Z8OQT

TABLE OF CONTENTS, (continued)

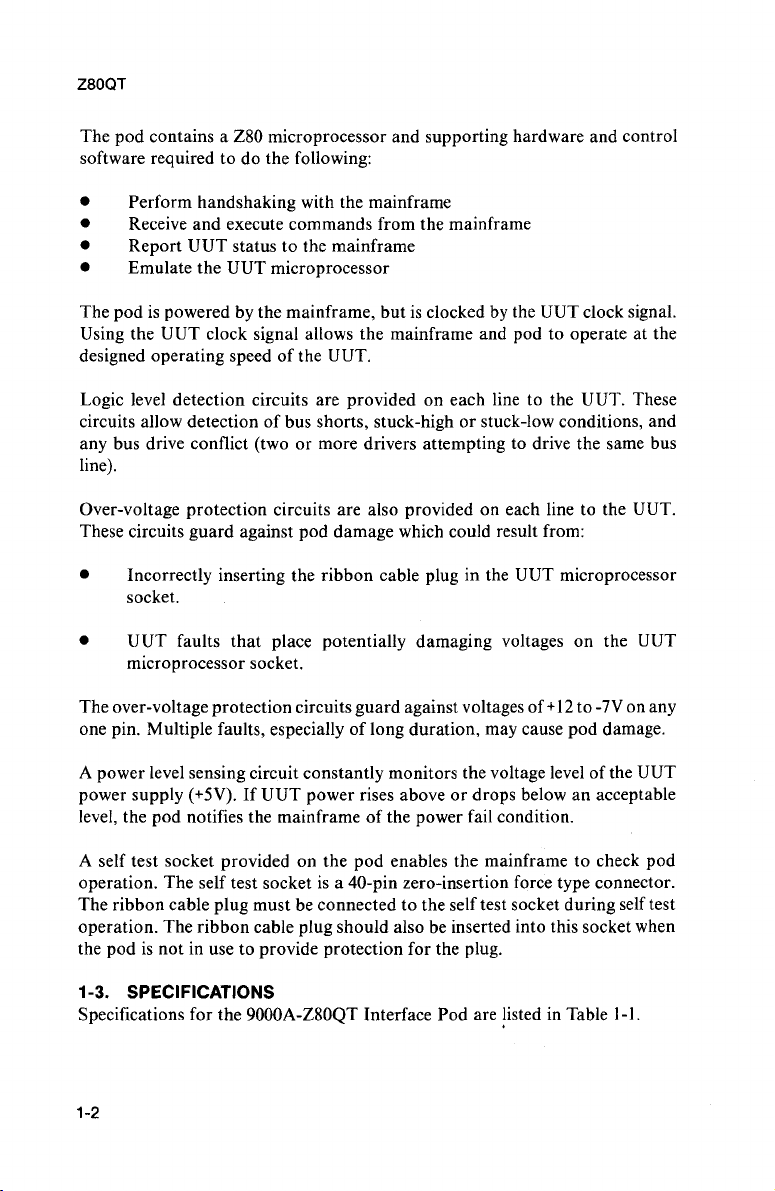

SECTION TITLE PAGE

3-18. Using the 9000 Series for Quick RAM Testing ....... 3-10

3-19. Using the 9000 Series for Quick ROM Testing ....... 3—13

3—20. Using the 9100 Series for Quick RAM Testing ....... 3-15

3—21. Using the 9100 Series for Quick ROM Testing ....... 3-15

3—22. QUICK FILL AND VERIFY ..................... 3-16

3—23. Using the 9000 Series for Quick Fill and Verify ...... 3-16

3-24. Using the 9100 Series for Quick Fill and Verify ...... 3-17

3-25. MARGINALOUT PROBLEMS .................. 3-19

3—26 Introduction ................................ 3—19

3-27. UUT Operating Speed and Memory Access ........ 3-19

3—28. UUT Noise Levels ............................ 3—19

3—29. Bus Loading ................................ 3-19

3-30. Clock Loading .............................. 3-20

3-31. POD DRIVE CAPABILITY ..................... 3-20

3-32. POWER FAILURE DETECTIONLIMITS ......... 3—20

THEORY OF OPERATION ............................ 4-1

4-]. INTRODUCTION ............................. 4-1

4-2. GENERALPOD OPERATION ................... 4-1

4—3. Processor Section ............................ 4-1

4-3. Processor Section ............................ 4-1

4-4. UUT Interface Section ........................ 4-4

4-5. Timing Section .............................. 4-4

4-6. UUT Power Sensing .......................... 4-5

4-7. DETAILED BLOCK DIAGRAM DESCRIPTION . . . . 4-5

4—8. ProcessorSection ............................ 4-5

4—9. UUT Interface Section 7General ................ 4—8

4-10. UUT Interface Section 7Data Lines ............. 4—9

4-11. UUT Interface Section —Address Lines ........... 4-12

4-12. UUT Interface Section 7Status and Control Lines ..4—12

4-13. Timing Section .............................. 4-13

MAINTENANCE .................................... 5—1

5—1. INTRODUCTION ............................. 5—l

5—2. SELF TEST .................................. 5-1

5-3. REPAIR PRECAUTIONS ...................... 5—4

5—4. TROUBLESHOOTING ......................... 5-4

5-5. Introduction ................................ 5—4

5—6. Pod Defective or Inoperative? ................... 5—5

5—7. Selecting aUUT for Pod Testing ................. 5-7

5—8. Troubleshooting aDefective Pod ................. 5—8

5-13. Troubleshooting an Inoperative Pod .............. 5-14

5-l4. DISASSEMBLY .............................. 5-19

ii (continued on page iii)