FLOWROX PV 80 Manual

PVPVE-190911-EN

Installation, operation, and maintenance

instructions for Flowrox valves

Open Valve (PV) & Enclosed Valve (PVE)

NOTE

These instructions must be read carefully and understood

prior to the installation, use, and servicing of this

product.

FLOWROX OY

P.O. Box 338

FI-53101 Lappeenranta, Finland

Tel. +358 (0)201 113 311, fax +358 (0)201 113 300

Web: www.flowrox.com

TABLE OF CONTENTS

1GENERAL................................................................................. 1

1.1 General safety instructions for PV & PVE valves ................................................1

2INTRODUCTION TO DEVICE........................................................... 2

2.1 Intended use............................................................................................2

2.2 Construction of device................................................................................2

2.2.1 Open body valve PV.................................................................................3

2.2.2 Enclosed body valve PVE ...........................................................................3

2.3 Valve function..........................................................................................4

3TRANSPORTATION, STORAGE AND LIFTING....................................... 5

3.1 Receiving ................................................................................................5

3.2 Storing....................................................................................................5

3.3 Lifting ....................................................................................................5

4INSTALLATION .......................................................................... 6

4.1 Open body model (PV)................................................................................6

4.2 Enclosed body model (PVE)..........................................................................7

4.3 Both models (PV and PVE) ...........................................................................7

5OPERATION.............................................................................. 8

5.1 First use .................................................................................................8

5.2 During operation.......................................................................................8

6MAINTENANCE .......................................................................... 9

6.1 Schedule.................................................................................................9

6.2 Changing the valve sleeve ...........................................................................9

6.2.1 Changing the valve sleeve in open model valve (PV)..........................................9

6.2.2 Changing valve sleeve with enclosed model valve PVE...................................... 10

6.3 Adjusting the valve..................................................................................11

6.4 Troubleshooting......................................................................................13

7TECHNICAL DATA .....................................................................14

7.1 Model and spare part codes .......................................................................14

7.1.1 Valve model selection ............................................................................ 14

7.1.2 Sleeve model selection........................................................................... 15

7.1.3 Sleeve materials for Flowrox valves............................................................ 15

8APPENDIXES............................................................................18

8.1 APPENDIX A: PV- Open Body Assembled ........................................................18

8.2 APPENDIX B: PVE-Enclosed Body Assembled ...................................................19

1

1GENERAL

1.1 General safety instructions for PV & PVE valves

In this manual, the following symbols are used to highlight the parts requiring particular

attention:

SYMBOL DESCRIPTION

DANGER

Risk to personal safety:

Neglecting the safety measures can cause serious

personal injury or death.

Electrical safety:

Neglecting the safety measures can cause serious

personal injury or death.

WARNING

Machinery or environmental risk:

Incorrect maintenance or operation of the product

can harm the environment or the product.

NOTE

Read the operation and maintenance instructions:

Read and understand the operation and

maintenance instructions before using the product.

2

2INTRODUCTION TO DEVICE

2.1 Intended use

Open type PV.

The open body is available in diameters starting from 80mm.

The open body construction is designed for applications with:

•Low pressures

•Low temperatures

•Non-hazardous media

The open body construction is light and simple, which makes it easy to access for service.

The open body also tolerates misalignment and vibration.

Enclosed type PVE.

The valve sleeve is covered by the body housing and thus protected from the

environmental impacts and sunlight.

•Body construction prevents leakage of flowing media to the environment

•The valve body can be equipped with a gauge indicating pressure changes inside the

body

2.2 Construction of device

Flowrox valves are made of three main components:

•flanged valve sleeve

•valve body, either open PV or enclosed PVE

•actuator and actuator control components, if applicable

The valve sleeve is the only part of the valve which is in contact with the medium flowing

in the pipeline.

All valve bodies are flange ended. The standard flange drillings can be made to meet all

standards (e.g. DIN, ANSI, BS, AS, JIS).

The face to face dimensions of Flowrox valves are according to ANSI/ISA 75.10.02:

•165 mm for valves DN25…DN65

•2 ½ times the nominal diameter for valves DN80 and bigger

3

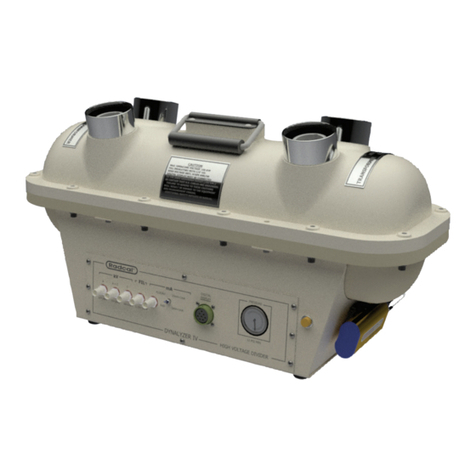

2.2.1 Open body valve PV

Fig. 1.

In the open body model the body and the actuator are connected

only to one of the end flanges (Fig. 1.). The construction allows a

slight deviation in the pipe angle and the valve can act as a

vibration absorber.

WARNING

Note that in case of a sleeve breakage, the flowing liquid

will leak to the environment.

2.2.2 Enclosed body valve PVE

Fig. 2. plug

The body of the enclosed model prevents leakage of flowing

media to the environment (Fig. 2.). The lower part of the body

has a plug, which can be opened to check for sleeve failure.

WARNING

In case of a sleeve failure, slight leakage will occur

through the bushings.

If you open the plug for checking, be careful as the

medium may flow out.

NOTE

Changing the sleeve at appropriate intervals prevents

leakages.

4

2.3 Valve function

DANGER

When the valve closes the actuator moves. Do not put

tools or parts of your body between the moving valve

parts. Note the injury risks (see drawings 3A and 3B).

Note the dangerous places (see drawings 3A and

3B)!

When the pinch valve closes, two pinch bars,

moved by the actuator, squeeze the sleeve,

closing on the center line. As the valve is fully

closed, the actuator has raised one half of the

valve diameter.

The actuator raises in both models (PV and PVE)

0.5 x valve nominal diameter (measure X).

In the open model the space between the pinch

bars, the space between the upper pinch bar and

fixing plate of the actuator and the space below

the lower pinch bar.

Fig. 3A -

PV open model

In the enclosed model the space between the

valve body and the fixing plate of the actuator

and the ends of the guide bars of lower pinch bar

below the valve body.

Fig. 3B -

PVE enclosed model

Regarding the actuators, follow the instructions of the manufacturer.

NOTE

Note the possible remote control of automatic valves and

turn it off before starting maintenance.

5

3TRANSPORTATION, STORAGE AND LIFTING

3.1 Receiving

Check the condition of the valve package on arrival. If it shows signs of transport

damage, check the operation of the valve carefully. Normally, a visual inspection of the

valve is sufficient. However, if valve has been damaged during transport, contact your

nearest Flowrox sales office immediately.

3.2 Storage

The sleeves must be stored as follows:

•The storing temperature should not exceed +25°C, preferably below +15°C but not

under +5 °C. Keep the storage temperature as constant as possible.

•Store the sleeves in a dry place. Prevent water from condensing on sleeve surfaces.

•Avoid ultraviolet light. Protect the sleeves against straight sunlight. Use warehouse

instead of storing outside.

•Remove all equipment generating ozone from the room where sleeves are stored.

Minimize the store room ventilation.

•Store sleeves so that they are free from tension. Sleeves should be stored in vertical

position on smooth support. Do not store sleeves one on top of another.

•Keep the sleeves off the chemical effect of solutions, semi-solids, impurities and

solvent vapours during storing.

•Try to keep the storing time of sleeves as short as possible. Always use first the

material which has been longest in stock.

3.3 Lifting

When lifting the valve, fasten the ropes to the valve body or around it. Note the center

of gravity and support the valve to avoid it turning around. In some models the center of

gravity is located towards the actuator.

6

4INSTALLATION

4.1 Open body model (PV)

Fig. 4.

The sleeve has not been designed to withstand axial forces.

The pipes must therefore be supported properly so that

neither tension nor compression is caused. Use cross-

tightening for flange bolts. Do not overtighten bolts.

Make sure that no inappropriate items get between the

pinch bars and the sleeve.

If possible, protect the sleeve from direct sunlight. Direct

sunlight and UV light deteriorate certain rubber qualities;

this must also be considered during normal use.

A lengthwise angle deviation of max. 5º in the pipe is allowed (Fig. 5).

Fig. 5. Fig. 6.

Deviation in the center line of the pipe (C), (Fig. 6):

PV 80…100 max. 5 mm

PV 125...250 max.10 mm

PV 300…500 max. 15 mm

PV 550…1000 max. 20 mm

7

4.2 Enclosed body model (PVE)

Make sure that no inappropriate items get between the valve body and the actuator.

4.3 Both models (PV and PVE)

The valve nominal size means the inner diameter of the sleeve. The pipe inner diameter

should match this diameter as closely as possible. Whenever possible, install the actuator

in a vertical position. Valve can be assembled either way in terms of flow direction.

If you have to install the actuator horizontally,

it has to be supported to ensure the operation,

especially if the actuator is heavy. Install a sliding

surface under the actuator (Fig 7).

The support can be fixed on the wall (1), on the

floor (2) or the pipeline (3).

The valve can be installed in either way depending

on the flow direction.

When installing the valve to the pipeline, it has to be

in the open position. Tighten the flange bolts smoothly crosswise

Fig. 7.

WARNING Do not fasten actuator or any part of it to the support.

8

5OPERATION

5.1 First use

Flowrox valves are normally delivered fully assembled and ready to use. Check the

condition of the valve visually.

After installation to the pipeline, check that all connections are leak-proof.

5.2 During operation

During the operation the valve does not normally require any maintenance. The sleeve

change is described in 6.2.

To ensure smooth operation, it is recommended to change the valve sleeve regularly.

Regarding the actuators, follow the instructions of the manufacturer.

NOTE

Note the valve functions, see 2.3.

9

6MAINTENANCE

6.1 Schedule

The sleeve is the only part of the valve which is in contact with the medium flowing in

the pipeline. With regular sleeve changing, the likelihood of malfunctions in the process

decreases. Wear resistance of the sleeve depends on the circumstances of the process

and may vary a lot.

If there is a flow through closed valve or leakage through bushings (PVE) or through

damaged sleeve (PV), change the sleeve immediately.

WARNING

PVE: In case of a sleeve failure, slight leakage can occur

through bushings.

PV: In case of a sleeve breakage, the flowing liquid will

leak into the environment.

6.2 Changing the valve sleeve

WARNING

Control the valve functions (see 2.3) and follow the

instructions for adjusting of valve (6.3) to prevent

accidents and to ensure the correct operation of the

valve.

6.2.1 Changing the valve sleeve in open model valve (PV)

Fig. 8.

See appendix A. Open the valve and detach it from

the pipeline. If the valve is equipped with opening

tags, loosen the fixing screws (8 pcs) at the pinch

bars and pull out the opening tags (Fig. 8).

Remove the broken sleeve by bending the rubber

flange of the sleeve and by wrenching it e.g. with a

pry bar / bending iron.

10

Put in the new sleeve by pressing the rubber flange on the opposite sides together,

pushing its edge as far as possible through the steel flange and wrenching the rest of the

sleeve through the flange e.g. with a pry bar / bending iron (see Fig. 9).

NOTE

The rubber flange of the sleeve allows bending. Do not

damage the sleeve with a sharp tool.

Fig. 9.

After putting in the new sleeve, fix the opening tags to the pinch bars. The excessive

length of the tags can be cut away. Adjust the pinch bars before installing to the

pipeline.

NOTE

At sleeve change, it is always important to check and

adjust the position of the pinch bars. See 6.3.

6.2.2 Changing valve sleeve with enclosed model valve PVE

See appendix B. (Part numbers refer to drawing number 410006 in appendix A). Open the

valve and detach it from the pipeline. Open the bolts (6.) between the valve body halves

and detach the lower part of the body. If the valve has opening tags, detach them (16.)

from upper (2.) and lower pinch bars (3.), 8 pcs screws (Fig.8). Take out the damaged

sleeve and put in a new one. If the sleeve is stiff, detach the lower pinch bar. Remember

to fix the opening tags if applicable. Check the body sealing (15.) between the body

halves and the condition of the bushings (4.). A worn sealing and/or worn bushings may

cause leakage to the environment in the event of a sleeve breakage. Assemble the valve

and adjust the pinch bars before installing the valve to the pipeline.

NOTE

At sleeve change, it is always important to check and

adjust the position of the pinch bars. See 6.3.

11

6.3 Adjusting the valve

After every sleeve change, the closing of the valve has to be checked and adjusted. A

wrong adjustment may shorten the lifetime of the sleeve and cause leakage from the

valve when the actuator is in the closed position.

WARNING Control the valve functions (see 2.3). Do not put tools or

parts of your body between the moving valve parts.

Before reinstallation of the valve into the pipeline:

• Close the valve by using the actuator. Adjust the pinch bars parallel to each other

with the nuts, which are on both sides of actuator fixing plate (Fig.10, nuts 1 and 2),

so that from one end of the sleeve an even, narrow light strip (appr. 0.5 mm) is

shown on the whole squeezed point of the sleeve or symmetrically on both sides (Fig.

10.1).

• Tighten both nuts (1) equally so, that the strip of light disappears.

• Unscrew the lower nuts (Fig. 10.2, nut 2) X mm from the attachment plate (see the

dimension X in the table, Fig. 11).

• When the nuts (Fig. 10.3, nut 1) on the upper side of the attachment plate are

tightened, the lower pinch bar rises and causes a sufficient squeeze on the sleeve to

close the flow against the pressure in the pipeline. After this has been done, open the

valve and it is ready to be installed to the pipeline.

If the valve is hand wheel operated, it is enough to check that the pinch bars are parallel

and the light slit is shown (Fig. 10.1). A sufficient squeeze is achieved by turning the

hand wheel 1/3...3/4 rounds after the valve feels tight: if the pressure in the pipeline is

1 bar - appr. 1/3 of a hand wheel rotation; PN 10 bar - appr. 1/2 of a hand wheel

rotation; PN 25 bar - appr. 3/4 of a hand wheel rotation. If the valve is supplied with a

reduction gear, the number of rotations is multiplied by the gear ratio.

A. Attachment plate

B. Upper pinch bar

C. Sleeve

D. Lower pinch bar

Fig. 10.

12

Fig. 10.1.

Fig. 10.2.

Fig. 10.3.

DIMENSION X [mm]

Fig. 11.

VALVE SIZE

(mm) PRESSURE CLASS (Bar)

1

6…10

16…25

25…100 1.5

2.5

3.5

125…250 2.0

3.0

4.0

300…500 3.0

4.0

550… 4.0

13

6.4 Troubleshooting

PROBLEM POSSIBLE REASON

ACTION

Valve leaks into the

environment. 1. Sleeve breakage.

2. End flanges loosely tightened. 1. Change and make adjustment of sleeve

2. Tighten the flange end screws

Leakage or flow

through the valve

when valve should be

closed.

Sleeve breakage.

(models PVE, PVS): check by the plug -

change and make adjustment of sleeve

Sleeve is not closed with

sufficient squeeze. Manual valves - turn the hand wheel more

tight.

Pneum. and hydr. actuators - check the

supply pressure for cylinder; if the pressure

is too low, the sufficient squeeze for the

sleeve cannot be reached. Check the

compactness of the cylinder seals.

Wrong adjustment of the sleeve.

Make the adjustment

Shorter lifetime of the

sleeve than before. Sleeve is not closed with

sufficient squeeze. Manual valves - turn the hand wheel more

tight.

Pneum. and hydr. actuators - check the

supply pressure for cylinder; if the pressure

is too low, the sufficient squeeze for the

sleeve cannot be reached. Check the

compactness of the cylinder sealings.

Wrong adjustment of the sleeve.

Make the adjustment.

1. Pneum. valves: wrong

adjustment of the end cushioning

in front end-block of cylinder.

2. Wrong adjustment of the

pneum. spring.

1. End cushioning in front end-block of

cylinder should be fully open.

2. Check adjustment of pneumatic spring .

Changes in customer process e.g.

∗composition of medium /

temperature

∗flow capacity

Check the best rubber qualityl

with

FLOWROX.

Select another valve size with FLOWROX

(particularly valves with positioners).

Sleeve is flapping

and/or flow capacity

is not sufficient.

Vacuum or pressure shocks in

pipeline, rubber has hardened

and does not open totally.

Chec

k

that the opening tags are fixed.

In case you cannot find the solution to your problem in the above table, please turn to

the nearest Flowrox representative. The serial number and type identification of the

valve in question will help getting the prompt answer.

14

7TECHNICAL DATA

7.1 Model and spare part codes

7.1.1 Valve model selection

PVE 100 AK 10 -

2 0 3 L R

TYPE SIZE (DN) ACTUATOR PRESSURE

CLASSES

(PN) -

FLANGE

DRILLINGS BODY

MATERIAL SHAPE OF

FLANGE OPENING

TAGS AUXILIARIES

PV = open

PVE = enclosed

PVS = sealed

PVE/S =

enclosed/sealed

25-1000

M=handwheel

A=pneumatic

AB=with

manual

override

AK=with

el.pneum.

positioner

AN=with pneum.

positioner

A

U=with pneum.

spring

A

V=with mech.

spring

H=hydraulic

HP=with

hydraulic

positioner

E=electro

mechanical

EO=electric

for control

1= 1bar

6= 6 bar

10= 10 bar

16= 16 bar

25= 25 bar

40= 40bar

64= 64 bar

100

=100bar

1 = -

2 = DIN PN 10

3 = DIN PN 16

4 = DIN PN 25

5 = DIN PN 40

6 = ANSI 150

7 = ANSI 300

8 = BS

TABLE D

9A = AS

TABLE D

9B = AS

TABLE E

9C = JIS 10

9D = JIS 16

Other on

request

0 = Cast iron /

Welded steel

1 = -

2 = AISI 316

3 = aluminium

4 = other

5 = plastic

types 1 - 4

Determined

by the

valve

manufactur

er

L= opening

tags

Q

= quick

exhaust

valve

R= inductive

limits

S= magnetic

proximity

limits

T= mechan.

limits

Z= solenoid

valve

X = must be

specified

15

7.1.2 Sleeve model selection

SBRT 10 100

/

250

/

3

L 2

SLEEVE MATERIALS PRESSURE

CLASSES (PN)

SLEEVE

INNER DIA

(mm) SLEEVE

LENGTH (mm)

SHAPE OF

FLANGE OPENING

TAGS FLANGE

DRILLINGS

SBRT = styrene butadiene

EPDM=ethylene propylene

CR = chloroprene

CSM = chloro-sulphone-ethene

FPM = fluorine rubber

HNBR = hydrogenated nitrile

IIR = butyl

NBR = nitrile

NBRF = nitrile foodstuff quality

NR = natural rubber

NRF = natural rubber foodstuff

quality

PU = polyurethane

_/PU = PU-coating inside the sleeve

_/M = Flowrox SensoMate sleeve

_/VAC = Vacuum sleeve

1= 1bar

6= 6 bar

10= 10 bar

16= 16 bar

25= 25 bar

40= 40bar

64= 64 bar

100 =100bar

25-1000

Depend on

the

sleeve inner

diameter

according to

ANSI/ISA

75.10.02:

type 1 - 4

Determined

by the

valve

manufactur

er

(depending

on

the valve

diameter /

pressure

class)

L= yes

1 = -

2 = DIN PN 10

3 = DIN PN 16

4 = DIN PN 25

5 = DIN PN 40

6 = ANSI 150

7 = ANSI 300

8 = BS TABLE D

9A = AS TABLE D

9B = AS TABLE E

9C = JIS 10

9D = JIS 16

X = Other, must

be specified

In spare sleeve orders, please use 4- or 5- figure code marked on the

sleeve.

7.1.3 Sleeve materials for Flowrox valves

STANDARD SLEEVE MATERIALS FOR FLOWROX VALVES

RUBBER QUALITY APPLICATION EXAMPLES TEMPERATURE

RANGE TYPICAL MEDIA

SBRT

Styrene Butadiene,

Flowrox Blend

Heavy wearing

High cycle frequency

-40°C - +110°C

Abrasive materials

Diluted acid, alkali and

chemical applications

EPDM

Ethylene Propylene Chemical applications

• Applicable to 75%

of all industrial

chemical applications

-40°C - +120°C Concentrated and oxidizing

chemicals

16

OTHER SLEEVE MATERIAL OPTIONS

RUBBER QUALITY APPLICATION EXAMPLES TEMPERATURE

RANGE TYPICAL MEDIA

NB

R

Nitrile Rubber Applications involving oils, fats

and hydrocarbons -30°C -

+100°C

Oils, Fats, Fuels

Hydrocarbon, Lubricants

N

R

Natural Rubber High wear applications

-40°C - +75°C

Abrasive materials

Diluted acids, alkali and

chemicals

HNB

R

Hydrogenated Nitrile High temperature

Applications -30°C -

+160°C

Oils, Fats, Fuels

Hydrocarbon, Lubricants

NRF

Natural Rubber

Foodstuff Quality

White inner lining

Foodstuff applications

Fulfils FDA (Food and Drug

Administration) requirements -40°C - +75°C

Media used in food and other

CIP (clean-in-place) processes

Alcohols

NBRF

Nitrile Rubber

White inner lining

Applications involving

fatty foodstuff

Fulfils FDA (Food and Drug

Administration) requirements

-30°C - +100°C

Vegetable and animal

oils and fats

EPDM/B

Ethylene Propylene,

Flowrox Blend

Pulp and paper industry’s

green liquor applications

-40°C - +100°C

Green liquor

Alkaline and extraneous

matter

in green liquor processes

C

R

Chloroprene Rubber Special-purpose

chemical

applications

• Resilient to ozone

and averse weather

-40°C - +100°C

Chemicals, Acids

Several solvents

Aliphatic oils

Fats, Lubricants

FP

M

Fluorine Rubber

(Viton®)

Special-purpose

chemical applications

• Resilient to ozone and

averse weather

-20°C +120°C

Chemicals

Aliphatic oils

Aromatic and halogenated

hydrocarbon

CS

M

Chloro-sulphone-

ethylene

(Hypalon®)

Special-purpose

chemical applications

• Resilient to ozone

and averse weather

-40°C - +100°C

Chemicals, Acids

Several solvents

Aliphatic oils

Fats, Lubricants

II

R

Butyl Special-purpose

chemical applications

• Impermeable to gas

-40°C - +100°C

Concentrated and

acidic chemicals

Vegetable oils

PU

Polyurethane

• With PU lining

or solid PU

Abrasive media

applications

-10°C - +80°C

Abrasive materials

Diluted chemicals

Hydrocarbons

Oils, Lubricants

For more information on sleeve materials for Flowrox valves, contact your nearest Flowrox

representative.

17

Opening tags

Reinforcing cords

Wear-resistant inner lining

18

8APPENDIXES

8.1 APPENDIX A: PV- Open Body Assembled

FLOWROX

1. Valve body 6. Allen screw

2. Flange 7. Valve plate

3. Upper pinch bar 8. Drive screw

4. Lower pinch bar 9. Fix. parts for opening tags

5. Hex. nut

This manual suits for next models

21

Table of contents

Other FLOWROX Control Unit manuals