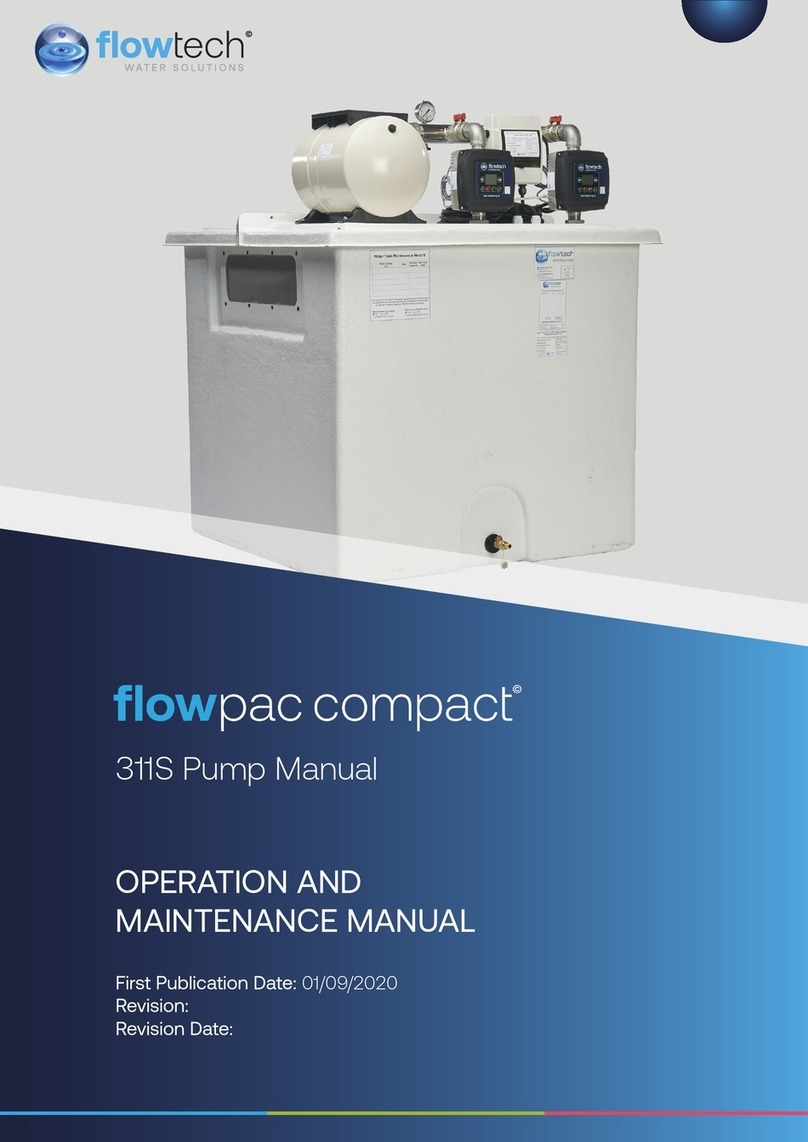

Pressure tank

A diaphragm pressure tank is used on the discharge side of the pump to maintain pressure in the pipes

when there is no water demand. The unit stops the pump from continuing to run at zero demand and reduce

the size ofthe tank that is required for supply purposes.

The tank must be permied and suitable for systems pressure.

Tank selection

Variable speed pressure booster sets can operate with smaller tanks compared to traditional systems. As a

rule, atank with a capacity in liters amounting to about 10% of the flow rate of a single pump expressed in

liters per minute is sucient. The required water volume may be distributed among multiple tanks.

Product function and use

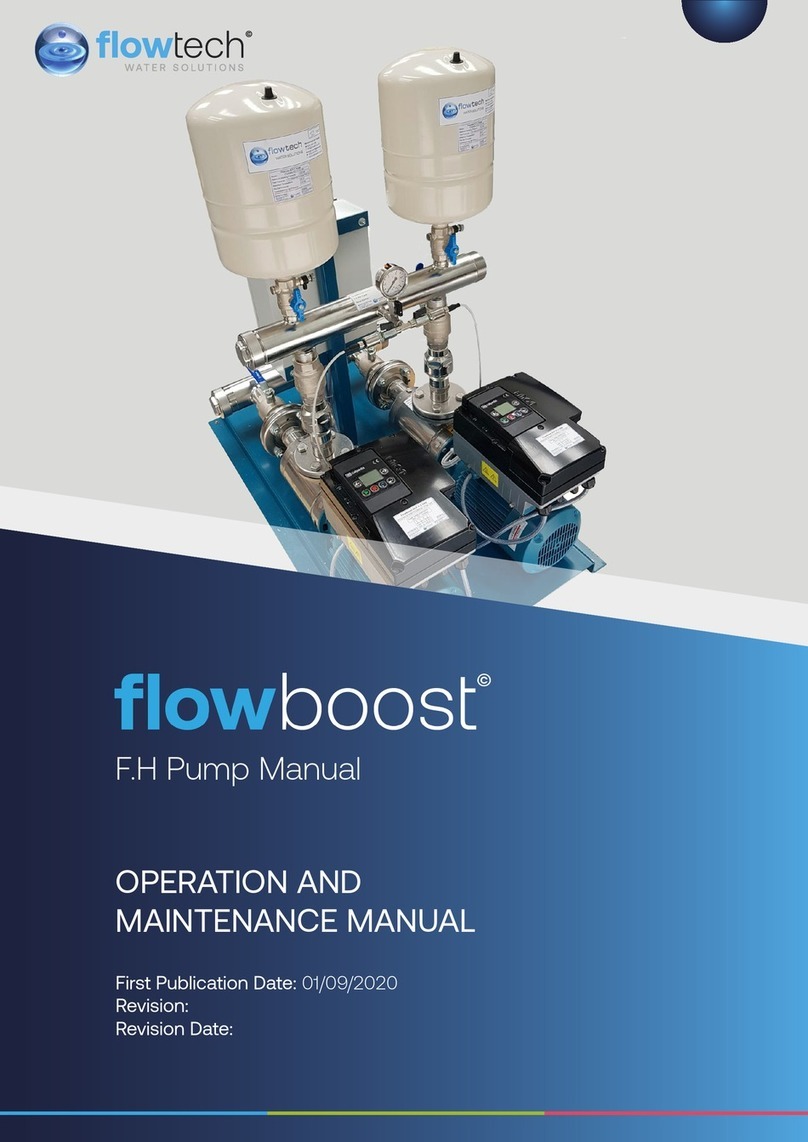

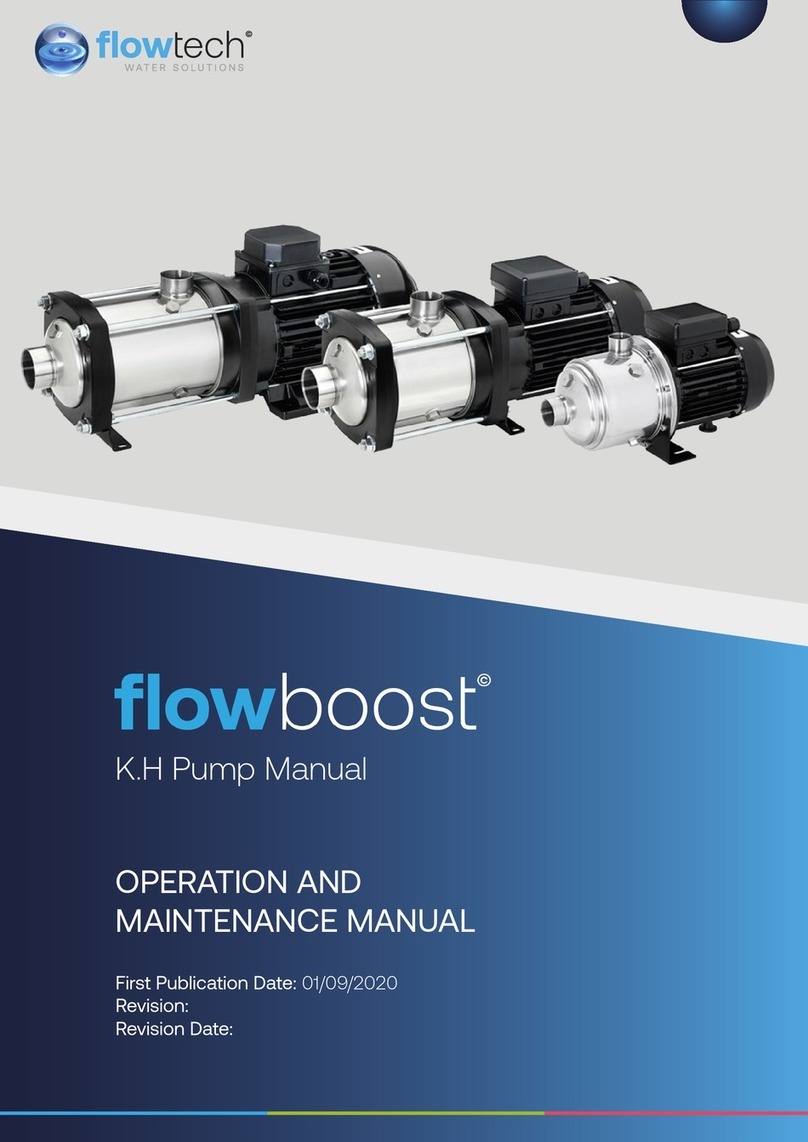

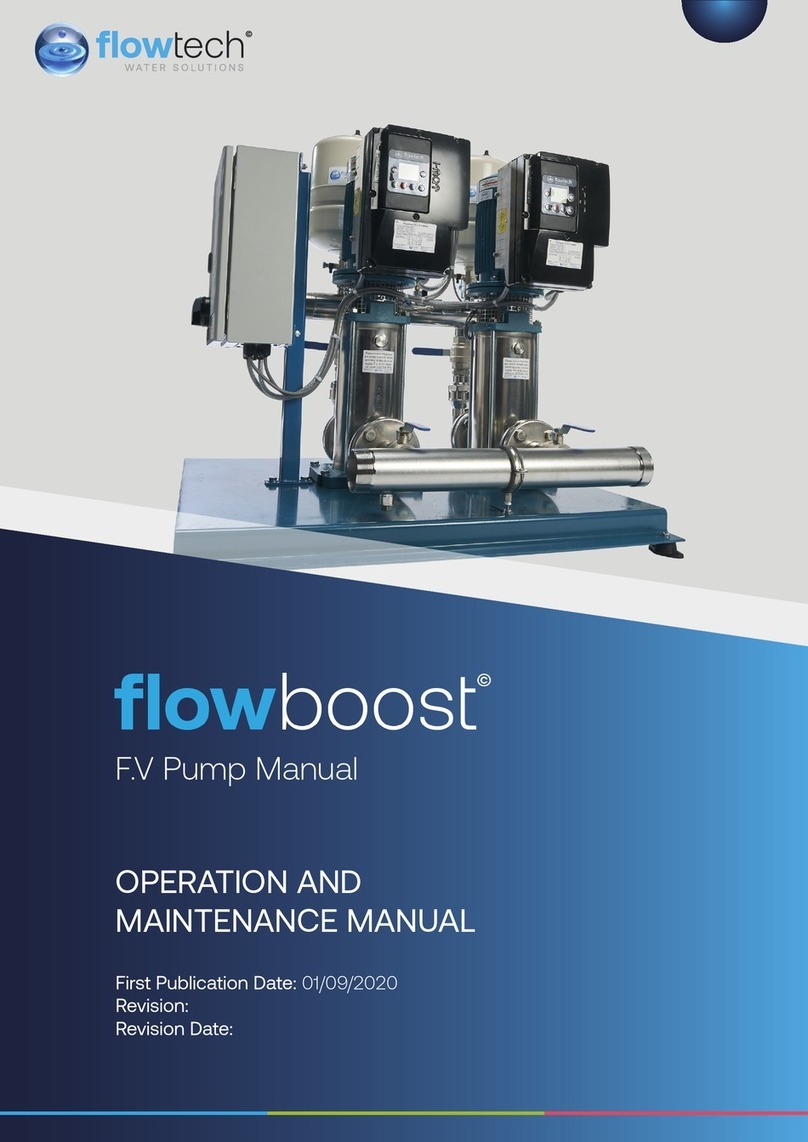

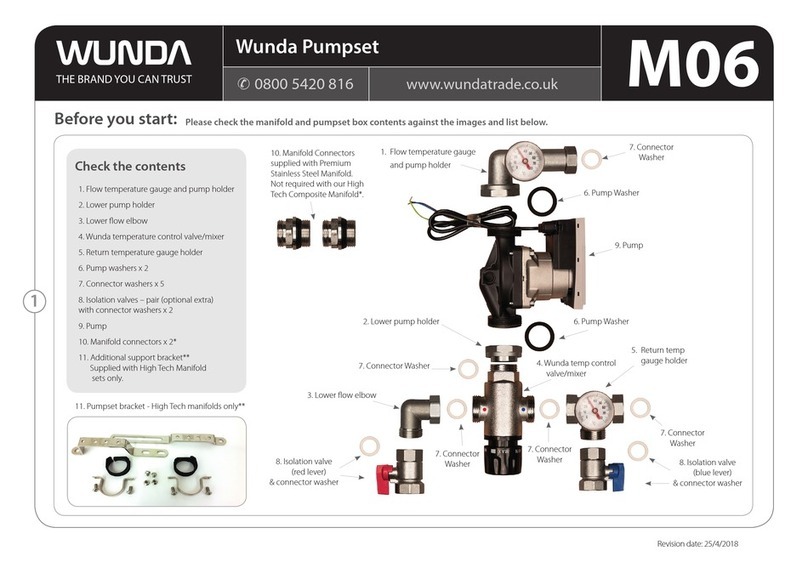

In its standard version, the product is a booster unit set which consists of identical variable speed electric

pumps that are connected in parallel. The pumps are mounted on a common stand, suction and delivery

manifolds, on-o valves, non-return valves, pressure gauge, pressure transmiers, and a single-phase or three-

phase control panel.

The system must be equipped with a membrane tank. The delivery manifold is fied with couplings that

are designed for the installation of 24 L tanks with an on-o valve. Along with the tanks, provide a applicable

manifoldsupport.

Extra floor-standing tanks may be installed and connected to the manifold.Intended use

The product can be used to pump:

Cold water

Refer to the standard Installation, Operation and Maintenance Manual for pump design specification.

The

variable speed booster sets are made for the following applications:

Default, pressure regulation (open loop systems)

Level and flow regulation (open loop systems)

Irrigation applications with single or multiple pumps.

Improper use

The product must not be used for closed loop systems.

Applications

The application alternatives for the product are the following:

Actuator (constant speed)

The unit operates as an actuator according to speed set point; this is done through user interface, the

corresponding analog input or the communication bus.

Controller (constant pressure)

This mode is set as the default operating mode and is used for a unit in a single pump operation.

Cascade serial / Cascade synchronous

The units are connected via the RS485 interface and communicate via the provided protocol.

The combination of the dierent units which are used in a multi-pump system depends on the system

requirements.

It is possible to run all pumps in cascade serial mode and cascade synchronous mode as well. If one unit fails,

theneach pump of the system can become the lead pump and can take control.

This mode is set as the default operating mode and is used for a booster set unit in a multipump operation.

Cascade serial mode is the standard configuration.

flowboost G.V Pump Manual

9