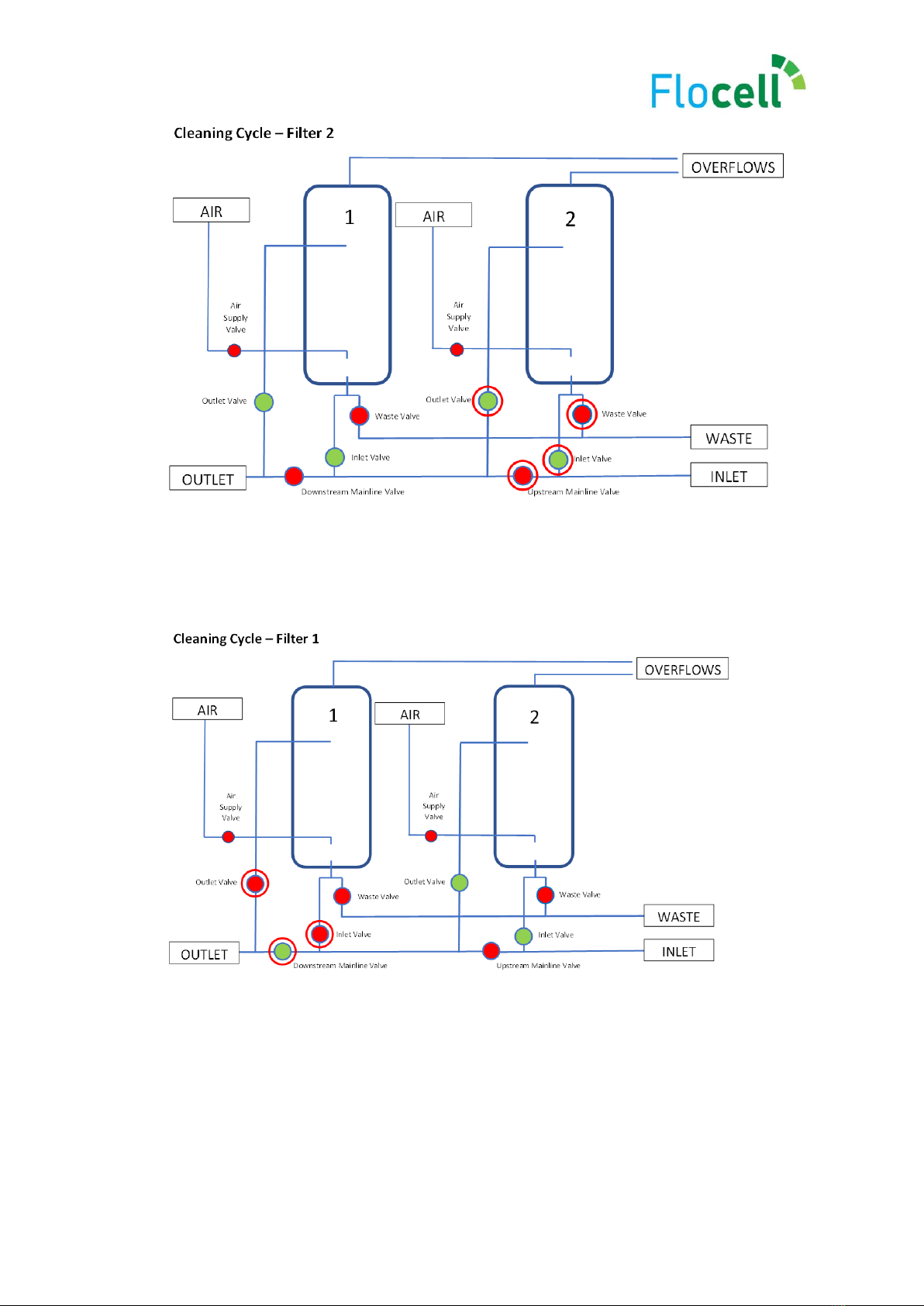

•Larger installations where multiple filters are installed in series or parallel

which may require independent cleaning but that have a linked overflow

line.

•Situations where an open return is a significant distance from drain, where

water recovery is vital but that cannot accommodate a suitable pipe-run.

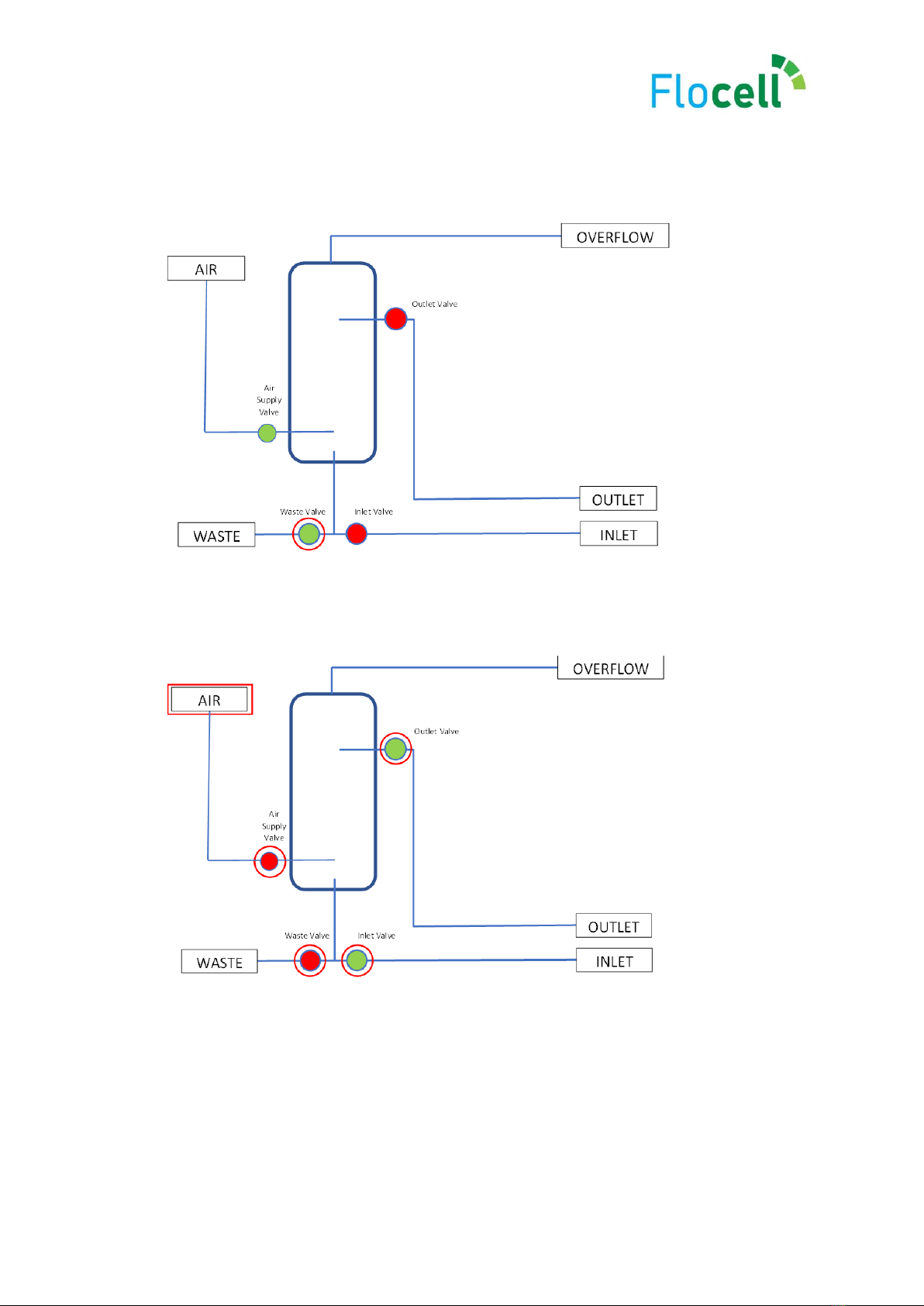

Care MUST be taken to ensure that when cleaning, the overflow line is OPEN. This

will allow for the media to be circulated by incoming air. If the overflow line is not

open, the incoming air will cease and the filter pack will not be able to be cleaned.