Flowtron LeafEater LE-800B User manual

SHREDS LEAVES,

GRASS

CLIPPINGS,

PINE NEEDLES . . .

OWNER’S

MANUAL

MODEL

LE-800B

• Assembly

• Operation

• Maintenance

• Repair Parts

WA R N I N G

Carefully read and

follow safety rules,

precautions and

operating instruc-

tions. Failure to do

so can result in

serious personal

i n j u r y.

Instructions given with this symbol are for per-

sonal safety. Be sure to follow them.

Flowtron Outdoor Products

15 Highland Ave, Malden, MA 02148 • an ARMATRON company

781-321-2300 • www.flowtron.com

F l o w t ron Leaf-Eater One Year Limited Wa r r a n t y

Flowtron, division of Armatron warrants your Leaf-Eater to be free from defects in materials or workmanship under

normal use and service for one year from date of the original purchase. All parts which are defective will be

repaired or replaced free of charge. Any implied warranties, including the implied warranty of merchantability are

also limited in duration for one year from the original purchase date. Some states do not allow limitations on how

long an implied warranty lasts, so the above limitations may not applyto you.

The provisions of this warranty shall not apply to any Leaf-Eater which has been subject to misuse, neglect or

accident, nor which is used for a purpose for which it is not designed, or which shall have been repaired or altered

in any way so as to adversely affect its performance and reliability. Service by unauthorized parties voids your

warranty. Warranty covers only the original purchaser. Commercial and/or professional use is excluded from war-

ranty coverage.

Flowtron neither assumes nor authorizes any person to assume for it any other liability in connection with its prod-

ucts. No responsibility is assumed for any consequential damages that may result from the use of a Flowtron

product, not for damages due to accident, abuse, lack of responsible care, the affixing of any unauthorized attach-

ments, loss of parts or subjecting this unit to any but the specified voltage. Some states do not allow the exclusion

or limitation of the incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Flowtron Outdoor Products, 15 Highland Ave., Malden, MA 02148 • an ARMATRON company

A lw ays Wear Eye Protection During Operation

page 2

A . I n t r o d u c t i o n

Your Flowtron Leaf-Eater is a quality built product

that is designed to provide you with a unit that is not

only affordable, but will perform with a minimum of

care and maintenance.

Special Features Include:

• Powerful universal electric motor

• Runs on normal household current

• Easily moved from place to place

• Can be used on a container or free standing on

its own legs (included with unit)

• Easily replaceable cutting cords with extras sup-

plied with each unit.

B . U n p a cking Instructions

Your unit has been carefully packed at the factory to

prevent damage during shipment and storage.

Carefully unpack the carton as follows:

1.Remove contents from carton

2.Check parts against list shown.

3.Examine for damage

KNOW YOUR FLOWTRON LEAF-EATER

C a r ton Contents

Key # D e s c r i p t i o n Q t y.

1F u n n e l 1

2 Upper Housing 1

3 Lower Housing Assembly 1

4Legs 3

5 Hardware Package 1

6Owner’s Manual 1

R E A R

L E F T S I D E

4

2

1

5

R I G H T S I D E

6

FIGURE 2

3

F R O N T

ASSEMBLY

H a rdware Bag Contents:

Q t y.D e s c r i p t i o n Looks Like

3Container Mounting Bracket

3Stud Plate

2 Screw, Pan Head, 10-32 x 3/8”

3 Screw, Sht. Mtl., #10 x 5/8”

4 Screw, Sht. Mtl., #10 x 1/2, Blk.

8Hex Nut, Self-Lock, 10-32

4 Washer, #10

3 Tinnerman Clips

3Leg Caps

36 Cutting Lines

A . Preparation

Your owner’s manual has been developed to help

you assemble the unit and to understand its safe

operation. It is important that you read your manual

completely to become familiar with the unit before

you begin assembly.

1. Read your owner’s manual

2. Tools you will need:

#2 Phillips Head Screwdriver

3/8” Nut Driver

page 3

ASSEMBLY (continued)

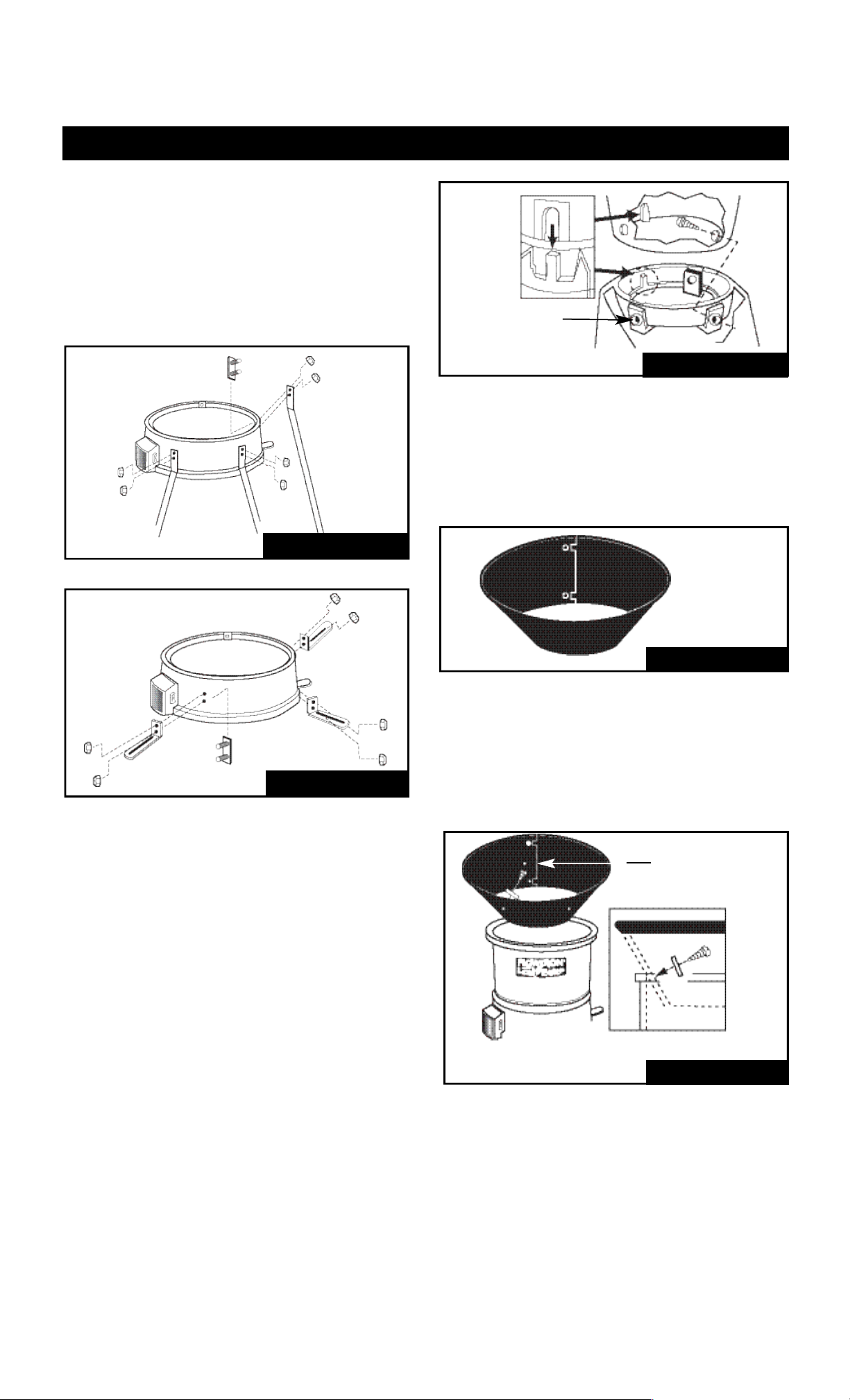

1 . A s s e m b ling Legs or Mounting Brack e t s

To install the three legs or the three mounting

brackets, align the three stud plates with the six

mating holes in the lower housing. Fasten the legs

or brackets with the six #10 - 32 self-locking hex

nutsas shown in Figures #3 or #4. When using

the legs,slip the three leg caps onto the end of

each leg.

2 . A s s e m b le Upper and Lower Housing

Install the three Tinnerman Clips onto the edge of

the Lower Housing in areas provided. Place both

Upper Housing and Lower Housing upside down

and align the slot in the edge of the Upper Housing

with the tab on the Lower Housing. Push the Lower

Housing down until it is seated firmly in the Upper

Housing. Position the assembly in the upright posi-

tion and fasten both housings together using the

three #10 x 5/8” sheet metal screws as shown in

Figure #5.

TINNERMAN CLIP

(THREE PLACES)

FIGURE 5

FIGURE 6

3 . A s s e m ble Funnel

Assemble funnel with tabs on outside and screw

together in two places using 10-32 x 3/8” screws

and 10-32 hex nuts. Place screw heads on inside

with nuts on outside.

4 . A t t a c h Funnel to Upper Housing

Align four (4) holes in Funnel with four holes in

Housing and fasten securely using four #10 x 1/2”

screws and #10 flat washer as shown in cutaway

view in figure 7.

#10 X 1/2" SCREW

AND #10 FLAT

WA S H E R

FIGURE 7

FIGURE 3

FIGURE 4

1 . Become familiar with all sections of this owner’s

manual before attempting to operate the shredder.

This shredder should be used solely for the pur-

pose it was intended.

2 . Use only parts or accessories specifically designed

for use with this shredder. Using other parts or

accessories could increase risk of injury.

3 . Keep Children Away – all visitors should be kept at

a distance from the work area.

4 . Never allow your hands or any part of your body or

clothing inside the upper housing area.

5 . Avoid DangerousEnvironments – do not use

shredder in damp or wet locations. Do not operate

or store shredder in wet areas. Do not operate in

rain. Store indoors when not in use, in a dry, and

high or locked-up place — out of reach of children.

6 . This shredder should be operated on a solid, level

s u r f a c e .

7 . Dress Properly – do not wear loose clothing or

j e w e l r y. They can be caught in moving parts. Use

of work gloves and substantial footwearis advised

when working outdoors. Wear protective hair cov-

ering to contain long hair.

8 . Stay Alert – Watch what you are doing. Use com-

mon sense. Do not operate shredder when you are

t i r e d .

9 . Do not Abuse Power or Extension Cords – Never

carry unit by its power cord or yank cord to discon-

nect from receptacle. Keep all cords clean and

away from heat, oil and sharp edges and inspect

for damage before each use.

1 0 . Ground unit properly. Follow instructions on page 7

when connecting to electrical outlet.

11 . Warning – To reduce the risk of electrical shock,

use only an extension cord intended for outdoor

use. See page 7 for additional information on

extension cords.

1 2 . Ground fault circuit interrupter (GFCI) protection

should be provided on the circuit(s) or outlet(s) to

be used for this shredder. Receptacles are avail-

able having built-in GFCI protection and may be

used for this measure of safety.

1 3 . If it is necessary for any reason to inspect, clean or

repairthe shredder, turn the shredder off and wait

until it comes to a complete stop, then disconnect

the power cord before attempting such inspection

or repair.

1 4 . Disconnect shredderfrom the power source when

not in use, before servicing, and when changing

cutting lines.

1 5 . When feeding material into the shredder be

extremely careful that pieces of metal, rocks, bot-

tles, cans or other foreign objects are not included.

1 6 . Do not force the shredder. It will do the job better

and with less likelihood of a risk of injury when

used at the rate for which it was designed.

1 7 . If the cutting mechanism strikes a foreign object or

if your shredder should start making an unusual

noise or vibration, immediately switch it off, wait

until the shredder has come to a complete stop,

then disconnect the power cord and take the fol-

lowing steps:

A. Remove any foreign or clogged material.

B. Check for any loose parts and tighten to

assure continued safe operation

C. Replace or repair any damaged parts.

1 8 . Avoid unintentional starting. Be sure switch is off

when plugging in the shredder.

1 9 . Always use safety glasses and face or dust mask if

operation is dusty.

2 0 . Check discharge area periodically after stopping

shredder to assure the processed material does

not build up and clog motor cooling vents.

2 1 . Do Not Overreach – keep proper footing and bal-

ance at all times.

2 2 . Do not move shredder when motor is running or

with finger on the switch.

2 3 . Maintain Shredder With Care – Follow instructions

for replacing cutting lines and for cleaning air fil t e r.

Inspect shredder power cord periodically, and if

damaged, have it repaired by an authorized serv-

ice facility. Keep handles dry, clean, and free from

oil and grease.

2 4 . Check Damaged Parts – Before further use of the

s h r e d d e r,any part that is damaged should be

carefully checked to determine that it will operate

properly and perform its intended function. Check

for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and anyother

condition that may affect its operation. A guard or

other part that is damaged should be properly

repaired or replaced by an authorized service cen-

ter unless indicated elsewhere in this manual.

SAFETY RULES AND PRECAUTIONS

Wa r n i n g : To reduce the risk of fir e , electric shock , and personal injury, the fo l l o w i n g

basic safety precautions should alw a ys be fo l l ow e d .

READ ALL INSTRUCTIONS

S AVE THESE INSTRUCTIONS

page 4

page 5

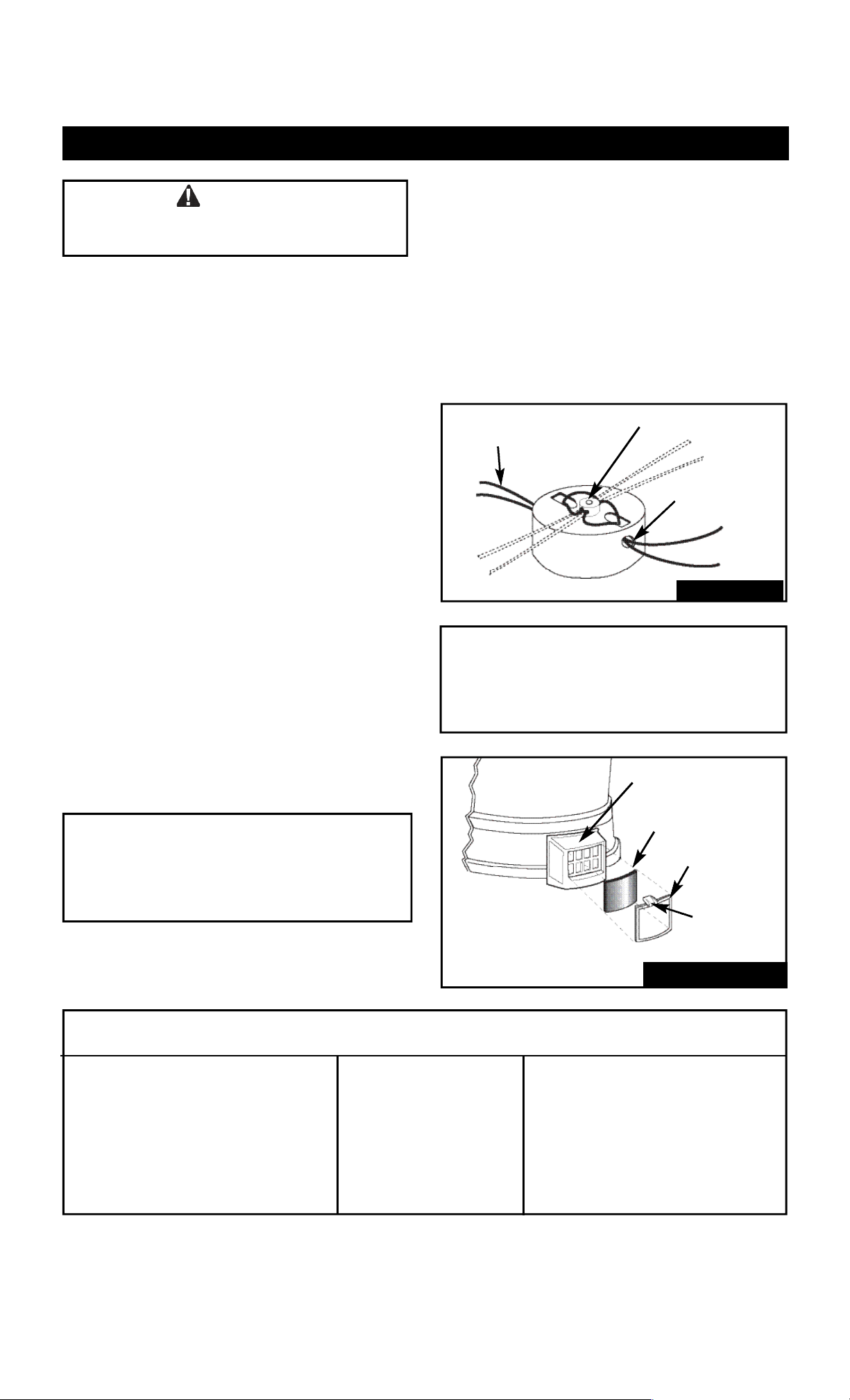

1 . On/Off Switch

The On/Offswitch is located on the side of the

Lower Housing. To turn unit on push switch to “On”

position, see figure 10. To turn unit “Off” push switch

down to “Off” position, see figure 10.

2 . C i r cuit Breaker/Reset Button

The circuit breaker/reset button is located on the

l o w e r, outside front of the motor housing as shown

in figure 10. The unit is designed to shut down in

the event of an overload. To restart, place on/off

switch in “off” position, push reset button, wait

approximately three minutes and then place switch

in “ON” position.

ELECTRICAL REQUIREMENTS

I m p o r t a n t : Use a 14 ga. or heavier extension cord with a maximum length of 100 ft.

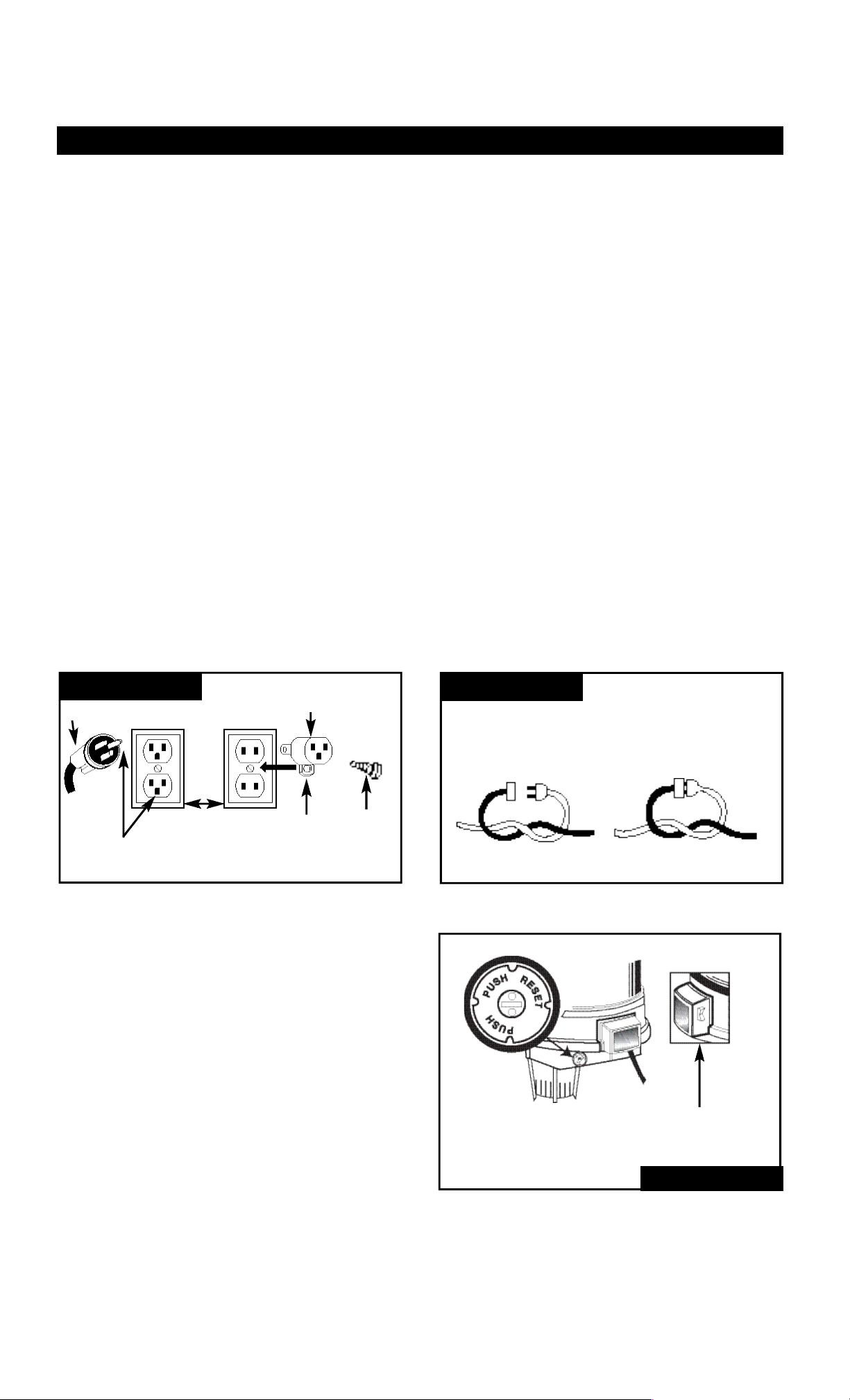

G r ounding Instructions

This shredder should be grounded while in use to

reduce the risk of electric shock to the operator.

The shredder is equipped with a three-conductor

cord and three-prong grounding plug. The green or

green and yellow conductor in the cord is the

grounding wire. Never connect the green or green

and yellow wire to a live terminal.

The shredder is intended for use on a circuit that

has a grounded outlet box that looks like the one

illustrated in figure 8, sketch A .

An adapter which looks like the adapter illustrated

in figure 8, sketch B is available for connecting

three-prong plugs to two-prong receptacles. T h e

green colored rigid ear, lug, or the like on the

a d a p t e r, must be connected to a permanent

ground, such as a properly grounded outlet box,

using a metal screw.

Check with a qualified electrician or serviceman if

the grounding instructions are not completely

understood, or if in doubt as to whether the shred-

der is properly grounded.

Extensions Cord s

Only use three-wire extension cords that have

three-prong grounding plugs and three-hole recep-

tacles that accept the shredder’splug. When using

an extension cord, make sure that it is in good con-

d i t i o n .

Use a 14 ga. or heavier extension cord with a max-

imum length of 100 ft. An undersized extension

cord will cause a drop in line voltage resulting in

lossof power and overheating.

Warning – To reduce the risk of electric shock, only

use extension cords intended for outdoor use, such

as cord types SW-A, SOW- A ,

S T W -A, STO W -A, SJW-A, SJOW-A, SJTW- A o r

S J T OW -A.

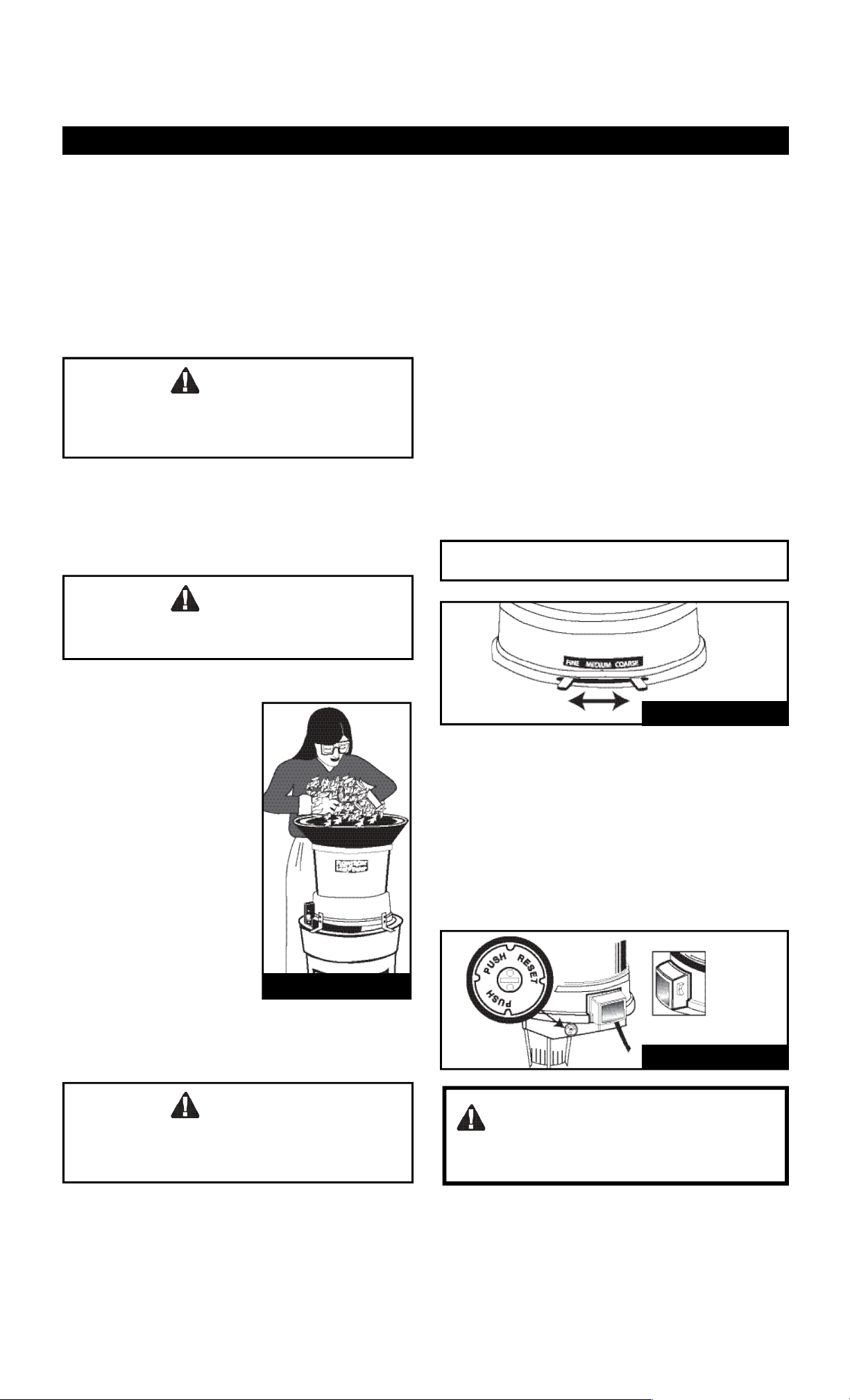

To prevent disconnection of the shredder cord from

the extension cord during operation, make a knot

as shown in figure 9. Devices for retaining exten-

sion cords are also available at your local hardware

r e t a i l e r.

FIGURE 8 FIGURE 8

G ROUNDING METHOD

( A )

G R O U N D I N G

P I N

P L U G

L U G M E TA L

S C R E W

A D A P T E R

( B )

COVER OF

G R O U N D E D

O U T L E T B O X

METHOD OF SECURING EXTENSION CORD

( B )

E X T E N S I O N

C O R D

TIE CORD AS SHOW

C O N N E C T PLUG & RECEPTA C L E

S H R E D D E R

C O R D

( A )

MOTOR INFORMATION

FIGURE 10

O N / O F F

S W I T C H

C I R C U I T B R E A K E R /

R E S E T S W I T C H

page 6

SAFE OPERATING INSTRUCTIONS

Disconnect power cord from extension cord

before moving machine from one location to

another location.

C AU T I O N

Your Flow t ron Leaf-Eater can be hazardous if impro p e r l y or carelessly used.

The instructions and figures shown below demonstrate the right way to use your mach i n e.

Read and understand the operating instructions before you operate your mach i n e .A l w a ys use

s a f e and cautious operating methods.

Please remember the operating and safety instructions have been written for your use. Fa i l u r e

to read all instructions may result in injury.

Be sure you have read “Rules for Safe Operation” b e f ore pro c e e d i n g .

1 . M o ving Your Unit

Disconnect the power cord from the extension

cord or power source, grasp the unit along the

ridge on the Upper Housing, liftand move to wher-

ever you choose.

Wear Safety Glasses when operating this

machine.

C AU T I O N

Do not operate your machine without the funnel

a t t a c h e d .

C AU T I O N

2 . Loading Your Mach i n e

With the machine running,

feed double handfuls of dry

leaves, or single handfuls

of wet leaves,into the hop-

p e r. Allow the machine to

shred the load completely

and regain speed before

reinserting the next load.

Do not overload the

machine by letting it labor

at low speed: this will

cause the circuit breaker to

shut the motor off. If this

happens, turn the switch

o f f, unplug the machine,

clear the unshredded

material from the hopper,

reset the breaker and continue

with your shredding.

FIGURE 12

3 . M u l c hing Control Lev e r

The Control Lever, see figure 12, controls the parti-

cle size and speed at which material goes through

the unit. With the Control Lever in the Coarse posi-

tion, material will process through the unit faster but

will give you a larger particle size than if the lever

were in the Fine position. The Fine position setting

will discharge material slower but will give the small-

est particle size.

F i n e : 3 0 - 1 M e d i u m : 1 5 - 1 C o a r s e : 8 - 1

Do not allow shredded material in trash

container or leaf bag to reach bottom of

motor housing. A reduction in airflow will

result and may cause permanent dam-

age to your motor

4 . C i r cuit Breaker

This machine is equipped with a circuit breaker that

is designed to shut off the machine in the event of

an overload. To restart your machine after the circuit

breaker activates,place On/Offswitch to the “Off ”

position, push in on the Reset Button, figure 13,

and wait for approximately three minutes. A f t e r

three minutes place the On/Off switch to the “On”

position and continue to operate.

FIGURE 13

FIGURE 11

page 7

MAINTENANCE

Disconnect power cord from power source

before attempting any maintenance.

C AU T I O N

1 . Cleaning Your Unit

Your unit requires a minimum of maintenance other

than cleaning. It is recommended that you clean out

built-up residue from inside the Housing area, and

from between Mulching Discs during and after each

use. Also tighten all nuts, boltsand screws periodi-

c a l l y.Replace cutting line as often as necessary,

see below, and clean Air Filter frequently, see fig u r e

15. Any other maintenance or repairs should be per-

formed by an authorized Flowtron Service Station.

2 . R e m o val/Replacement of Cutting Line

Your unit is supplied with six strips of six (6) cutting

lines each (for a total of 36 cutting lines). To separate

individual lines simply pinch the indent between lines

nearest strip end and peel away.

Replace cutting cord when a noticeable decrease in

shredding efficiency is observed. To remove used

cutting lines pull used line out of the spinner head

inside the housing. To install new cutting lines place

each end of new line through the two holes in the

post on top of the spinner head and pull through so

that both ends of the line are even. Thread lines

through the two ferrules on the side of the spinner

head and pull tight so that ends are even.

See figure 14.

WARNING: Use only .080 diameter monofilament

cord 12 3/4" long. Use of thicker lines, lines made

of substitute materials, or lines greater than 12 3/4"

long MAY RESULT IN PERMANENT DAMAGE TO

YOUR MOTOR AND/OR INJURY.

Tro u b le Shooting

S y m p t o m P r o bl e m C o r r e c t i o n

Motor will not start No electric power. Check to be sure power cord is connected to

the power source.

Circuit breaker has tripped. Clean filter and residue inside housing.

No cutting action. Cutting line is worn or residue Replace cutting line with new line.

is built-up inside of housing. Clean out built-up residue in housing.

Motor does not sound like it is running properly. Air filter is dirty. Remove and clean air filter.

Circuit breaker trips. Unit bound with debris. Clean unit.

N o t e : LER-100 Cutting Line Kit for model

LE 800 contains 12 replacement lines and may be

purchased from your local dealer.If not available,

order direct from Flowtron Outdoor Products or on

line at w w w. flow t ro n . c o m .

3 . R e m o val/Cleaning Air Filter

The Air Filter is located on the side of the Lower

Housing by the On/Off switch. To remove push down

and out on the tab on top of the Filter Cover, see fig-

ure 15. Remove Air Filter and rinse with clear water

and air dry. Replace Air Filter before using machine.

I m p o r t a n t

Do not attempt to run or use your machine with

the Air Filter removed. Check frequently to

insure that the Air Filter is clean. Always discon-

nect the power cord prior to removing Air Filter.

FIGURE 15

AIR FILTER HOUSING

AIR FILTER ELEMENT

air filter cover

TAB: PUSH

DOWN A N D

O U T

B O T H E N D S

M U S T B E E V E N

P U T T H R O U G H

F E R R U L E H O L E

T H R E A D T H R O U G H TO P H O L E

FIGURE 14

357 3389 REV 5

page 8

2 1

1 7

1 8

2 4

1 9

2 0

4

2 3

2 2

1 6

1 5

1 4

1 2

3 6

3 9

3 8

2 6

2 7

4 0

2 9 3

3 0

1 2

1 3

3 1

3 7

3 2

4

4 2

3 4

3 5

1 0

11 9

8

7

1 8

W H I T E

G R E E N

2 5

3 3

4 1

1 2

3 3

2 8 5

6

3 5

2 8

2 0

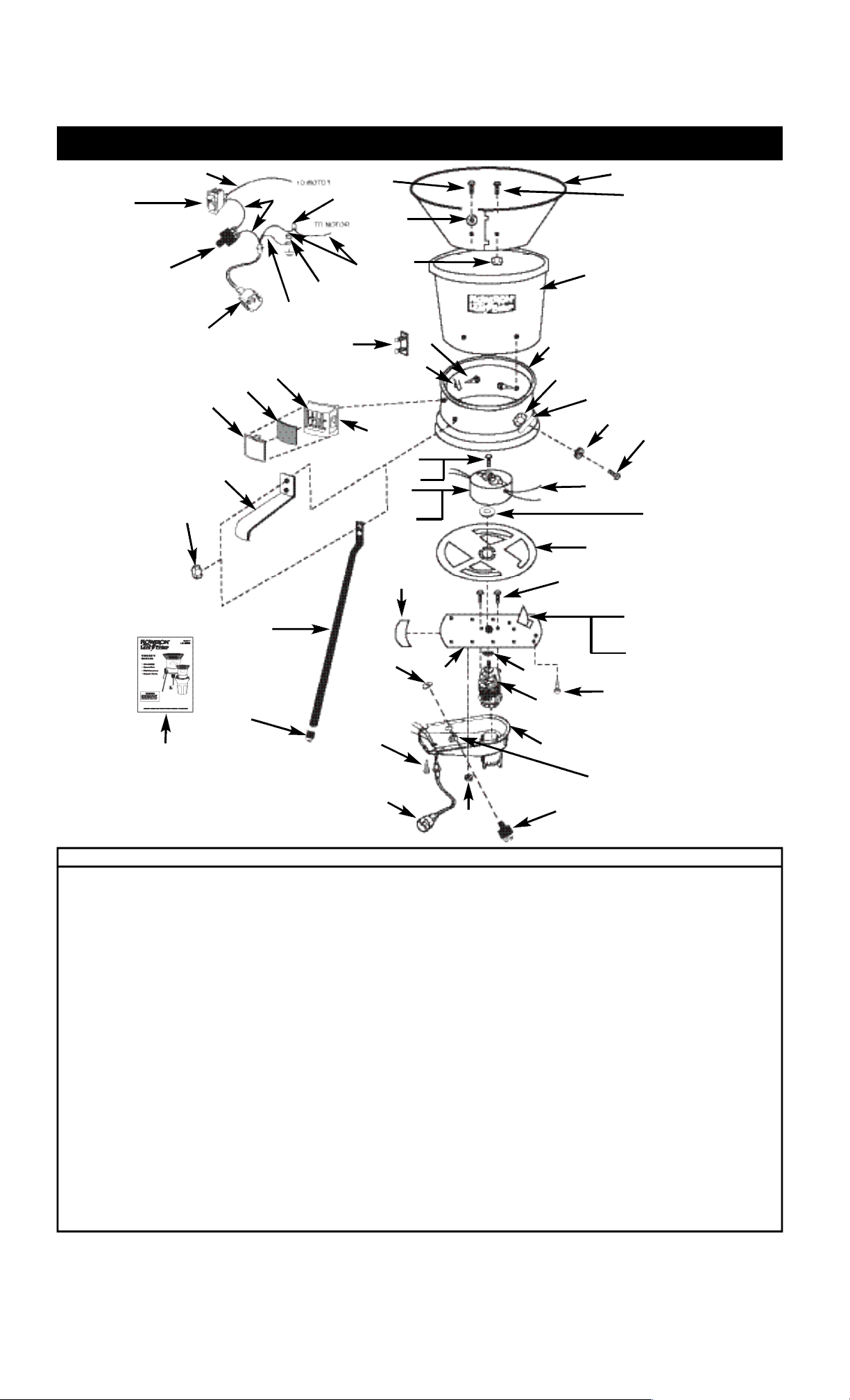

Ref. # Part # Description Qty.

1 355 1672 F U N N E L 1

2 245 6237 P40 S C R E W, SHT. MET., PAN HD., PHIL, #10 x 1/2, BLK. 4

3 355 3103 DISK SUPPORT 3

4 245 6269 P06 HEX NUT, 10-32, SELF-LOCK 8

5 245 6225 P51 S C R E W, PAN HD., PHIL, BLACK, 10-32 x 3/8 2

6 355 1305 UPPER HOUSING 1

7 345 1316 TINNERMAN CLIP 3

8 245 6236 P41 S C R E W, SHT. MTL. #10 x 5/8” 3

9 305 3530 LOWER HOUSING A S S Y. 1

1 0 396 2877 p01 CUTTING LINE 2

11 305 3399 STUD PLAT E 3

1 2 245 6269 P33 HEX NUT, 10-32, BLACK, SELF-LOCK 11

1 3 345 2978 S C R E W, PHIL, HD, #10-24 x 3/8 2

1 4 368 3392 P1 L E G 3

1 5 352 3430 PL5 C O N TAINER MOUNTING BRACKET 3

1 6 596 494LEG CAP 3

1 7 355 3105 S PACER, CIRCUITB R E A K E R 1

1 8 394 3511 C I R C U I T B R E A K E R 1

1 9 367 1429 P01 M O T OR PLATE SEAL 1

2 0 312 2517 POWER CORD 1

2 1 355 2062 M O T OR DUCT 1

Ref. # Part # Description Qty.

2 2 345 3501 PA N E L N U T, CIRCUITB R E A K E R 1

2 3 379 3449 M O T O R 1

2 4 305 3395 MOUNTING PLATE A S S E M B LY, MOTO R 1

2 5 566 399 P O P R I V E T, 1/8” 2

2 6 355 3096 MULCHING DISC 1

2 7 305 1779 SPINNER HEAD A S S E M B LY 1

2 8 394 3014 SWITCH, ON/OFF 1

2 9 355 1304 F I LTER COVER 1

3 0 367 1884 F I LTER ELEMENT 1

3 1 355 1303 F I LTER HOUSING 1

3 2 595 1506 WIRE NUT 1

3 3 245 6245 P28 S C R E W, SHT. MET., HEX HD., #8 x 1/2” 3

3 4 245 6225 P54 S C R E W, PAN HD., PHIL, BLACK 10-32 x 3/4” 3

3 5 245 6272 P24 F L AT WASHER, BLACK, #10 7

3 6 345 3512 NYLON SCREW 1

3 7 352 3149 C U T OFF BLADE 1

3 8 345 1683 JAM WASHER, SPINNER 1

3 9 567 4675 “O” RING (NOTS H O W N ) 1

4 0 369 1689 I N S E R T, SPINNER (NOTS H O W N ) 1

4 1 567 9929 “O” RING 1

4 2 357 3389 OWNER’S MANUAL 1

FLOWTRON EXPLODED VIEW OF LE-800B

B L AC K

W H I T E

21

Table of contents

Popular Paper Shredder manuals by other brands

Royal

Royal 112MX Operation manual

WHITAKER BROTHERS

WHITAKER BROTHERS intimus 26SC2 operating instructions

SEM

SEM 2226 Series Operation and maintenance manual

Intimus

Intimus 240 Crusher operating instructions

UNITED OFFICE

UNITED OFFICE UAV 150 A1 - 5 operating instructions

Fellowes

Fellowes POWERSHRED 90S instructions

UNITED OFFICE

UNITED OFFICE UAV 380 A1 - 2 operating instructions

KRUG+PRIESTER

KRUG+PRIESTER IDEAL 2604 operating instructions

Fellowes

Fellowes DS-3 user manual

Fellowes

Fellowes POWERSHRED 90S instructions

UNITED OFFICE

UNITED OFFICE UAV 190 B2 operating instructions

Techko

Techko AUTOTECH HAF080 Operation instructions