Fluidwell C401 User manual

Page 1

FW-C401-M_v0105_01_EN.docx

C401

DISPENSER

Signal input flowmeter: RS485 Modbus master interface

Options: RS232 FTL Communication for Truck On Board Computer

RS232 Ticket Printer Communication (ASCII)

C-Series - Indicators and Controllers for custody transfer in hazardous areas.

More info: www.fluidwell.com/cseries.

Page 2

FW-C401-M_v0105_01_EN.docx

SAFETY INSTRUCTIONS

•Any responsibility is lapsed if the instructions and procedures as described in this manual

are not followed.

•LIFE SUPPORT APPLICATIONS: The C401 is not designed for use in life support

appliances, devices, or systems where malfunction of the product can reasonably be

expected to result in a personal injury. Customers using or selling these products for use

in such applications do so at their own risk and agree to fully indemnify the manufacturer

and supplier for any damages resulting from such improper use or sale.

•Electro static discharge does inflict irreparable damage to electronics! Before installing or

opening the C401, the installer has to discharge himself by touching a well-grounded

object.

•The C401 must be installed in accordance with the EMC guidelines (Electro Magnetic

Compatibility).

•Do connect a proper grounding to the housing as indicated if the C401 is used on a ship,

truck or other application with no physical earth.

DISPOSAL OF ELECTRONIC WASTE

•At the end of its life this product should be disposed of according to the (inter)national

regulations regarding waste electronic equipment. If a battery is installed in this product it

should be disposed of separately. The separate collection and recycling of your waste

equipment will help to conserve natural resources and ensure that it is recycled in a

manner that protects the environment.

SAFETY RULES AND PRECAUTIONARY MEASURES

•The manufacturer accepts no responsibility whatsoever if the following safety rules and

precautions instructions and the procedures as described in this manual are not followed.

•Modifications of the C401 implemented without preceding written consent from the

manufacturer, will result in the immediate termination of product liability and warranty

period.

•Installation, use, maintenance and servicing of this equipment must be carried out by

authorized technicians.

•Check the mains supply voltage and information on the manufacturer's plate before

installing the C401.

•Check all connections, settings and technical specifications of the various peripheral

devices with the C401 supplied.

•Never open the enclosure in hazardous areas while connected to power supplying or

consuming devices other than the internal battery supply.

•Open the C401 only if all leads are free of potential.

•Never touch the electronic components (ESD sensitivity).

•Never expose the system to heavier conditions than allowed according to the enclosure

classification.

•If the operator detects errors or danger, or disagrees with the safety precautions taken,

then inform the owner or principal responsible.

•The local labor and safety laws and regulations must be adhered to.

Page 3

FW-C401-M_v0105_01_EN.docx

ABOUT THE OPERATION MANUAL

This operation manual is divided into two main sections:

•The daily use of the C401 is described in chapter 2 “Operational”. These instructions are meant

for users.

•The following chapters and appendices are exclusively meant for electricians/technicians. These

provide a detailed description of all software settings and hardware installation guidance.

This operation manual describes the standard C401 as well as most of the options available. For

additional information, please contact your supplier.

A hazardous situation may occur if the C401 is not used for the purpose it was designed for

or is used incorrectly. Please carefully note the information in this operating manual

indicated by the pictograms:

A "warning !" indicates actions or procedures which, if not performed correctly, may lead to

personal injury, a safety hazard or damage of the C401 or connected instruments.

A "caution !" indicates actions or procedures which, if not performed correctly, may lead to

personal injury or incorrect functioning of the C401 or connected instruments.

A "note !" indicates actions or procedures which, if not performed correctly, may indirectly

affect operation or may lead to an instrument response which is not planned.

Hardware version : CM110104 / CD110104

Software version : LR: 01.05.01 / NLR: 01.03.01

Manual : FW-C401-M_v0105_01_EN.docx

© Copyright 2021 : Fluidwell B.V. –The Netherlands.

Information in this manual is subject to change without prior notice. The manufacturer is

not responsible for mistakes in this material or for incidental damage caused as a direct

or indirect result of the delivery, performance or use of this material.

© All rights reserved. No parts of this publication may be reproduced or used in any form

or by any means without written permission of your supplier.

Page 4

FW-C401-M_v0105_01_EN.docx

CONTENTS MANUAL

SAFETY INSTRUCTIONS....................................................................................................................................2

DISPOSAL OF ELECTRONIC WASTE................................................................................................................2

SAFETY RULES AND PRECAUTIONARY MEASURES.....................................................................................2

ABOUT THE OPERATION MANUAL...................................................................................................................3

CONTENTS MANUAL..........................................................................................................................................4

1INTRODUCTION.....................................................................................................................................5

1.1 System description of the C401............................................................................................... 5

2OPERATIONAL......................................................................................................................................6

2.1 General information ................................................................................................................. 6

2.2 Operator information and functions ......................................................................................... 6

2.3 Control panel............................................................................................................................ 7

2.4 Making deliveries ..................................................................................................................... 9

2.5 Forced stop............................................................................................................................ 11

2.6 Error information .................................................................................................................... 11

2.7 Delivery record.......................................................................................................................13

3CONFIGURATION AND INFORMATION.............................................................................................15

3.1 General .................................................................................................................................. 15

3.2 MENU- and SETUP-level....................................................................................................... 15

3.3 MENU: Zeigen Logbuch......................................................................................................... 17

3.4 MENU: Zertifikat ansehen (QR-code)....................................................................................18

3.5 MENU: Zeigen Gerätinformationen .......................................................................................19

3.6 MENU: Zeigen Coriolis-Informationen...................................................................................19

3.7 MENU: Setup aufrufen........................................................................................................... 20

3.8 Configuration with Configuration Tool.................................................................................... 23

3.9 Ticket printing.........................................................................................................................24

4INSTALLATION....................................................................................................................................26

4.1 General directions..................................................................................................................26

4.2 Installation / surrounding conditions ...................................................................................... 26

4.3 Mechanical Installation........................................................................................................... 27

4.4 Electrical Installation..............................................................................................................28

4.5 Terminal Connectors.............................................................................................................. 29

4.6 USB connection.....................................................................................................................30

5CERTIFICATIONS................................................................................................................................31

5.1 Hazardous Area Applications ................................................................................................ 31

5.2 Custody Transfer Applications...............................................................................................31

5.3 Label information ................................................................................................................... 35

6MAINTENANCE....................................................................................................................................36

6.1 General directions..................................................................................................................36

6.2 Replacement of RTC backup battery..................................................................................... 36

6.3 Changing or initializing an uninitialized clock ........................................................................37

TECHNICAL SPECIFICATION...............................................................................................38

PROBLEM SOLVING.............................................................................................................40

DECLARATION OF CONFORMITY.......................................................................................41

INDEX OF THIS MANUAL..................................................................................................................................42

LIST OF FIGURES .............................................................................................................................................43

Page 5

FW-C401-M_v0105_01_EN.docx

1 INTRODUCTION

1.1 SYSTEM DESCRIPTION OF THE C401

Functions and features

The C401 Dispenser is designed to be mounted inside a cabinet on a trailer to perform deliveries of

Hydrogen or other gasses in combination with a Rheonik Coriolis flowmeter with RHE28 or similar

transmitter.

This product has been designed with a focus on:

•Good readings in full sunlight and darkness through a bright backlight.

•Ruggedness for harsh surrounding

•Usability: wide operational temperature, high ingress protection rating and international

certification.

•Aluminum enclosure with high quality industrial two component coating.

•High quality electronics to meet extreme applications.

Fig. 1: Overview of the C401 Dispenser

For the application “Truck dispensing of Hydrogen” (or other gasses), the C401 consists of a large

graphical LCD screen with backlight and six solid control keys. By default, the C401 will act at

Operator level. For more advanced users there is a Menu available from where several extended

functions are available. Also a Setup level to configure the C401 can be reached from the Menu.

Page 6

FW-C401-M_v0105_01_EN.docx

2 OPERATIONAL

2.1 GENERAL INFORMATION

This chapter describes the daily use of the C401. This instruction is meant for users / operators.

The display must show BEREIT in order to make valid custody transfer deliveries.

•The C401 may only be operated by personnel who are authorized and trained by the

owner of the installation. All instructions in this manual are to be observed.

•Take careful notice of the “Safety rules, instructions and precautionary measures”in the

front of this manual.

By default, the C401 shows delivery information based on mass. By enabling the volume

calculation functions, the unit can also be configured to show volume deliveries.

On the right side of the display, the selected measurement unit is shown together with

the Volumen or Masse flag for volume and mass indication. Anywhere at operator level,

pressing the ▲or ▼key causes the display to switch from volume to mass, and vice-versa.

2.2 OPERATOR INFORMATION AND FUNCTIONS

When the C401 Dispenser is at Operator level and ready to perform a new task, one of the following

delivery screens is shown, depending on the configuration of the volume calculation functions:

At the top of the screen a status bar is displayed. Below the status bar, the main part of the screen is

used to show the actual process values. These contain the totalized mass or volume for the current

delivery (Gelieferte Menge) and the actual mass or volume flow rate (Durchfluss).

On the right side of the display, the corresponding measurement units are displayed, together with

the Volumen or Masse flag for volume and mass indication. Anywhere at operator level, pressing

the ▲ or ▼ key will cause the display to switch from volume to mass, and vice-versa. After about 20

seconds the display will return to the default unit, as configured in the menu.

When the quantity is shown in units of volume, the temperature, pressure and density at reference

conditions are also indicated.

The status bar contains the following information:

•On the left side of the status bar, the current time and date are shown. This gives the operator

the possibility to verify the correct setting of time and date at any time. If enabled in the

configuration, the clock is automatically adjusted for summer time and winter time.

During a delivery, this indication will change to show the current duration (Dauer) of the delivery.

•On the right side of the status bar, either a text appears or status icons appear, to give

information about the C401.

The text indication includes:

oVerbunden: connected to the Flowmeter

oGetrennt: disconnected from the Flowmeter

The icons show:

oIcon : Indicates the connection to the Flowmeter. When blinking, the connection

is not available (Getrennt), when shown permanently the connection is good

(Verbunden).

oIcon : Indicates an (internal) error status is present.

oIcon : Indicates the unit is ‘unlocked’. When this icon is shown, the C401 is NOT

ready to start a new dispense action as it has been put into service mode.

Page 7

FW-C401-M_v0105_01_EN.docx

•In the middle of the status bar, the current process status is indicated.

Currently following statuses (indicated in German, English and French) are available:

German

English

French

Status description

BEREIT

READY

PRET

The C401 is ready to start a new dispense

action.

SERVICE

SERVICE

SERVICE

The C401 is NOT ready to start a new

dispense action as it has been put into service

mode. Consult chapter 5 on how to return to

operational mode.

ZEROING

ZEROING

ZEROING

The C401 has sent the Zeroing command to

the Flowmeter and is waiting for it to finish the

Zeroing process.

LIEFERN

RUNNING

LIVRER

The actual delivery process is started, the

quantity that passes through the Flowmeter is

recorded and added to the delivered quantity

(Gelieferte Menge).

BEENDEN

ENDING

FINIR

The dispense process is being stopped and

the C401 is waiting for the flow to reach 0

(zero).

KOMPLETT

COMPLETE

TERMINE

The delivery process is finished and the C401

shows a delivery summary.

Depending on the selected display language, the C401 will show its status either in German,

English or French as indicated in the previous table.

For the remainder of this manual, all references to the status will be shown in German.

When specific user interaction is required, an instruction for the operator will be shown at the bottom

of the screen. E.g. ‘Drücke CLEAR zum Fortfahren’.

2.3 CONTROL PANEL

The following keys are available:

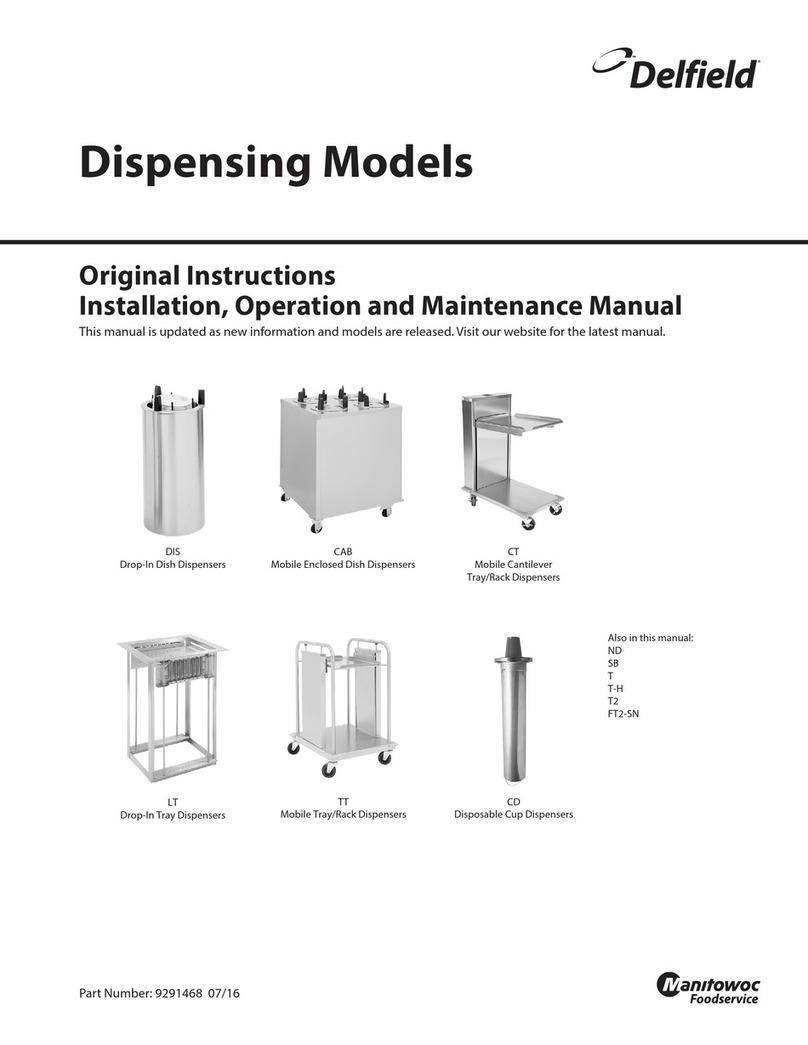

Fig. 2: Control panel

The functions of the keys at operator level, depend on the actual status of the C401:

Functions of the keys in BEREIT status

The operator can perform the following actions:

START key

This key is used to start a new dispense operation.

00 key

This key is used to zero the Flowmeter without starting a new dispense operation.

Note that the zeroing process can take up to 2 minutes to complete.

PROG / ENTER key

This key is used to gain access to the Menu (press and hold the key for 3 seconds).

▲ or ▼key

These keys can be used to switch between Masse indication

and Volumen indication (if volume calculation functions are enabled).

Page 8

FW-C401-M_v0105_01_EN.docx

Functions of the keys in ZEROING status

The operator cannot perform any operation and has to wait until the zeroing process finishes.

The following action is available:

▲ or ▼key

These keys can be used to switch between Masse indication

and Volumen indication (if volume calculation functions are enabled).

Functions of the keys in LIEFERN status

The operator has the possibility to perform the following actions:

STOP / CLEAR key

This key is used to stop the current dispense operation.

▲or ▼key

These keys can be used to switch between Masse indication

and Volumen indication (if volume calculation functions are enabled).

Functions of the keys in BEENDEN status

The operator cannot perform any operation and has to wait until the ending process finishes.

However, if this process does not finish within 5 minutes, a forced stop can be given.

The following actions are available:

STOP / CLEAR key

This key is used to perform a forced stop by pressing it for at least 3 seconds in the

rare event that the flow rate does not return to zero (0).

This function only becomes available after a 5 minute waiting period and is indicated

on the display with a warning text.

▲or ▼key

These keys can be used to switch between Masse indication

and Volumen indication (if volume calculation functions are enabled).

Functions of the keys in KOMPLETT status

A summary of the delivery is shown and the operator has the possibility to perform the following

actions:

STOP / CLEAR key

This key is used to close the current dispense operation and return the C401

to BEREIT status..

▲or ▼key

These keys can be used to switch between Masse indication

and Volumen indication (if volume calculation functions are enabled).

Any error received from the Flowmeter during the delivery process is logged but not displayed to the

Operator. Instead, an alarm indication is given and error information can later on be reviewed in the

logbook.

Page 9

FW-C401-M_v0105_01_EN.docx

2.4 MAKING DELIVERIES

2.4.1 Powering up

After power-up, the C401 will show the BEREIT status on the screen, together with the delivered

quantity (initialised to 00000.000) and the current flow rate as given by the Flowmeter.

Depending on the configuration of the volume calculation functions, the display either starts

with Masse indication or Volumen indication.

2.4.2 Zeroing the flowmeter

After each power-up, the flowmeter needs to be initialised. This is automatically done by the C401

by sending the Zeroing command to the flowmeter every time a new delivery is started.

The Zeroing process is also started manually when the operator presses the 00 /◄key

in BEREIT status. The process usually takes about 90 seconds to complete and cannot be

interrupted, nor can the operator cannot perform any operation on the C401 during that time.

During the zeroing process, the ZEROING status is shown on the display. However, when

initiated by starting a new delivery, the first few seconds of the zeroing procedure will be used to

show a checker-field on the display to indicate that it is working correctly.

At the end of the Zeroing process, the flow rate will display zero (0). If the Zeroing process was

initiated by the start of a delivery, the C401 continues in LIEFERN status. When it was initiated

by the operator, the C401 will return to the BEREIT screen.

If the Zeroing operation was not successful (e.g. when the flowrate was not set to zero), an error will

be displayed.

The C401 waits for the flowmeter to finish the Zeroing process. If this fails, a 2 minute

timeout on the Zeroing process guarantees that the Zeroing process will always finish.

The time and date are normally configured by the installer and are internally updated

by a backup battery. In the rare event that the C401 starts up with an uninitialized

clock, this needs to be corrected before any delivery can be performed.

Please see paragraph 6.3: Changing or initializing an uninitialized clock on how to

correct this error.

Page 10

FW-C401-M_v0105_01_EN.docx

2.4.3 Delivery

When the C401 is in BEREIT status, a new delivery can be started by the operator by pressing

the START key. The date and time shown on the display will change to show the duration (Dauer) of

the delivery.

During the LIEFERN and KOMPLETT status, pressing the ▲or ▼ key causes the

display to switch between Masse indication and Volumen indication.

A delivery starts with the zeroing of the flowmeter (see previous paragraph).

When the initialisation is successful (flow rate should be zero), the delivery total is initialised, the

C401 enters the LIEFERN status and the operator can open the manual valve.

When the valve is opened, the delivery total starts incrementing and the actual flow rate is

continuously updated and shown on the display.

When the required amount is dispensed, the delivery is stopped by the operator by pressing the

STOP / CLEAR key. The C401 will now enter the BEENDEN status in which it waits for the flow rate

to drop down to zero (0). This is also the moment at which the operator must close the manual valve

within 5 minutes.

When the flow rate has reached zero (0), the C401 will enter the KOMPLETT status: the delivery

is completed and a delivery summary is shown indicating the delivered quantity, the duration of the

delivery and the unique delivery number (Lieferungsnummer).

When the operator presses the STOP / CLEAR key at this point, the C401 will return to

the BEREIT status.

Page 11

FW-C401-M_v0105_01_EN.docx

2.5 FORCED STOP

If, for some reason, it is not possible to return the flow rate to zero (0), the C401 will wait 5 minutes

before signalling a warning:

At this point, if the operator is able to stop the flow, the delivery will be finished without any error.

If the operator is not able to stop the flow, he can overrule this demand and force the delivery to stop

by pressing the STOP / CLEAR key for several seconds. The delivery will be finished and stored with

the delivery status ‘Forced stop’ (Zwangsstop).

2.6 ERROR INFORMATION

If an error occurs during a delivery, the error is logged and the delivery itself is marked as faulty. All

error information can then be reviewed in the error logbook and delivery logbook.

The presence of an error during a delivery is indicated by showing a large alarm symbol on the left

side of the screen. When the delivery is finished, the delivery summary will show the delivery status

with an error. In below example, the door was opened during the delivery, which raised an error:

The delivery summary only shows basic (textual) error information. If several errors are present, the

most severe error is shown, allowing the operator to determine if further investigation of the error is

required. For errors with a severity level higher than level 4 (Eich Schloss), it is recommended to

inspect the Int-error field in the delivery record as indicated in the following paragraph.

When the flow rate monitoring function is enabled, a flow alarm is indicated in the following way:

Although the low-flow limit (Low-Flow Grenze) and cut-off limit (Abschaltgrenze) flow alarms can

indicate a certain problem, these situations can also occur during a normal delivery process or basic

operations by the operator. Therefore, its occurrence does not trigger an error nor will a delivery be

marked as faulty.

Page 12

FW-C401-M_v0105_01_EN.docx

The below table shows the basic (textual) error information that can be displayed on the screen,

together with their respective severity level:

German

English

French

Level

Lieferstatus

Delivery

status

Etat

livraison

Meaning

8

Fehler

Error

Erreur

Other, more severe, errors occurred

during the delivery.

E.g. Error indicated by the transmitter of

the Coriolis flowmeter.

7

Zwangsstopp

Forced stop

Arrêt force

The delivery was forced to stop by the

user after the initial stop command and

following timeout period of 5 minutes.

During this time the flow rate did not

reach zero or communication with the

flowmeter was not possible.

6

Kein

Coriolis

No Coriolis

Aucun

Coriolis

During the delivery, the connection to the

flowmeter was lost.

5

Stromausfall

Powerdown

Eteindre

The delivery was stopped because the

power to the device was interrupted.

4

Eich Schloss

Metrological

lock

Verrou

métrologique

During the delivery, the metrological lock

was open / opened.

3

Servicemodus

Service mode

Mode service

During the delivery, the service mode

was active / activated.

2

Türschalter

Door switch

Contact de

porte

During the delivery, the door of the C401

was open / opened.

1

Zeit vom

Benutzer

Time set

by user

Heure par

utilisateur

The clock was set in user-mode and not

in service-mode.

0

Normal

Normal

Normal

The delivery was completed successfully

without errors.

For every delivery that does not finish with status Normal, the delivery itself is marked as faulty and

the delivery record will contain more extensive error information.

To provide more insight into the course of the faulty delivery, the moment at which the first error

occurred is recorded and the delivered quantity is split into two parts:

Part

German

English

French

Description

1

Gelieferte Menge

Delivered quantity

Quantité livrée

The delivered quantity before

the error-status occurred.

2

Gestörte Menge

Faulty quantity

Quantité erroné

The delivered quantity after the

error-status occurred.

Start

Stop

Delivery without errors

Delivered quantity

Start

Error occurred

Stop

Delivery with errors

Delivered quantity

Faulty quantity

Page 13

FW-C401-M_v0105_01_EN.docx

2.7 DELIVERY RECORD

When a delivery is finished, a record is created and stored in the delivery logbook (Logbuch

Lieferungen). The record of a successfully finished delivery contains the following information:

German

English

French

Fieldname

Description

Datensatznummer

Record number

No d'enregistr.

Internal record number

Lieferungsnummer

Delivery number

No de livraison

Unique number for this delivery

Status

Status

Etat

Status of the delivery when finished.

If the status is not ‘normal’, a basic

textual indication of the error is shown,

but it is advised to inspect the Int-Error

field for detailed error information.

Fahrzeug

Vehicle

Véhicule

Identification of the vehicle the

measuring system is install onto. E.g.

license plate.

Nullstellung

Zero time

Heure zéro

Timestamp start of zeroing-procedure of

the flowmeter

Lieferanfang

Start time

Heure début

Timestamp start of delivery

Lieferende

End time

Heure de fin

Timestamp end of delivery

Lieferdauer

Delivery

period

Durée

livraison

Time the delivery was running

(Time difference between the start and

end of delivery)

Zählerstand

Start

Meter read

start

Compteur

début

Flowmeter counter value at start of

delivery

Zählerstand

Ende

Meter read

end

Compteur

fin

Flowmeter counter value at end of

delivery

Gelieferte

Menge

Delivered

quantity

Quantité

livrée

Delivered quantity –without errors *

•When the delivery was finished

without errors, this indicates the

difference between the counter value

at the start of delivery and the

counter value at the end of delivery.

•When the delivery was finished with

errors, this indicates the difference

between the counter value at the start

of delivery and the counter value

when the (first) error occurred.

Dichte [Tb,Pb]

Density [Tb,Pb]

Densité [Tb,Pb]

Current density value *

Ref. Druck

(Pb)

Ref. pressure

(Pb)

Ref. press.

(Tb)

Reference pressure *

Ref. Temp.

(Tb)

Ref. temp.

(Tb)

Ref. temp.

(Pb)

Reference temperature *

Nullpunkt

Zero point

Point zéro

Zero point of flowmeter after zeroing-

procedure

Tube Temp.

Start

Tube temp.

start

Tube temp.

début

Flowmeter tube temperature at start of

delivery

Tube Temp.

Ende

Tube temp.

end

Tube temp.

fin

Flowmeter tube temperature at end of

delivery

* : Density, reference pressure, reference temperature and volumetric delivered quantity are only indicated when volume

conversion is enabled.

Page 14

FW-C401-M_v0105_01_EN.docx

When a delivery is finished with errors, the following additional error information becomes available:

German

English

French

Fieldname

Description

Lieferfehler

Error time

Heure erreur

Timestamp the (first) error occurred

Zählerstand

Fehler

Meter read

error

Compteur

erreur

Flowmeter counter value at the moment the (first)

error occurred

Gestörte

Menge

Faulty

quantity

Quantité

erroné

Delivered quantity –with errors *

•When the delivery was finished with errors, this

indicates the difference between the counter

value when the (first) error occurred and the

counter value at the end of the delivery.

* : Volumetric faulty quantity is only indicated when volume conversion is enabled.

Error fields

Description

Int-Error

Error status of the delivery.

This field contains a bitfield for the following error-bits:

0x0001 An error occurred during the delivery.

This can either be an error indicated by the Flowmeter or an (internal)

error of the device.

0x0002 Flowmeter error during zeroing procedure

0x0004 Flowmeter error during delivery

0x0008 The delivery was forced to stop by the user.

This generally happens when the flow does not reach zero within 5

minutes after the stop request and the user performs the forced stop

after this time.

0x0010 The device was powered down during the last delivery

0x0020 During the delivery, the connection with the Flowmeter was lost.

0x0040 The service mode was enabled at the beginning or during the delivery.

0x0080 The metrology lock was disabled at the beginning or during the

delivery.

0x0100 The door of the C401 was open at the beginning or during the

delivery.

0x0200 This bit indicates that at the end of the delivery, communication with

the Flowmeter was restored and is only valid if the connection lost

error (0x020) is also set.

If this bit is set, it means that when the delivery was stopped, up-to-

date counter and error-values were available from the Flowmeter.

If this bit is not set, it means that when the delivery was stopped, no

up-to-date counter and error-values were available from the

Flowmeter and the delivered quantity should be reviewed.

0x0400 As an exception, the clock has been set with access level user. Under

normal circumstances, the clock can only be set with access level

installer or higher.

Error-bits are OR-ed together in the error field.

E.g. error 0x0011 shows there was an error (0x0001) and the error was caused

by a power failure (0x0010).

Ext-Error

Flowmeter error field

All flowmeter errors during delivery OR-ed

Ext-SoftError

Flowmeter soft error field

All flowmeter soft errors during delivery OR-ed

Ext-Warning

Flowmeter warning field

All flowmeter warnings during delivery OR-ed

Ext-Hard Error Cnt

Flowmeter Hard error counter

Ext-Range Error Cnt

Flowmeter Range error counter

Ext-Zeroing Cnt

Flowmeter Zeroing counter

Ext-Hard Lock Cnt

Flowmeter Hard lock counter

Page 15

FW-C401-M_v0105_01_EN.docx

3 CONFIGURATION AND INFORMATION

3.1 GENERAL

From BEREIT or SERVICE status, the user can enter the Menu by pressing the PROG / ENTER

key for 3 seconds. To exit the Menu and return to Operator level, the PROG / ENTER key must be

pressed for 3 seconds again.

At the second line of the screen, a ‘bread-crumb’trail is shown. This line will show where you are

inside the menu, e.g. MENU > Konfig > Datum / Zeit

From within the menu, the user can perform the following actions:

oZeigen Logbuch: Review the logged deliveries, events and errors.

oZertifikat ansehen: Scan the QR-code that will direct him to certification and calibration

data (not functional yet).

oZeigen Geräteinformation: Review information and status of the C401 Dispenser

oZeigen Coriolis-Infos: Review information and status of the connected Flowmeter.

oSETUP aufrufen: Enter the Setup level where configuration parameters can be

changed.

Operation

A menu item can be selected by pressing the ▲and ▼ keys. To open/close a sub-menu (indicated

by the ‘>>’ sign) or enter/leave an information screen, press the ◄and ►keys.

To change the value of a parameter, select the parameter to change with the ▲and ▼ keys. By

pressing the PROG / ENTER key the programming mode is entered and a different value can be

selected. To confirm the new value, press the PROG / ENTER key again. To dismiss the changes, press

the STOP / CLEAR key.

3.2 MENU- AND SETUP-LEVEL

The following table shows the build-up of the menu inside the C401 and the settings available at

SETUP-level.

MENU Entry

Description and available settings

Access

Level

Zeigen Logbuch

Ereignisse

Event logbook

User

Lieferungen

Delivery logbook

User

Fehler

Error logbook

User

Zertifikat ansehen

Review QR code

Metrologic

Zeigen Gerateinformation

Information about the C401 Dispenser

-

Zeigen Coriolis-Infos

Information about the connected Flowmeter

-

Setup aufrufen

→See following page

-

Note: Access Level indicates the minimum level required to change the parameter.

See paragraph 5.2.3: Access Level / Zugangsstufe for more information on Access Levels.

Page 16

FW-C401-M_v0105_01_EN.docx

MENU Entry

Description and available settings

Access

Level

Setup aufrufen

Sprache

English –Deutsch –Français

User

Datum und Uhrzeit

DD-MM-YYYY hh:mm

Installer

Allgemein

Messgerät

Measurement system identification number

(serial number)

Metrologic

Fahrzeug

Vehicle identification number (e.g. license plate)

Installer

Helligkeit

Backlight level (0…100%)

User

Konstrast

LCD contrast setting (-15…0…+15)

User

Volumen Umrechnung

Berechnung

Enable –disable

Installer

Ref. Druck (Pb)

Reference pressure applicable to the density

(1.000 bar)

Metrologic

Ref. Temp (Tb)

Reference temperature applicable to the density

(15.00 °C)

Metrologic

Dichte

Density at reference conditions

(0.0841 kg/m3)

Metrologic

Liefereinheit

Initial unit displayed during the delivery phase.

kg –m3

Installer

Zusammenfassungs-

einheit

Initial unit displayed on the delivery summary

screen.

kg –m3

Installer

Durchflussalarme

Überwachung

Enable –disable

Installer

Low-Flow Grenze

0.0000 kg/min (0 = disabled) (1.333 kg/min)

Installer

Abschaltgrenze

0.0000 kg/min (0 = disabled) (0.800 kg/min)

Installer

Hysterese

0.0 … 100.0% (10.0%)

Installer

Alarmverzögerung

0.0 …9.9 seconds (0 seconds)

Installer

Drucker

Testticket drucken

Press the STOP / CLEAR key to print a test-ticket

-

Ticket Sprache

English –Deutsch –Français

Installer

Baudrate

Communication-settings of the connected

printer.

(default: 9600 baud, No parity, 8 databits,

1 startbit, 1 stopbit, no protocol)

Installer

Daten Bits

Installer

Stopp-Bits

Installer

Parität

Installer

Protokoll

Installer

Druck nach Lieferung

Print directly after delivery or only via logbook

Installer

Zeilenende

Line-termination: CR, LF, CR/LF

Installer

Seite Abschluss (FF)

Page-termination: none, FF (form feed)

Installer

Leere Zeile oben

Number of empty lines at start: 0…10 (2)

Installer

Leere Zeile unten

Number of empty lines at end: 0…10 (2)

Installer

Kopfzeile 1…10

Up to 10 user configurable lines

(20 characters wide)

Installer

FTL Protokoll

Geräte ID

System ID for the FTL protocol

Installer

Artikelnummer

Article number for the FTL protocol

Installer

Maßeinheit

kg –m3

Installer

Kommunikation Coriolis

Baudrate

Communication-settings of the connected

Flowmeter.

(default: 57600 baud, Even, 8 databits,

1 startbit, 1 stopbit, RTU, address 1)

Installer

Parität

Installer

Stopp-Bits

Installer

Adresse

Installer

Note: Bold marked symbols represent default values.

Access Level indicates the minimum level required to change the parameter.

See paragraph 5.2.3: Access Level / Zugangsstufe for more information on Access Levels.

Page 17

FW-C401-M_v0105_01_EN.docx

3.3 MENU: ZEIGEN LOGBUCH

To review the stored events (Ereignisse), deliveries (Lieferungen) and errors (Fehlers), enter the

MENU, select ‘Zeigen Logbuch’ with the ▲ and ▼ keys and enter the submenu by pressing ►.

3.3.1 Sub-Menu: Ereignisse

To review the event logbook (Ereignisse), select ‘View Log archives’ (Zeigen Logbuch) with the ▲

and ▼ keys from the MENU. On the next screen, select ‘Events’ (Ereignisse) and enter the

submenu by pressing ►.

▲▼►

By selecting the submenu ‘View list’ (Liste aufrufen) the list with available records is shown.

Select the required record using the ▲and ▼ keys and open the record by pressing ►.

▲▼►

Use the ▲and ▼ keys to scroll through the fields in the record. When finished reviewing the record,

press ◄ several times to return to the previous menu items.

3.3.2 Sub-Menu: Lieferungen

To review the delivery logbook (Lieferungen), select ‘View Log archives’ (Zeigen Logbuch) with the

▲and ▼ keys from the MENU. On the next screen, select ‘Deliveries’ (Lieferungen) and enter the

submenu by pressing ►.

▲▼►

Page 18

FW-C401-M_v0105_01_EN.docx

By selecting the submenu ‘View list’ (Liste aufrufen) the list with available records is shown.

Select the required record using the ▲and ▼ keys and open the record by pressing ►.

▲▼►

Use the ▲and ▼ keys to scroll through the fields in the record. When finished reviewing the record,

press ◄ several times to return to the previous menu items.

Please see paragraph 2.7 for more information on the various fields in the delivery record.

3.3.3 Sub-Menu: Fehlers

To review the error logbook (Fehlers), select ‘View Log archives’ (Zeigen Logbuch) with the ▲ and

▼ keys from the MENU. On the next screen, select ‘Errors’ (Fehlers) and enter the submenu by

pressing ►.

▲▼►

By selecting the submenu ‘View list’ (Liste aufrufen) the list with available records is shown.

Select the required record using the ▲and ▼ keys and open the record by pressing ►.

▲▼►

Use the ▲and ▼ keys to scroll through the fields in the record. When finished reviewing the record,

press ◄ several times to return to the previous menu items.

3.4 MENU: ZERTIFIKAT ANSEHEN (QR-CODE)

This menu is meant to supply the user with a QR-code that can be scanned with a mobile phone.

The QR-code will redirect him to a webpage containing actual certification and calibration data.

If no (online) certification data is currently available, the QR-code will redirect to the Fluidwell

website or the website configured via the configuration software.

To review the QR code, select ‘View Certificate (QR-Code)’ (Zertifikat ansehen (QR-Code)) with the

▲and ▼ keys from the MENU and enter the submenu by pressing ►.

►

When finished reviewing the information, press ◄ to return to the main menu.

Page 19

FW-C401-M_v0105_01_EN.docx

3.5 MENU: ZEIGEN GERÄTINFORMATIONEN

To review detailed information about the C401, select ‘View Device Info’ (Zeigen Geräteinformation)

with the ▲and ▼ keys from the MENU and enter the submenu by pressing ►.

►

Use the ▲and ▼ keys to scroll through the information. When finished, press ◄ to return to the

main menu.

3.6 MENU: ZEIGEN CORIOLIS-INFORMATIONEN

To review detailed information about the connected Flowmeter, select ‘View Coriolis Info’ (Zeigen

Coriolis-Infos) with the ▲ and ▼ keys from the MENU and enter the submenu by pressing ►.

►

Use the ▲and ▼ keys to scroll through the information. When finished, press ◄ to return to the

main menu.

Page 20

FW-C401-M_v0105_01_EN.docx

3.7 MENU: SETUP AUFRUFEN

•Mounting, electrical installation, start-up and maintenance of the instrument may only be

carried out by trained personnel authorized by the operator of the facility. Personnel must

read and understand this manual before carrying out its instructions.

•The C401 may only be operated by personnel who are authorized and trained by the

operator of the facility. All instructions in this manual are to be observed.

•Ensure that the measuring system is correctly wired up according to the wiring diagrams.

The housing may only be opened by authorized personnel.

•Take careful notice of the “Safety rules, instructions and precautionary measures” in the

front of this manual.

•SETUP functionality is exclusively meant for electricians and non-operators.

Configuration of the C401 is done via the Configuration Tool in combination with the right Access

Level. Which configuration parameters are available to change, depend on the current Access Level.

The table of paragraph 3.2: MENU- and SETUP-level shows for each parameter the minimum

required level. See paragraph 5.2.3: Access Level / Zugangsstufe for more information on Access

Levels.

Almost all settings can be reviewed on the device via the SETUP menu. Only the settings for

language (access level: User) and date / time (access level: Installer) can be changed directly via

the control panel on the device.

To review and change the configuration, enter the MENU, select ‘Enter SETUP’ (Setup aufrufen)

with the ▲and ▼ keys and enter SETUP by pressing ►.

►

3.7.1 SETUP-menu: Sprache

To change the current language selection, select ‘Language’ (Sprache) with the ▲ and ▼ keys from

the SETUP-menu and enter the setting pressing PROG / ENTER.

PROG

Select the required value with the ▲and ▼ keys and confirm the new setting by pressing PROG /

ENTER. To cancel the changes, press the STOP / CLEAR key.

PROG

Table of contents