4 of 13 DeltaSpan (IS) LD31 / LD32 Series 31 MAR 11

MN301031 Rev C

Introduction

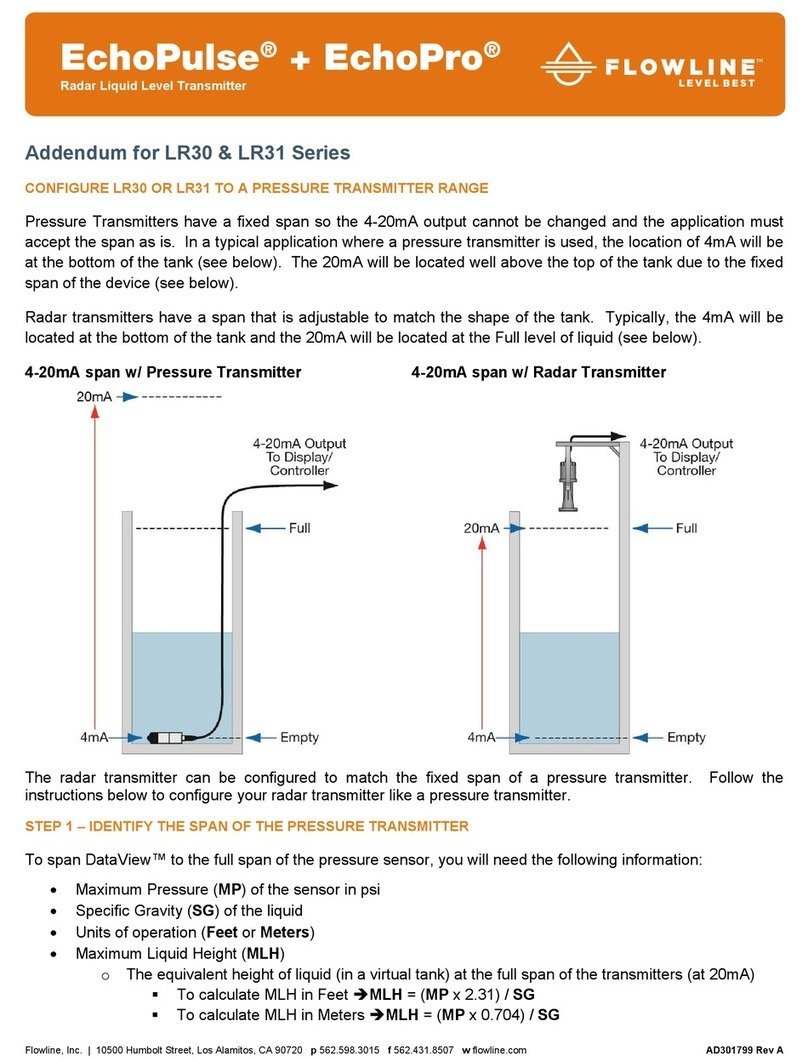

The LD31 / LD32 series Intrinsically Safe DeltaSpan Submersible / Waste Water Level Transmitters are

manufactured for years of trouble free service in the harshest applications. The pressure transmitter measures

the height of liquid above the position in the tank referenced to atmospheric pressure. The transmitter consists

of a piezoresistive sensing element, encased in 316 SS housing. The LD31 series features a bullet nose design

protects the diaphragm from damage.

Superior lightning and surge protection utilizing dual arrestor technology, grounded to case, eliminating both

power supply surges and lightning ground strike transients. Large diameter 316 SS diaphragm seal is non-

clogging and damage resistant to floating solids.

The transmitter is equipped with a 270-pound tensile strength shielded and vented cable. Ventilation tube in the

cable automatically compensates for changes in atmospheric pressure above the tank. The vent is protected

with a maintenance free filter eliminating particulate or water droplets from entering the transducer.

Excellent chemical compatibility with 316 construction

Lightning and surge protection on all models

Maintenance free vent filter

LD31 series features slim design for tight applications

LD32 series features large diameter, non-clogging, damage resistant, 316 SS diaphragm seal

Table of Contents

Introduction ..........................................................................................................................4

About this Manual................................................................................................................5

Components .........................................................................................................................6

Technology ..........................................................................................................................6

Specifications .......................................................................................................................7

Dimensions ..........................................................................................................................8

Material Compatibility .........................................................................................................8

Getting Started .....................................................................................................................8

How to convert Pressure into Liquid Height?..........................................................9

How does Specific Gravity affect pressure transmitters? ........................................9

How to select the correct pressure transmitter? .....................................................10

Electrical Installation .........................................................................................................10

Wiring – Control Drawing .....................................................................................11

Installation..........................................................................................................................12

Interference ............................................................................................................12

Termination ............................................................................................................12

Maintenance .......................................................................................................................12

Testing the transmitter ...........................................................................................13