FLOWTECH flowboost F.H User manual

1

First Publication Date: 01/09/2020

Revision:

Revision Date:

OPERATION AND

MAINTENANCE MANUAL

F.H Pump Manual

CONTENTS

OPERATION & MAINTENANCE

General Information 3

Safety Information 4

Safety Warnings & Precautions 5

Customer / Contractor Responsibilities 6

Technical 7

Intended use 7

Improper use 7

Marking 7

Technical data 7

Operating conditions 8

General provisions 8

Transportation 8

Handling 9

Installation Dimensions 9

Unpacking 9

Installation 9

Pipes 9

Suction pipe 10

Delivery pipe 10

Electrical connection 10

Start-up and Operation 11

Maintenance 12

Disposal 12

Spare-parts request 12

Troubleshooting 13

2

Definitions of Safety Warnings and

Precautions

WARNING!

Indicates a potentially hazardous situation which, if

not avoided, can result in serious injury or death.

CAUTION!

Indicates a potentially hazardous situation which, if

not avoided. Can result in minor to moderate injury, or

serious damage to the product.

General

Information

These instructions are to assist in the installation of the flowboost F.H Pump please follow

them carefully.

If, having read this Operation & Maintenance Manual, there is any doubt about any aspect of

the installation please don't hesitate to contact our technical team.

flowboost F.H Pump Manual

3

Safety

Information

It is essential that correct and safe working practices are adhered to at all times when installing,

operating and/or maintaining any piece of equipment. Always consult safety data sheets, operating

and maintenance manuals, Health & Safety legislation and recommendations and specific

requirements of any equipment manufacturer, site controller, building manager or any other persons

or organisation relating to the procurement, installation, operation and/or maintenance of any piece

of equipment associated or in conjunction with any product provided by flowech Water Solutions.

This document is intended for ALL installers, operators, users and persons carrying out maintenance

of this equipment and must be kept with the equipment, for the life of the equipment and made

available to all persons at all times. Prior to carrying out any work associated with the set it is essential

that the following sheets are read, fully understood and adhered to at all times.

Equipment must only be installed, operated, used, and/or maintained by a competent person. A

competent person is someone who is technically competent and familiar with all safety practices

and all of the hazards involved.

Any damage caused to any equipment by misapplication, mishandling or misuse could lead to risk of

Electrocution, Burns, Fire, Flooding, death or injury to people and/or damage to property dependent

upon the circumstances involved. flowech Water Solutions accepts no responsibility or liability for

any damage, losses, injury, fatalities or consequences of any kind due to misapplication, mishandling

or misuse of any equipment, or as a result of failure to comply with this manual.

Failure to install, operate, use or maintain the equipment in accordance with the information contained

within this document could cause damage to the equipment and any other equipment subsequently

connected to it, invalidating any warranties provided by flowech Water Solutions to the buyer.

4

Safety Warnings &

Precautions

These instructions should be read and clearly understood before working on the system. Please

read this manual carefully and all of the warning signs aached before installing or operating the

equipment keep this manual handy for your reference. This equipment should be installed, adjusted

and serviced by trained and qualified personnel. Failure to observe this precaution could result in

bodily injury.

WARNING! - Install an emergency stop key separately from the isolator. Rotating

shas can be hazardous.

WARNING! - This equipment has a high leakage current and must be permanently

fixed to earth.

WARNING! - Do not aach or remove wiring or connectors when the power is applied.

Do not check signals during operation. When the power is turned on and the running

command is on, the motor will start rotating. The stop key is only eective when the

function is set. If there is a power failure and an operation instruction is given the unit

may start automatically when the power is reinstated.

WARNING! - Make sure that the input voltage is correct. Be sure to install the unit in

a room that is not exposed to direct sunlight and is well ventilated.

Avoid environments which have a high ambient temperature, high humidity or

excessive condensation. Avoid dust. Corrosive gas, explosive gas, inflammable gas,

grinding-fluid mist and salt damage, etc.

WARNING! - Do not connect the power source to any terminals except power

connectors.

WARNING! - Motor control equipment and electronic controllers are connected to

hazardous line voltages. When servicing drives and electronic controllers, you may be

exposed to components at or above the line potential. Extreme care should he taken

to protect against shock. Dangerous voltage may exist aer the power light is o.

Wait more than 5 minutes aer turning o the power supply before performing

maintenance or inspection. Hazard of electric shock. Disconnect incoming power

before working on this unit.

WARNING! - The inverter should be protected separately against ground fault.

Observe the regional regulations for electrical installation!

flowboost F.H Pump Manual

5

Customer / Contractor

RESPONSIBILITIES

It is the responsibility of the customer and/or the contractor:

• To ensure that anyone working on the equipment is wearing all necessary protective gear

and/or clothing.

• Is aware of appropriate health & safety warnings.

• Has read the information in this section of the manual.

CAUTION! - It is strongly recommended that all electrical equipment conforms

to National Electrical Codes and local regulations. Only qualified personnel should

perform installation, alignment and maintenance. The manufacturer reserves the right

to alter the technical data in order to make improvements or update information.

CAUTION! - Failure to observe these rules will render the guarantee invalid. The same

applies to repair jobs and/or replacement. Your legal rights are not aected.

CAUTION! - The manufacturer declines all responsibility in the event of damage or

injury caused as a result of tampering with the equipment.

CAUTION! - Do not switch on/o power supply to run/stop the motor/system! Start

the unit only by using run buon or external run command.

6

Technical

Horizontal Multi-Stage Close Coupled Pumps in stainless steel.

Intended use

For clean liquids: non-explosive and non-flammable, non-hazardous for health or the environment, non-

aggressive for pump materials, not containing abrasives, solid or fibrous particles.With seal rings in EPDM the

pump is not suitable for use with oil.

Liquid temperature from - 15°C to + 110 °C.

Improper use

The device is designed and built only for the purpose described. Improper use of the device is forbidden,

as is use under conditions other than those indicated in these instructions. Improper use of the product

reduces the safety and the eciency of the device, Flowtech shall not be responsible for failure or accident

due to improper use. Do not use in ponds, tanks or swimming pools or where people may enter or come into

contact with the water.

Marking

The following picture is a copy of the name-plate that is on the external case of the pump

Technical data

Dimensions and weight (see technical catalogue).

Nominal speed 2900/3450 rpm

Protection IP 54

Supply voltage / Frequency:

up to 240V 1~ 50/60 Hz

up to 480V 3~ 50/60 Hz

Check that the mains frequency and voltage correspond to the electrical characteristics shown on the

indicator plate. The electric data marked on the label are referred to the nominal power of the motor.

Sound pressure: < 70 dB (A).

Max. Starts per hour: 30 at regular intervals (15 for 206-406, 20-32-48).

Maximum permissible pressure in the pump casing: 80m (8 bar), 100 m (10 bar) for 20-32-48.

The max. Inlet water pressure: PN (Pa) - Hmax (Pa).

flowboost F.H Pump Manual

7

Operating conditions

Installation in well ventilated location protected from the weather, with a max ambient temperature of 40°C.

General provisions

Before using the product it is necessary to know all the safety indications.

Carefully read all operating instructions and the indications defined for the dierent steps: from transportation

to disposal.

The specialized technicians must carefully comply with all applicable standards and laws, including local

regulations of the country where the pump is sold.

The device has been built in conformity with the current safety laws. The improper use could damage people,

animals and objects.

The manufacturer declines any liability in the event of damage due to improper use or use under conditions

other than those indicated on the name-plate and in these instructions.

Follow the routine maintenance schedules and the promptly replace damaged parts, this will allows the

device to work in the best conditions.

Use only original spare parts provided from Flowtech or an Authorised distributor.

Don’t remove or change the labels placed on the device.

Do not start the device in case of defects or damaged parts.

Maintenance operations, requiring full or partial disassembly of the device, must be done only aer

disconnection from the supply.

Safety devices

The device has an external case that prevents any contact with internal parts.

Residual Risks

The appliance designed for use when inline with the design and safety rules, doesn’t have residual risks.

Information and Safety signals

For this kind of product there will not be any signals on the product.

Individual protection devices

During installation, starting and maintenance it is suggested to the authorized operators to consider the use

of individual protection devices suitable for described activities.

During ordinary and extraordinary maintenance interventions, safety gloves are required.

Signal individual protection device

Hand Protection - Gloves for protection against chemical, thermal and mechanical risks.

Transportation

The product is packed to maintain the content intact.

During transportation avoid to stack excessive weights.

Ensure that during the transportation the box cannot move.

8

It is not necessary to use any special vehicle to transport the packaged device.

The transport vehicles must comply, for the weight and dimensions, with the chosen product (see technical

catalogue dimensions and weights).

Handling

Handle with care, the packages must not receive impacts.

Avoid to impact onto the package materials that could damage the pump.

If the weight exceeds 25 Kg the package must be handled by two person at the same time.

Raise the pump-motor unit slowly, making sure it does not move from side to side in an uncontrolled way, to

avoid the risk of imbalance and tipping up.

Installation Dimensions

For the dimensions of the device (see technical catalogue).

Ambient requirements and installation site dimensions

The customer has to prepare the installation site in order to guarantee the right installation and in order to fulfil

the device requirements (electrical supply, etc.).

The place where the device will be installed must fulfil the requirements.

It’s absolutely forbidden to install the machine in an environment with potentially explosive atmosphere.

Unpacking

Inspect the device in order to check any damages which may have occurred during transportation.

Package material, once removed, must be discarded/recycled according to local laws of the destination

country.

Installation

The pumps must be installed with the rotor axis in the horizontal position and with the feet under the pump.

Place the pump as close as possible to the suction source.

Provide space around the pump for motor ventilation, to allow for checking of sha rotation, for filling and

draining the pump and to allow for collection of the liquid to be removed (especially for draining liquids which

are harmful or have to be removed at temperatures higher than 60°C).

Pipes

Ensure the insides of pipes are clean and unobstructed before connection.

ATTENTION: The pipes connected to the pump should be secured to rest clamps so that they do not

transmit stress, strain or vibrations to the pump.

Tighten the pipes or union coupling to the extent sucient to ensure a tight seal.

Excessive torque may cause damage to the pump.

When the pipe or union coupling is mounted, keep the pump casing connection blocked with a second

wrench, making sure the connection is not deformed by excessive tightening.

The pipe diameters must not be smaller than the pump connections.

flowboost F.H Pump Manual

9

Suction pipe

If the suction pipe is longer than 10m, use an internal pipe diameter larger than the pump suction connection.

The suction pipe must be perfectly airtight and be led upwards in order to avoid air pockets.

With a pump located above the water level (suction li operation) fit a foot valve with strainer which must

always remain immersed.

If operating with flexible hoses use a reinforced spiral suction hose, in order to avoid the hose narrowing due

to suction vacuum.

With the liquid level on the suction side above the pump (inflow under positive suction head, fit an inlet gate

valve.

For suction from a storage tank fit an anti-backflow valve. Follow local specifications if increasing network

pressure.

Install a strainer on the suction side of the pump to prevent foreign particles from entering the pump.

Delivery pipe

Fit a gate valve in the delivery pipe to adjust delivery and head.

Install a pressure gauge.

With a geodetic head at outlet over 15m fit a check valve between the pump and the gate valve in order to

protect the pump from water hammering.

Electrical connection

Electrical connection must be carried out only by a qualified electrician in accordance with local regulations.

Follow all safety standards.

The unit must be properly earthed (grounded).

Connect the earthing (grounding) conductor to the terminal with the marking.

Compare the frequency and mains voltage with the name-plate data and connect the supply conductors to

the terminals in accordance with the appropriate diagram inside the terminal box cover.

ATTENTION: never allow washers or other metal parts to fall into the internal cable opening between

the terminal box and stator.

If this occurs, dismantle the motor to recover the object which has fallen inside. If the terminal box is provided

with an inlet gland, use a flexible power supply cord of the H07 RN-F type. If the terminal box is provided with

an inlet bushing, connect the power supply cord through a conduit. For use in swimming pools (not when

persons are in the pool), garden ponds and similar places, a residual current device with IN not exceeding

30 mA must be installed in the supply circuit.

Install a device for disconnection from the mains (switch) with a contact separation of at least 3mm in all

poles.

With a three-phase motor install an overload protection device with curve D appropriate for the rated current

of the pump.

Single-phase are supplied with a capacitor connected to the terminals and (for 220-240 V - 50 Hz) with an

incorporated thermal protector.

ATTENTION: When the pump is fed by a frequency converter, the minimum frequency should not fall below

25Hz and in any case the total head of the pump should never be lower than 3m.

10

Start-up and Operation

Preliminary checks before start-up of the pump

Do not start-up the device in case of damaged parts.

First starting

ATTENTION: never run the pump dry.

Start the pump aer filling it completely with liquid.

When the pump is located above the water level

Suction li operation or with a positive suction head which is too low (less than 1m) to open the non-return

valve, fill the pump through the priming hole.

When the liquid level on the suction side is above the pump

(inflow under positive suction head, fill the pump by opening the suction gate valve slowly and completely,

keeping the delivery gate valve open to release the air.

Before starting, check that the sha turns by hand. For this purpose use the screwdriver notch on the sha

end on the ventilation side.

When starting, with a three-phase motor, check that the direction of rotation

Is as shown by the arrows on the lantern bracket.

Otherwise, disconnect electrical power and reverse the connections of two phases.

Check that the pump works within its field of performance and that the absorbed current shown on the

name-plate is not exceeded. Otherwise adjust the delivery gate valve or the seing of any pressure switches.

If a priming loss occurs (interruption of delivery flow) or if a pressure oscillation is indicated by the pressure

gauge, make sure all the suction pipe couplings are perfectly sealed and tighten the two sealed plugs on the

pump casing.

Never run the pump for more than five minutes with a closed gate valve.

Prolonged operation without a change of water in the pump causes dangerous increases of temperature and

pressure.

When the water is overheated due to prolonged operation with a closed port, stop the pump before opening

the gate valve.

To avoid any risk of danger to users and the creation of harmful thermal stress in the pump and system due

to large temperature dierentials, wait until the water has cooled inside the pump before starting again.

If the water is overheated on account of prolonged operation with a non-primed or insuciently filled pump

(suction li operation), wait until cool before opening the draining and filling plugs.

Care must be taken when the pumped fluid has a high temperature. Do not touch the fluid when its

temperature is higher than 60°C. Do not touch the pump when the surface temperature is higher than 80°C.

Switch o of the pump

The appliance must be switch o every time there are faults. (See troubleshooting).

The product is designed for a continuous duty, the switch o is performed by disconnecting the power

supply by means the expected disconnecting devices. (See Electrical connection).

flowboost F.H Pump Manual

11

Maintenance

Before any operations it’s necessary to disconnect the power supply. If required ask to an electrician or to an

expert technician.

Every maintenance operations, cleaning or reparation executed with the electrical system under voltage, it

could cause serious injuries to people.

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

In case of extraordinary maintenance, or maintenance operations that require part-removing, the operator

must be a qualified technician able to read schemes and drawings.

It is suggest to register all maintenance operation executed.

During maintenance keep particular aention in order to avoid the introduction of small external parts that

could compromise the device safety.

It is forbidden to execute any operations with the direct use of hands. Use water-resistant, anti-cut gloves to

disassemble and clean the filter or in other particular cases.

During maintenance operations external personnel is not allowed.

Maintenance operations that are not described in this manual must be made only by special personnel

authorized by Flowtech.

For further technical information regarding the use or the maintenance of the device, contact Flowtech.

Routine maintenance

Before every maintenance operations disconnect the power supply and make sure that the device could not

accidentally operate.

In the case of water containing chloride (chlorine, sea water), the risk of corrosion increases in stagnant water

conditions (also with an increase in temperature and decrease of pH value). In these cases, if the pump

remains inactive for long periods, it must be emptied completely and, preferably, dried.

For good measure, as in the case of temporary operation with dirty liquids, run the pump briefly with clean

water to remove deposits. When the pump remains inactive it must be emptied completely if there is a risk of

freezing.

Before restarting the unit, check that the sha is not jammed and fill the pump casing completely with liquid.

Dismantling the pump

Close the suction and delivery gate valves and drain the pump casing before dismantling the pump. For

dismantling and re-assembly see construction in the cross section drawing. By removing the screws and the

square nuts (2,4,8) the motor can be taken out complete, with all internal parts of the pump, without removing

the pump casing and the pipes.

Disposal

The final disposal of the device must be done by specialised company. Make sure the company follows the

classification of the material parts for the separation.

Observe the local regulations and dispose the device accordingly with the international rules for environment

protection.

Spare-parts request

When ordering spare parts, please quote their designation, position number in the cross section drawing and

rated data from the pump name plate (type, date and serial number).

12

Troubleshooting

WARNING: Turn o the power supply before performing any operations.

Do not allow the pump or motor to run when dry even for a short period.

Strictly follow the user instructions and if necessary contact an authorised service centre.

Problem Probable Causes Possible Remedies

The motor does not

start

1a. Unsuitable power

supply

1a. Check that the mains frequency and voltage

correspond to the electrical characteristics shown on the

indicator plate

1b. Incorrect electrical

connections

1b. Connect the power supply cable to the terminal board

correctly. Check that the thermal overload protection is

set correctly (see data on the engine indicator plate) and

make sure that the fuse board up line of the engine has

been properly connected

1c. Engine overload

protective device cuts in

1c. Check the power supply and make sure that the pump

sha is turning freely. Check that the thermal overload

protection has been set correctly (see engine indicator

plate)

1d. Blown or defective

fuses

1d. Replace the fuses, check the electric power supply

and points a) and c)

1e. Sha blocked 1e. Remove the cause of blockage as indicated in the

“Blocked pump” instruction booklet

1f. If the above causes

have already been

checked the engine may

be malfunctioning

1f. Repair or replace the engine by applying to an

authorised service center

Pump blocked 2a. Prolonged periods of

inactivity with formation of

rust inside the pump

2a. Rotation may be started directly from the pump sha

or from the joint (remember to turn o the electricity

supply first ) or contact an authorised service centre

2b. Presence of solid

bodies in the pump rotor

2b. If possible, dismantle the pump casing and remove

any solid foreign bodies inside the rotor, if necessary

contact an authorised service centre

2c. Bearings seized 2c. If the bearings are damaged replace them or if

necessary contact an authorised service centre

The pump functions

but no water comes

out

3a. Possible infiltration

of air from suction tube

connections, drain plugs

or filling of pump or from

the gaskets of the suction

pipe

3a. Check which part is not tight and seal the connection

adequately

3b. Foot valve blocked

or suction pipe not fully

immersed in liquid

3b. Clean or replace the boom valve and use a suction

pipe suitable for the application

3c. Suction filter blocked 3c. Clean the filter, if necessary, replace it. See point 2a)

also.

flowboost F.H Pump Manual

13

Insucient flow 4a. Pipes and accessories

with diameter too small

causing excessive loss of

head

4a. Use pipes and accessories suitable for the specific

application

4b. Presence of deposits

or solid bodies in the

internal passages of the

rotor

4b. Clean the rotor and install a suction filter to prevent

other foreign bodies from entering

4c. Rotor deteriorated 4c. Replace the rotor, contact Flowtech

4d. Worn rotor and pump

case

4d. Replace the rotor and the pump casing

4e. Excessive viscosity of

the liquid pumped (if other

than water)

4e. The pump is unsuitable

4f. Incorrect direction of

rotation

4f. Invert the electrical connections on the terminal board

or control panel

4g. Suction head

excessive in relation to the

suction capacity of pump

4g. Try to close the feeder gate partially and/or reduce

the dierence in level of the pump and the liquid being

aspirated

4h. Suction pipe too long 4h. Bring the pump closer to the suction tank so as to use

a shorter pipe. If necessary use a pipe of a wider diameter

Noise and vibrations

from the pump

5a. Rotating part

unbalanced

5a. Check that no solid bodies are obstructing the rotor

5b. Worn bearings 5b. Replace the bearings

5c. Pump and pipes not

firmly aached

5c. Anchor the delivery and suction piping as needed

5d. Flow too strong for the

diameter of the delivery

pipe

5d. Use bigger diameters or reduce the pump flow

5e. Functioning in

cavitation

5e. Reduce the flow by adjusting the feeder gate and/or

using pipes with a bigger internal diameter. See point 4g)

too

5f. Unbalanced power

supply

5f. Check that the mains voltage is right

5g. Incorrect alignment of

pump-motor unit

5g. If necessary, the unit must be re-aligned

Leakage from the

mechanical seal

6a. The mechanical seal

has functioned when dry

or has stuck

6a. Make sure that the pump casing (and the suction pipe

if the pump is not self-priming) are full of liquid and that all

the air has been expelled. See point 5 e) too.

6b. Mechanical seal

scored by presence of

abrasive parts in the liquid

pumped

6b. Install a suction filter and use a seal suited to the

characteristics of the liquid being pumped.

6c. Mechanical seal

unsuitable for the type of

application

6c. Choose a seal with characteristics suitable for the

specific application

6d. Slight initial drip during

filling or on first start-up

6d. Wait for the seal to adjust to the rotation of the sha. If

the problem persists, see points 6a), 6b) or 6c) or contact

an authorised service center.

In cases 6a), 6b) and 6c), replace the seal, if necessary contact an authorised service center

14

flowboost F.H Pump Manual

15

contact us

FOR FURTHER INFORMATION OR ASSISTANCE

Flowtech Water Solutions are experts in water services and water booster sets.

We have continuously supplied a wide range of standard and custom products since

being founded in 1996.

TELEPHONE : 0333 200 1756 TELEPHONE : 0333 200 1813

MANUFACTURE & SUPPLY SERVICE & MAINTENANCE

ADDRESS : Unit 1 Lock Flight Buildings, Wheatlea Industrial Estate,

Wigan, Greater Manchester WN3 6XP United Kingdom

EMAIL: info@flowtech.org.uk EMAIL: service@flowtech.org.uk

WEBSITE: .flowtech.org.uk

REGISTERED

ISO

9001 :2015

Certificate No. 185352020Membership No. 700106

This section of the flowech©website holds

information exclusively for members. Members will

need to log in to gain access to these pages.

Our member’s will be granted exclusive access to

our technical resource library. Within this resource

is a wide range of product information including

data sheets, technical drawings, O&M Manuals

and training videos

At flowech©we operate a network of Service

Engineers located throughout the UK who are

supported by our oces located in and Greater

Manchester. The distribution of engineers means

that in the majority of cases we are less than 4

hours away from aending a customer call out.

We place great emphasis on providing technical

back up to support our Service Engineers in

resolving some dicult operational and technical

issues. We pride ourselves on completing a

project on time, within budget and never leaving

a problem unresolved, or a customer waiting.

This quality of service has made us the first

choice for our customers.

Copyright © 2020 • All Rights Reserved • Flowtech Water Solutions Limited • Company Number: 05125479 • VAT Number: 836 8024 19

Table of contents

Other FLOWTECH Water Pump manuals

FLOWTECH

FLOWTECH flowpress WMDA User manual

FLOWTECH

FLOWTECH flowboost F.V User manual

FLOWTECH

FLOWTECH flowpac compact 311S User manual

FLOWTECH

FLOWTECH flowpac compact 1F.D User manual

FLOWTECH

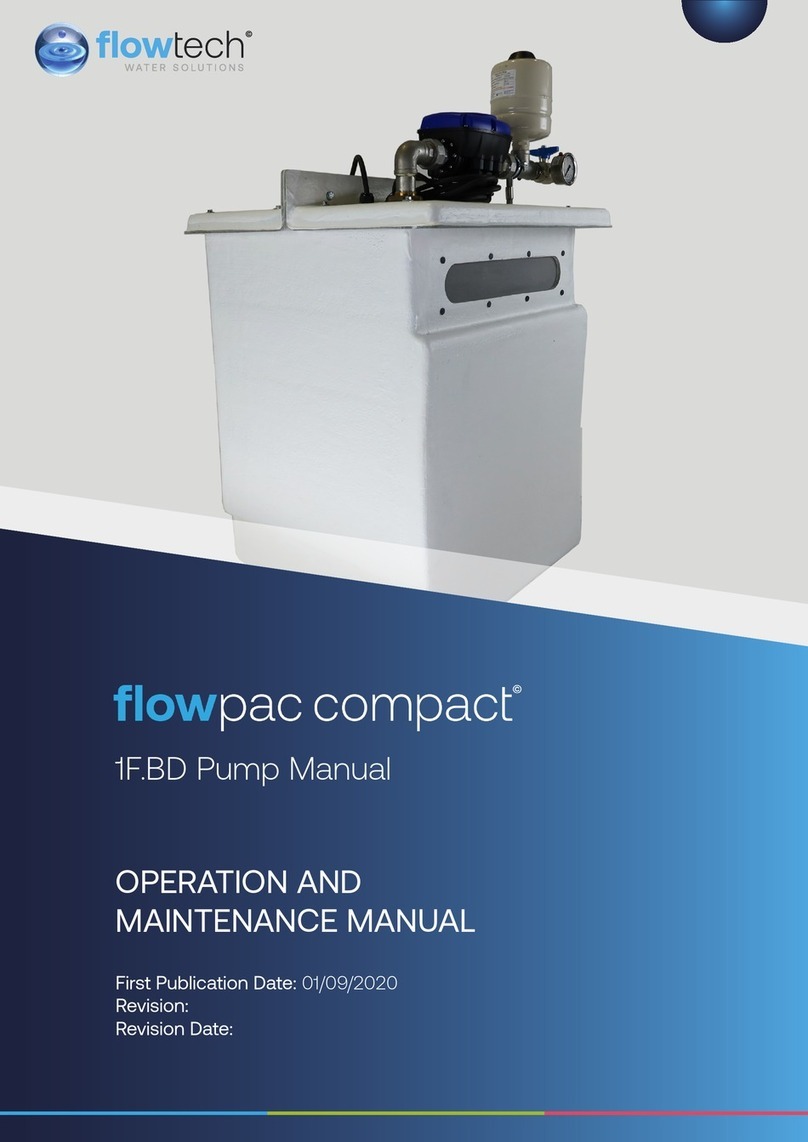

FLOWTECH flowpac compact 1F.BD User manual

FLOWTECH

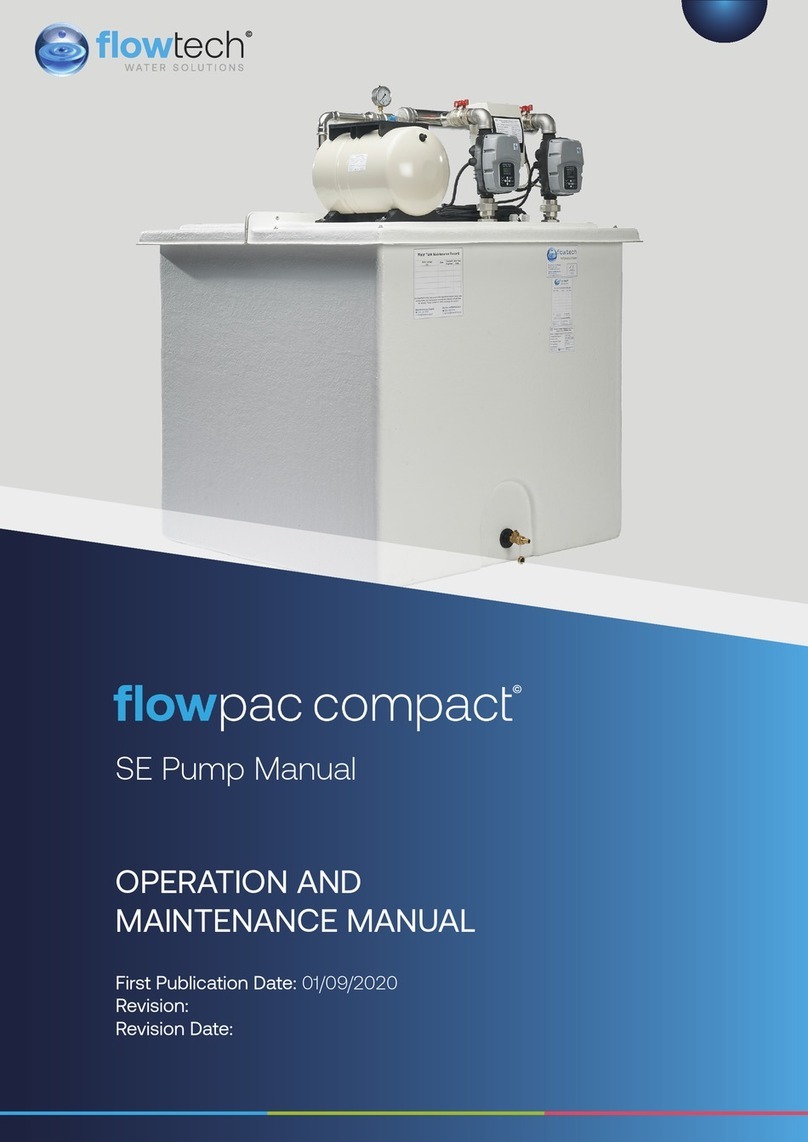

FLOWTECH flowpac compact SE User manual

FLOWTECH

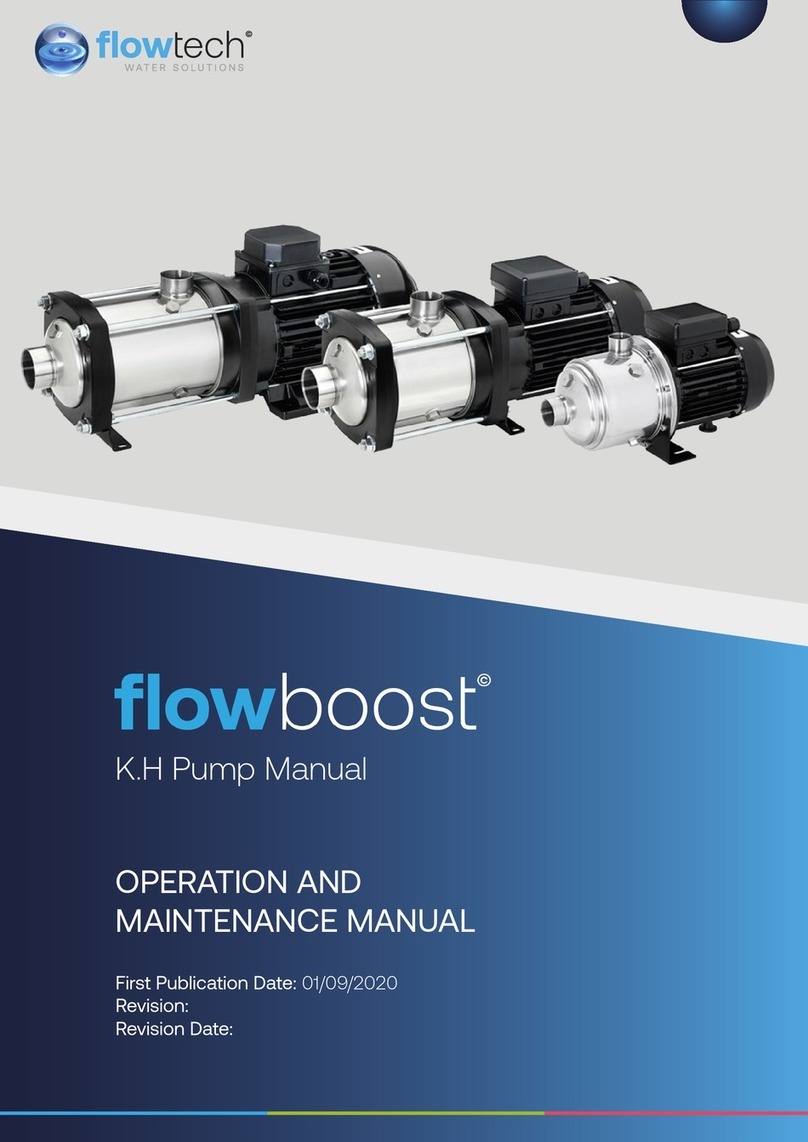

FLOWTECH flowboost K.H User manual

FLOWTECH

FLOWTECH Flowpress Mini Single User manual

FLOWTECH

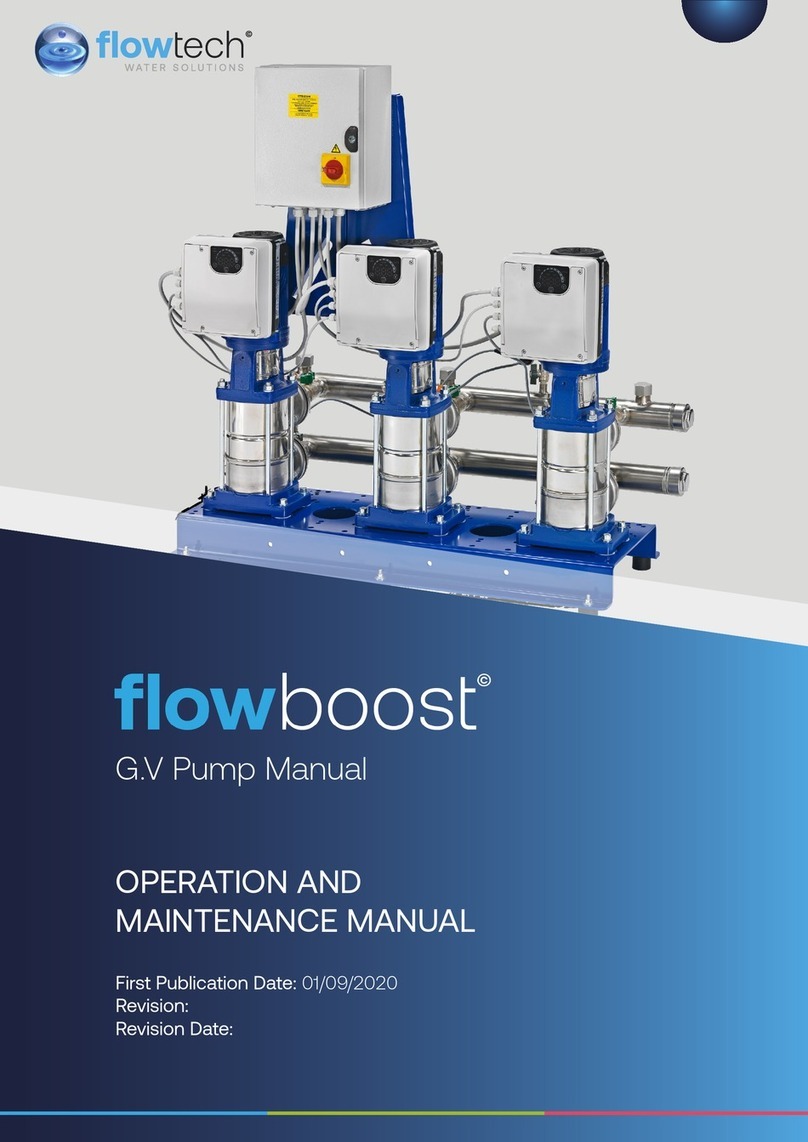

FLOWTECH flowboost G.V User manual