We Do Your Level Best

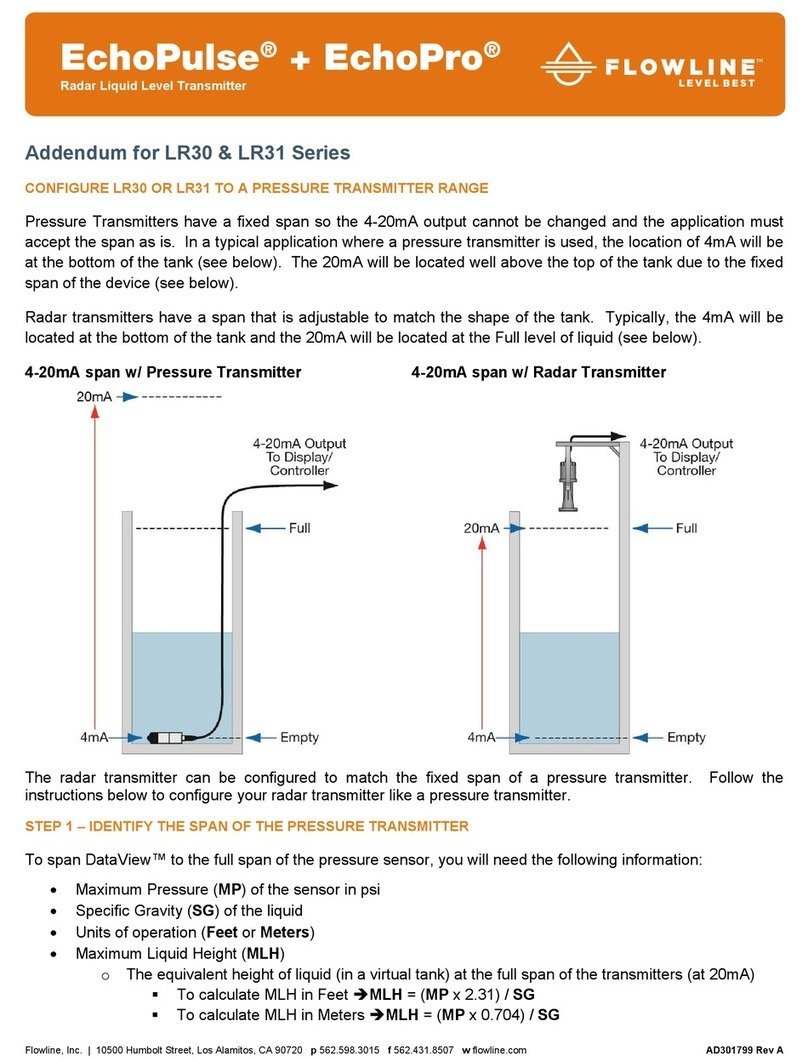

The LD30 Series Pressure Transmitters convert a single positive pressure into a

standard 4-20 mA output signal. The LD30 Series can be used to accurately measure

compatible gases and liquids; full scale accuracy is 0.25%. Designed for industrial

environments with a NEMA 4X (IP66) housing, this transmitter resists most effects of

shock and vibration. This Quick Start includes everything you’ll need to get the

DeltaSpan up and running. For complete information, please refer to DeltaSpan

documentation located at www.flowline.com.

Compensated

Temperature Range

Installation

First, select a location. The DeltaSpan should be located within a temperature

range of 0 and 175°F (-18 to 79°C). Distance from the receiver is limited only by total

loop resistance. While the tubing or piping supplying pressure to the unit can be

practically any length, remember that long lengths will increase response time slightly.

Next, position the DeltaSpan. Although the transmitter is not position sensitive,

standard models are factory calibrated in a position with the pressure connection

downward. The DeltaSpan functions at greatest accuracy in this position.

Create a pressure connection. Use a small amount of plumber’s tape or other

suitable sealants to prevent leaks. Be sure the pressure passage inside the port is not

blocked.

Finally, check your Electrical Connections. The maximum length of wire connecting

the transmitter and receiver is a function of wire size and receiver resistance. Wiring

should not contribute more than 10% of the receiver resistance to total loop resistance.

For runs exceeding 1000 feet, choose receivers with higher resistance to minimize the

size and cost of connecting leads. Where wiring length is under 100 feet, wire as small

as 22 AWG can be used.

Electrical connections to the pressure transmitters are made to the terminal block

located inside the housing. Remove the screws and lift off the cover. Wire as shown in

the diagram below. When using cable version of General Purpose Housing with Cable,

black wire is negative (-) and red wire is positive (+).

Current (4-20 mA) Output Operation

An external power supply delivering 13-30 VDC with minimum current capability of 40

mA DC (per transmitter) is required to power the control loop. The Current Output

diagram (above) shows the connection of the power supply, transmitter and receiver.

The range of appropriate receiver load resistance (RL) for the DC power supply

voltage available is expressed by the formula: RLMax = Vps-13

20 mA DC

Shielded cable should always be used for control loop wiring.

Maximum Loop Resistance is 1300ohms @ 30VDC.

Maintenance

After final installation of the pressure transmitter and its companion receiver, no

routine maintenance is required. A periodic check of system calibration is suggested.

The LD30 transmitters are not field repairable and should be returned if repair is

needed.

Troubleshooting

If you face any issues not addressed in this Quick Start, please refer to the DeltaSpan

Manual located on Flowline website at www.flowline.com.

Where personal safety or significant property damage can occur due to a spill,

the installation must have a redundant backup safety system installed.

Welcome to the DeltaSpan Quick Start

The DeltaSpan Quick Start is meant to show some of the more common setup solutions

to getting the DeltaSpan up and running quickly. If you run into an issue that is not

addressed here or wish to install or set up with a non-standard configuration, please

address the DeltaSpan Manual or refer to the Flowline website at www.flowline.com.

CAUTION

Do not exceed specified supply voltage ratings. Permanent damage

not covered by warranty will result. This device is not designed for

120 or 240 volt AC operation. Use only on 13 to 30 VDC.